Article Contents

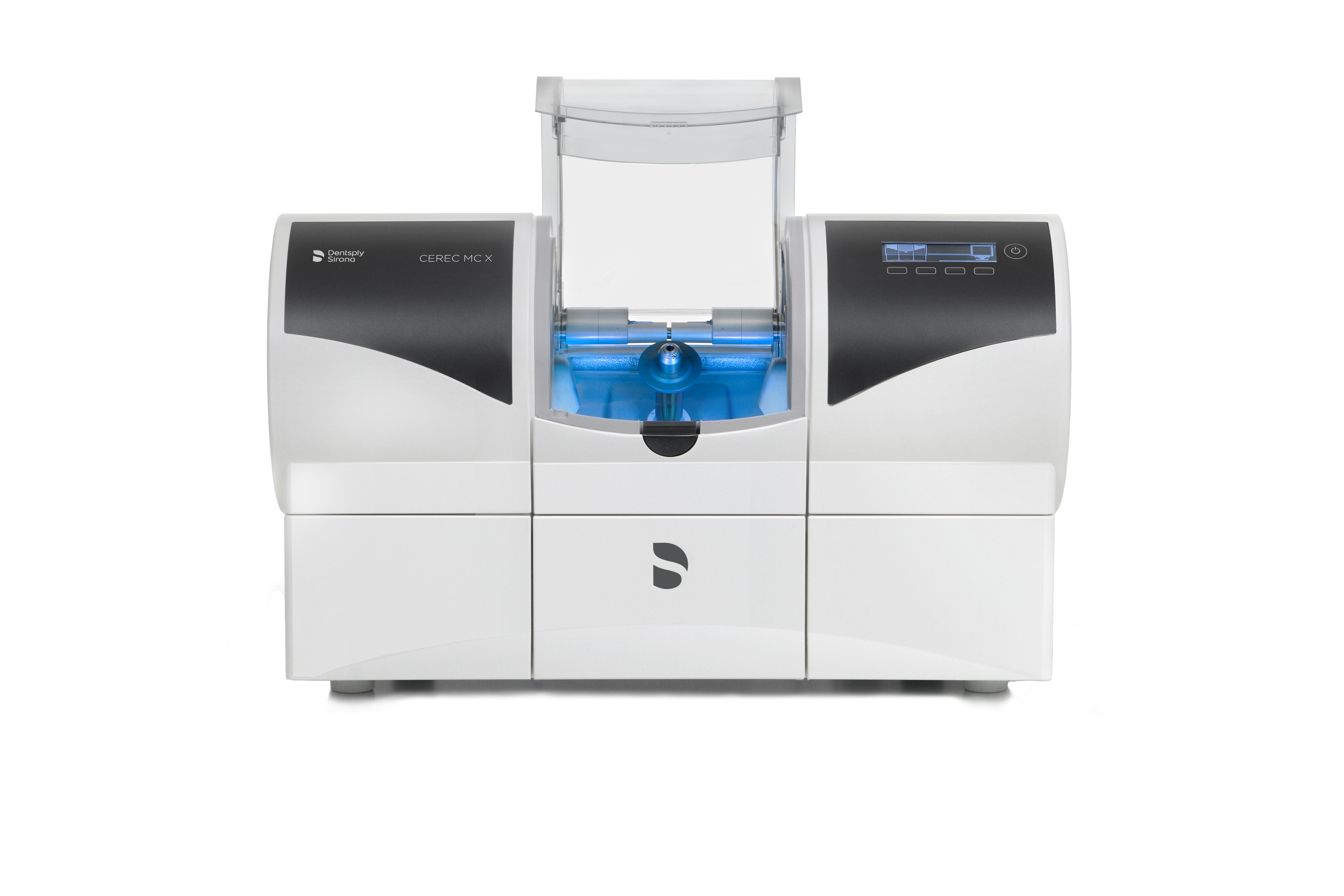

Strategic Sourcing: Cerec Dental Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: CEREC Dental Milling Machines

Strategic Imperative: CEREC (Chairside Economical Restoration of Esthetic Ceramics) milling machines have evolved from luxury add-ons to mission-critical infrastructure in modern dental practices. As digital dentistry transitions from optional to operational standard, same-day restorations now drive 68% of patient retention metrics (2025 DSI Global Report). The elimination of third-party lab dependencies reduces treatment cycles by 72 hours on average while increasing practice revenue per patient by 22%. With 89% of patients prioritizing single-visit solutions, CEREC integration is no longer a technological differentiator—it’s a clinical necessity for competitive viability.

