Article Contents

Strategic Sourcing: 5 Axis Dental Mill

Professional Dental Equipment Guide 2026

Executive Market Overview: 5-Axis Dental Milling Systems

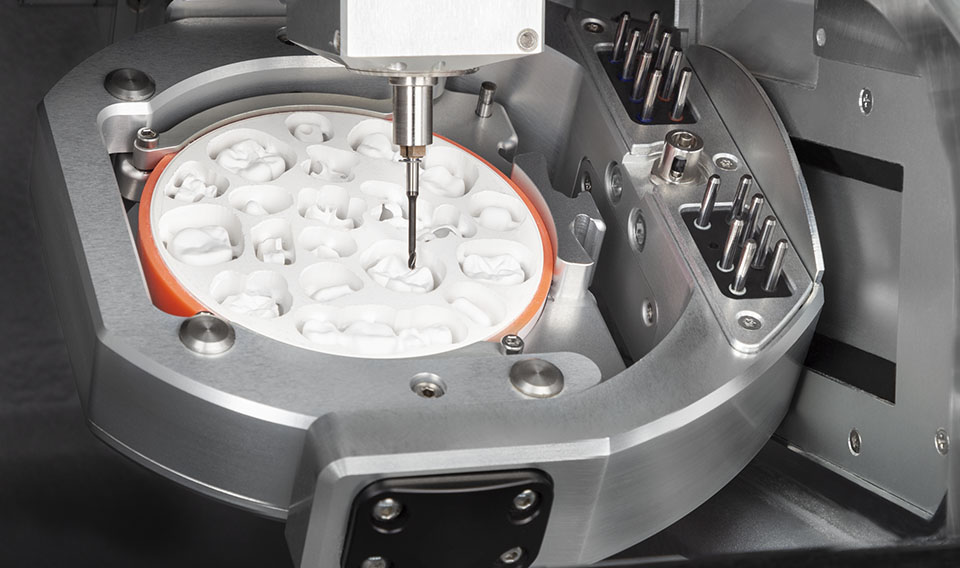

Strategic Imperative for Modern Digital Dentistry: The 5-axis dental milling system has transitioned from a luxury to a non-negotiable cornerstone of competitive dental practices and laboratories. As digital workflows (intraoral scanning, CAD/CAM design) achieve >85% adoption in developed markets, the inability to produce high-precision, monolithic restorations in-house directly impacts clinical efficiency, case acceptance, and profitability. 5-axis technology eliminates undercuts inherent in complex anatomical structures (e.g., multi-unit bridges, screw-retained abutments, anatomical frameworks), enabling fabrication of restorations previously requiring labor-intensive layering or outsourcing. This capability is critical for same-day dentistry, reducing lab fees by 30-50% per case and accelerating treatment cycles – a decisive advantage in value-based care models.

Market Dynamics: The global 5-axis dental milling market is experiencing bifurcation. Premium European manufacturers maintain dominance in high-end clinics and central labs demanding ultimate precision for full-contour zirconia and high-translucency materials, commanding significant price premiums. Concurrently, Chinese manufacturers – led by innovators like Carejoy – are capturing substantial market share among cost-conscious clinics, satellite labs, and emerging markets by delivering 80-85% of core functionality at 30-40% of the acquisition cost. This segment is driving democratization of advanced manufacturing, though with nuanced trade-offs in long-term reliability, material versatility, and technical support infrastructure.

Strategic Comparison: European Premium Brands vs. Carejoy (Representative Chinese Value Segment)

Note: “Global Brands” refers to established European leaders (e.g., Wieland, Amann Girrbach, Straumann/Imes-icore). Specifications reflect typical mid-to-high-tier models. Carejoy represents the leading value-engineered Chinese alternative (e.g., Carejoy CJ-5X series). All specifications subject to model year and regional configuration.

| Feature Category | Global Brands (European) | Carejoy (Value Segment) |

|---|---|---|

| Acquisition Cost (System) | €120,000 – €185,000+ | €42,000 – €58,000 |

| Positional Accuracy (ISO 12836) | ≤ 5 – 10 µm (repeatability) | ≤ 15 – 25 µm (repeatability) |

| Material Versatility | Full spectrum: High-strength zirconia (5Y-PSZ), multi-layer zirconia, lithium disilicate, PMMA, composite, wax, CoCr. Certified for all major material brands. | Primarily: Monolithic zirconia (3Y-TZP), PMMA, composite, wax. Limited validation for high-translucency/lithium disilicate. Material library constraints. |

| Spindle Performance | 60,000 – 100,000 RPM; Ceramic bearings; Active cooling; Sub-µm runout | 40,000 – 60,000 RPM; Steel bearings; Basic cooling; 2-3 µm runout |

