Article Contents

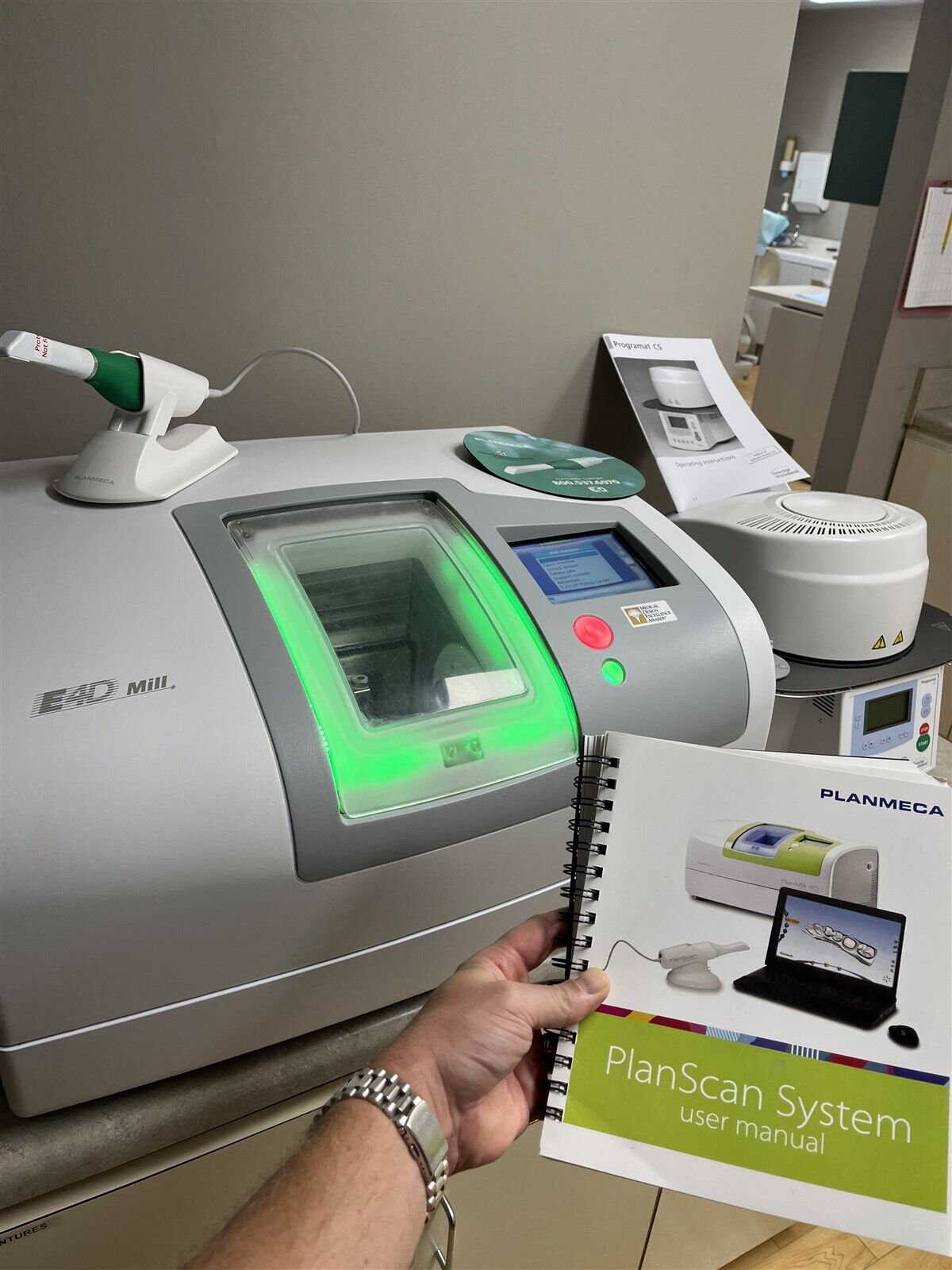

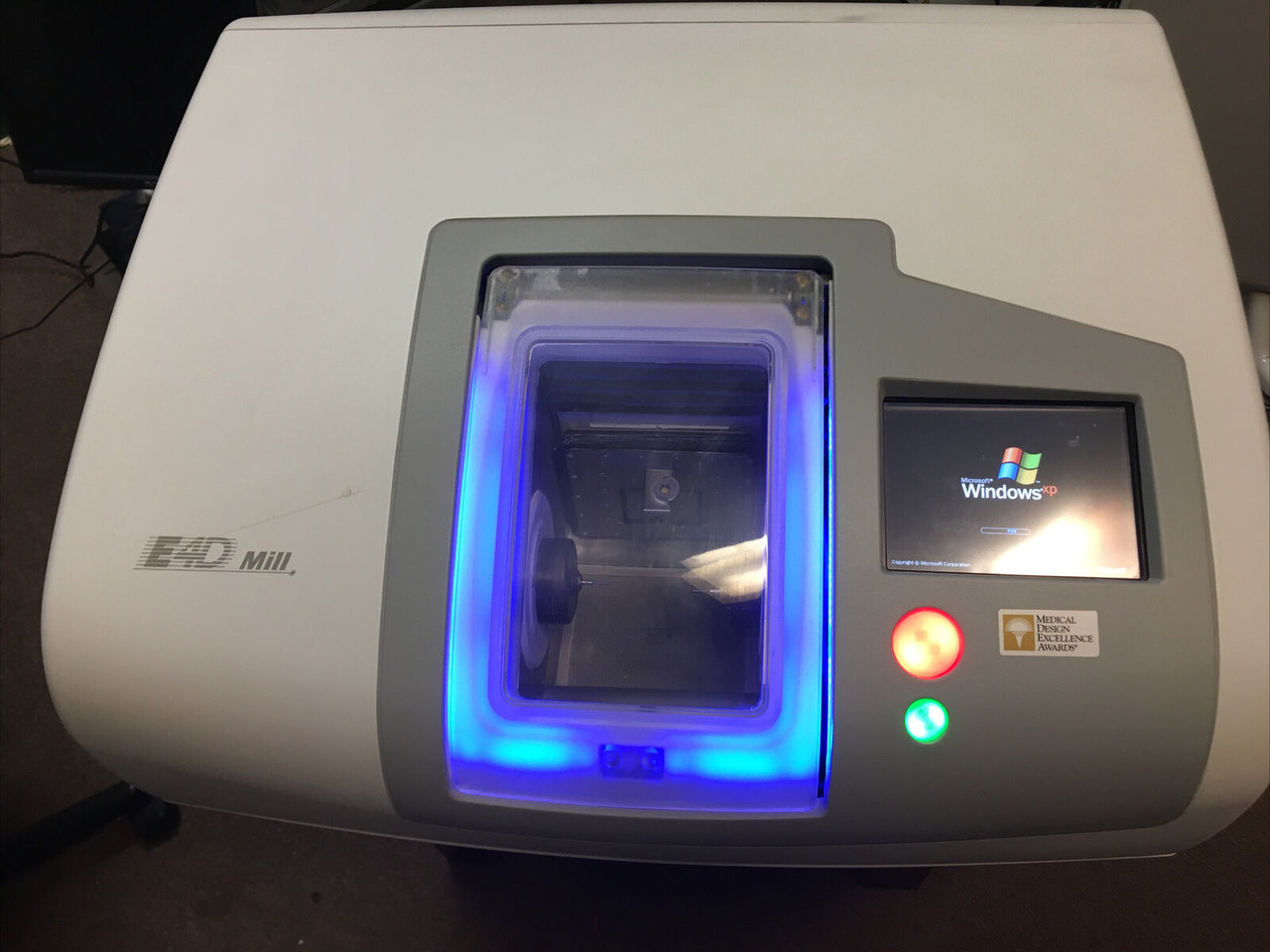

Strategic Sourcing: E4D Milling Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