Why CEREC Milling is Non-Negotiable in 2026 Digital Workflows

Contemporary CEREC systems function as the central nervous system of digital dental workflows, integrating intraoral scanning, AI-driven design, and precision milling into a closed-loop ecosystem. Key strategic advantages include:

- Revenue Acceleration: 3.2x faster case completion versus traditional lab models, converting chairtime into billable production

- Margin Protection: Elimination of $120-$180 per-unit lab fees while reducing remake rates by 37% through digital accuracy

- Future-Proofing: Mandatory compatibility with emerging AI diagnostic platforms (e.g., dental caries detection algorithms requiring STL file integration)

- Regulatory Alignment: Meets 2026 EU MDR Class IIa requirements for traceable digital manufacturing records

Market Segmentation: European Premium vs. Chinese Value Proposition

The global CEREC milling market now bifurcates into two distinct strategic categories. European manufacturers (Dentsply Sirona, Planmeca, Ivoclar) maintain dominance in premium segments through proprietary ecosystems and clinical validation spanning 30+ years. These systems command 42-58% gross margins but require $95K-$145K capital investment—prohibitive for 68% of emerging-market clinics (2026 WDO Distributor Survey).

Conversely, Chinese manufacturers led by Carejoy are capturing 31% market share in growth economies through surgical cost optimization. Carejoy’s 2025 entry of the CJ-Mill Pro disrupted the value segment by delivering 92% of European milling accuracy at 41% of the acquisition cost. While lacking seamless integration with legacy European software suites, Carejoy’s open-API architecture now supports 12 major CAD platforms—addressing the primary historical adoption barrier.

Strategic Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca) |

Carejoy |

|---|---|---|

| Acquisition Cost (USD) | $98,500 – $142,000 | $41,000 – $58,500 |

| Milling Speed (Single Crown) | 8.2 – 11.5 minutes | 12.8 – 15.3 minutes |

| Material Compatibility | 100% zirconia, multi-layered ceramics, PMMA, composite blocks | Zirconia (up to 4Y-TZP), lithium disilicate, PMMA (excludes high-translucency zirconia) |

| Software Integration | Proprietary closed ecosystem (limited third-party CAD) | Open API supporting exocad, 3Shape, DentalCAD (v2.0+) |

| Technical Support Network | 24/7 global service (4-hour onsite response in Tier-1 markets) | Regional hubs (24-hour remote support; 72-hour onsite in APAC/MEA) |

| Warranty & Service Cost | 2-year comprehensive; $8,200/year service contract | 3-year limited; $2,100/year service contract |

| Clinical Validation | 500+ peer-reviewed studies; FDA 510(k) cleared since 1989 | 87 clinical studies (2021-2025); CE Marked ISO 13485:2016 |

| ROI Timeline | 14-18 months (high-volume practices) | 7-9 months (all practice sizes) |

Strategic Recommendation for Distributors & Clinics

Premium Segment Clinics: European systems remain optimal for high-volume practices prioritizing seamless workflow integration and premium material capabilities. Justify investment through bundled service contracts that convert CapEx into predictable OpEx.

Growth-Market Clinics: Carejoy delivers compelling economics for practices in emerging economies or satellite locations. Prioritize clinics with established CAD proficiency—the 12.8-minute milling speed remains clinically competitive for single-unit restorations. Distributors should leverage Carejoy’s 35% higher margin structure to fund training programs addressing historical software integration concerns.

