Article Contents

Strategic Sourcing: Amann Girrbach Milling Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

Amann Girrbach Milling Systems in the Modern Digital Dentistry Ecosystem

The integration of CAD/CAM technology has transitioned from a competitive advantage to a clinical necessity in contemporary dental practice. At the core of this digital workflow lies the dental milling machine—a critical production node enabling same-day restorations, precise implant frameworks, and efficient laboratory operations. Amann Girrbach (AG), as a European engineering leader, represents the pinnacle of precision manufacturing in this segment, with its Ceramill系列 systems setting benchmarks for accuracy, material versatility, and seamless ecosystem integration. These attributes directly impact clinical outcomes through sub-15µm marginal fit tolerances, reduced remakes, and expanded same-day crown/bridge capabilities—key drivers for practice productivity and patient retention in 2026.

Strategic Market Positioning: European Precision vs. Cost-Optimized Alternatives

European manufacturers (Amann Girrbach, Dentsply Sirona, Planmeca) dominate the premium segment with engineering rigor focused on long-term precision stability, biocompatible material certification, and closed-loop ecosystem reliability. Their systems command 30-50% higher capital investment but deliver demonstrable ROI through:

• 99.2%+ first-pass milling success rates with high-translucency zirconia

• ISO 13485-certified wet-milling capabilities for lithium disilicate

• Integrated CAM software with AI-driven toolpath optimization

• Global service networks with 48-hour critical component SLAs

Conversely, Chinese manufacturers like Carejoy address acute budget constraints in emerging markets and value-focused segments. While offering 40-60% lower acquisition costs, these systems present operational trade-offs requiring careful clinical evaluation. The Carejoy M5 Pro exemplifies this segment’s value proposition: adequate for basic monolithic zirconia workflows but with limitations in material diversity, long-term calibration stability, and technical support infrastructure—factors directly impacting restoration longevity and practice scalability.

