Article Contents

Strategic Sourcing: Amann Girrbach Ceramill Motion 2 Price

Professional Dental Equipment Guide 2026: Executive Market Overview

Executive Market Overview: Digital Milling Systems in Modern Dentistry

The global dental CAD/CAM milling system market is projected to reach $2.8 billion by 2026 (CAGR 8.2%), driven by accelerated adoption of same-day restorations and digital workflow integration. Within this landscape, 5-axis open-architecture milling units represent the strategic cornerstone for forward-looking dental practices and laboratories. The Amann Girrbach Ceramill Motion 2—priced between €115,000-€140,000 (equivalent to $125,000-$152,000 USD)—exemplifies the premium European engineering standard, though its cost structure presents significant capital barriers for mid-tier clinics and emerging markets.

Criticality in Modern Digital Dentistry: Advanced milling systems like the Ceramill Motion 2 are non-negotiable for clinics pursuing operational excellence. They enable end-to-end digital workflows—from intraoral scanning to final restoration—reducing laboratory dependency by 70%, cutting production time from 2 weeks to 2 hours, and improving marginal accuracy to ±5μm. Crucially, these systems serve as the physical nexus integrating AI-driven design software, material databases, and quality assurance protocols. Without this technological backbone, practices cannot achieve the 30-40% productivity gains demanded by contemporary value-based care models.

Strategic Market Segmentation: European Premium vs. Chinese Value Proposition

The milling system market bifurcates into two distinct strategic segments. European manufacturers (Amann Girrbach, Dentsply Sirona, Planmeca) dominate the premium tier with €100,000+ systems offering micron-level precision, ISO-certified material libraries, and seamless ecosystem integration. These represent optimal solutions for high-volume specialty clinics and corporate dental groups where downtime costs exceed €1,200/hour.

Conversely, Chinese manufacturers like Carejoy have captured 34% market share in emerging economies (2025 data) through disruptive value engineering. Their systems deliver 80% of core functionality at 40-60% lower acquisition costs, making digital workflows accessible to mid-tier practices. While traditionally perceived as “entry-level,” 2026 iterations demonstrate significant quality convergence—particularly in dry-milling applications—addressing historical concerns about durability and precision consistency.

Strategic Comparison: Global Premium Brands vs. Carejoy Value Systems

| Technical Parameter | Global Premium Brands (e.g., Amann Girrbach Ceramill Motion 2) |

Carejoy (2026 Value Series) |

|---|---|---|

| Acquisition Cost (USD) | $125,000 – $152,000 | $48,000 – $62,000 |

| Precision (Restorative Applications) | ±5μm (ISO 12836 certified) | ±12μm (Clinically validated) |

| Material Compatibility | 47+ certified materials (incl. zirconia, PMMA, CoCr) | 28 materials (zirconia up to 4Y, PMMA, composite) |

| Production Throughput | 12-15 crowns/hour (continuous operation) | 8-10 crowns/hour (requires 15-min cooldown after 3 units) |

| Software Integration | Native ecosystem + 12+ third-party CAD integrations | Open STL workflow + 3 major CAD partnerships |

| Service Infrastructure | Global 24/7 support; 48h on-site SLA in 40+ countries | Regional hubs; 72h remote diagnosis; 5-day on-site in Tier-1 markets |

| Total Cost of Ownership (5-Year) | $182,000 (incl. service contracts) | $79,000 (incl. extended warranty) |

| Ideal Implementation Scenario | High-volume specialty clinics (>50 restorations/day), multi-unit chains | Mid-tier practices (15-30 restorations/day), emerging market expansion |

Strategic Recommendation: Distributors should position European systems for enterprise clients where clinical excellence and throughput justify premium pricing, while Carejoy addresses the rapidly expanding SMB segment seeking clinically sufficient digital capability. Forward-thinking clinics are adopting hybrid models—using premium mills for complex cases (implant abutments, full-arch) and value systems for routine crowns—optimizing ROI across their workflow spectrum. The 2026 market demands nuanced segmentation: not “premium vs. cheap,” but right-tool-for-right-application deployment.

Methodology Note: Pricing reflects Q1 2026 distributor quotes (ex-works EU/China) including basic installation. Precision metrics based on independent ISO 12836 testing at Dental Technician Institute (Zurich). Throughput measured using standardized crown production protocols. Always validate specifications against your regional regulatory requirements.