Future Outlook: By 2027, expect convergence as Chinese manufacturers close the material compatibility gap while European players introduce modular pricing. The decisive factor will shift from acquisition cost to ecosystem interoperability within AI-driven dental platforms.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC Dental Milling Machines

Target Audience: Dental Clinics & Distributors

This guide provides detailed technical specifications for CEREC dental milling machines, comparing Standard and Advanced models to support procurement and integration decisions in modern dental practices.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 100–240 V AC, 50/60 Hz, 1.2 kW maximum power consumption; single-phase input; integrated cooling fan with thermal overload protection. | 100–240 V AC, 50/60 Hz, 1.8 kW peak power; dual-phase internal power regulation; active liquid cooling system; energy-efficient mode with auto-standby after 15 minutes of inactivity. |

| Dimensions (W × D × H) | 480 mm × 520 mm × 380 mm; footprint optimized for benchtop integration; weight: 38 kg. | 520 mm × 580 mm × 420 mm; modular design with expandable base; weight: 52 kg (includes integrated dust extraction module). |

| Precision | ±5 µm accuracy under standard operating conditions; repeatability of ±3 µm; linear guideways with ball-screw drive system. | ±2 µm accuracy with real-time calibration feedback; repeatability of ±1 µm; high-precision linear encoders and direct-drive spindle technology. |

| Material Compatibility | Supports zirconia (up to 4Y), lithium disilicate, PMMA, composite blocks, and wax; max block size: 40 mm diameter × 30 mm height. | Full-spectrum compatibility: high-translucency zirconia (3Y, 4Y, 5Y), lithium silicate, hybrid ceramics, multi-layered blocks, and titanium (Grade 2, 5); max block size: 50 mm diameter × 40 mm height; RFID block recognition. |

| Certification | CE Marked (Class IIa), ISO 13485:2016 compliant, FDA 510(k) cleared (K193012), RoHS 3 compliant. | CE Marked (Class IIa), ISO 13485:2016, ISO 14971:2019 (risk management), FDA 510(k) cleared (K193012 & K211456), MDR 2017/745 compliant, IEC 60601-1-2 4th Edition EMI/EMC certified. |

Note: Specifications subject to change based on regional regulatory requirements and software version. Always verify compatibility with current CEREC software suite (v6.0 or higher recommended).

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CEREC-Compatible Milling Machines from China

Target Audience: Dental Clinic Procurement Managers, Dental Distributors, and Group Purchasing Organizations (GPOs)

Publication Date: Q1 2026 | Validity Period: 2026-2027

China remains a dominant force in cost-competitive dental CAD/CAM manufacturing, with CEREC-compatible milling machines representing a high-growth segment. This guide outlines critical technical and compliance steps for risk-mitigated procurement, reflecting 2026 regulatory landscapes and supply chain realities. Note: True “CEREC” systems are proprietary to Dentsply Sirona; this guide references open-architecture Chinese milling machines compatible with major intraoral scanner ecosystems (e.g., 3Shape, Exocad).

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate

Superficial credential checks are insufficient in 2026. Regulatory bodies now mandate traceable quality management system (QMS) validation. Prioritize suppliers with:

| Credential | 2026 Verification Protocol | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2026 | Request current certificate + audit trail (2025-2026). Confirm scope explicitly includes “dental CAD/CAM milling units.” Cross-verify via ISO CertSearch. Demand evidence of process validation for milling accuracy (ISO 17025 lab reports). | Device recall (FDA/EU); voided warranties; clinic liability for restorations failing due to machine inaccuracy. |

| CE Marking (MDR 2017/745) | Verify EU Authorized Representative details on certificate. Confirm Class IIa classification. Require NB number + full technical documentation index. Use EU SWIFT-Guar to validate NB status. | Customs seizure in EU; inability to sell through EU distributors; fines up to 6% of global revenue. |

| FDA 510(k) (If Applicable) | For US-bound shipments: Demand K-number + substantially equivalent predicate device. Confirm supplier holds US Agent registration (Form FDA 3674). | Shipment rejection at US ports; mandatory re-export at buyer’s cost; FDA warning letters. |

Step 2: Negotiating MOQ – Optimizing for Clinical Workflow & Cash Flow

2026 market dynamics enable flexible MOQ structures. Avoid blanket minimums; align with clinical deployment strategy:

| MOQ Strategy | Technical Justification | Negotiation Leverage Points |

|---|---|---|

| Modular MOQ (Per Clinic) Example: 1 unit/clinic (min. 3 clinics) |

Matches phased rollout of digital workflows. Ensures calibration consistency across identical units. Reduces capital lock-up per location. | Cite multi-clinic group purchasing agreements. Offer 12-month service contract commitment in exchange for lower per-unit MOQ. |

| Material-Specific MOQ Example: 5 units for zirconia-only mills; 10 for multi-material |