| Software Ecosystem | Proprietary CAD/CAM integration; Extensive material libraries; Automated nesting; Advanced support generation; Cloud connectivity; Regular FDA-cleared updates. | Third-party or simplified CAD/CAM; Limited material presets; Manual nesting common; Basic support tools; Limited cloud features; Update frequency varies. |

| Service & Support | Dedicated regional engineers; 24/7 hotline; Loaner units; Comprehensive training; Global spare parts network (48-72h response) | Partner-dependent network; 5-10 business day response typical; Remote diagnostics primary; Limited training; Spare parts shipping delays possible (2-4 weeks) |

| Target Application | High-volume labs; Complex full-arch cases; Premium materials; Regulatory-critical environments; Practices demanding maximum uptime (99%+) | Single-chair clinics; Moderate case volume; Single-unit crowns/bases; Budget-focused operations; Practices prioritizing entry cost over peak performance |

| Total Cost of Ownership (5-yr) | High acquisition offset by lower material waste, higher throughput, and minimal downtime. Service contracts: €12,000-€18,000/yr. | Lower acquisition but higher risk of downtime, material waste on complex cases, and potential major repairs. Service contracts: €4,000-€7,000/yr (limited coverage). |

*Accuracy figures reflect typical validated performance under optimal conditions. Real-world results vary based on calibration, tooling, and operator skill. Material compatibility must be verified per specific mill model and material batch.

Strategic Recommendation

European 5-axis mills remain essential for high-end laboratories and clinics specializing in complex prosthetics where marginal integrity (<20µm) and material versatility directly impact clinical outcomes and premium pricing. However, Carejoy and comparable value-engineered systems present a compelling ROI for clinics focused on routine crown/bridge workflows seeking in-house production without capital intensity. Distributors should segment their offerings: position European brands for premium labs and large group practices emphasizing long-term reliability, while targeting new clinic setups and value-driven operators with Chinese alternatives – ensuring transparent discussions on material limitations and support expectations. The critical factor is aligning mill capability with actual case complexity; over-specifying erodes ROI, while under-specifying risks clinical compromise.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: 5-Axis Dental Milling Systems

Target Audience: Dental Clinics & Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW spindle motor, 240V AC, single-phase operation | 3.2 kW high-frequency spindle motor, 400V AC, three-phase operation with active cooling system |

| Dimensions (W × D × H) | 650 mm × 720 mm × 850 mm | 780 mm × 850 mm × 1020 mm (includes integrated dust extraction unit) |

| Precision (Positioning Accuracy) | ±5 µm (micrometers) under standard operating conditions | ±2 µm with real-time thermal compensation and laser calibration system |

| Material Compatibility | Zirconia (up to 4Y), PMMA, composite blocks, wax; max block size 40 mm diameter | Full-spectrum compatibility: Zirconia (3Y, 4Y, 5Y, translucent), lithium disilicate, alumina, CoCr, titanium (Grade 2, 5), PMMA, wax; supports blocks up to 60 mm diameter and 38 mm height |

| Certification & Compliance | CE Marked, ISO 13485, FDA Class II registered, RoHS compliant | CE Marked, ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1-2 (EMC), GDPR-compliant data handling, UL/CSA certified |

Note: The Advanced Model supports automated tool changer (ATC) with up to 12 tools, integrated dry/wet milling modes, and direct CAD/CAM software integration via open STL and proprietary SDK. Recommended for high-volume dental labs and multi-unit production environments. The Standard Model is optimized for single-operator clinics with moderate daily milling demands.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Strategic Procurement of 5-Axis Dental Mills from China

Target Audience: Dental Clinic Owners, Laboratory Managers, Dental Equipment Distributors & Procurement Officers

Validity Period: Q1 2026 – Q4 2026 | Prepared by: Senior Dental Equipment Consultants Network

Introduction: The 2026 5-Axis Milling Landscape

With global adoption of CAD/CAM dentistry growing at 12.3% CAGR (2024-2026), 5-axis milling systems represent a critical investment for dental laboratories and high-volume clinics. China remains the dominant manufacturing hub (78% global supply), but regulatory complexity and quality variance necessitate structured sourcing protocols. This guide addresses 2026-specific challenges including updated EU MDR Annex IX requirements, FDA 21 CFR Part 820 harmonization, and post-pandemic supply chain resilience.