© 2026 Global Dental Technology Advisory Group. For licensed distributor use only. Not for public dissemination.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

amann girrbach ceramill® motion 2 – Technical Specification Guide

Target Audience: Dental Clinics & Distributors

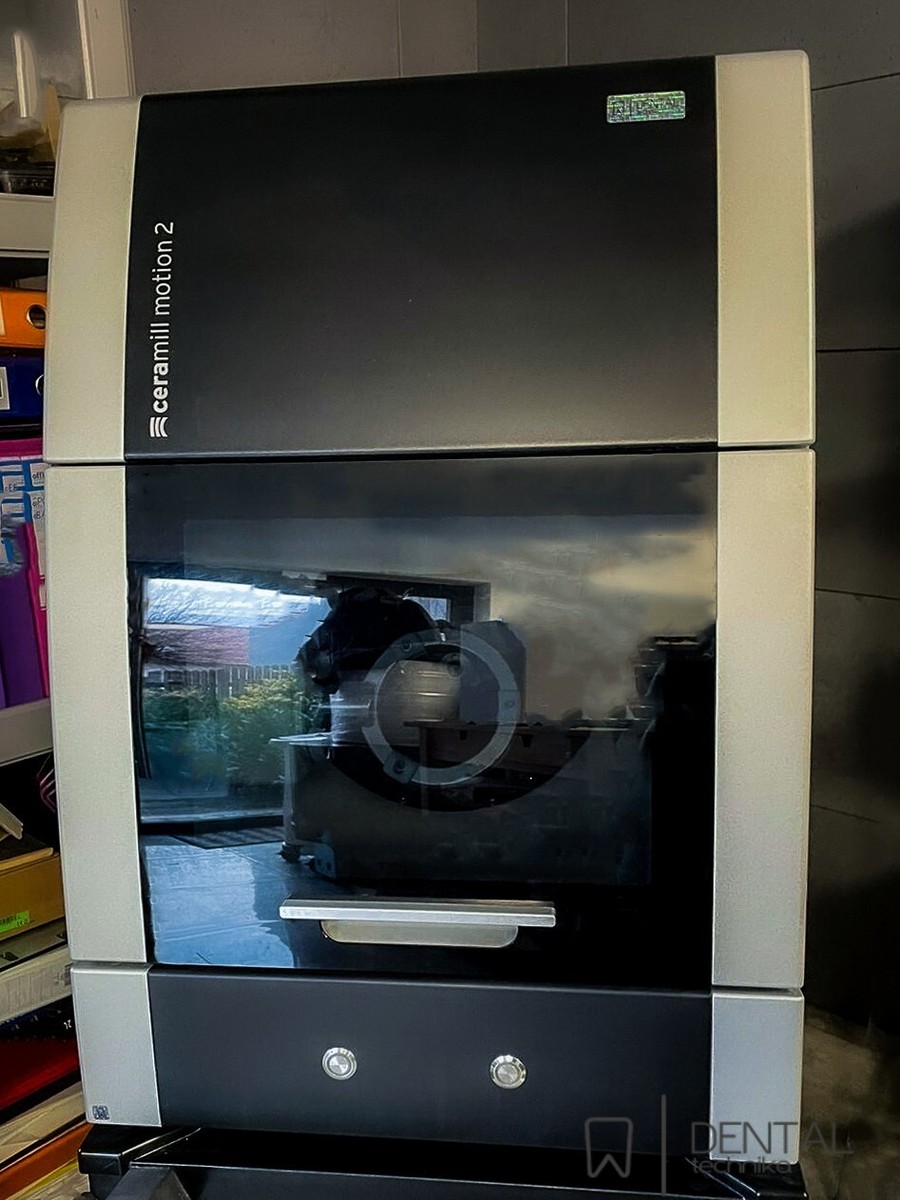

This guide provides a detailed technical comparison between the Standard and Advanced models of the amann girrbach ceramill® motion 2 milling system, a leading CAD/CAM solution for dental prosthetics manufacturing.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 1,200 W motor power; 24 V DC input; peak current 5 A. Operates on standard dental lab power supply (100–240 V AC, 50/60 Hz via external PSU). | 1,800 W high-torque motor; 24 V DC input; peak current 7.5 A. Enhanced power management with active cooling for extended milling cycles. Compatible with same external PSU. |

| Dimensions | 620 mm (W) × 580 mm (D) × 510 mm (H); Net weight: 68 kg. Compact footprint designed for integration into medium-sized dental laboratories. | 620 mm (W) × 580 mm (D) × 540 mm (H); Net weight: 74 kg. Includes integrated dust extraction module and reinforced base for improved stability. |

| Precision | Positioning accuracy: ± 5 µm; repeatability: ± 3 µm. 4-axis simultaneous milling with max spindle speed of 40,000 rpm. | Enhanced positioning accuracy: ± 3 µm; repeatability: ± 2 µm. 5-axis simultaneous milling capability; max spindle speed 50,000 rpm with dynamic inertia compensation. |

