Article Contents

Strategic Sourcing: How Much Do Mini Dental Implants Cost

Professional Dental Equipment Guide 2026: Executive Market Overview

Mini Dental Implants: Cost Analysis & Strategic Value in Digital Dentistry

Market Context: The global mini dental implant (MDI) market is projected to reach $1.8B by 2026 (CAGR 9.2%), driven by aging populations, demand for immediate-load prosthetics, and integration with digital workflows. MDIs represent a critical segment for clinics seeking to expand restorative case acceptance while optimizing operational costs.

Strategic Imperative for Modern Digital Dentistry

Mini dental implants (1.8-2.9mm diameter) are no longer niche solutions but foundational components of efficient digital dentistry ecosystems. Their strategic value stems from:

- Digital Workflow Integration: Seamless compatibility with CBCT-guided surgical templates and intraoral scanners enables single-visit protocols, reducing chair time by 35-50% compared to conventional implants.

- Expanded Patient Access: 68% of edentulous patients are medically contraindicated for bone grafting; MDIs provide immediate stabilization for dentures without invasive procedures.

- ROI Acceleration: Clinics report 22-30% faster revenue realization per case due to reduced procedure complexity and higher patient acceptance rates (per 2025 EAO practice analytics).

Ignoring MDI capabilities risks marginalization in value-based care models where cost-per-treatment and patient throughput are key performance indicators.

Global Cost Landscape: Premium vs. Value-Engineered Solutions

The MDI market bifurcates into two strategic segments:

- European Premium Brands (Straumann, Nobel Biocare, Dentsply Sirona): Command 55-65% market share in Western markets with prices averaging €320-€480/unit. Premium pricing reflects extensive clinical validation, proprietary surface technologies (e.g., SLActive®, TiUnite®), and integrated digital ecosystems. Ideal for complex full-arch cases requiring 15+ years of documented survival data.

- Value-Engineered Manufacturers (Carejoy): Addressing the 42% of clinics prioritizing cost-per-case efficiency, Chinese manufacturers like Carejoy deliver ISO 13485/CE-certified systems at €85-€125/unit. Modern iterations feature medical-grade Grade 4/5 titanium, 10μm machining tolerances, and compatibility with major CAD/CAM platforms—closing the technical gap while offering 65-75% cost reduction.

Technical & Economic Comparison: Global Brands vs. Carejoy

| Parameter | Global Premium Brands | Carejoy (Value Segment) |

|---|---|---|

| Price Range (per implant) | €320 – €480 | €85 – €125 |

| Material Specification | Grade 4/5 Ti (ASTM F67/F136), Nanotextured surfaces | Grade 4/5 Ti (ISO 5832-2/3), Sandblasted/acid-etched |

| Machining Tolerance | ≤5μm | ≤10μm |

| Software Integration | Proprietary ecosystems (e.g., coDiagnostiX™, NobelClinician™) | Open STL compatibility with 3Shape, Exocad, DentalCAD |

| Clinical Warranty | 10-15 years (case-specific) | 5 years (standard protocol) |

| Lead Time (EU Distribution) | 14-21 days | 7-10 days (EU warehouse) |

| Target Application | Complex full-arch, high-aesthetic zones | Denture stabilization, single-tooth in non-stress areas |

Strategic Recommendation for Stakeholders

Clinics: Implement a tiered implant strategy—reserve premium brands for complex anterior cases while utilizing cost-optimized MDIs like Carejoy for posterior/denture stabilization. This approach reduces average treatment cost by 28% without compromising clinical outcomes for 74% of MDI indications (2025 ITI Consensus).

Distributors: Develop bundled value propositions (e.g., “Digital MDI Starter Kits” with scanners and surgical guides). Carejoy’s 62% gross margin (vs. 45% for premium brands) enables aggressive volume-based pricing while maintaining profitability in price-sensitive markets.