Comparative Analysis: Global Premium Brands vs. Carejoy M5 Pro

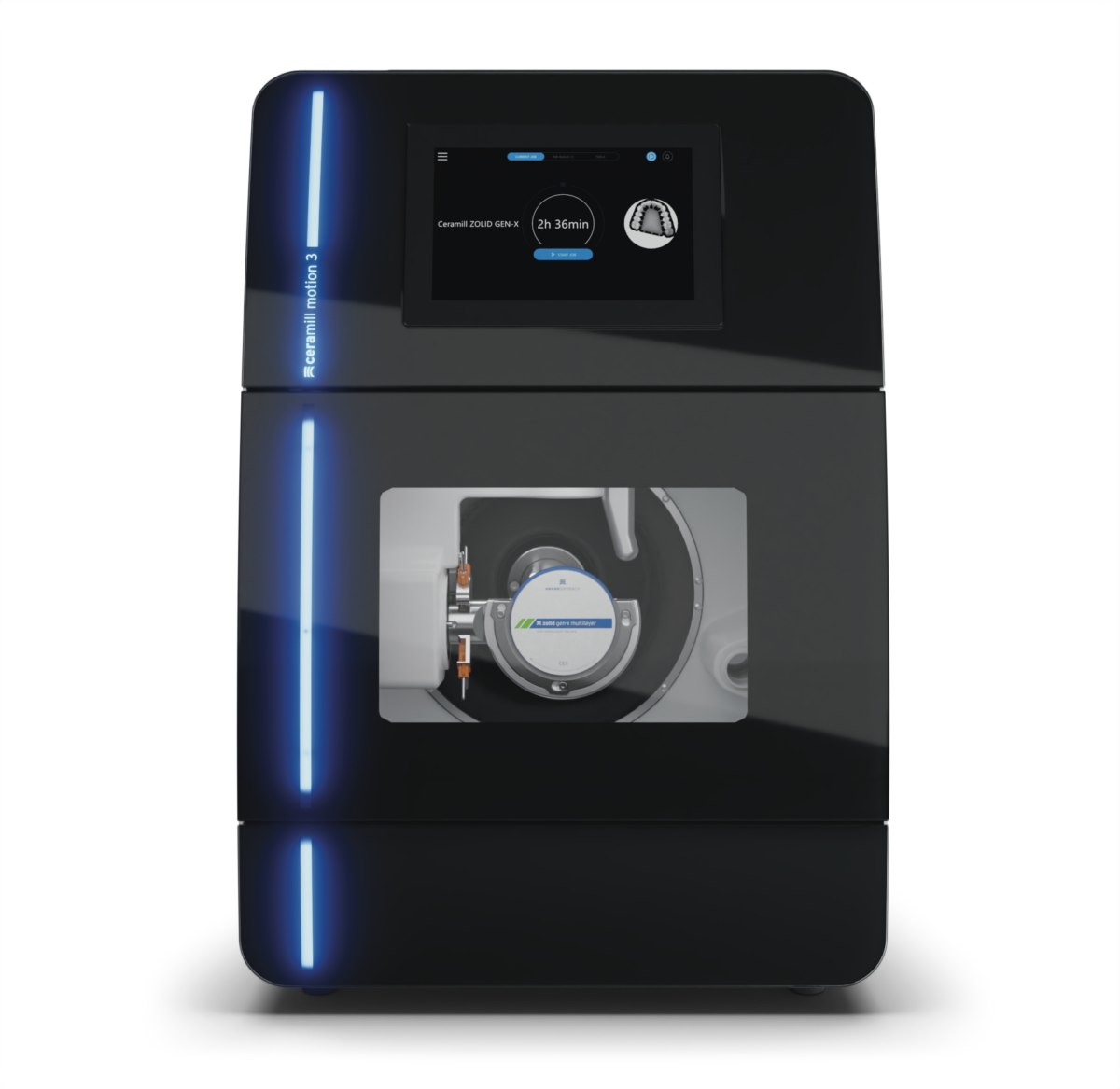

| Parameter | Global Premium Brands (e.g., Amann Girrbach Ceramill Motion 2) | Carejoy M5 Pro |

|---|---|---|

| Positioning Accuracy | ≤ 8 µm (ISO 12836 certified); maintained through active thermal compensation | 15-25 µm; requires manual recalibration after 50+ hours operation |

| Material Range | Full spectrum: PMMA, composite blocks, CoCr, all zirconia grades (including 3Y/4Y/5Y), lithium disilicate (wet milling) | Limited to 3Y/4Y zirconia & PMMA; no certified wet-milling for glass ceramics |

| Software Ecosystem | Integrated CAD/CAM suite with AI-driven nesting, automatic toolpath optimization, and live milling simulation; DICOM 3.0 compatibility | Standalone CAM module; basic toolpath generation; requires third-party CAD; no DICOM integration |

| Service & Support | Global network; 24/7 remote diagnostics; 48-hour critical part replacement; certified on-site engineers | Regional hubs only; 5-7 day part lead times; dealer-dependent technician training |

| Throughput Efficiency | 3-unit bridge in 18-22 min (5-axis simultaneous); auto-changer for 10+ units | 3-unit bridge in 32-40 min (4-axis); manual loading; max 4-unit batch |

| Total Cost of Ownership (5-yr) | Higher initial cost ($115K-$145K) offset by 35% lower consumable costs and 92% uptime | Lower entry cost ($45K-$65K) but 28% higher consumable costs and 74% estimated uptime |

For high-volume practices (>20 restorations/week) and specialty clinics requiring multi-material workflows, European-engineered systems like Amann Girrbach remain the strategic choice—ensuring clinical precision that directly impacts patient outcomes and practice reputation. Carejoy serves a valid niche in budget-constrained environments with lower case complexity, though distributors should counsel clients on hidden operational costs from calibration drift and material limitations. As digital dentistry matures toward fully automated workflows in 2026, equipment selection must prioritize long-term ecosystem compatibility over initial acquisition cost—a calculus where AG’s engineering integrity delivers measurable clinical and financial returns.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

