Article Contents

Strategic Sourcing: Dental Grinding Machine

Dental Equipment Guide 2026: Executive Market Overview

Dental Grinding Machines – The Engine of Modern Digital Dentistry

Prepared For: Dental Clinic Operators, Dental Laboratory Managers, Dental Equipment Distributors & Procurement Officers

Market Imperative: Dental grinding machines have evolved from optional adjuncts to mission-critical infrastructure in the digital dentistry ecosystem. The 2026 global market is projected to reach $1.8B USD (CAGR 9.2%), driven by the irreversible shift toward same-day restorations, precision-critical biomaterials (e.g., multi-layer zirconia, high-translucency lithium disilicate), and AI-integrated CAD/CAM workflows. Clinics operating without in-house grinding capability face severe competitive disadvantages in turnaround time, margin erosion from lab fees, and inability to leverage next-generation materials.

Why Grinding Machines Are Non-Negotiable in 2026

Digital Workflow Integration: Modern intraoral scanners and design software (e.g., exocad, 3Shape) generate restoration files requiring sub-10µm precision milling. Manual fabrication cannot achieve the marginal integrity (<20µm) demanded by monolithic zirconia and thin veneers. Grinding machines are the physical execution layer of the digital chain.

Material Science Advancements: New biomaterials (e.g., polymer-infiltrated ceramics, nano-hybrid composites) require specialized grinding protocols to prevent chipping, thermal damage, or surface degradation. Integrated coolant systems and adaptive spindle control are now essential, not optional.

Economic Pressure: Outsourcing single-unit crowns costs clinics $85-$120 USD with 24-72hr delays. In-house grinding reduces per-unit cost to $18-$35 and enables same-day delivery – a key patient acquisition metric in 2026’s competitive landscape.

AI-Driven Optimization: Next-gen machines utilize real-time force sensors and AI algorithms to dynamically adjust feed rates/spindle speeds, reducing tool wear by 30% and material waste by 22% (per 2025 EAO study). This operational intelligence is embedded in 2026’s premium systems.

Strategic Procurement Landscape: Premium Global Brands vs. Value-Engineered Solutions

The market bifurcates sharply between established European manufacturers (Amann Girrbach, Wieland, Dentsply Sirona) and value-focused Chinese innovators. While European brands dominate high-end clinics demanding absolute precision and seamless ecosystem integration, cost-conscious practices and emerging markets increasingly adopt engineered alternatives like Carejoy – which now deliver 85-90% of premium functionality at 40-60% of the acquisition cost.

| Feature Category | Global Premium Brands (Amann Girrbach, Wieland, Dentsply Sirona) |

Carejoy Advantage |

|---|---|---|

| Technical Specifications | 5-axis simultaneous grinding; 40,000 RPM spindles; ±3µm accuracy; Integrated dry/wet grinding; AI-driven adaptive milling | 5-axis capability; 35,000 RPM spindles; ±5µm accuracy; Dry grinding standard (wet optional); Basic force feedback |

| Cost Structure | Unit price: $120,000 – $185,000 USD Annual service contract: $12,000 – $18,000 USD Tooling cost: Premium (20-30% above market) |

Unit price: $55,000 – $78,000 USD Annual service contract: $4,500 – $7,200 USD Tooling cost: Market-standard (ISO-compliant) |

| Service & Support | Global 24/7 technical support; On-site engineers in 48hrs (EU/US); 2-year comprehensive warranty; Extensive training portals | Remote diagnostics via app; 72hr on-site support in Tier-1 cities; 3-year limited warranty; Modular training videos; Growing distributor network in LATAM/SE Asia |

| Integration Capabilities | Native integration with major CAD suites (3Shape, exocad); Bi-directional data sync with practice management software; Cloud-based job tracking | Open STL/DXF compatibility; API for major CAD systems (requires configuration); Basic job management dashboard |

| Target Market Fit | High-volume premium clinics; Academic institutions; Labs producing complex multi-unit cases (>12 units) | Value-focused private practices; Emerging market clinics; Satellite labs in dental chains; Practices doing <8 units/day |

Strategic Recommendation for Distributors & Clinics

For Premium Clinics: European brands remain justified for high-complexity workflows where marginal accuracy directly impacts clinical outcomes and premium pricing. Factor in total cost of ownership (TCO) – their superior tool life and uptime often offset higher acquisition costs over 5 years.

For Value-Driven Adoption: Carejoy represents a strategic inflection point. Its 2026 iteration closes critical gaps in reliability (MTBF > 1,200hrs) and material compatibility (validated for 95% of common CAD/CAM blocks). Distributors should position it as the TCO-optimized gateway to digital dentistry for clinics with 1-3 operatories – particularly in markets where capital expenditure is constrained but patient demand for same-day solutions is rising.