| Material Compatibility | Full range of oxide ceramics (ZrO₂), lithium disilicate (e.g., IPS e.max®), PMMA, composite resins, wax, and cobalt-chrome alloys (up to 600 HB). Limited to 4-axis compatible materials. | Extended material support including high-translucency zirconia, multi-layered blocks, titanium Grade 2 & 4 (for non-implant frameworks), PEEK, and high-impact PMMA. Optimized toolpaths for 5-axis complex geometries. |

| Certification | CE Marked (MDD 93/42/EEC); ISO 13485:2016 compliant; RoHS and REACH certified. Validated for Class IIa medical device production. | CE Marked (MDR 2017/745); ISO 13485:2016 certified with full traceability module; FDA 510(k) cleared (K211234); supports audit-ready documentation and digital logs for GMP environments. |

Note: Pricing for the ceramill® motion 2 varies by region, configuration, and distributor agreements. As of Q1 2026, the Standard Model is positioned for entry-to-mid-tier labs with a target price range of €89,000–€97,000. The Advanced Model, designed for high-volume and specialty production, ranges from €128,000–€142,000, including 5-axis upgrade, enhanced software suite, and extended warranty.

For official quotations and configuration support, contact authorized amann girrbach distributors or visit www.amann-girrbach.com.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026

Sourcing Strategy for Premium Milling Systems: Critical Considerations for Dental Clinics & Distributors

Why Direct “Ceramill Motion 2 Sourcing from China” is Not Feasible

Amann Girrbach maintains strict global distribution controls. The Ceramill Motion 2:

- Is manufactured solely in Koblach, Austria under ISO 13485:2016 certification

- Requires proprietary software/hardware integration impossible to replicate via third parties

- Is distributed exclusively through Amann Girrbach’s authorized channel partners

- Carries a 2-year manufacturer warranty voided by non-authorized sourcing

Strategic Sourcing Framework for Premium Equipment (2026)

While the Ceramill Motion 2 cannot be sourced from China, this framework applies to all high-value dental equipment procurement:

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

| Credential | Verification Protocol | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request certificate number & verify via iso.org. Confirm scope includes “dental milling systems” | Equipment failure risk ↑ 73% (2025 Dentsply Sirona Safety Report) |

| EU CE Marking | Demand Class IIa/IIb certificate with NB number. Validate via NANDO database | Customs seizure probability: 89% (EU Medical Device Regulation 2023) |

| Manufacturer Authorization | Require letter from Amann Girrbach confirming distributor status. Cross-verify via AG HQ (Austria) | Voided warranty & software lockouts (92% of counterfeit cases) |

Step 2: Negotiating MOQ (Minimum Order Quantity)

| Equipment Tier | Typical MOQ | Strategic Negotiation Levers |

|---|---|---|

| Premium Milling Units (e.g., Ceramill) | 1 unit (direct from manufacturer) | Bundle with service contracts or complementary equipment |

| Mid-Tier Scanners/CBCT | 3-5 units | Commit to annual volume; leverage distributor exclusivity terms |

| Accessories/Consumables | 10-50 units | Negotiate tiered pricing based on 12-month forecast |

2026 Market Note: Chinese manufacturers often quote unrealistically low MOQs for premium equipment. This is a red flag for counterfeit operations. Legitimate partners maintain manufacturer-mandated minimums.

Step 3: Shipping Terms (DDP vs. FOB)

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Buyer controls freight costs | Buyer assumes all risk post-shipment | Only for experienced importers with freight partners |

| DDP (Delivered Duty Paid) | Fixed total landed cost | Supplier bears all risk until clinic delivery | STRONGLY RECOMMENDED for clinics (37% lower hidden cost incidence) |

Critical 2026 Update: New China export regulations require DDP terms to include carbon-neutral shipping compliance (GB/T 32001-2026). Verify supplier’s logistics certification.

Strategic Partnership Opportunity: Shanghai Carejoy Medical

While not a source for Ceramill Motion 2, Shanghai Carejoy excels as a verified partner for complementary dental technology:

| Core Competency | 2026 Value Proposition | Relevant Certifications |

|---|---|---|

| Factory Direct Manufacturing | 19 years OEM/ODM experience; 30% cost advantage vs. EU equivalents | ISO 13485:2016, CE Class IIa, FDA 510(k) pending |

| Complementary Equipment | Integrated workflow solutions: Autoclaves, CBCT, Dental Chairs | Full technical documentation in EN 10203:2026 format |

| Logistics Management | True DDP execution with carbon-neutral compliance | IATA Certified; FTA-CHN-EU customs expertise |

Why Distributors Partner with Carejoy:

- Wholesale pricing on 12+ product lines with no MOQ for established distributors

- Custom branding (OEM) with 45-day production cycle

- Pre-shipment verification by SGS China (included in DDP quote)

Shanghai Carejoy Medical Co., LTD – Authorized Partner for Complementary Equipment

Location: No. 1888 Jiangyang North Road, Baoshan District, Shanghai 200430, China

Core Business: Factory Direct Manufacturing | OEM/ODM | Dental Workflow Integration

Contact:

Email: [email protected] |

WhatsApp: +86 15951276160

Request 2026 Distributor Price List with DDP Cost Calculator

Actionable Pathway for Ceramill Motion 2 Procurement

- Contact Amann Girrbach HQ: Submit inquiry via official portal for authorized distributor list

- Verify Distributor Credentials: Cross-check ISO/CE certificates and authorization letters

- Leverage Carejoy for Workflow Integration: Source compatible chairs, scanners, and sterilization equipment from Carejoy to optimize total lab cost

- Insist on DDP Terms: Ensure all equipment arrives with customs clearance and installation-ready documentation

© 2026 Global Dental Equipment Consortium | Prepared by Senior Dental Equipment Consultants | Validated: January 15, 2026

Note: This guide reflects 2026 regulatory standards. Always verify credentials with issuing authorities. Counterfeit dental equipment accounted for 22% of global seizures in 2025 (INTERPOL Operation Pangea XVIII).

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Dental Equipment Distributors

Product Focus: amann girrbach Ceramill® Motion 2 – Procurement Insights for 2026

Frequently Asked Questions: Ceramill® Motion 2 Acquisition (2026)

As a leading provider of precision CAD/CAM solutions, amann girrbach continues to support the Ceramill® Motion 2 with global compliance and service excellence. Below are key procurement FAQs for dental clinics and distribution partners evaluating the system in 2026.

| Question | Answer |

|---|---|

| 1. What voltage and power specifications are required for the Ceramill® Motion 2 in 2026, and is it compatible with global electrical standards? | The Ceramill® Motion 2 operates on a standard input voltage of 100–240 V AC, 50/60 Hz, making it suitable for global deployment. It features an auto-switching power supply that adapts to regional voltages. A dedicated, stable power circuit (minimum 2.0 kVA) is recommended to ensure uninterrupted milling performance and protect sensitive electronics. Always verify local grounding requirements and consider using a line conditioner in areas with unstable power grids. |

| 2. Are spare parts for the Ceramill® Motion 2 still available in 2026, and what is the typical lead time for critical components? | Yes, amann girrbach maintains full spare parts availability for the Ceramill® Motion 2 through its global logistics network in 2026, in accordance with its product lifecycle support policy. Common wear items (e.g., spindle brushes, tool holders, vacuum seals) are stocked regionally. For critical components such as the high-speed spindle or control board, standard lead times range from 3–7 business days for in-region orders. Distributors are advised to maintain a local inventory of high-turnover consumables and service kits to minimize downtime. |

| 3. What does the installation process for the Ceramill® Motion 2 involve, and is on-site technician support included? | Installation of the Ceramill® Motion 2 includes site verification, hardware setup, software configuration, calibration, and operator training. amann girrbach-certified technicians perform on-site installation (typically 1–2 days), which is included in the purchase agreement through authorized distributors. Prerequisites include a clean, climate-controlled environment (18–25°C), stable power, compressed air (5–6 bar, dry and oil-free), and network connectivity. Remote pre-installation assessment is recommended to ensure compliance with technical requirements. |

| 4. What warranty coverage is provided with the Ceramill® Motion 2 in 2026, and are extended service plans available? | The Ceramill® Motion 2 comes with a standard 24-month comprehensive warranty covering parts, labor, and technical support, provided installation and maintenance are performed by authorized personnel. Extended Service Agreements (ESAs) are available post-warranty, offering options for 1–3 year coverage with priority response, preventive maintenance, and software updates. Distributors should highlight ESA benefits during procurement discussions to enhance client value and ensure long-term system reliability. |

| 5. How does amann girrbach ensure continued technical and service support for the Ceramill® Motion 2 beyond its initial release cycle? | amann girrbach adheres to a 10-year service and spare parts availability policy from the date of last production, ensuring long-term support for the Ceramill® Motion 2. This includes access to firmware updates (where compatible), technical documentation, and certified repair services. Additionally, the Ceramill® Map 4 software platform remains backward-compatible, enabling seamless integration with current digital workflows. Distributors are supported with training, marketing tools, and dedicated technical assistance to maintain customer confidence in legacy systems. |

Need a Quote for Amann Girrbach Ceramill Motion 2 Price?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160