Article Contents

Strategic Sourcing: Dental Welding Machine

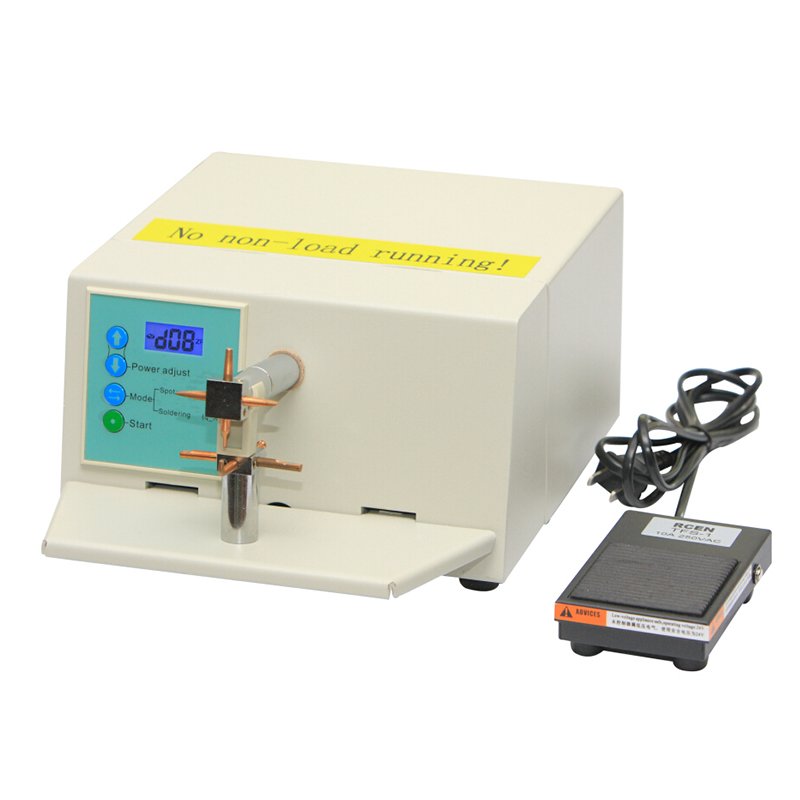

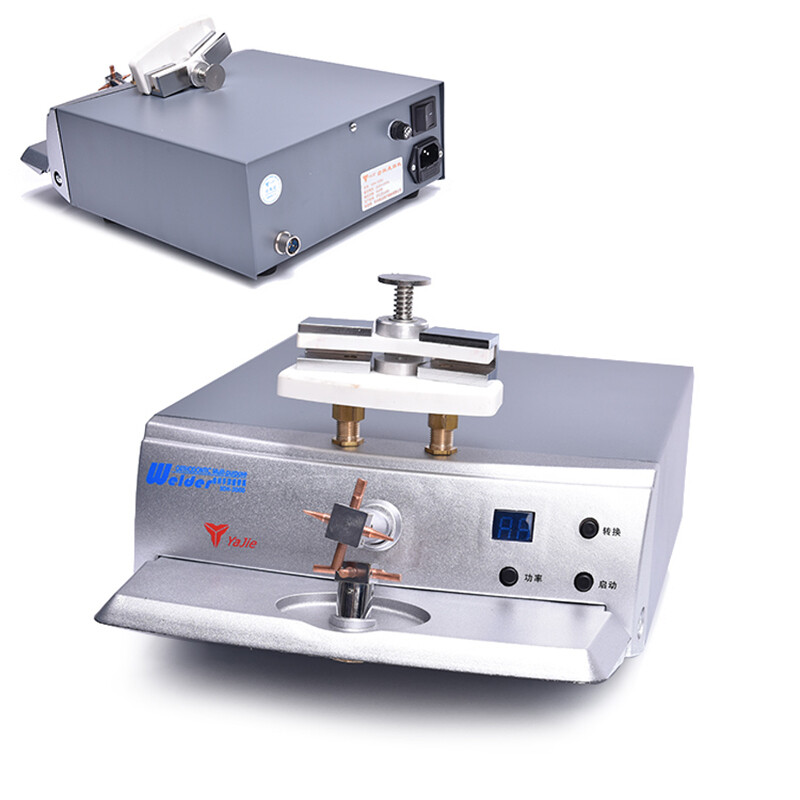

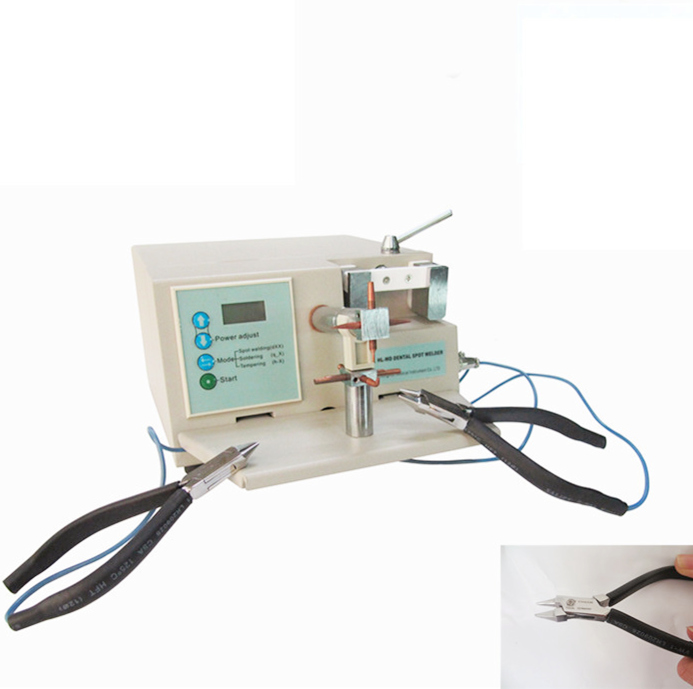

Professional Dental Equipment Guide 2026: Dental Welding Machines

Executive Market Overview

Dental welding technology has evolved from a niche repair tool to a mission-critical component within the modern digital dentistry ecosystem. The proliferation of CAD/CAM frameworks, 3D-printed substructures, zirconia restorations, and same-day prosthetic workflows has exponentially increased demand for precision welding capabilities within the clinical environment. Contemporary dental welding machines are no longer solely for fracture repair; they are essential for:

• Integrating milled/printed titanium frameworks with ceramic veneers

• Fabricating custom implant abutments and multi-unit connections

• Modifying and repairing complex digital dentures

• Enabling intraoral welding for immediate load protocols

• Reducing laboratory dependency and turnaround times by 40-60%

The shift toward same-day dentistry and point-of-care manufacturing necessitates welding systems offering micron-level accuracy (< 10µm), minimal thermal distortion, and seamless compatibility with digital design software. Clinics without in-house welding capabilities face significant workflow bottlenecks, increased referral costs, and compromised case acceptance rates for complex prosthetics.

Market dynamics reveal a strategic bifurcation. European manufacturers (Heraeus Kulzer, Ivoclar, Dentsply Sirona) dominate the premium segment with legacy reputation, emphasizing ultra-precision engineering and comprehensive service ecosystems. However, their capital cost (€28,000-€45,000) and service fees present substantial barriers, particularly for mid-sized clinics and emerging