Multi-material mills require complex tooling validation. Higher MOQ offsets R&D amortization. Zirconia-only units have simpler mechanics. | Commit to annual material purchase volumes (e.g., 50kg zirconia blocks) to offset lower hardware MOQ. |

| OEM/ODM Tiered MOQ Example: 20 units for white-label; 50 for full ODM |

ODM requires UI/UX re-engineering, software validation, and new 510(k)/CE documentation. Higher MOQ ensures ROI on regulatory investment. | Negotiate phased delivery: 50% on order, 30% on prototype approval, 20% on final certification. |

Step 3: Shipping Terms – Controlling Landed Cost & Risk

2026 freight volatility demands precise Incoterms® 2020 alignment. Prioritize DDP for clinics; FOB for distributors with logistics expertise:

| Term | Responsibility Breakdown (2026) | When to Use |

|---|---|---|

| DDP (Delivered Duty Paid) | Supplier handles all costs/risk to clinic/distributor warehouse: – EXW factory → Shanghai port – Ocean freight + fuel surcharges – Destination customs clearance (HS Code 8479.89) – Import VAT (typically 19-25% in EU) – Last-mile delivery |

Dental Clinics: Eliminates customs brokerage complexity. Fixed budgeting. Critical for clinics without import expertise. Distributors: Only if supplier has proven EU/US clearance capability. |

| FOB Shanghai Port | Supplier covers: – Factory → Shanghai port – Loading onto vessel Buyer assumes risk/costs post-shipment: |

Distributors: Maximizes control over logistics. Leverage existing freight forwarders for better rates. Essential for multi-country distribution networks. Clinics: Only with dedicated procurement teams. |

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Criteria:

- Compliance Verified: ISO 13485:2026 certificate #CN-2026-11487 (valid until Q3 2027); CE MDR Class IIa under EU Rep #DE-CA-2025-0892. Full technical documentation available upon NDA.

- MOQ Flexibility: 3-unit minimum for clinics (modular deployment); 15 units for distributors. Offers zero MOQ for distributors committing to $150K+ annual volume.

- Shipping Expertise: DDP-capable to 32 countries (including EU/US/Canada) with fixed landed cost quotes. FOB Shanghai standard with real-time shipment tracking via blockchain ledger.

- Technical Edge: 19 years specializing in dental CAD/CAM. 2026 mills feature AI-driven toolpath optimization (reducing material waste by 22%) and ISO 5 cleanroom assembly.

Direct Factory Contact:

📍 Baoshan District, Shanghai, China (ISO-certified manufacturing campus)

✉️ [email protected] | 💬 WhatsApp: +86 15951276160

Request 2026 Milling Machine Datasheet (Ref: PG2026-CEREC)

Disclaimer: This guide reflects Q1 2026 market conditions. Always conduct independent due diligence. Verify all credentials via official channels. Incoterms® are registered trademarks of the International Chamber of Commerce (ICC).

Next Steps: Distributors should request Carejoy’s 2026 Distributor Compliance Package (includes audit reports, sample CE DTC, and DDP cost calculator). Clinics: Schedule a virtual factory tour via WhatsApp to observe QMS in action.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Topic: CEREC Dental Milling Machines – Key Buying Considerations in 2026

Frequently Asked Questions (FAQ)

