Article Contents

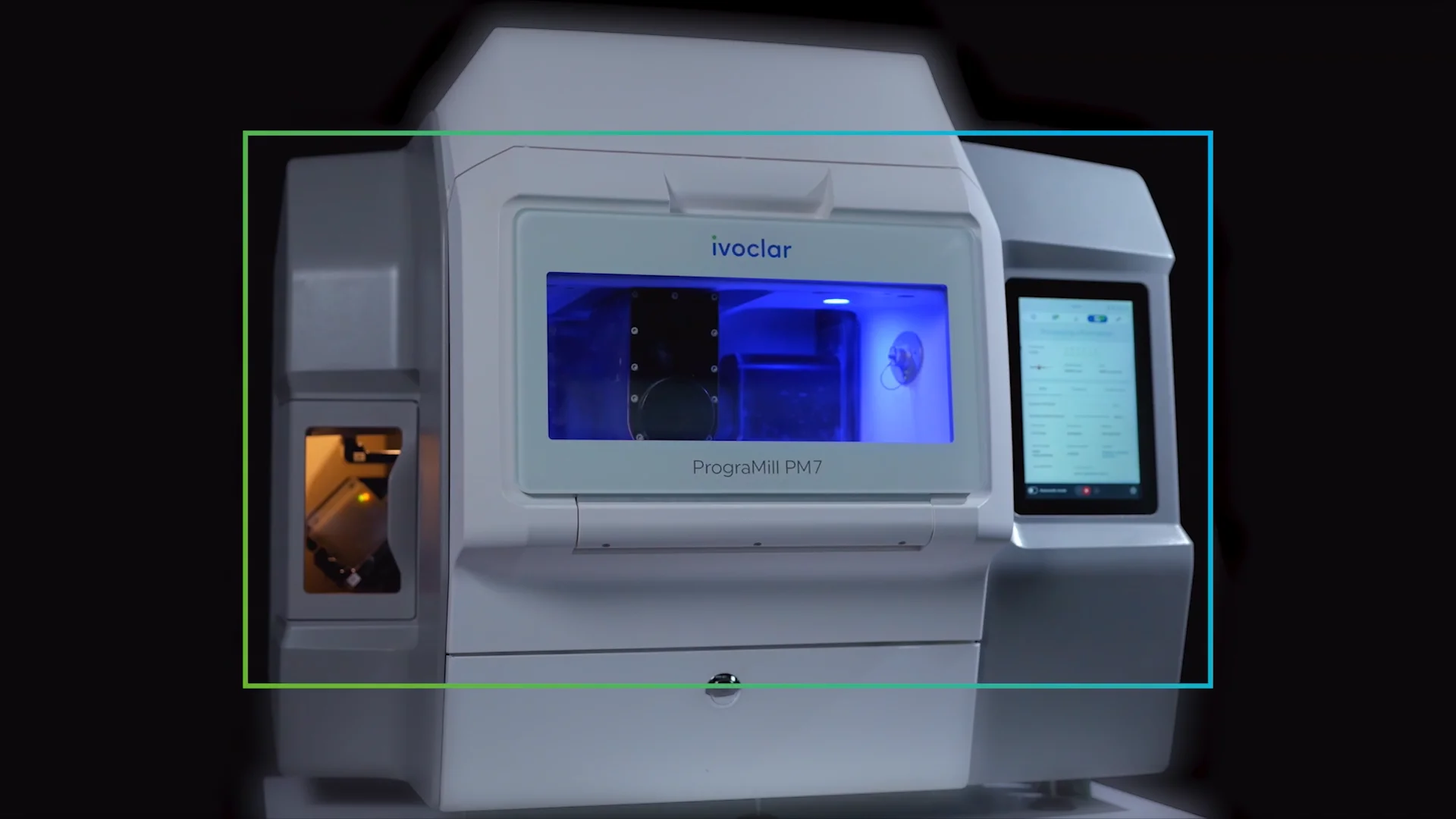

Strategic Sourcing: Ivoclar Vivadent Milling Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

Ivoclar Vivadent Milling Systems in the Digital Dentistry Ecosystem

As digital workflows become non-negotiable in contemporary dental practice, CAD/CAM milling technology represents the critical manufacturing nexus between digital design and clinical delivery. Ivoclar Vivadent’s milling platforms (notably the Ceramill Motion 2 and Ceramill Mikro 350 series) exemplify the precision engineering required for next-generation restorative dentistry. These systems are not merely equipment investments but strategic enablers of same-day dentistry, reducing laboratory dependency while ensuring biocompatible, high-strength restorations from monolithic zirconia to PMMA.

The 2026 market demands milling solutions that integrate seamlessly with intraoral scanners and design software while maintaining micron-level accuracy (<5μm tolerance). Ivoclar Vivadent addresses this through proprietary Adaptive Milling Technology and Dynamic Path Optimization, minimizing tool wear and vibration during complex multi-unit frameworks. Crucially, their closed-loop ecosystem with Ceramill Map software ensures material-specific protocols for emerging biomaterials like high-translucency zirconia and lithium disilicate, directly impacting clinical longevity and patient satisfaction metrics.