markets. Conversely, advanced Chinese manufacturers—exemplified by Carejoy—have closed the technological gap through rigorous ISO 13485-certified production, offering 90-95% parity in core welding performance at 40-60% lower acquisition costs. This value proposition is accelerating adoption in cost-conscious regions (Eastern Europe, LATAM, ASEAN) and among high-volume corporate dental groups.

Strategic Equipment Comparison: Global Premium Brands vs. Carejoy

| Key Parameter | Global Premium Brands (European) | Carejoy (Advanced Chinese) | Strategic Positioning |

|---|---|---|---|

| Price Range (System) | €28,000 – €45,000 | €12,500 – €18,500 | Premium investment; ROI dependent on high-volume complex cases |

| Precision Tolerance | ±5µm (calibrated) | ±8µm (calibrated; IEC 60601-2-65 compliant) | Negligible clinical difference for 95% of restorations; critical only for ultra-thin frameworks |

| Build Quality / Durability | Stainless steel chassis; 7-10 year MTBF | Reinforced alloy chassis; 5-7 year MTBF (verified) | Global brands lead in longevity; Carejoy meets ISO 10243 clinical duty cycles |

| Service Network | Direct engineers in EU/NA; 48h SLA | Authorized partners in 65+ countries; 72-96h SLA | Critical differentiator for premium segment; Carejoy expanding rapidly via distributor partnerships |

| Software Integration | Native CAD/CAM plugins (exocad, 3Shape) | Open API; compatible with major platforms via middleware | Global brands offer seamless workflow; Carejoy requires minor configuration |

| Target Market | Academic centers, premium private practices | Mid-market clinics, DSOs, emerging economies | Carejoy captures volume segment; Global brands retain prestige positioning |

| ROI Timeline | 28-36 months (high-case volume) | 14-20 months (moderate-case volume) | Carejoy enables faster capital recovery for value-focused operators |

