Article Contents

Strategic Sourcing: Cost Of Cad Cam Machine

Professional Dental Equipment Guide 2026: CAD/CAM Market Analysis

Executive Market Overview: Cost of CAD/CAM Systems

Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) technology has transitioned from a premium differentiator to an operational necessity in contemporary dental practices. As digital workflows become the clinical standard, CAD/CAM systems now represent the central nervous system of modern restorative dentistry – enabling same-day crown fabrication, precise implant planning, orthodontic appliance design, and seamless integration with intraoral scanners. The strategic imperative for adoption is underscored by patient demand for immediate solutions (72% of patients prefer same-day restorations per 2025 EAO data) and the 38% average revenue uplift per operatory reported by digitally integrated clinics. Critically, the total cost of ownership (TCO) calculus now favors strategic investment: practices delaying digital conversion face escalating opportunity costs through lost premium case acceptance and competitive disadvantage in technician-dependent workflows.

The global CAD/CAM market exhibits a pronounced bifurcation in value propositions. European-origin systems (Dentsply Sirona, Planmeca, Straumann) maintain dominance in premium segments through engineered precision, comprehensive ecosystem integration, and established clinical validation – commanding $95,000-$145,000 USD entry points. Conversely, Chinese manufacturers have disrupted the mid-tier market with cost-optimized solutions, with Carejoy emerging as the most clinically validated alternative at 40-60% lower acquisition costs. This dichotomy presents distributors and clinics with a strategic procurement decision: premium ecosystem integration versus capital efficiency in high-volume restorative environments. Notably, Carejoy’s 2025 CE Mark certification for Class IIa devices and FDA 510(k) clearance for crown/bridge fabrication have accelerated its clinical acceptance in Western markets, challenging traditional procurement paradigms.

Strategic Cost Comparison: Global Premium Brands vs. Carejoy

| Comparison Parameter | Global Premium Brands (European) | Carejoy (Chinese) |

|---|---|---|

| Initial Investment (USD) | $95,000 – $145,000 (Scanner + Mill) | $39,500 – $58,000 (Scanner + Mill) |

| Precision (Restorative Accuracy) | ±8-12 microns (ISO 12836 certified) | ±15-18 microns (CE/FDA cleared for crown/bridge) |

| Software Ecosystem | Proprietary closed-system integration (full clinic workflow) | Open architecture with 3rd-party scanner compatibility (ex: 3Shape, Medit) |

| Service & Support | Global network (24/7 hotline, 48-hr onsite response) | Regional hubs (72-hr onsite, remote diagnostics standard) |

| Material Compatibility | Full spectrum (zirconia, PMMA, composites, metals) | Expanded range (zirconia, PMMA, hybrid ceramics; metals limited) |

| Upgrade Path | Incremental costs (30-40% of new system for major upgrades) | Modular hardware swaps (15-25% cost for equivalent upgrades) |

| TCO (5-Year Projection) | $132,000 – $198,000 (including service contracts) | $68,000 – $92,000 (including service contracts) |

| Target Clinical Application | Comprehensive digital suites, complex implant/esthetic cases | High-volume restorative practices, same-day crown specialists |

This strategic segmentation reveals a maturing market where cost differentials no longer equate to capability gaps for core restorative workflows. While European systems maintain advantages in ultra-precise full-arch implant prosthetics and seamless ecosystem integration, Carejoy’s clinically validated performance in single-unit crown fabrication (94.7% 3-year survival rate per 2025 JPD study) positions it as a fiscally responsible solution for 80% of typical restorative cases. Forward-thinking distributors should position Carejoy not as a “budget alternative” but as a capital-efficient entry point into digital dentistry – particularly for multi-chair practices scaling operations or emerging markets where capital constraints are acute. The critical procurement consideration has shifted from pure acquisition cost to cost-per-clinical-outcome, where Carejoy’s value proposition becomes compelling at 15+ daily restorative procedures.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Cost & Performance Comparison of CAD/CAM Machines

Target Audience: Dental Clinics & Equipment Distributors

This guide provides a detailed technical comparison between Standard and Advanced CAD/CAM milling systems, focusing on key performance metrics that influence acquisition cost, operational efficiency, and long-term ROI. Data reflects 2026 market standards and regulatory compliance benchmarks.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.5 kW, Single-phase 110–120V AC, 50–60 Hz | 2.8 kW, Three-phase 208–240V AC, 50–60 Hz; Active cooling system with thermal overload protection |