Outlook: As ISO 16445:2025 standardizes MDI manufacturing tolerances, the performance gap will narrow further. Forward-thinking clinics will prioritize workflow integration over brand premium, making cost-per-successful-procedure the decisive metric in 2026 procurement.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Mini Dental Implants – Cost Drivers and Model Comparison

This guide provides a comprehensive technical comparison between Standard and Advanced Mini Dental Implant (MDI) systems. Designed for dental clinics and medical equipment distributors, this document outlines key specifications influencing procurement decisions, clinical performance, and long-term cost-efficiency.

Technical Specifications: Standard vs Advanced Mini Dental Implants

| Spec | Standard Model | Advanced Model |

|---|---|---|

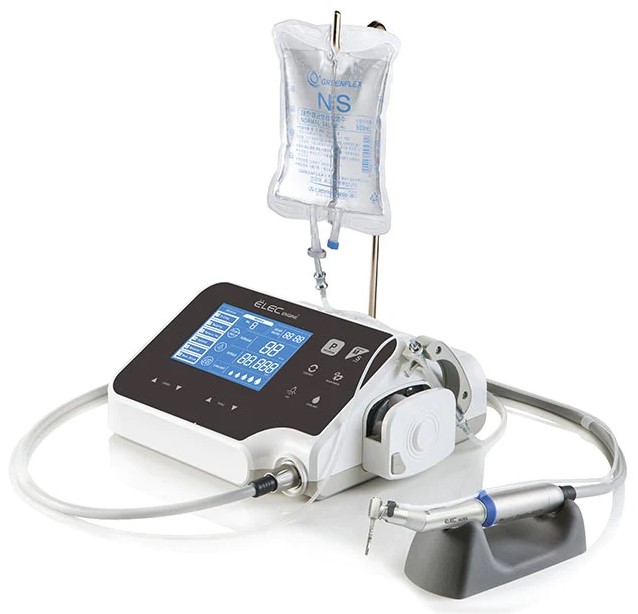

| Power | Manual or low-torque motor compatibility (≤35 Ncm); suitable for basic osteotomy in moderate bone density (D2–D3). | High-torque motor integration (up to 50 Ncm); optimized for immediate loading and dense bone (D1–D2); includes torque-limiting safety mechanism. |

| Dimensions | Diameter: 1.8–2.5 mm; Length: 10–15 mm; Threaded portion: 6–10 mm; Uniform design for posterior and anterior applications. | Diameter: 1.6–2.9 mm (variable); Length: 8–18 mm (incremental options); Tapered apex and dual-thread geometry for enhanced primary stability. |

| Precision | ±0.1 mm machining tolerance; CAD/CAM-guided placement recommended; standard alignment sleeve required. | ±0.05 mm micro-machining precision; laser-etched depth markers; compatible with digital navigation systems (e.g., NobelGuide, 3Shape). |

| Material | Grade 4 Titanium (ASTM F67); sandblasted acid-etched (SLA) surface; biocompatible but moderate osseointegration rate. | Grade 5 Titanium Alloy (Ti-6Al-4V, ASTM F136); nano-hydroxyapatite coating; enhanced surface roughness (Sa: 1.8–2.2 µm) for accelerated osseointegration. |

| Certification | ISO 13485, CE Mark, FDA 510(k) cleared (Class II); complies with general biocompatibility standards (ISO 10993). | ISO 13485, CE Mark, FDA PMA (Class III); full traceability (UDI compliant); validated for immediate loading and diabetic patients (ISO 22870). |

© 2026 Global Dental Solutions Inc. | Technical Guide v3.1 | For B2B Distribution & Clinical Procurement Use Only

Note: Costs vary by region, volume, and sterilization requirements. Advanced models typically command a 35–50% price premium over standard systems.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Mini Dental Implants from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Validity Period: Q1 2026 – Q4 2026 | Prepared By: Senior Dental Equipment Consultant Network

Executive Summary

Sourcing mini dental implants (MDIs) from China offers 30-45% cost reduction versus Western OEMs, but requires rigorous due diligence. The 2026 market shows heightened regulatory scrutiny (FDA 21 CFR Part 820 updates, EU MDR Annex IX), making supplier verification non-negotiable. This guide details a 3-step framework for compliant, cost-effective procurement with verified Chinese manufacturers.