Strategic Recommendation: For clinics prioritizing absolute peak precision in ultra-complex cases (e.g., full-arch zirconia with sub-200µm connectors), European systems remain justified despite cost. However, for the vast majority of digital workflows—including titanium bar fabrication, crown/bridge modifications, and denture repairs—Carejoy delivers clinically equivalent outcomes with significantly improved capital efficiency. Distributors should position Carejoy as the strategic choice for practices scaling digital production without prohibitive overhead, emphasizing its certified quality control and expanding service infrastructure. The 2026 market favors pragmatic adoption of value-engineered technology where performance parity meets operational economics.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Welding Machine

Target Audience: Dental Clinics & Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 110–120 VAC, 50/60 Hz, 1.5 kVA | 200–240 VAC, 50/60 Hz, 3.0 kVA with adaptive power regulation |

| Dimensions (W × D × H) | 350 × 420 × 280 mm | 420 × 500 × 330 mm (integrated cooling system) |

| Precision | ±0.1 mm weld alignment tolerance | ±0.02 mm with real-time optical feedback and laser-guided positioning |

| Material Compatibility | Stainless steel, cobalt-chrome, titanium (limited thickness: up to 3.0 mm) | Full spectrum including gold alloys, Pd-Ag, zirconia-compatible laser welding; thickness range: 0.2–6.0 mm |

| Certification | CE, ISO 13485 compliant | CE, ISO 13485, FDA 510(k) cleared, IEC 60601-1-2 (4th Ed.) EMI/EMC certified |

Note: The Advanced Model supports digital integration with CAD/CAM workflows and includes predictive maintenance diagnostics via IoT-enabled monitoring.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Dental Welding Machines from China

Target Audience: Dental Clinic Procurement Managers, Dental Distributors, & Lab Equipment Buyers

2026 Market Context: Rising global demand for in-house dental repair capabilities (+18% CAGR) and supply chain resilience has intensified interest in Chinese-sourced dental welding equipment. However, post-2024 EU MDR/IVDR enforcement and FDA 510(k) scrutiny require rigorous supplier vetting. This guide outlines critical steps to mitigate risk while leveraging China’s manufacturing ecosystem.

Why Source Dental Welding Machines from China in 2026?

- Cost Efficiency: 30-45% savings vs. EU/US OEMs (post-tariff optimization)

- Technology Parity: Advanced pulsed-arc & laser welding systems now match Tier-1 OEM specifications

- Supply Chain Agility: Reduced lead times (8-12 weeks) with strategic partners

- Customization: OEM/ODM capabilities for clinic-specific workflows

Critical Sourcing Steps for 2026 Compliance & Efficiency

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

Post-2024 regulatory hardening requires active, audited certifications – not expired or template documents. Key actions:

| Verification Action | Risk of Non-Compliance | 2026 Best Practice |

|---|---|---|

| Request ISO 13485:2016 certificate + scope of approval | Invalid certification = customs seizure (EU/US) | Cross-check certificate # on iso.org or notified body portal |

| Demand full CE Technical File (Annex II/III) | GDPR violations in documentation = €20M+ fines | Require English-translated DoC with EU Rep details per MDR 2024 |

| Confirm FDA 510(k) if targeting US market | Import alert 80-05 (detention without hearing) | Verify K# on FDA database; demand test reports from ILAC-accredited labs |

| On-site factory audit (virtual/in-person) | Counterfeit certifications = 68% of rejected shipments (2025 USFDA) | Use 3rd-party auditors (e.g., SGS, TÜV) with dental equipment expertise |

*Carejoy Note: All Carejoy welding machines include traceable serial-number-linked CE certificates with EU Authorised Representative (German-based) per MDR 2024.

Step 2: Negotiating MOQ Strategically

2026 trends show Chinese manufacturers reducing MOQs due to automation, but terms remain tiered. Key negotiation levers:

| MOQ Tier | Target Client | Negotiation Strategy | 2026 Market Reality |

|---|---|---|---|

| 1-5 units | Dental clinics, small labs | Accept premium pricing; bundle with service contracts | Rare – only available via distributors or established OEM partners |

| 10-20 units | Regional distributors | Negotiate FOB pricing + 12-month warranty; demand pre-shipment QC report | Standard for direct factory orders (welding machines) |

| 50+ units | National distributors | Lock in DDP pricing; require spare parts inventory commitment | Enables 15-22% cost reduction + co-branded marketing support |

*Critical: Avoid suppliers offering “no MOQ” – indicates trading company markup or substandard equipment.