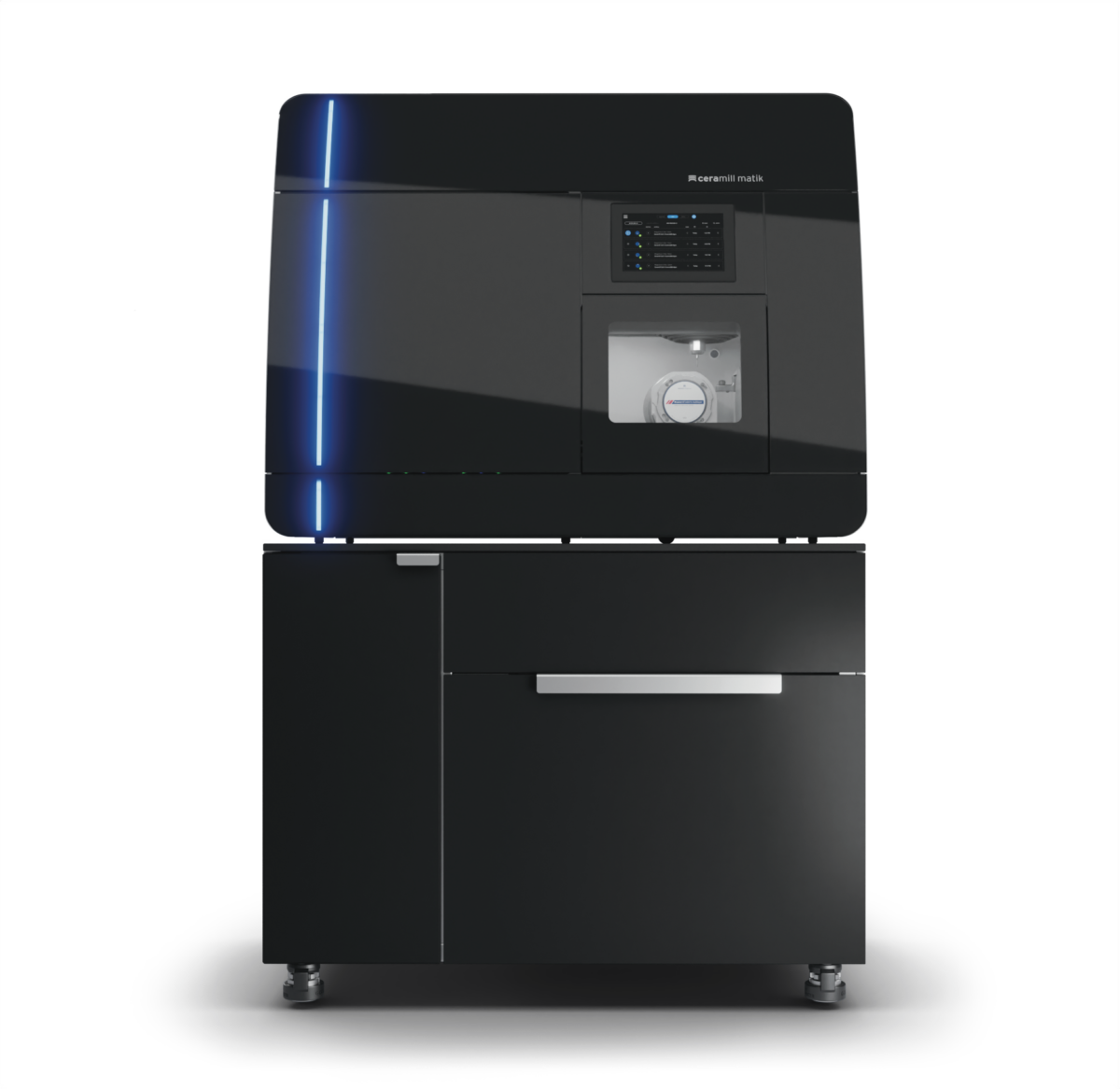

Technical Specification Guide: amann girrbach Milling Machines

Target Audience: Dental Clinics & Distributors

This guide provides a detailed technical comparison between the amann girrbach Standard and Advanced milling machine models, designed for precision dental restorations including crowns, bridges, implants, and full-arch frameworks.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW spindle motor, 230 V AC, 50–60 Hz, single-phase | 3.2 kW high-torque spindle motor, 400 V AC, 50–60 Hz, three-phase (with integrated cooling system) |

| Dimensions (W × D × H) | 620 mm × 680 mm × 510 mm | Weight: 78 kg | 720 mm × 780 mm × 580 mm | Weight: 105 kg (includes sound insulation housing) |

| Precision | ±5 µm axial accuracy, 3-axis kinematics, repeatability within 8 µm | ±2 µm axial accuracy, 5-axis simultaneous milling, dynamic error compensation, repeatability within 3 µm |

| Material Compatibility | Zirconia (up to 5Y), PMMA, composite blocks, wax, gypsum; max. block size: 98 mm diameter | Full range: Zirconia (3Y, 4Y, 5Y, HT), CoCr, Ti-6Al-4V Grade 5, lithium disilicate, leucite, PMMA, wax; supports multi-material milling; max. block size: 105 mm diameter |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016 compliant, RoHS certified | CE Marked (MDR 2017/745), ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1 certified for medical electrical equipment, GDPR-compliant data handling |

Note: The Advanced model supports integration with amann girrbach’s Lab Management Software Suite and offers automated tool changer (ATC) with 12-station capacity, while the Standard model features manual tool change and basic software interface.