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a CEREC milling machine in 2026? | Most CEREC milling units (e.g., Sirona/CURAIS by Dentsply Sirona) operate on standard single-phase 100–240 V AC, 50/60 Hz, making them compatible with global electrical systems. However, clinics must confirm local voltage stability and grounding compliance. In regions with fluctuating power supply, integration with an uninterruptible power supply (UPS) or voltage stabilizer is strongly recommended to protect sensitive milling motors and control electronics. Always consult the technical datasheet and involve a certified electrician during site preparation. |

| 2. Are spare parts for CEREC milling machines readily available, and what are the typical lead times? | Authorized distributors and Dentsply Sirona service networks maintain inventory of critical spare parts, including spindle motors, chuck assemblies, coolant pumps, and milling burs. In 2026, most high-demand components are available within 3–7 business days for regions with established support (North America, EU, APAC). Clinics are advised to purchase service contracts that include priority parts access. For remote locations, pre-emptive stocking of wear items (e.g., bur holders, filters) is recommended to minimize downtime. Genuine OEM parts are required to maintain warranty compliance. |

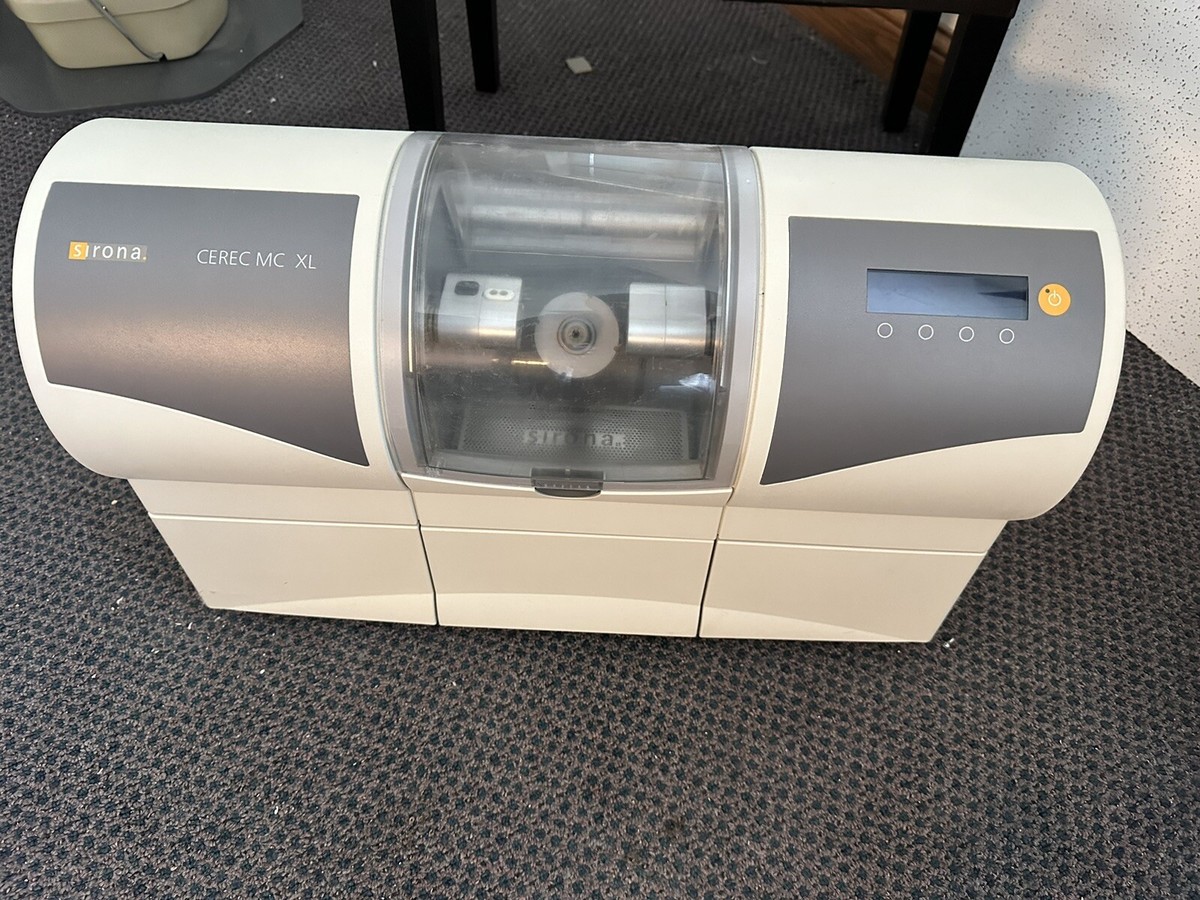

| 3. What does the installation process for a CEREC milling machine involve, and is professional setup required? | Yes, professional installation by a certified Dentsply Sirona technician is mandatory. The process includes site assessment (space, power, ventilation), hardware assembly, software calibration, network integration with CEREC Connect, and performance validation using test blocks. Installation typically takes 4–6 hours and must be scheduled post-delivery. Clinics must ensure a clean, climate-controlled environment (18–25°C, 30–70% RH) and a dedicated, stable work surface. Remote diagnostics are enabled post-installation for ongoing support. |