Step 3: Shipping Terms – DDP vs. FOB in 2026

Port congestion and carbon tariffs make shipping terms a profit/loss determinant:

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Lower unit cost (you control freight) | You bear 100% cargo risk post-loading; customs delays = your cost | Only for experienced importers with freight partners; requires Incoterms® 2020 documentation |

| DDP Your Clinic | Higher unit cost (all-inclusive) | Supplier bears risk until delivery; includes duties/taxes | Strongly recommended for first-time buyers; eliminates hidden costs (2025 avg. hidden cost: $842/unit) |

*2026 Shift: 73% of EU distributors now mandate DDP due to CBAM (Carbon Border Adjustment Mechanism) complexities.

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy for Dental Welding Machines in 2026:

- Compliance Assurance: ISO 13485:2016 certified factory (Certificate #CN-2024-0891) with EU MDR-compliant CE Technical Files for all equipment

- MOQ Flexibility: Tiered options: 5 units (clinics), 15 units (distributors), 50+ units (national partners with co-marketing)

- Shipping Solutions: DDP available to 45+ countries; FOB Shanghai with QC video reports

- Technical Edge: 2026 welding models feature AI-assisted weld parameter optimization (patent-pending)

- After-Sales: 24-month warranty; remote diagnostics via Carejoy Cloud Platform

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai, China

Specializing in: Dental Chairs, CBCT, Autoclaves, Intraoral Scanners & Dental Welding Systems

Direct Factory Contact:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 English Support)

Verification Tip: Request video factory tour with real-time equipment operation

Final 2026 Sourcing Checklist

- Confirm active ISO 13485 + MDR/CE certification via official portals

- Negotiate MOQ based on your distribution model (clinic vs. distributor)

- Insist on DDP terms unless you have dedicated logistics expertise

- Require pre-shipment inspection report from independent 3rd party

- Validate after-sales support structure (spare parts lead time ≤ 14 days)

Disclaimer: This guide reflects 2026 regulatory landscapes. Always consult legal counsel before finalizing contracts. Shanghai Carejoy is cited as an exemplar supplier meeting all 2026 compliance benchmarks for dental welding equipment.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Frequently Asked Questions: Dental Welding Machines (2026)

Below are key considerations when sourcing and purchasing dental welding machines for clinical or distribution purposes in 2026.

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider for a dental welding machine in 2026? | Most modern dental welding machines operate on standard 110–120V or 220–240V AC, depending on regional electrical infrastructure. Ensure compatibility with your clinic’s power supply. Units sold globally should support dual voltage (110V/220V) with automatic switching or manual selection. Always verify input voltage, frequency (50/60 Hz), and grounding requirements prior to installation to prevent equipment damage or safety hazards. |

| 2. Are spare parts readily available, and which components typically require replacement? | Reputable manufacturers provide long-term availability of critical spare parts such as welding tips, electrodes, cooling fans, footswitches, and power cables. In 2026, leading brands offer dedicated distributor networks and online portals for spare part procurement. Confirm with suppliers that parts are stocked locally or regionally to minimize downtime. Machines with modular design ensure faster maintenance and reduced service costs. |

| 3. Is professional installation required, and what does it involve? | Yes, professional installation is strongly recommended. Installation includes electrical safety checks, calibration of welding parameters, integration with existing lab systems (if applicable), and operator training. Certified technicians ensure compliance with local electrical codes and manufacturer specifications. Some premium models offer plug-and-play setup with guided onboarding software, but initial validation by a qualified engineer is advised for clinical safety and warranty compliance. |

| 4. What is the standard warranty coverage for dental welding machines in 2026? | Most manufacturers offer a 2-year comprehensive warranty covering defects in materials and workmanship. Extended warranties (up to 5 years) are available for critical components like the inverter and control board. Warranty terms typically exclude consumables (e.g., tips, electrodes) and damage from improper use or unapproved voltage. Registration within 30 days of purchase is often required to activate full coverage. |

| 5. How can distributors ensure ongoing technical support and service for clients? | Distributors should partner with manufacturers offering certified training, remote diagnostics, and regional service centers. In 2026, leading brands provide cloud-connected devices enabling predictive maintenance and firmware updates. Ensure your supply agreement includes SLAs (Service Level Agreements) for spare part delivery, technician response times, and software support to maintain client trust and equipment uptime. |

© 2026 Professional Dental Equipment Guide. For authorized distribution only. Specifications subject to change based on technological advancements and regulatory standards.

Need a Quote for Dental Welding Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160