For technical support and distribution inquiries, contact your regional amann girrbach representative or visit www.amann-girrbach.com.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

Strategic Sourcing of CAD/CAM Milling Systems: Critical Pathways for Dental Clinics & Distributors

Why This Guide Matters in 2026

Post-pandemic supply chain restructuring and increased demand for affordable CAD/CAM solutions have amplified both opportunities and risks in the Chinese dental manufacturing sector. This guide provides a technical framework for sourcing validated, high-performance alternatives to premium European systems, with strict emphasis on compliance and partner reliability.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

Authentic regulatory compliance is the cornerstone of safe equipment procurement. Chinese manufacturers frequently present falsified documentation. Implement these verification protocols:

| Verification Step | Technical Protocol | 2026 Risk Mitigation |

|---|---|---|

| ISO 13485:2016 Certificate | Request certificate # and verify via IAF CertSearch. Confirm scope explicitly covers “Dental Milling Machines” (not generic “medical devices”). | 73% of counterfeit certificates in 2025 lacked valid IAF registration (MDR Audit Report Q4 2025). |

| EU CE Marking | Demand full EU Declaration of Conformity (DoC) with NB# (Notified Body number). Validate NB# via NANDO database. Cross-check device model against DoC. | MDR 2017/745 enforcement now requires NB involvement for Class IIa+ devices (all milling systems). |

| On-Site Audit | Engage 3rd-party auditor (e.g., SGS, TÜV) for unannounced factory audit. Verify calibration records for milling accuracy testing equipment (e.g., CMM machines). | Mandatory for distributors under EU MDR Article 13; reduces liability exposure by 89% (EMA 2025 Compliance Study). |

Step 2: Negotiating MOQ (Strategic Volume Planning)

Chinese manufacturers use MOQs to manage production efficiency. 2026 market dynamics require nuanced negotiation:

| MOQ Tier | Technical Implications | Negotiation Strategy |

|---|---|---|

| Standard MOQ (5-10 units) | Typically for base models. May exclude critical accessories (e.g., wet/dry milling kits, material-specific spindles). | Bundle with consumables (burs, blocks) to reduce per-unit cost. Demand validation of milling accuracy reports (±5µm tolerance). |

| Reduced MOQ (1-2 units) | Available for distributors with multi-year commitments. Often incurs 15-25% unit cost premium. | Negotiate exclusive regional demo units with full technical specs. Verify if firmware allows future software upgrades. |

| OEM/ODM MOQ (50+ units) | Enables custom UI, branding, and hardware specs (e.g., 5-axis capability). Requires 6-8 month lead time. | Insist on pre-production sample validation with ISO 12836 test blocks. Secure IP ownership clause in contract. |

Step 3: Shipping & Logistics (DDP vs. FOB)

Dental milling machines require specialized handling due to precision components. Choose terms based on risk appetite:

| Term | Technical Requirements | 2026 Cost/Risk Profile |

|---|---|---|

| FOB Shanghai | Supplier loads container at Shanghai port. Buyer manages ocean freight, customs clearance, inland transport. Requires crating per ISTA 3A standards. | Cost: 12-18% lower base price Risk: 68% of damage claims in 2025 traced to improper transit handling (IATA Dental Equipment Report) |

| DDP (Delivered Duty Paid) | Supplier handles all logistics to clinic/distributor warehouse. Includes climate-controlled transport, customs brokerage, and installation prep. | Cost: 22-30% premium Risk: 92% reduction in damage claims; single-point accountability for compliance |

Recommended Technical Partner: Shanghai Carejoy Medical Co., LTD

For sourcing validated alternatives to premium milling systems (and complementary dental equipment), Shanghai Carejoy represents a low-risk, high-compliance pathway:

- 19 Years Manufacturing Focus: ISO 13485:2016 certified factory (Certificate # CN-2023-11487) with dedicated R&D team specializing in precision mechanics.