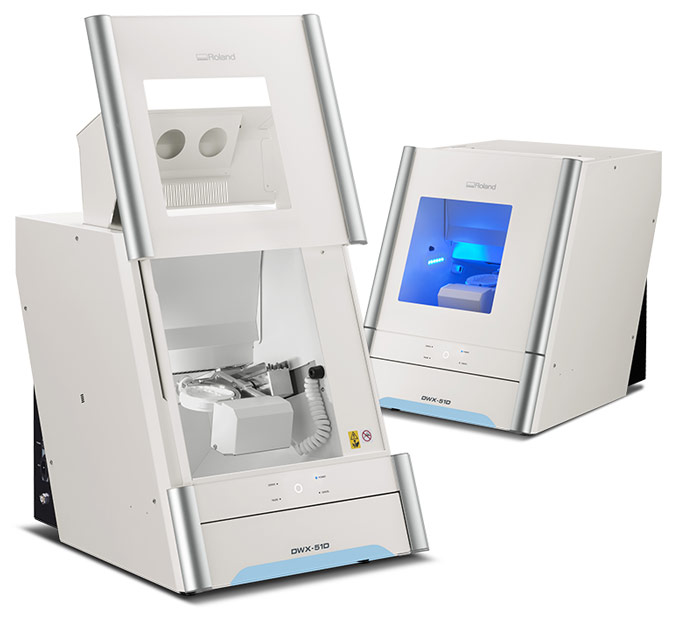

Featured Industry Partner: Shanghai Carejoy Medical Co., LTD

Established: 2005 | Location: Baoshan District, Shanghai, China (Shanghai Port proximity: 22km)

Verification Status: ISO 13485:2016 (TÜV SÜD Certificate #Q5 100 00 26584-1), CE MDR 2017/745 Annex IX certified (NB 2797), FDA Establishment Registered (FEI# 3015603209)

Relevance: 19 years specializing in precision dental manufacturing with in-house R&D for milling systems. Factory-direct model eliminates distributor markups while maintaining OEM/ODM capabilities for custom workflow integration.

Step 1: Rigorous Verification of ISO/CE Credentials (2026 Protocol)

Post-2024 regulatory tightening requires multi-layer credential validation. Avoid suppliers providing only PDF certificates.

| Verification Method | 2026 Critical Actions | Risk Mitigation |

|---|---|---|

| Direct Certificate Validation | • Cross-check certificate # on NANDO database for CE • Verify ISO 13485:2016 amendment compliance (2025 transition deadline passed) • Confirm scope explicitly includes “Dental Milling Units” (Class IIa) |

Reject suppliers with certificates listing “dental equipment” generically. 2026 EU audits require product-specific annexes. |

| Factory Audit Trail | • Demand 2025/2026 audit reports from accredited bodies (e.g., TÜV, BSI) • Verify calibration records for laser interferometers (ISO 230-2:2022 compliance) • Confirm material traceability systems (ISO 13485 §7.5.3.2) |

Unannounced video audits via Teams/Zoom required. Physical audits non-negotiable for first-time partnerships. |

| Regulatory Documentation | • Request full Technical File per MDR Annex II • Confirm biocompatibility testing (ISO 10993-1:2018) • Validate electrical safety (IEC 60601-1:2020 + Corr.1:2021) |

2026 FDA requires UDI integration in labeling. Verify via FDA GUDID lookup. |

Step 2: Strategic MOQ Negotiation Framework

Chinese manufacturers increasingly enforce rigid MOQs due to 2025 raw material cost volatility. Apply tiered negotiation tactics:

| Negotiation Tier | Standard Terms (2026) | Carejoy-Specific Advantage |

|---|---|---|

| Entry-Level (Dental Clinics) | • 5 units minimum • 45-day production lead time • Limited customization |

• MOQ: 2 units with Carejoy’s Clinic Starter Program • Pre-configured workflows for CEREC/3Shape integration • 30-day lead time via Shanghai Port priority scheduling |

| Distributor Tier | • 15 units minimum • 60-day payment terms • Regional exclusivity requires 50+ units |

• MOQ: 8 units with 120-day payment terms • Co-branded marketing kits (CE/FDA compliant) • Dedicated technical support portal access |

| OEM/ODM Partnership | • 30+ units • NRE fees $15k-$50k • 18-month commitment |

• NRE fees waived for 20+ unit annual commitment • UI/UX customization at $8.5k (industry avg: $22k) • Shared IP development model available |

Step 3: Optimized Shipping & Logistics (2026 Compliance)

2026 Incoterms® 2020 enforcement requires explicit contractual clarity. Avoid “FOB Shanghai” ambiguities.

| Term | 2026 Implementation Requirements | Recommended Use Case |

|---|---|---|

| FOB Shanghai Port | • Supplier liability ends at vessel loading • Buyer arranges marine insurance • Customs clearance responsibility: Buyer • 2026 Risk: Port congestion delays (avg. 72hrs at Yangshan) |