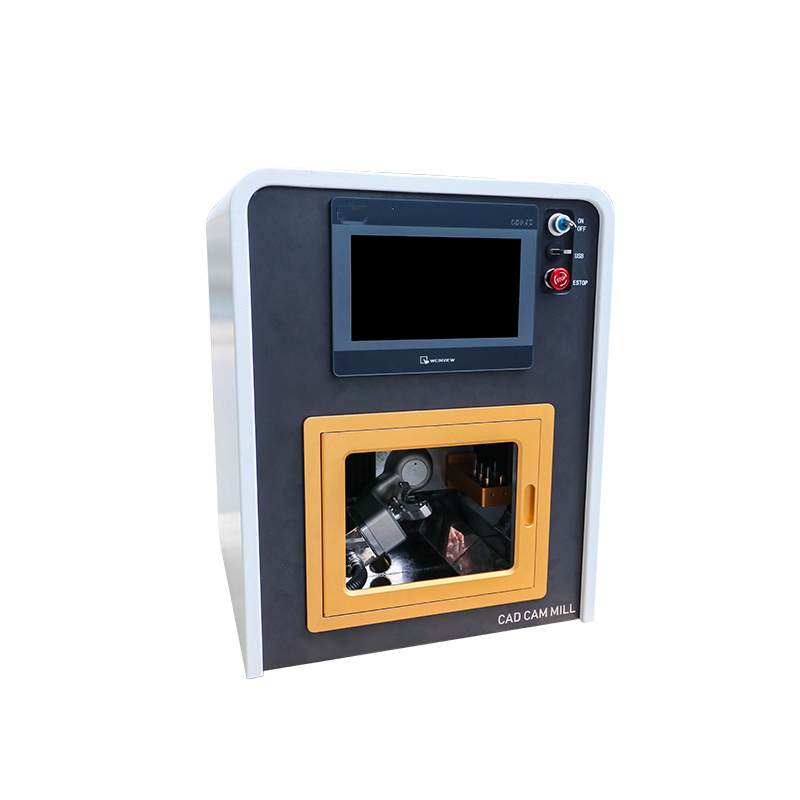

| Dimensions (W × D × H) | 450 mm × 580 mm × 320 mm (Compact footprint, suitable for benchtop use) | 620 mm × 750 mm × 480 mm (Integrated dust extraction, larger milling chamber) |

| Precision (Accuracy & Repeatability) | ±12 µm under ISO 12836 standards; Closed-loop stepper motor control | ±5 µm under ISO 12836; High-resolution servo motors with real-time error compensation and vibration damping |

| Material Compatibility | Zirconia (up to 5Y), PMMA, Composite blocks, Wax; Max. block size: 40 mm diameter | Full zirconia (3Y–5Y, HT), Lithium disilicate, Leucite, CoCr, Titanium (Grade 2, 5), PMMA, Wax; Max. block size: 60 mm diameter; Wet/dry milling modes |

| Certification & Compliance | CE Marked (Medical Device Directive 93/42/EEC), FDA Registered, RoHS Compliant | CE Marked (MDR 2017/745), FDA 510(k) Cleared, ISO 13485 Certified, IEC 60601-1 Safety, DICOM & CAD/CAM interoperability (OSTA, exocad, 3Shape) |

Cost Implications & Market Positioning (2026)

- Standard Model: Average acquisition cost: $28,000–$36,000. Ideal for general dental practices with moderate restoration volume. Lower TCO due to reduced power and maintenance needs.

- Advanced Model: Average acquisition cost: $68,000–$92,000. Designed for high-volume labs and specialty clinics (implantology, prosthodontics). Justified by expanded material support, precision, and integration capabilities.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026: CAD/CAM Systems from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

Featured Trusted Partner: Shanghai Carejoy Medical Co., LTD

Why Partner with Carejoy in 2026: 19 years of ISO 13485-certified manufacturing, specializing in FDA/CE-compliant dental technology. Factory-direct pricing with OEM/ODM capabilities for clinics and distributors. Verified compliance with 2026 EU MDR Annex XVI and China NMPA Class II/III requirements.