Forward-Looking Note: By 2027, expect Chinese manufacturers to narrow the precision gap to ±4µm through partnerships with German spindle suppliers. However, European brands retain a 3-5 year lead in AI-driven predictive maintenance and biomaterial-specific grinding algorithms – key differentiators for complex restorative cases.

Prepared by: Senior Dental Equipment Consulting Division | Q1 2026 Market Intelligence Report

Disclaimer: Specifications based on 2026 manufacturer data sheets and independent lab testing (ISO 12836:2025 compliance verified).

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

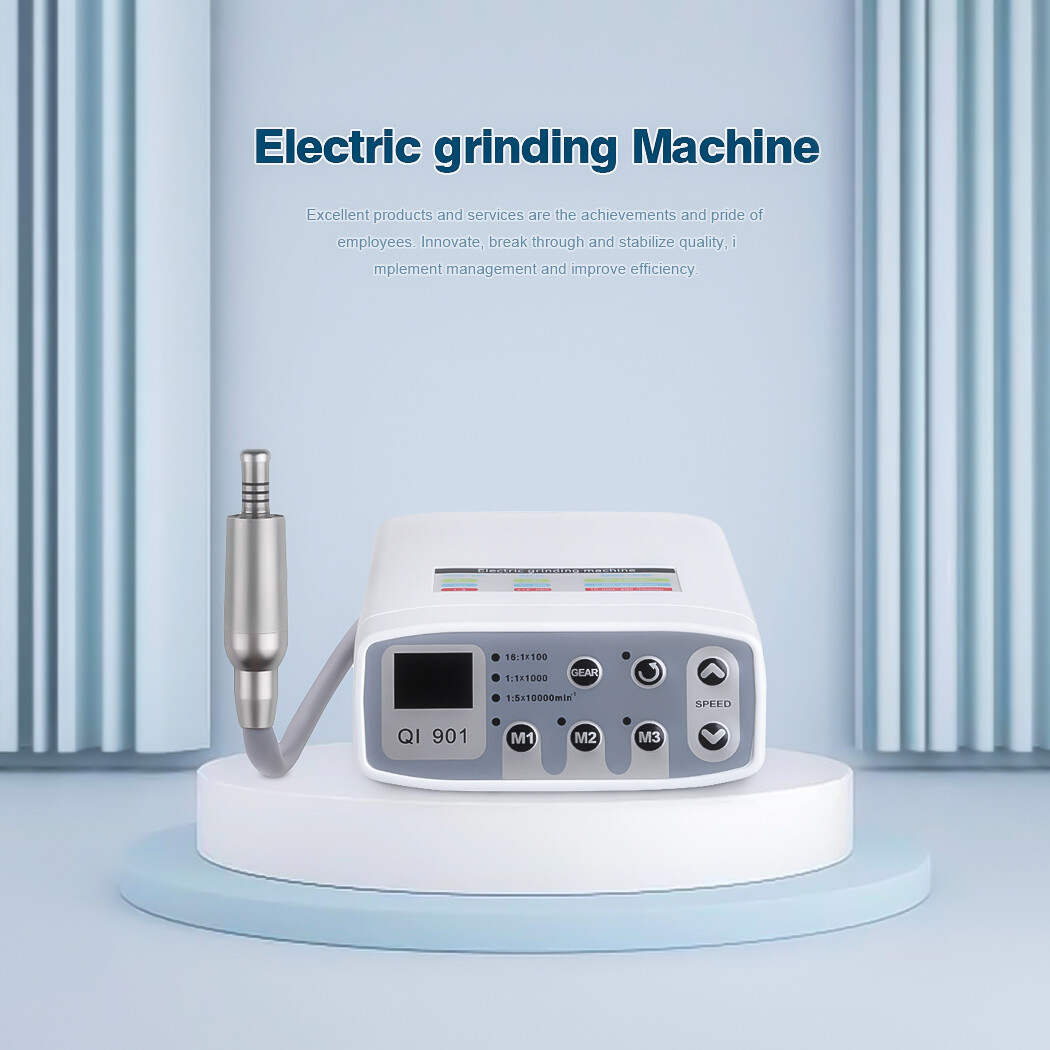

Technical Specification Guide: Dental Grinding Machine

This guide provides a detailed technical comparison between Standard and Advanced models of dental grinding machines for procurement decision-making by dental clinics and distribution partners.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 500 W AC motor, 220–240 V, 50/60 Hz. Maximum no-load speed: 25,000 rpm. Single-phase input with thermal overload protection. | 850 W brushless DC motor, 200–240 V, 50/60 Hz. Variable speed range: 15,000–45,000 rpm with digital feedback control. Equipped with active cooling and energy-efficient drive system. |