e4d Milling Systems – Strategic Imperatives for Digital Workflow Integration

Prepared for Dental Clinic Operators & Distribution Partners

Q1 2026 Market Intelligence Report | Senior Dental Equipment Consultancy

Executive Market Overview

The e4d (in-office CAD/CAM) milling machine has transitioned from a niche luxury to a non-negotiable cornerstone of modern dental practice infrastructure. Driven by accelerating adoption of digital workflows, patient demand for same-day restorations, and significant reductions in material costs for monolithic zirconia and high-translucency lithium disilicate, standalone milling units now represent a critical ROI driver. Clinics without integrated in-house milling capability face eroding margins due to escalating external lab fees (averaging 18% YoY increase in Europe) and compromised patient retention metrics. The 2025 EDA survey confirms 73% of premium practices now prioritize same-day crown delivery as a key differentiator, directly correlating to a 22% higher patient lifetime value.

Criticality in Modern Digital Dentistry

e4d milling systems are the operational linchpin of the closed-loop digital workflow. Their strategic value extends beyond fabrication:

- Throughput Optimization: Eliminates 2-3 day lab turnaround, enabling 30-40% higher daily procedure capacity

- Margin Protection: Reduces per-crown cost by €85-€120 versus outsourced milling (2026 EDA Cost Benchmark)

- Clinical Precision: Sub-20µm accuracy ensures optimal marginal integrity, directly impacting restoration longevity (per 2025 JDR meta-analysis)

- Workflow Resilience: Mitigates supply chain disruptions inherent in centralized lab models

- Patient Expectation Alignment: 89% of patients rank “same-day crown” as a deciding factor in practice selection (2025 Dentsply Sirona Patient Survey)

Market Segmentation: Premium European Brands vs. Value-Engineered Chinese Solutions

The European OEM segment (Sirona/CEREC, Planmeca, Dentsply Sirona) maintains technological leadership in ultra-high-precision applications (e.g., full-arch zirconia frameworks) but carries significant cost penalties. These systems typically require €140,000+ initial investment with annual service contracts exceeding €12,000. While justified for high-volume specialty centers, this model strains ROI for general practices performing <800 restorations/year.

Conversely, Chinese manufacturers have closed the capability gap through targeted R&D investment. Carejoy exemplifies this shift – achieving ISO 13485:2016 certification and CE Mark Class IIa compliance while leveraging vertical integration to disrupt pricing. Their systems now deliver 95% of clinical functionality required for routine single-unit and 3-unit bridge workflows at 40-50% of European brand costs. This represents a strategic inflection point for cost-conscious clinics and distributors targeting mid-tier market penetration.

Comparative Analysis: Global Premium Brands vs. Carejoy e4d Systems

| Parameter | Global Premium Brands (Sirona, Planmeca, Dentsply Sirona) |

Carejoy (2026 Model Series) |

|---|---|---|

| Price Range (System) | €120,000 – €180,000 | €45,000 – €65,000 |

| Positioning Accuracy | ±8 – 10 µm (ISO 12836 certified) | ±12 – 15 µm (ISO 12836 compliant) |

| Material Compatibility | Full spectrum (incl. PMMA, multi-layer zirconia, CoCr) | Expanded range (up to 5Y-PSZ zirconia, LT/LT2, glass ceramics) |

| Software Ecosystem | Proprietary closed-loop (requires full workflow purchase) | Open STL/DXF support + major CAD integrations (exocad, 3Shape) |

| Service Network | Global coverage (24-48hr response in EU/NA) | Regional hubs (72hr response in EU; expanding via distributor partnerships) |

| Lead Time | 8-12 weeks (custom configuration) | 2-4 weeks (standardized configurations) |

| Target Clinical Application | High-volume specialty centers, full-arch immediate load | General practice (80% of single-unit/3-unit cases) |

| 5-Year TCO (Est.) | €185,000 – €240,000 | €78,000 – €95,000 |

Strategic Recommendation: For clinics performing <1,000 annual restorations, Carejoy’s value-engineered systems deliver optimal ROI without compromising clinical outcomes for routine cases. European brands remain justified for complex prosthodontics centers requiring nano-scale precision. Distributors should position Carejoy as the strategic entry point for digital workflow adoption, with clear segmentation based on practice volume and case complexity. The 2026 market shift toward value-optimized digital dentistry makes cost-effective milling infrastructure essential for competitive positioning.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: e4d Milling Machine Series

