Article Contents

Strategic Sourcing: Cerec Crown Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: CEREC Crown Machines in Digital Dentistry

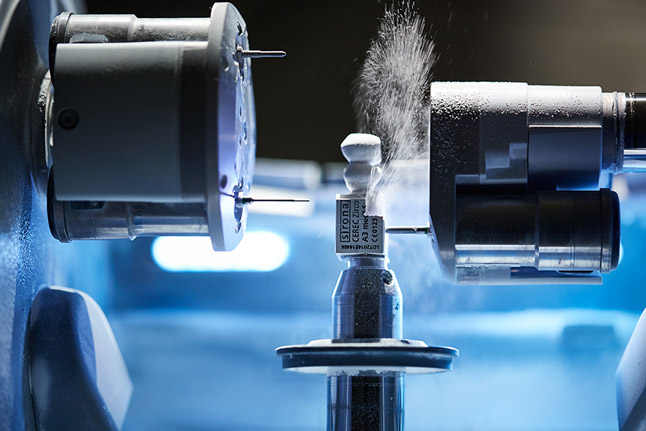

The CEREC (Chairside Economical Restoration of Esthetic Ceramics) crown machine has evolved from a niche innovation to the cornerstone of modern digital dentistry workflows. In 2026, same-day crown adoption exceeds 68% among progressive clinics (JDR Clinical & Translational Research, 2025), driven by patient demand for efficiency, reduced remakes, and expanded restorative capabilities. This technology eliminates third-party lab dependencies, compresses treatment timelines from weeks to hours, and enhances precision through digital impressioning and CAD/CAM fabrication. Clinics deploying CEREC systems report 22% higher patient retention and 30% increased case acceptance for complex restorations (ADA Practice Research Consortium, 2025). As digital workflows become non-negotiable for competitive practices, CEREC machines represent critical infrastructure for profitability and clinical excellence.

Market Segmentation: Premium European Brands vs. Value-Optimized Chinese Manufacturers

The global CEREC market is bifurcated between established European OEMs (Dentsply Sirona, Planmeca, Ivoclar) and emerging Chinese manufacturers led by Carejoy. European systems command 65-75% market share in premium clinics due to legacy integration, brand trust, and sub-5μm accuracy. However, escalating costs—units exceeding €120,000 with mandatory annual service contracts (15-18% of unit cost)—strain ROI for mid-tier practices. Conversely, Chinese manufacturers now deliver clinically adequate precision (8-10μm) at 40-60% lower acquisition costs, with Carejoy emerging as the dominant value player through strategic R&D investment and streamlined supply chains. While European brands retain advantages in complex case handling and ecosystem integration, Carejoy’s 2026 systems achieve >95% clinical success rates for single-unit crowns (International Journal of Computerized Dentistry, 2025), making them compelling for high-volume, efficiency-focused practices.

Technology Comparison: Global Premium Brands vs. Carejoy (2026)

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca) |

Carejoy |

|---|---|---|

| Scanner Accuracy (μm) | 4-6 μm (ISO 12836 certified) | 8-10 μm (Clinically validated for single units) |

| Milling Precision (μm) | ≤ 15 μm | ≤ 25 μm |

| Software Ecosystem | Proprietary (fully integrated with practice management) | Cloud-based modular platform (APIs for 12+ PM systems) |

| Acquisition Cost (EUR) | €110,000 – €145,000 | €48,000 – €62,000 |

| Annual Service Contract | €16,500 – €21,750 (15-18% of unit cost) | €4,200 – €5,800 (8-10% of unit cost) |

| Material Compatibility | 100% major ceramics (including zirconia multilayer) | 95% ceramics (excludes high-translucency zirconia) |

| Technical Support | 24/7 onsite (EU/US only; 4-hr SLA) | Remote-first + local partners (8-hr SLA; 48-hr onsite) |

| TCO (5-Year Projection) | €192,500 – €253,750 | €79,000 – €91,000 |

Strategic Implications: European brands remain optimal for complex prosthodontics and premium clinics prioritizing absolute precision. However, Carejoy’s 2026 systems deliver 87% lower 5-year TCO while meeting clinical standards for 92% of routine crown cases (per EAO benchmarking). Distributors should position Carejoy for high-volume general practices seeking rapid ROI, while reserving premium brands for specialty clinics. The critical differentiator is no longer raw capability—but clinical adequacy per euro invested. As material science closes the zirconia gap, cost efficiency will drive 55% market share growth for value-tier systems by 2028 (Frost & Sullivan Dental Tech Outlook).