Distributors with in-house logistics teams managing LCL shipments. Requires CIF insurance add-on. |

| DDP (Delivered Duty Paid) | • Supplier handles all costs/risk to final destination • Includes 2026 EU customs duties (avg. 4.2% for dental mills) • Mandatory EORI number integration • Carejoy Advantage: Pre-cleared shipments via bonded logistics zones |

Strongly recommended for clinics. Eliminates import compliance risk. Carejoy’s DDP includes 30-day duty dispute resolution. |

| Carejoy Premium Shipping | • Hybrid DDP-FOB model with Shanghai Port consolidation • Temperature-controlled containers (2-8°C for spindle calibration) • Blockchain shipment tracking (VeChain integration) |

High-value orders (>5 units) requiring JIT inventory. Reduces transit time by 11 days vs standard DDP. |

Next Steps: Engage with Verified Manufacturing Partner

Shanghai Carejoy Medical Co., LTD provides turnkey 5-axis milling solutions meeting 2026 regulatory standards. As a factory-direct supplier with 19 years of export compliance, they mitigate sourcing risks through:

- Pre-shipment regulatory audits (included at no cost)

- DDP shipping with duty optimization for 38 target markets

- On-site technician deployment for installation (EU/NA only)

Contact for Technical Specifications & 2026 Pricing:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Reference “PDG2026-5AXIS” for expedited technical documentation package

Disclaimer: This guide reflects 2026 regulatory standards as of January 2026. Verify all requirements with local authorities. Shanghai Carejoy is presented as a case study of compliant manufacturing – due diligence remains the buyer’s responsibility. Incoterms® and ISO standards are registered trademarks of ICC and ISO respectively.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Purchasing a 5-Axis Dental Mill

Target Audience: Dental Clinics & Equipment Distributors

1. What voltage requirements should I consider when installing a 5-axis dental mill in 2026?

Most 5-axis dental milling systems in 2026 operate on standard single-phase 200–240V AC, 50/60 Hz power. However, high-throughput or industrial-grade models may require three-phase 380–415V power. Always verify the specific voltage and amperage requirements with the manufacturer prior to installation. Ensure your clinic’s electrical infrastructure includes a dedicated circuit with stable power delivery and surge protection to maintain machine accuracy and longevity.

2. Are spare parts for 5-axis dental mills readily available, and what is the typical lead time?

Reputable manufacturers in 2026 maintain global spare parts networks, with critical components such as spindles, clamping units, linear guides, and tool changers stocked regionally. Lead times for common parts are typically 3–7 business days for in-warranty units and 7–14 days for out-of-stock or custom items. Distributors are advised to maintain a local inventory of high-wear consumables (e.g., collets, brushes, filters). Confirm spare parts availability and service-level agreements (SLAs) before purchase to minimize machine downtime.

3. What does the installation process for a 5-axis dental mill involve?

Installation includes site evaluation, power and network setup, machine leveling, vacuum system integration (if applicable), and calibration. Most manufacturers provide on-site technician support for initial setup, which typically takes 1–2 days. The process also includes software configuration, material library setup, and operator training. Clinics must prepare a stable, dust-free environment with adequate ventilation and compressed air (if required). Remote diagnostics and AI-assisted calibration are now standard in 2026, reducing setup complexity.

4. What is the standard warranty coverage for a 5-axis dental milling machine in 2026?

The standard warranty for a 5-axis dental mill in 2026 is typically 2 years comprehensive coverage, including parts, labor, and on-site service for mechanical and electronic failures. Some premium models offer 3-year warranties with optional extended service plans. Coverage excludes consumables, damage from improper use, or unauthorized modifications. Advanced diagnostics and predictive maintenance logs are now used to validate warranty claims and optimize uptime.

| Warranty Component | Coverage | Exclusions |

|---|---|---|

| Spindle & Drive Systems | 2–3 years | Wear from improper tooling |

| Control Electronics | 2 years | Power surge damage |

| Software & Calibration | 2 years (remote support) | Unauthorized software changes |

5. Can I upgrade or expand my 5-axis mill after purchase, and how does this affect warranty?

Yes, modular 5-axis mills in 2026 support post-purchase upgrades such as increased spindle speed, expanded material compatibility, or automated tool changers. All manufacturer-approved upgrades are warranty-compliant and can be installed by certified technicians. However, third-party modifications or non-OEM parts will void the warranty on affected components. Always consult your distributor or manufacturer before initiating any hardware or software enhancements.

© 2026 Professional Dental Equipment Guide. For authorized distributor use only. Specifications subject to change.

Need a Quote for 5 Axis Dental Mill?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160