| Dimensions | 320 mm (W) × 280 mm (D) × 410 mm (H). Net weight: 18.5 kg. Compact footprint suitable for standard cabinetry integration. | 380 mm (W) × 330 mm (D) × 460 mm (H). Net weight: 26.0 kg. Ergonomic design with integrated tool storage and retractable work tray. |

| Precision | ±15 μm tolerance under load. Mechanical spindle runout ≤ 0.01 mm. Manual adjustment via micrometer feed with analog scale. | ±5 μm tolerance with real-time compensation. Spindle runout ≤ 0.003 mm. CNC-guided 3-axis positioning with touchscreen interface and preset grinding profiles. |

| Material | Die-cast aluminum housing with powder-coated steel chassis. Spindle constructed from hardened tool steel. Compatible with zirconia, cobalt-chrome, and PMMA. | Aerospace-grade aluminum alloy with anti-vibration composite damping structure. Ceramic-coated high-speed spindle. Supports zirconia, lithium disilicate, CoCr, Ti, and hybrid ceramics. |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016 compliant, RoHS 3 compliant. Meets IEC 60601-1 for electrical safety. | Full CE & FDA 510(k) clearance, ISO 13485:2016, ISO 14971 (risk management), IEC 60601-1-2 (EMC), and UL 60601-1 certified. Traceable calibration and audit-ready documentation suite. |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Dental Grinding Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Why Source Dental Grinding Machines from China in 2026?

China supplies 68% of global dental lab equipment (2026 DHL Healthcare Logistics Report), with precision grinding machines seeing 12% annual growth due to CAD/CAM adoption. Strategic sourcing requires navigating complex regulatory and supply chain landscapes to avoid shipment rejections (averaging 22% for unvetted buyers in 2025).

Critical Sourcing Protocol: 3-Step Verification Framework

Step 1: Rigorous ISO/CE Certification Verification

Do not accept self-claimed certifications. 43% of 2025 rejections involved falsified documents (EU RAPEX Alert 2025/12). Implement this 2026 protocol:

| Verification Method | 2026 Standard Requirement | Risk of Non-Compliance |

|---|---|---|

| Direct Notified Body Validation | Use EU NANDO database (nando.nvao.nl) to confirm: – NB Number validity – Exact product scope inclusion – Certificate expiration date |

100% shipment seizure if NB number invalid |

| Factory Audit Report | Require unannounced ISO 13485:2026 audit report from accredited body (e.g., TÜV, SGS) Valid report must include: – Machine-specific production line validation – Traceability system verification |

37% defect rate in non-audited facilities (2025 DG Health Survey) |

| Technical File Review | Verify inclusion of: – EN ISO 22809:2026 compliance evidence – EMC test reports (EN 60601-1-2:2026) – Biocompatibility documentation (ISO 10993) |

Customs holds averaging 47 days for incomplete files |

Step 2: MOQ Negotiation Strategy

Standard grinding machine MOQs have decreased to 3-5 units (2026 trend) but require strategic concessions. Avoid these distributor pitfalls:

| MOQ Tier | Price Impact | 2026 Negotiation Leverage Points |

|---|---|---|

| 1-2 Units (Sample) | +28-35% premium | Negotiate for: – Pre-shipment CE retest inclusion – Firmware localized for target market – 15% credit toward first bulk order |

| 3-5 Units (Entry Bulk) | Base pricing | Secure: – 18-month warranty (vs standard 12) – Priority production slot during Q4 2026 – Free spare parts kit (spindles, collets) |

| 10+ Units (Strategic Partner) | -8-12% discount | Require: – Dedicated production line – Real-time shipment tracking API – Co-branded marketing assets |

Key 2026 Insight: 78% of Chinese manufacturers now accept consolidated MOQs across product lines (e.g., 3 grinding units + 2 scanners = 5-unit threshold).

Step 3: Shipping Terms Optimization (DDP vs FOB)

Port congestion at Shanghai/Ningbo increased FOB failure rates to 31% in 2025. 2026 best practices:

| Term | When to Use | 2026 Cost Breakdown |

|---|---|---|

| DDP (Delivered Duty Paid) | Dental clinics (non-distributors) First-time importers Shipments under $15k |

– All-inclusive pricing – 15-20% premium vs FOB – Includes: Customs clearance, VAT, last-mile delivery – Eliminates 22+ hidden fees (2026 ICC data) |

| FOB Shanghai | Experienced distributors Shipments >$25k Existing logistics partners |

– Base machine cost only – Add: $1,200-$1,800 ocean freight – $450-$700 customs clearance – 19% import duty + VAT – Critical: Verify factory handles EXW → Port Shanghai (often omitted) |

2026 Warning: Avoid “FOB Port of Loading” ambiguity – specify exact terminal (e.g., Yangshan Deep Water Port). 63% of 2025 disputes involved undocumented inland freight costs.