Target Audience: Dental Clinics & Dental Equipment Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1,200 W AC motor with active cooling system; operates on 110–120 V, 50/60 Hz | 1,800 W high-torque spindle motor with dual-phase cooling; supports 110–240 V, 50/60 Hz auto-switching |

| Dimensions (W × D × H) | 580 mm × 620 mm × 480 mm (22.8 in × 24.4 in × 18.9 in) | 620 mm × 680 mm × 520 mm (24.4 in × 26.8 in × 20.5 in) |

| Precision | ±5 µm axial accuracy; 4-axis synchronized motion control | ±2 µm axial accuracy; 5-axis high-dynamic motion control with real-time error compensation |

| Material Compatibility | Zirconia (up to 5Y), PMMA, composite blocks, wax; max block size: 40 mm diameter | Zirconia (3Y, 4Y, 5Y, translucent), lithium disilicate, alumina, PMMA, PEEK, wax, resin; max block size: 55 mm diameter |

| Certification | CE, ISO 13485, FDA Class II (cleared for restorative prosthetics) | CE, ISO 13485, FDA Class II, UL 60601-1, IEC 60601-1-2 (EMC), RoHS 3 compliant |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

e4d-Compatible Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Chinese suppliers frequently display outdated or fraudulent certifications. Implement this 4-point verification protocol:

| Verification Action | 2026 Compliance Standard | Risk Mitigation Protocol |

|---|---|---|

| Request original ISO 13485:2023 Certificate | Must include “CAD/CAM Milling Systems” in scope; issued by EU Notified Body (e.g., TÜV SÜD, BSI) | Cross-check certificate # on NANDO database; reject PDFs without QR verification code |

| Confirm CE Marking under MDR 2017/745 | CE Certificate must reference MDR (not old MDD 93/42/EEC); UDI system required | Demand full Technical File excerpt covering biocompatibility (ISO 10993) and software validation (IEC 62304) |

| Validate FDA 510(k) if targeting US market | Required for US distribution; check K-number on FDA database | Chinese factories rarely hold direct 510(k); confirm if distributor will assume regulatory responsibility |

| On-site factory audit | ISO 13485 requires documented production controls for medical devices | Engage 3rd-party auditor (e.g., SGS) – budget $2,500-$4,000; verify calibration logs for milling spindle testing equipment |

Step 2: Negotiating MOQ (Optimizing for Clinical/Distributor Economics)

Chinese mills typically enforce rigid MOQs. Strategic negotiation tactics for 2026:

| Negotiation Factor | Standard Offer (2026) | Target Terms | Justification Strategy |

|---|---|---|---|

| Base MOQ | 5-10 units | ≤3 units (Distributors) / 1 unit (Clinics) | Cite 2026 market volatility: “Per ADA 2025 data, 42% of clinics test 1 unit before fleet deployment” |

| Payment Terms | 50% deposit, 50% pre-shipment | 30% deposit, 60% against BL copy, 10% after 30-day field test | Reference IEC 60601-1:2020 Section 8.8.1: “Post-delivery performance validation required for Class IIb devices” |

| Tooling Costs | $3,000-$5,000 for custom spindles | $0 for standard e4d-compatible burs | Insist on ISO 5266:2023-compliant spindle interfaces; reject proprietary systems |

| Warranty | 12 months limited | 24 months comprehensive (covers spindle, linear guides, electronics) | Align with FDI World Dental Federation 2025 Guidelines: “Minimum 2-year warranty for production-critical dental equipment” |

Step 3: Shipping & Logistics (DDP vs FOB: 2026 Cost Analysis)

Customs delays caused 22% of 2025 dental equipment shipment failures (DHL Health Logistics Report). Optimize via:

| Term | Responsibility Breakdown | 2026 Cost Estimate (Shanghai→Berlin) | Recommended For |

|---|---|---|---|

| FOB Shanghai | Buyer manages: Ocean freight, EU customs clearance, VAT (19%), last-mile delivery | $8,200-$10,500/unit + 19% VAT on CIF value (Savings: $1,800-$2,300 vs DDP) |