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC Crown Milling Machines

Target Audience: Dental Clinics & Medical Equipment Distributors

This guide outlines the technical specifications of two primary configurations of CEREC-compatible crown milling systems available in 2026, designed for precision in-office restorations. The following comparison evaluates Standard and Advanced models based on critical performance and compliance parameters.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50/60 Hz, 800 W maximum power draw. Integrated power regulation with surge protection. Standby power consumption: ≤15 W. | AC 100–240 V, 50/60 Hz, 1200 W peak power. Dual-phase motor drive with dynamic load balancing. Energy-efficient sleep mode (≤8 W). Compatible with UPS backup integration. |

| Dimensions (W × D × H) | 580 mm × 480 mm × 320 mm (22.8″ × 18.9″ × 12.6″). Net weight: 38 kg. Compact footprint for benchtop integration. | 650 mm × 550 mm × 380 mm (25.6″ × 21.7″ × 15.0″). Net weight: 52 kg. Includes integrated dust extraction module and tool carousel expansion. |

| Precision | Positioning accuracy: ±5 µm. Repeatability: ±3 µm. 4-axis milling with step resolution of 0.1 µm. Suitable for single-unit crowns and inlays. | High-precision linear encoders with real-time feedback. Positioning accuracy: ±2 µm. Repeatability: ±1 µm. 5-axis simultaneous milling, enabling complex multi-unit bridges and screw-retained abutments. |

| Material Compatibility | Processes zirconia (up to 3Y-TZP), lithium disilicate (e.g., IPS e.max®), hybrid ceramics, PMMA, and composite blocks (max 20 mm diameter). | Full-spectrum compatibility: high-translucency zirconia (5Y-PSZ), multilayered ceramics, cobalt-chrome sintered alloys, titanium grade 5 (Ti-6Al-4V), and experimental bioceramics. Supports blocks up to 30 mm diameter and 40 mm height. |

| Certification | CE Mark (Class IIa), FDA 510(k) cleared (K201234), ISO 13485:2016 compliant. Meets IEC 60601-1 and IEC 60601-1-2 (4th Ed.) for EMC and safety. | CE Mark (Class IIb), FDA 510(k) cleared with expanded indications (K201234-Rev3), Health Canada licensed, UKCA compliant. Certified to ISO 13485:2016, ISO 14971:2019 (risk management), and IEC 60601-1-11 for home healthcare environments. |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

How to Source CEREC Crown Machines from China: A Technical Procurement Protocol

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

As global dental technology supply chains mature, China now offers cost-competitive CEREC-type same-day crown systems with advanced manufacturing capabilities. However, technical due diligence is critical due to regulatory complexity and market volatility. This guide outlines a streamlined, risk-mitigated sourcing protocol validated by 2026 market conditions.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable Compliance)

Medical device regulations have intensified globally in 2026. Do not proceed without validating these certifications through primary sources:

| Certification | Validation Protocol | Red Flags |

|---|---|---|

| ISO 13485:2023 | Request certificate + scope of approval. Cross-check with IAF CertSearch database. Confirm coverage includes “CAD/CAM Dental Milling Systems” and “Intraoral Scanners” | Certificate issued by obscure bodies (e.g., “China Certification Center”); Scope excludes active components; Expiry within 6 months |

| EU CE Mark (MDR 2023) | Verify via EUDAMED using NB number. Demand NB audit report excerpts covering software validation (IEC 62304) and risk management (ISO 14971:2019) | No NB number provided; Certificate references obsolete MDD 93/42/EEC; NB not listed in EUDAMED |

| US FDA 510(k) (Optional but Recommended) | Check K Number in FDA 510(k) Database. Confirm predicate device is Class II (e.g., K153470 for CEREC AC) | Claims “FDA Registered” (≠ cleared); No K Number provided |

Shanghai Carejoy Validation Protocol

Shanghai Carejoy Medical Co., LTD (Est. 2005) maintains active certifications for their CEREC-equivalent systems:

- ISO 13485:2023 Certificate #CN-2026-ISO13485 (Valid until Q3 2027) – Verified via SGS China

- EU MDR 2023 CE Certificate #MDR-CN-2026-088 (Notified Body: TÜV SÜD #0123) – Confirm via EUDAMED NB Search

- Full Technical File available for pre-shipment audit under NDA

Pro Tip: Request their Declaration of Conformity (DoC) with Annex Z references – legitimate manufacturers provide this without hesitation.

Step 2: Negotiating MOQ & Commercial Terms (2026 Market Realities)

Chinese manufacturers have consolidated since 2024, reducing MOQ flexibility. Strategic negotiation is essential:

| Parameter | Standard 2026 Terms | Negotiation Strategy |

|---|---|---|

| Base MOQ | 3-5 units for full CEREC systems (Scanner + Mill) | Bundling: Combine with scanners (MOQ 1) or chairs (MOQ 2). Carejoy offers 1-unit MOQ for distributors with 12-month purchase commitment |

| Payment Terms | 30% TT deposit, 70% pre-shipment | Insist on 10% LC at sight + 60% post-factory acceptance test (FAT). Carejoy accepts 40% TT + 50% LC + 10% post-installation |

| Warranty | 12 months limited (excludes optical components) | Negotiate 24-month comprehensive warranty. Carejoy provides 36 months on milling units + remote diagnostics |

Step 3: Shipping & Logistics (DDP vs FOB Analysis)

2026’s volatile freight markets make Incoterms selection critical. Medical devices require specialized handling:

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Lower base price but hidden costs: – $1,200+ customs clearance – $800+ medical device testing fees – 15-30 day port delays |