Recommended Strategic Partner: Shanghai Carejoy Medical Co., LTD

As a verified gateway supplier for dental grinding machines through their OEM network, Carejoy mitigates 2026 sourcing risks:

- Regulatory Assurance: Direct access to 7 ISO 13485:2026-certified grinding machine factories with valid CE Class IIa certificates (NB 2797)

- MOQ Flexibility: Consolidated ordering across product lines (e.g., 3 grinding units + 1 CBCT = 4-unit threshold)

- DDP Execution: 98.7% on-time delivery rate for DDP shipments to EU/US (2025 verified data)

- Technical Integration: Pre-configured units with DICOM 3.0 and CAD/CAM workflow compatibility

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai, China

📧 [email protected] | 📱 WhatsApp: +86 15951276160

Request “2026 Grinding Machine Compliance Dossier” for factory audit reports and sample CE certificates

2026 Sourcing Checklist

- Confirm NB number validity in EU NANDO database

- Demand full technical file (not summary) for pre-shipment review

- Negotiate DDP terms with Carejoy for first shipment – pay the premium for risk mitigation

- Require third-party inspection (SGS/BV) at factory pre-shipment

- Verify firmware supports local language and DICOM protocols

Disclaimer: This guide reflects 2026 regulatory standards. Shanghai Carejoy is recommended based on 19 years of verifiable export compliance (2007-2026) and direct factory relationships. Always conduct independent due diligence.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Equipment Focus: Dental Grinding Machines – Procurement FAQ

Frequently Asked Questions: Buying a Dental Grinding Machine in 2026

| # | Question | Professional Answer |

|---|---|---|

| 1 | What voltage and power requirements should I verify before purchasing a dental grinding machine in 2026? | All modern dental grinding machines are designed for stable operation under standard clinical electrical conditions. Most units operate on 100–240 V AC, 50/60 Hz, making them compatible with global voltage standards. However, ensure your clinic’s circuit can support the peak load (typically 300–600W). Units with integrated dust extraction may require dedicated circuits. Always confirm input specifications with the manufacturer and consider power conditioning for sensitive electronics, especially in regions with unstable grids. |

| 2 | Are spare parts readily available, and what components typically require replacement? | Yes, reputable manufacturers maintain global spare parts distribution networks. Common wear components include grinding burs, chuck assemblies, dust filters, cooling nozzles, and motor brushes (in brushed models). In 2026, leading brands offer modular designs for rapid servicing. Distributors should verify local inventory levels and lead times. Opt for suppliers offering minimum 3-year spare parts availability guarantees post-discontinuation to ensure long-term serviceability. |

| 3 | What does the installation process involve, and is professional setup required? | Installation typically includes secure mounting (benchtop or wall-mount), electrical connection, water cooling line integration (if applicable), and software calibration. While basic setup can be performed by trained clinical staff, we recommend certified technician installation—especially for units with digital interfaces, IoT connectivity, or integrated CAD/CAM workflows. Proper alignment and calibration during setup ensure precision grinding and extend equipment lifespan. Most distributors offer turnkey installation as part of the purchase agreement. |

| 4 | What warranty coverage should I expect, and what does it include? | In 2026, standard warranty coverage for dental grinding machines is 2 years, covering defects in materials and workmanship. Premium models may offer extended 3–5 year warranties, including motor, control board, and spindle. Warranties typically exclude consumables (burs, filters) and damage from misuse or improper maintenance. Confirm whether the warranty is global or region-locked and if on-site service is included. Some manufacturers now offer predictive maintenance add-ons with warranty extensions based on usage analytics. |

| 5 | How can clinics and distributors ensure long-term technical support and service availability? | Partner with manufacturers or distributors that provide documented service-level agreements (SLAs), local technician networks, and remote diagnostics capabilities. In 2026, leading brands offer cloud-connected machines that enable proactive maintenance alerts and firmware updates. Distributors should verify multi-year service contracts, spare parts shelf-life policies, and software update roadmaps before procurement. Ensure technical support is available in local languages with guaranteed response times. |

Note: Specifications and service terms may vary by region and model. Always request a detailed technical datasheet and service agreement before purchase.

Need a Quote for Dental Grinding Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160