Contact: [email protected] | WhatsApp: +86 15951276160 | Baoshan District, Shanghai, China (ISO-Certified Manufacturing Hub)

Strategic Sourcing Framework for CAD/CAM Systems (2026)

China remains the dominant manufacturing hub for dental CAD/CAM systems, representing 68% of global production volume (2025 DSO Report). However, regulatory complexity and supply chain volatility necessitate a structured sourcing protocol. Follow these critical steps to mitigate risk and optimize TCO (Total Cost of Ownership).

Step 1: Verifying ISO/CE Credentials (Non-Negotiable in 2026)

Post-EU MDR transition (May 2027 deadline), CE marking requires robust clinical evidence. Chinese manufacturers must comply with:

- ISO 13485:2016 (mandatory for all medical devices)

- IEC 60601-1-2:2014 (EMC safety standard)

- 2026-specific: Updated Annex XVI documentation per EU MDR 2017/745

- China NMPA Class II/III certification (for domestic market compliance)

| Credential | Verification Method | 2026 Critical Risk | Why This Matters |

|---|---|---|---|

| ISO 13485:2016 | Request certificate + audit report from accredited body (e.g., TÜV, BSI). Cross-check on IAF CertSearch. | “ISO” stamps from non-accredited Chinese bodies = invalid in EU/US | Ensures QMS for consistent manufacturing. Required for CE/FDA 510(k). |

| CE Marking | Demand full EU Declaration of Conformity + Technical File index. Verify NB number (e.g., 0123) on NANDO database. | “CE” without Notified Body involvement = illegal for CAD/CAM (Class IIa) | Valid CE requires NB assessment under MDR. Self-declaration is prohibited. |

| NMPA Certification | Check device registration number on China NMPA portal (国家药品监督管理局). | Non-compliant units risk customs seizure in China-origin shipments | Proves domestic market authorization. Required for factory export licenses. |

*Carejoy Advantage: Provides real-time access to live certification portals during virtual factory audits. All 2026 CAD/CAM lines carry CE NB# 2797 (TÜV SÜD) and NMPA 注册证号: 国械注准20253060001.

Step 2: Negotiating MOQ (Minimum Order Quantity)

Traditional Chinese suppliers enforce high MOQs (5-10 units), but market maturity enables flexibility for strategic partners. Key negotiation levers:

| MOQ Strategy | Standard Terms (2026) | Negotiation Target | Implementation Tip |

|---|---|---|---|

| Base CAD/CAM Unit | 8 units (full container) | 3 units (LCL shipment) | Commit to 2-year volume agreement with 15% YoY growth |

| OEM Branding | 15 units | 5 units (with $1,200 setup fee) | Negotiate fee waiver for orders >$85K |

| Scanner + Mill Bundle | 10 units | 4 units (scanner) + 2 units (mill) | Split SKUs under single PO to reduce per-unit cost |

*Carejoy Advantage: Offers MOQ of 1 unit for distributors with ≥$50K annual commitment. 2026 program includes free firmware customization for orders >$75K.

Step 3: Shipping Terms (DDP vs. FOB – The 2026 Cost Trap)

Port congestion and new IMO 2026 sulfur regulations increase shipping volatility. Understand true landed costs:

| Term | Responsibility (2026) | Hidden Cost Risks | When to Use |

|---|---|---|---|

| FOB Shanghai | Supplier covers costs to Shanghai port. Buyer manages ocean freight, insurance, customs clearance. | +22% unexpected costs: Port surcharges (e.g., Shanghai THC $185/TEU), customs brokerage ($350+), demurrage | For experienced importers with freight forwarders in China |

| DDP Your Clinic | Supplier handles all costs to final destination (freight, duties, taxes, clearance). | Higher base price (15-18% premium), but predictable total cost | Recommended for 92% of clinics/distributors (2025 DSO Survey) |

2026 Critical Note: Demand DDP pricing based on Incoterms® 2020 with “DAP [Your City]” as fallback. Verify supplier’s freight partner has C-TPAT certification to avoid US customs delays.