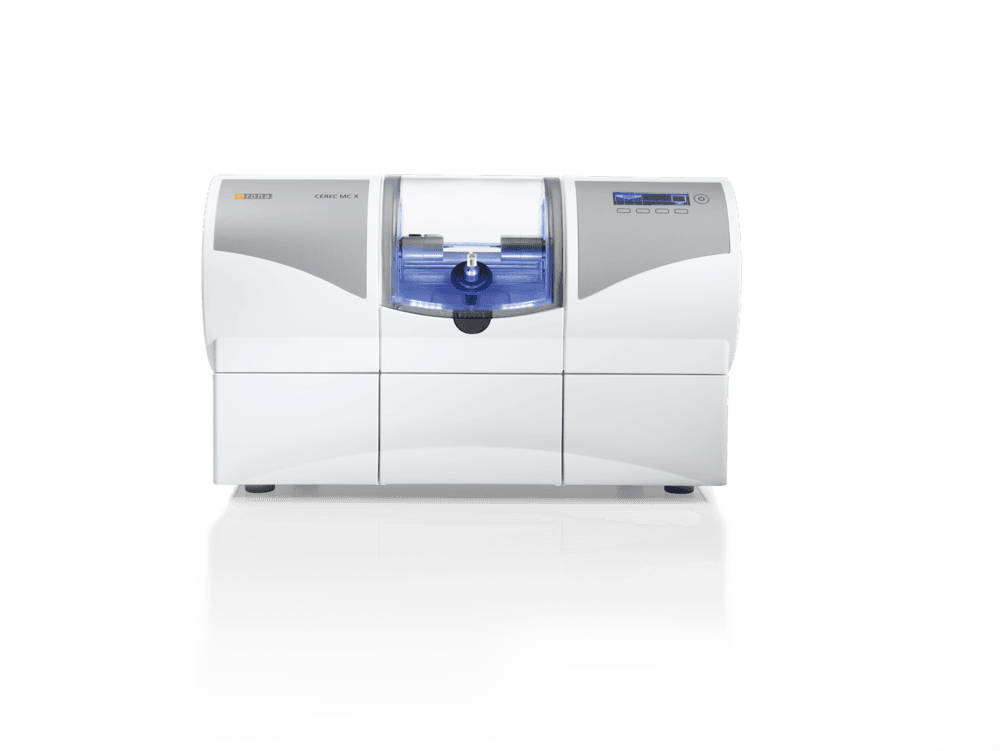

| 4. What warranty coverage is provided with a new CEREC milling machine in 2026, and what does it include? | New CEREC milling units (e.g., CEREC MC XL, CEREC CW 5.0) come with a standard 2-year comprehensive warranty covering parts, labor, and mechanical/electronic failures. The warranty requires registration within 30 days of installation and is contingent upon use of genuine materials and adherence to maintenance schedules. Extended warranty options (up to 5 years) are available through service agreements. Note: Damage from power surges, improper handling, or non-OEM consumables is excluded. |

| 5. How are firmware updates and technical support handled under the warranty and service plans? | Firmware updates are delivered securely via the CEREC Connect platform and can be installed remotely or on-site. Routine updates are included in the warranty and service contracts, enhancing milling strategies, material libraries, and connectivity. 24/7 technical support is available through regional service centers, with priority response (within 4 business hours) for critical downtime incidents under premium service agreements. Regular preventive maintenance (recommended annually) optimizes machine longevity and performance accuracy. |

Note: Specifications and service terms are subject to change based on regional regulations and manufacturer updates. Always verify details with your authorized distributor prior to purchase.

Need a Quote for Cerec Dental Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160