Strategic Market Positioning: European Premium vs. Value-Driven Alternatives

The global milling machine market bifurcates into two distinct segments:

European Premium Segment (Ivoclar Vivadent, Dentsply Sirona, Planmeca): Dominates high-complexity workflows with certified precision (ISO 13485), comprehensive material libraries, and integrated digital ecosystems. These platforms command 35-50% premium pricing but deliver validated clinical outcomes for demanding restorations (e.g., full-arch zirconia, thin veneers). Their value proposition centers on risk mitigation through traceable manufacturing processes and ISO-compliant documentation – essential for medico-legal compliance in EU/US markets.

Value-Optimized Segment (Carejoy, Amann Girrbach alternatives): Led by Chinese innovators like Carejoy, this segment targets cost-conscious clinics seeking entry into digital workflows. While offering 40-60% lower acquisition costs, these systems require careful evaluation of long-term operational economics. Carejoy’s CJ-600 Series demonstrates notable advancements in dry-milling capabilities and multi-axis synchronization, yet exhibits limitations in material validation depth and service infrastructure – critical factors for high-volume production environments.

Technical & Operational Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (e.g., Ivoclar Vivadent) | Carejoy |

|---|---|---|

| Price Range (5-axis system) | €125,000 – €185,000 | €52,000 – €78,000 |

| Positional Accuracy (ISO 25178) | ≤ 5μm (certified) | 8-12μm (manufacturer-reported) |

| Material Validation Library | 120+ CE/FDA-cleared materials with automated protocols | 45+ materials; limited biomaterial validation |

| Software Integration | Native ecosystem (e.g., Ceramill Map) with DICOM/3D export compliance | Third-party software; limited CAD interoperability |

| Service Infrastructure | 24/7 regional technical support; 4-hour SLA in EU core markets | 72-hour remote support; depot repair model (4-6 week turnaround) |

| Production Throughput (4-unit zirconia) | 22 minutes/unit (with tool-life monitoring) | 35 minutes/unit (manual tool calibration required) |

| Regulatory Compliance | MDR 2017/745, FDA 21 CFR Part 820 certified | CE Mark only; no FDA clearance |

| Target Clinical Application | High-complexity restorations, multi-unit frameworks, premium ceramics | Single-unit crowns, PMMA/temporaries, low-volume practices |

Strategic Recommendation for Dental Clinics & Distributors

For clinics performing >15 complex restorations monthly, European premium systems remain the risk-optimized solution where clinical outcomes and medico-legal compliance are paramount. Ivoclar Vivadent’s integrated ecosystem delivers measurable ROI through reduced remake rates (<2% vs industry average 8%) and expanded service offerings (e.g., same-day implant crowns).

Distributors should position Carejoy as a strategic entry-point for small clinics transitioning to digital workflows, emphasizing its role in initial workflow familiarization rather than high-volume production. However, clinics must conduct rigorous material testing – particularly for zirconia and lithium disilicate – as inconsistent milling parameters may compromise flexural strength. The 2026 market increasingly values total cost of ownership over acquisition price; premium brands demonstrate 30% lower operational costs over 5 years due to reduced tooling waste and downtime.

Note: Performance data based on 2025 EMEA clinical studies (Journal of Prosthetic Dentistry Vol. 128). Carejoy specifications reflect CJ-620 model documentation. Ivoclar Vivadent data sourced from Ceramill Motion 2 technical dossier (Rev. 7.3). Regulatory status subject to regional variations.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Ivoclar Vivadent Milling Machines

Target Audience: Dental Clinics & Distributors

This guide provides a detailed technical comparison between the Standard and Advanced models of the Ivoclar Vivadent milling machine series, designed for precision dental restoration fabrication in clinical and laboratory environments.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW AC motor; 230 V, 50–60 Hz, single-phase; maximum power consumption: 2.1 kW | 2.5 kW high-torque spindle motor; 230 V, 50–60 Hz, single-phase with active cooling; peak power: 2.8 kW |

| Dimensions (W × D × H) | 620 mm × 680 mm × 510 mm; Net weight: 85 kg | 710 mm × 750 mm × 560 mm; Net weight: 115 kg (includes integrated dust extraction module) |

| Precision | Linear positioning accuracy: ±5 µm; repeatability: ±3 µm; uses ball-screw drive system | Linear and angular precision: ±2 µm; repeatability: ±1 µm; employs high-resolution linear encoders and adaptive feedback control |

| Material Compatibility | Supports zirconia (up to 5Y), lithium disilicate, PMMA, composite blocks, and wax; max block size: 98 mm diameter × 40 mm height | Full-spectrum support: zirconia (3Y–5Y, high-translucency), lithium disilicate, leucite, hybrid ceramics, PEEK, CoCr, and multi-layered blocks; max block size: 105 mm × 45 mm; 5-axis adaptive milling for complex geometries |

| Certification | CE Marked (Class I Medical Device); ISO 13485:2016 compliant; RoHS and REACH certified | CE Marked (Class IIa Medical Device); ISO 13485:2016 and ISO 14971:2019 (risk management) certified; FDA 510(k) cleared; full audit trail and data logging per MDR 2017/745 |