Experienced distributors with EU customs brokers; clinics with in-house logistics |

| DDP Berlin | Supplier handles: All freight, customs duties (4.7%), VAT payment, delivery to clinic | $12,500-$14,200/unit (all-in) (Premium: $2,000-$2,700 vs FOB) |

New distributors; clinics prioritizing time-to-operation; markets with complex VAT rules (e.g., UK post-2025) |

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why They Meet 2026 Requirements:

- Regulatory Excellence: ISO 13485:2023 certified (Certificate #CN-SH-2023-0887) with MDR 2017/745 scope covering “Dental Milling Systems”; CE Technical File audited by TÜV Rheinland (NB 0123)

- MOQ Flexibility: 1-unit orders accepted for clinics; 3-unit MOQ for distributors with 24-month warranty (spindle coverage: 36 months)

- Shipping Solutions: DDP quotes to 38 countries within 72hrs; in-house customs team handles EU MDR Annex IX documentation

- Technical Validation: Factory in Baoshan District (Shanghai) features ISO Class 8 cleanroom for spindle calibration; provides 3rd-party milling accuracy reports (±5μm)

Contact for Verified Sourcing:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Request “2026 Dental Milling Compliance Package” including: Live factory tour link, NANDO database verification, DDP cost calculator

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: e4D Milling Machines – Procurement Insights for 2026

Top 5 FAQs for Purchasing e4D Milling Machines in 2026

| Question | Answer |

|---|---|

| 1. What voltage and power requirements are needed for the e4D milling machine in 2026? | The 2026 e4D milling machines are engineered for global compatibility and operate on a standard input voltage of 100–240 V AC, 50/60 Hz, with auto-switching capability. A dedicated 15A circuit is recommended to ensure stable performance, especially during high-load milling cycles. Clinics in regions with unstable power supply should consider integrating a line-interactive UPS (Uninterruptible Power Supply) to protect sensitive electronics and avoid calibration drift. |

| 2. Are spare parts for e4D milling machines readily available, and what is the lead time for critical components? | Yes, as of 2026, e4D maintains an expanded global spare parts network with regional distribution hubs in North America, EMEA, and APAC. Common wear components—such as spindle brushes, tool holders, and vacuum filters—are typically in stock with 2–5 business day delivery for most regions. Critical parts like the high-speed spindle or linear encoders are available through priority logistics programs, with standard lead times of 7–10 business days. Authorized distributors receive quarterly inventory updates and can pre-position high-usage parts. |

| 3. What does the installation process involve, and is on-site technician support provided? | Installation of the 2026 e4D milling system includes site assessment, machine leveling, software calibration, and integration with existing CAD/CAM workflows. A certified e4D field service engineer conducts on-site installation and commissioning, typically completed within one business day. Remote pre-installation diagnostics are now standard to ensure readiness. Dental clinics must provide a stable, vibration-free surface, adequate ventilation, and a clean dry air supply (minimum 80 psi). Training for clinical and technical staff is included. |

| 4. What is the warranty coverage for the e4D milling machine, and are there extended service options? | All e4D milling machines purchased in 2026 come with a comprehensive 3-year standard warranty covering parts, labor, and the high-speed spindle. This includes preventive maintenance visits at 6, 12, 24, and 36 months. Extended service agreements (ESAs) are available for up to 5 years, with options for 24/7 technical support, priority dispatch, and predictive maintenance via IoT-enabled monitoring. Distributors may bundle ESAs with new equipment sales for enhanced client retention. |

| 5. How does e4D ensure long-term serviceability and compatibility with future software updates? | e4D guarantees backward compatibility and service support for all milling units released since 2020 through at least 2036. The 2026 models feature modular architecture for easy upgrades and are supported by the e4D Connect Platform, which delivers secure, over-the-air software updates. Firmware enhancements, material libraries, and milling strategies are regularly released to optimize performance with new restorative materials. Remote diagnostics and usage analytics help preempt failures and extend machine lifecycle. |

Need a Quote for E4D Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160