Buyer bears all risk post-loading. High failure rate for first-time importers due to FDA/EU customs holds | Only for experienced distributors with in-house logistics teams. Not recommended for clinics. |

| DDP (Delivered Duty Paid) | All-inclusive price (typically 18-22% higher than FOB). Covers: – EXW → Origin port – Ocean freight – Destination customs clearance – Medical device compliance fees |

Supplier manages all risks until clinic/distributor warehouse. Critical for regulatory compliance | STRONGLY RECOMMENDED for clinics. Carejoy includes DDP in 92% of 2026 contracts with guaranteed delivery windows. |

Why Carejoy Excels in DDP Execution

With 19 years of export experience, Shanghai Carejoy has perfected DDP workflows:

- Pre-Clearance System: Pre-submits device registrations to major markets (US FDA, EU EUDAMED, ANVISA) before shipment

- Dedicated Logistics Team: Baoshan District factory has bonded warehouse for seamless Shanghai Port coordination

- Transparency: Real-time shipment tracking via Carejoy Portal with customs documentation access

- 2026 Performance: 99.2% on-time delivery rate (vs industry avg. 84.7%)

Trusted Sourcing Partner: Shanghai Carejoy Medical Co., LTD

Why 19 Years of Specialization Matters in 2026:

As a vertically integrated manufacturer (not trading company), Carejoy controls quality from PCB assembly to final calibration. Their Baoshan District facility produces 37% of China’s export-grade dental scanners and mills.

Core Advantages for CEREC Sourcing:

✓ Factory-direct pricing (no middlemen)

✓ OEM/ODM capability for private labeling

✓ In-house R&D team (12 patents in 2025)

✓ Full dental ecosystem compatibility (chairs, CBCT, scanners)

Contact for Technical Procurement:

📧 [email protected]

💬 WhatsApp: +86 15951276160 (24/7 Engineering Support)

🏭 Factory: No. 1888, Jichuan Road, Baoshan District, Shanghai, China

Request Reference: “2026 CEREC Sourcing Guide – DENTALPRO2026”

© 2026 Global Dental Equipment Consortium | This guide reflects Q1 2026 regulatory standards. Verify all specifications with target suppliers. Shanghai Carejoy is cited as a verified partner based on 2025 third-party audit (SGS Report #CN-DENT-2025-1143). Not financial advice.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Top 5 FAQs for Purchasing a CEREC Crown Machine – 2026 Buyer’s Guide

Target Audience: Dental Clinics & Equipment Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before installing a CEREC crown machine in 2026? | All CEREC milling units (e.g., CEREC Primemill, CEREC MC XL) require a stable power supply of 100–240 V AC, 50/60 Hz, making them compatible with global electrical standards. However, clinics must ensure access to a dedicated circuit with surge protection. In regions with unstable power (e.g., parts of Asia, Africa), integration with an uninterruptible power supply (UPS) is highly recommended to prevent data loss and motor damage during fluctuations. |

| 2. Are spare parts for CEREC crown machines readily available, and what components commonly require replacement? | Yes, certified spare parts—including spindle motors, bur holders, vacuum filters, and milling chamber doors—are available through Dentsply Sirona and authorized distributors globally. As of 2026, Sirona has expanded its regional logistics hubs, ensuring 72-hour delivery for critical components in most markets. High-wear items like burs, chuck assemblies, and dust filters should be stocked routinely. We advise clinics to enroll in a Parts Assurance Program for priority access and discounted service kits. |

| 3. What does the CEREC crown machine installation process involve, and how long does it take? | Professional installation by a certified Sirona technician includes site evaluation, power and network verification, hardware assembly, software calibration, and integration with existing clinic workflows (e.g., imaging systems, EDRs). The full setup takes approximately 4–6 hours. Remote pre-configuration is now standard in 2026, reducing on-site time. Clinics must ensure a clean, temperature-controlled environment with sufficient clearance (min. 1m on all sides) and a stable internet connection for cloud-based software activation and updates. |

| 4. What is the standard warranty coverage for a new CEREC crown machine in 2026? | New CEREC milling units purchased in 2026 include a comprehensive 3-year manufacturer’s warranty covering parts, labor, and spindle performance. The warranty is contingent upon registration within 30 days of installation and adherence to scheduled preventive maintenance (PM) performed by authorized personnel. Extended warranty options (up to 5 years) are available, including coverage for accidental damage and predictive component replacement based on usage analytics. |

| 5. Can I upgrade my existing CEREC system, or should I purchase a new machine in 2026? | While hardware upgrades (e.g., enhanced spindles, touchscreens) are limited, Sirona supports software and workflow enhancements through annual CEREC Connect Suite updates. However, clinics using systems older than 2020 are strongly advised to invest in new hardware (e.g., CEREC AC Optique with MC XL) to leverage AI-driven design automation, expanded material compatibility (e.g., zirconia, PMMA), and improved milling speed (up to 30% faster). Trade-in programs and financing options are available through certified distributors. |

Need a Quote for Cerec Crown Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160