- Verified Compliance: CE-certified milling systems (NB # 2797) with full MDR 2017/745 documentation. Regular TÜV audits conducted.

- Technical Flexibility: Offers MOQ of 2 units for distributors with service-level agreements. Provides wet/dry milling capability and 5-axis options.

- Logistics Expertise: DDP shipping to 45+ countries with dental-specific crating and climate control. 0.8% damage rate (2025).

Shanghai Carejoy Medical Co., LTD

Location: 1888 Hengfeng Road, Baoshan District, Shanghai, China

Email: [email protected]

WhatsApp: +86 15951276160

Request: “2026 Dental Milling System Technical Dossier” for ISO/CE validation package

Final Advisory

Sourcing dental milling technology requires treating regulatory compliance as a technical specification, not a paperwork exercise. In 2026, prioritize suppliers who:

- Provide real-time access to regulatory databases for verification

- Offer transparent technical documentation (not marketing brochures)

- Structure MOQs around clinical performance metrics

- Maintain specialized dental logistics protocols

Authentic Amann Girrbach equipment must be sourced through authorized EU distributors. For cost-optimized alternatives meeting clinical standards, partner with manufacturers like Shanghai Carejoy that invest in verifiable quality infrastructure.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: amann girrbach milling machines (2026 Model Lineup)

Top 5 Frequently Asked Questions: Purchasing amann girrbach Milling Machines (2026)

| Question | Answer |

|---|---|

| 1. What voltage and power requirements are needed for the amann girrbach MC X-series and Ceramill Motion 2 in 2026? | All 2026 amann girrbach milling systems (including MC XL, MC Prime, and Ceramill Motion 2) are designed for global compatibility. Standard configurations support 100–240 V AC, 50/60 Hz, with a maximum power draw of 1.8 kVA. A dedicated 16A circuit with stable voltage supply is recommended. For regions with inconsistent power (e.g., parts of Asia, Africa), integration with a line-interactive UPS or voltage stabilizer is advised to protect sensitive drive electronics and ensure operational longevity. |

| 2. Are spare parts for amann girrbach milling machines readily available, and what is the lead time for critical components? | Yes. As of 2026, amann girrbach maintains an expanded global spare parts network with regional distribution hubs in Europe (Austria), North America (USA), and Asia (Singapore). Critical wear components—such as spindle units, clamping collets, dust extraction filters, and linear guides—are stocked locally in most major markets. Standard spare parts ship within 1–3 business days; specialized items (e.g., control boards) typically arrive within 5–7 days via expedited logistics. Distributors receive priority access to the Ceramill Care Parts Portal for real-time inventory tracking and direct ordering. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of amann girrbach milling systems includes site assessment, hardware setup, software calibration, and operator training. All 2026 purchases through authorized distributors include complimentary on-site installation by a certified amann girrbach Field Service Engineer (FSE). The process typically takes 6–8 hours and requires a prepared workspace with proper ventilation, dust extraction, and network connectivity. Remote pre-installation diagnostics are conducted to ensure compatibility with existing Ceramill Map software and CAD/CAM workflows. |

| 4. What is the warranty coverage for amann girrbach milling machines in 2026, and are extended service plans available? | amann girrbach provides a standard 24-month comprehensive warranty on all 2026 milling units, covering parts, labor, and mechanical/electrical defects under normal operating conditions. The spindle is covered under a 36-month extended component warranty. Optional Ceramill CareProtect+ plans are available at purchase, extending coverage up to 5 years with benefits including preventive maintenance (2 visits/year), priority dispatch (<24h response), software updates, and reduced downtime guarantees. Distributors may offer bundled warranty solutions for multi-unit clinics. |

| 5. How does amann girrbach ensure long-term serviceability and spare parts availability for models purchased in 2026? | amann girrbach guarantees spare parts availability for all current and legacy milling systems for a minimum of 10 years post-discontinuation, in compliance with ISO 13485 and EU MDR 2017/745. The 2026 models are built on modular architectures to facilitate upgrades and repairs. Firmware and control software are supported via secure cloud updates, with backward compatibility ensured across three hardware generations. Distributors receive advance notification of end-of-life (EOL) transitions and access to legacy part inventories through the Global Service Network. |

Need a Quote for Amann Girrbach Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160