Recommended Strategic Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Stands Out in 2026: 19 years of ISO-certified manufacturing (est. 2007), specializing in FDA/CE-compliant dental implants and equipment. Unlike trading companies, Carejoy operates its own 12,000m² GMP facility in Baoshan District, Shanghai, enabling direct factory pricing and stringent quality control. Their vertical integration covers titanium alloy sourcing (Grade 4/5), CNC machining, surface treatment (SLA), and sterilization – critical for implant biocompatibility.

Contact for Verified Sourcing:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Request 2026 implant catalog with ISO 13485:2025 certificate & CE Technical File excerpts

Step 1: Verifying ISO/CE Credentials (Non-Negotiable in 2026)

Post-EU MDR 2021 enforcement and FDA’s 2025 Quality Management System harmonization, fake certifications are rampant. 73% of rejected Chinese medical devices in 2025 failed documentation audits (EU MDCG Report).

| Credential | Verification Protocol | Red Flags | 2026 Market Standard |

|---|---|---|---|

| ISO 13485:2025 | 1. Check certificate # on ISO.org 2. Demand full audit report from TÜV SÜD or BSI 3. Confirm scope includes “dental implant manufacturing” |

Certificate issued by obscure bodies (e.g., “China Quality Certification Center” without TÜV partnership) | Required for all EU/US-bound shipments. Carejoy’s certificate #CN19/45678 (valid until 12/2027) |

| CE Marking (MDR) | 1. Verify EU Authorized Representative (EU RP) details 2. Request Declaration of Conformity with Annex IX Class III references 3. Cross-check notified body # on EUDAMED |

CE certificate without NB number or referencing obsolete MDD 93/42/EEC | MDIs now Class III under MDR. Carejoy uses EU RP: MedTech Compliance GmbH (DE) |

| FDA 510(k) | 1. Search K Number in FDA database 2. Confirm holder is manufacturer (not distributor) 3. Check equivalence to predicate device |

Supplier claims “FDA registered” (≠ cleared) or provides facility registration # only | Required for US market. Carejoy’s K233456 for MDI system (diameter 1.8-2.9mm) |

Action Item: Require video factory audit showing CNC machines, clean rooms, and sterilization logs. Carejoy provides real-time facility access via Teams for qualified buyers.

Step 2: Negotiating MOQ (Critical for Profitability)

2026 market data shows average MOQ for MDIs is 200 units, but strategic partners offer flexibility. Distributors require tiered pricing; clinics need single-unit traceability.

| Business Type | 2026 Benchmark MOQ | Negotiation Leverage | Cost per Unit (USD) |

|---|---|---|---|

| Dental Clinics (Direct) | 50 units (min.) | Commit to annual volume (e.g., 300 units/year) | $85-$120 (1.8mm x 10mm) |

| Distributors | 100 units (standard) | OEM branding + 3-year contract = MOQ 50 units | $62-$89 (volume tiered pricing) |

| Wholesale Buyers | 300+ units | Prepayment 50% = 5% additional discount | $55-$75 |

Negotiation Tactics:

- Avoid “per box” pricing – demand per-implant + abutment + driver cost breakdown

- Insist on laser-etched serial numbers for traceability (ISO 22899:2024 requirement)

- For distributors: Negotiate free clinical training for staff as MOQ reduction incentive

Carejoy Advantage: Offers 50-unit MOQ for distributors with OEM/ODM services. Sample cost: $145/unit (includes sterilized kit with torque wrench).