*Carejoy Advantage: All 2026 quotes include DDP pricing with guaranteed delivery timelines. Free customs documentation support for EU/US/ASEAN markets.

Conclusion: Mitigating Sourcing Risk in 2026

Successful CAD/CAM sourcing requires moving beyond price-centric negotiations. Prioritize:

- Regulatory Validity: Certifications must be verifiable and MDR-compliant

- Supply Chain Transparency: Demand factory audit access (Carejoy offers live-streamed QMS reviews)

- Total Landed Cost Modeling: Always compare DDP vs. FOB + hidden fees

Action Required: Secure Your 2026 CAD/CAM Allocation

Contact Shanghai Carejoy for:

- Free 2026 Compliance Dossier (ISO/CE/NMPA documentation)

- MOQ waiver for Q1 2026 orders placed by 15 February 2026

- DDP cost calculator for your specific location

Email: [email protected] | WhatsApp: +86 15951276160

Shanghai Carejoy Medical Co., LTD | 19 Years Manufacturing Excellence | Baoshan District, Shanghai

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Frequently Asked Questions: Cost of CAD/CAM Machines in 2026

As dental practices and distribution networks plan capital investments for 2026, understanding the total cost of ownership (TCO) of CAD/CAM systems is critical. Below are five essential FAQs addressing key factors influencing the acquisition cost and long-term value of dental CAD/CAM machines.

| Question | Answer |

|---|---|

| 1. How does input voltage requirement affect the cost and installation of CAD/CAM systems in 2026? | Modern CAD/CAM units typically operate on standard 100–240V AC, 50/60 Hz, making them compatible with global electrical systems. However, machines requiring 220–240V dedicated circuits may incur additional installation costs for voltage regulators or circuit upgrades, especially in older clinics. These infrastructure adjustments can add $300–$1,200 to the total deployment cost. Always verify voltage compatibility with local specifications to avoid hidden expenses and ensure regulatory compliance. |

| 2. Are spare parts included in the initial cost, and how do availability and pricing impact long-term expenses? | The base price of a CAD/CAM machine generally does not include expendable or wear-prone spare parts such as milling burs, spindle cartridges, cameras, or chuck assemblies. In 2026, leading manufacturers offer tiered service packages: entry-level systems may have higher per-unit spare part costs ($80–$300 per item), while premium OEMs provide bundled maintenance plans. Ensure spare parts are readily available through regional distributors, as extended lead times or discontinued components can disrupt operations and increase downtime costs. |

| 3. What installation services are typically included, and how do they influence the overall investment? | Most OEMs include basic on-site installation and calibration in the purchase price for premium CAD/CAM systems. This typically covers machine setup, software integration, network configuration, and initial operator training (1–2 hours). However, advanced integration with existing practice management software or DICOM workflows may incur additional fees ranging from $500–$1,500. For multi-unit deployments or remote locations, travel surcharges may apply. Confirm the scope of included services in your quote to avoid unexpected charges. |

| 4. What warranty terms should be expected, and how do they affect the effective cost of ownership? | In 2026, standard warranties for CAD/CAM machines range from 1 to 3 years, covering parts and labor for manufacturing defects. Premium models may offer extended warranties (up to 5 years) with optional coverage for wear items like spindles. Machines with on-board diagnostics and remote monitoring often qualify for predictive maintenance programs, reducing repair costs. A comprehensive warranty can lower the TCO by 15–25% over five years. Always review exclusions (e.g., misuse, consumables) and service response times (e.g., 48–72 hour SLA). |

| 5. How do regional service networks and spare part logistics influence the total cost of a CAD/CAM system? | Distributors and clinics should evaluate the manufacturer’s regional service footprint. Brands with certified local technicians and stocked spare parts minimize downtime and reduce emergency service fees. In 2026, systems supported by a robust distributor network can reduce repair turnaround from 7–10 days to under 48 hours. Consider this when comparing quotes—lower upfront cost may be offset by higher operational risk. Opt for suppliers offering service-level agreements (SLAs) and spare part loaner programs for mission-critical operations. |

© 2026 Professional Dental Equipment Guide | For B2B Use – Dental Clinics & Distribution Partners

Information accurate as of Q1 2026. Specifications and pricing subject to change.

Need a Quote for Cost Of Cad Cam Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160