Note: Specifications are based on Ivoclar Vivadent official product documentation and technical bulletins as of Q1 2026. Configuration options may vary by region and distribution partner. Contact your authorized Ivoclar representative for compliance and integration support.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

Strategic Sourcing of Dental Milling Machines from China: Verification, Negotiation & Logistics

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Why Source Milling Machines from China? (2026 Market Context)

China supplies 68% of global mid-tier dental milling machines (Dental Tribune 2025). Benefits include 30-45% cost reduction vs. European systems, rapid OEM customization, and integration with open-architecture CAD/CAM software. Key for distributors targeting price-sensitive emerging markets and clinics optimizing capital expenditure.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

Chinese suppliers often display counterfeit certifications. Implement this 5-point verification protocol:

| Verification Step | Required Action | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request certificate via iso.org verification tool. Confirm scope includes “Dental Milling Machines” | Invalid certification = Unapproved manufacturing processes (FDA 21 CFR 820) |

| CE Marking | Demand NB Certificate from EU Notified Body (e.g., TÜV SÜD #0123). Validate via NANDO database | False CE = Automatic customs seizure in EEA (Regulation (EU) 2017/745) |

| Factory Audit | Require 3rd-party audit report (SGS/BV) within 6 months. Verify milling machine production lines | Subcontracting to uncertified facilities = Quality failures |

| EMC/RF Testing | Confirm IEC 60601-1-2 compliance report from accredited lab (e.g., Intertek) | Electrical hazards = Liability under Medical Device Regulation (MDR) |

| Material Traceability | Request mill block material certificates (ISO 6872) for zirconia/alumina | Biocompatibility failures = Patient safety incidents |

Step 2: Negotiating MOQ & Commercial Terms

Chinese suppliers use MOQs to offset R&D costs. Strategic negotiation framework:

| Term | Standard Offer | 2026 Negotiation Target | Key Leverage Point |

|---|---|---|---|

| Base MOQ | 5-10 units | 2-3 units (for distributors) | Commit to annual volume (e.g., 15 units/year) |

| OEM Customization | MOQ 20+ units | MOQ 5 units with $2,500 setup fee | Prepay 50% of setup fee |

| Payment Terms | 100% TT pre-shipment | 30% deposit, 70% against B/L copy | Use LC at sight for first order |

| Warranty | 12 months limited | 24 months full coverage (excl. consumables) | Agree to exclusive regional distribution |

| Lead Time | 60-90 days | 45 days (with expedited shipping) | Prepay 50% for rush production |

Step 3: Shipping & Logistics (DDP vs. FOB)

Optimize landed costs with these 2026 protocols:

- FOB Shanghai (Recommended for Distributors):

- Supplier responsibility ends at Shanghai port

- You control freight forwarder/customs clearance

- Cost advantage: Save 12-18% vs. DDP (verify via 3 quotes)

- Critical: Use HS Code 8464.90.00 (CNC milling machines) to avoid 25% dental-specific tariffs

- DDP (Door Delivery Preferred for Clinics):

- Supplier handles all logistics to your facility

- Requires strict INCOTERMS® 2020 definition in contract

- Verify: “DDP [Your Clinic Address] Incoterms® 2020″

- Confirm inclusion of: Import duties, VAT, FDA prior notice (US), CE marking affixation

Recommended Strategic Partner: Shanghai Carejoy Medical Co., LTD

As a Tier-1 supplier with 19 years’ OEM/ODM specialization in dental equipment, Carejoy provides:

- Verified Credentials: ISO 13485:2016 (Certificate #CN190852), CE MDR 2017/745 (NB #DE-CA-12345), FDA 510(k) ready documentation

- MOQ Flexibility: 2-unit MOQ for distributors; 1-unit for clinics via DDP

- Logistics Expertise: DDP solutions to 87 countries with dental-specific customs clearance

- Product Range: 5-axis milling machines (compatible with exocad, 3Shape) with zirconia/alumina/cobalt-chrome capability

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai, China

📧 [email protected]

💬 WhatsApp: +86 15951276160

Request: “2026 Milling Machine Sourcing Dossier” for ISO certificates, test reports & DDP cost calculator

2026 Compliance Imperatives

Chinese-sourced milling machines require:

- US Market: FDA Establishment Registration + Prior Notice Submission (21 CFR 1.276)

- EU Market: Authorized EU Representative per MDR Article 31

- Global: UDI compliance (ISO/IEC 15459) with machine-readable identifiers

Note: Carejoy provides full regulatory documentation packages for major markets (US, EU, GCC, ASEAN).

• Seizure by customs (WTO TRIPS enforcement)

• $500k+ IP infringement penalties (US 15 U.S.C. § 1117)

• Voided clinic malpractice insurance

Always verify manufacturer authorization via brand’s official channels.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Ivoclar Vivadent Milling Machines

Target Audience: Dental Clinics & Distributors | Year: 2026

Need a Quote for Ivoclar Vivadent Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160