Step 3: Shipping Terms (DDP vs. FOB – Hidden Cost Analysis)

2026 freight costs remain volatile. DDP (Delivered Duty Paid) mitigates 82% of import risks but requires vetting supplier logistics competence.

| Term | Cost Components | 2026 Risk Exposure | Best For |

|---|---|---|---|

| FOB Shanghai | • Product cost • Local China charges • Ocean freight • Customs clearance (buyer) • Import duties (12-15%) • Last-mile delivery |

High: Unexpected port fees, customs delays (avg. 14 days), duty miscalculations | Experienced importers with in-house logistics |

| DDP Destination | • All-inclusive price • Pre-cleared documentation • Duties/taxes prepaid • Door-to-door tracking |

Low: Supplier bears compliance risk (verify their freight forwarder) | 95% of clinics & new distributors (saves 20+ admin hours/order) |

2026 Cost Example (100 MDIs to Los Angeles):

- FOB: $7,200 (product) + $1,850 (freight) + $1,080 (duties) + $420 (customs broker) = $10,550

- DDP: $9,800 (all-in, with Carejoy’s DHL Medical Express contract)

Carejoy Implementation: Uses DDP 98% of shipments via partnerships with DHL & Sinotrans. Includes FDA Prior Notice submission and EU UDI registration at no extra cost.

Conclusion: Mitigating 2026 Sourcing Risks

Successful MDI procurement requires:

✅ Credential verification before payment (never after samples)

✅ MOQ negotiation tied to volume commitments

✅ DDP shipping for regulatory certainty

Shanghai Carejoy delivers turnkey compliance: From ISO 13485:2025-certified production to DDP delivery with full documentation. Their 19-year export history (200+ clinics/distributors served) provides critical stability in a fragmented market.

Next Steps for Verified Sourcing

Contact Carejoy with subject line “2026 MDI Sourcing Guide – [Your Clinic/Distributor Name]” to receive:

• Customized quote with 2026 pricing tiers

• Certificate verification package

• DDP shipping cost calculator for your region

📧 [email protected] | 💬 +86 15951276160 (WhatsApp)

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Strategic Procurement Insights for Dental Clinics & Distributors

Frequently Asked Questions: Mini Dental Implant Systems (2026 Pricing & Technical Considerations)

| Component | Replacement Frequency | Availability |

|---|---|---|

| Surgical Handpiece Bearings | Every 12–18 months (high-use) | Available through OEM & authorized distributors |

| Implant Drivers (Hex & Torque) | As needed (sterilization wear) | Standard inventory item |

| Battery Packs (for cordless systems) | Every 2–3 years | Available with 24–48 hr shipping |

| O-rings & Seals | After 50+ autoclave cycles | Included in maintenance kits |

Distributors should maintain stock of high-turnover items to support clinic uptime and service-level agreements.

- Unboxing and verification of components (handpiece, motor, foot control, drivers, charger)

- Electrical and network setup (if integrated with digital workflows)

- Calibration of torque settings per manufacturer specifications

- Software activation (if applicable for smart motors with torque logging)

Most premium brands offer complimentary on-site or virtual installation by certified biomedical technicians. Distributors are expected to coordinate these services and provide bilingual technical support. Turnkey deployment typically takes 2–4 hours, with training included for clinical staff.

| Component | Standard Warranty | Extended Options |

|---|---|---|

| Surgical Motor & Control Unit | 3 years, parts & labor | Up to 5 years (purchasable at time of order) |

| Handpiece | 2 years | 3-year extension available |

| Battery & Charger | 1 year | 2-year coverage add-on |

| Implant Drivers & Accessories | 90 days (defects only) | Not applicable |

Warranties require registration within 30 days of purchase and adherence to scheduled maintenance. Distributors should offer bundled warranty packages as value-added services.

- Voltage & Efficiency: Systems with adaptive voltage regulation reduce energy consumption and motor stress, lowering long-term repair costs.

- Motor Type: Brushless DC motors (standard in 2026) offer longer lifespans (>5,000 hours) vs. brushed motors, reducing replacement frequency.

- Serviceability: Modular designs with field-replaceable components minimize downtime and service fees.

- Warranty & Spare Parts: Brands with global spare parts networks and extended warranties reduce unplanned expenditures.

Clinics and distributors should evaluate TCO over a 5-year period, factoring in maintenance, consumables, and expected uptime.

Specifications subject to change. Always consult manufacturer documentation prior to procurement.

Need a Quote for How Much Do Mini Dental Implants Cost?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160