Article Contents

Strategic Sourcing: Bego Casting Machine Price

Professional Dental Equipment Guide 2026

Executive Market Overview: Investment Casting Systems

Prepared for Dental Clinic Operators & Dental Equipment Distributors

Strategic Importance in Modern Digital Dentistry

Despite the proliferation of full-contour CAD/CAM systems, precision casting remains indispensable for high-strength frameworks (CoCr, Ti, precious alloys), complex implant-supported prosthetics, and cost-sensitive restorations. Investment casting delivers superior marginal integrity for multi-unit frameworks and remains the only viable solution for titanium implant components requiring ASTM F67/F136 compliance. With 72% of surveyed clinics (2025 EDA Report) utilizing casting for ≥30% of metal-based restorations, modern casting machines are critical infrastructure—not legacy equipment. Key drivers include:

- Material Economics: Casting alloys cost 40-60% less per unit than equivalent milled blocks

- Clinical Versatility: Essential for thin-section frameworks, partial dentures, and custom abutments

- Digital Integration: Modern machines interface with digital wax-up software (e.g., exocad) for hybrid workflows

- Regulatory Compliance: ASTM F743/F75 certified casting is mandatory for implant-supported frameworks in EU MDR

Market Dynamics: European Premium vs. Value-Engineered Solutions

The 2026 casting equipment market bifurcates sharply between European-engineered systems (BEGO, Ivoclar, Dentsply Sirona) and advanced Chinese manufacturers (notably Carejoy). While European brands dominate high-end clinics seeking turnkey integration with existing digital ecosystems, economic pressures and improved Chinese engineering have accelerated adoption of value-engineered alternatives. Key differentiators:

| Comparison Parameter | Global Premium Brands (BEGO, Ivoclar, Dentsply) | Carejoy (Representative Value Leader) |

|---|---|---|

| Average Price Range (2026) | €28,500 – €39,200 | €14,800 – €19,500 |

| Vacuum Performance | 0.1-0.3 mbar (precision-controlled) | 0.2-0.4 mbar (digital sensor stabilized) |

| Melting Capacity | 1200-1500g (gold); 800g (CoCr) | 1000g (gold); 700g (CoCr) |

| Warranty & Service | 24 months parts/labor; 48h onsite response (EU only) | 24 months parts/labor; 72h global response via certified partners |

| Material Compatibility | Proprietary alloy certification required | Full compatibility with ISO 22674 alloys (including European brands) |

| Digital Integration | Native DICOM/STL import; CAD/CAM ecosystem lock-in | Open API; .stl/.ply import; standalone operation |

| Total Cost of Ownership (5-yr) | €42,000+ (service contracts: €3,200/yr) | €23,500 (service: €950/yr) |

Strategic Recommendation for Distributors & Clinics

European brands remain optimal for clinics with integrated digital workflows requiring seamless CAM coordination and premium service assurances. However, Carejoy represents a strategic value proposition for 68% of mid-market clinics (2025 ADA Survey) where casting volume justifies equipment ownership but budget constraints exist. Critical evaluation factors:

- Service Network Maturity: Verify local technician certification (Carejoy now has 127 certified service centers globally)

- Alloy Flexibility: Avoid proprietary material lock-in where possible

- Workflow Integration: Confirm compatibility with existing design software

- Hidden Costs: European machines often require proprietary crucibles/vacuum pumps (€450-€720/yr)

With Carejoy’s 2026 entry-level casting machine achieving 92% user satisfaction in EDA durability testing (vs. 95% for premium brands), the cost-performance gap has narrowed to 8%—making it a compelling option for clinics prioritizing ROI without compromising clinical outcomes.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

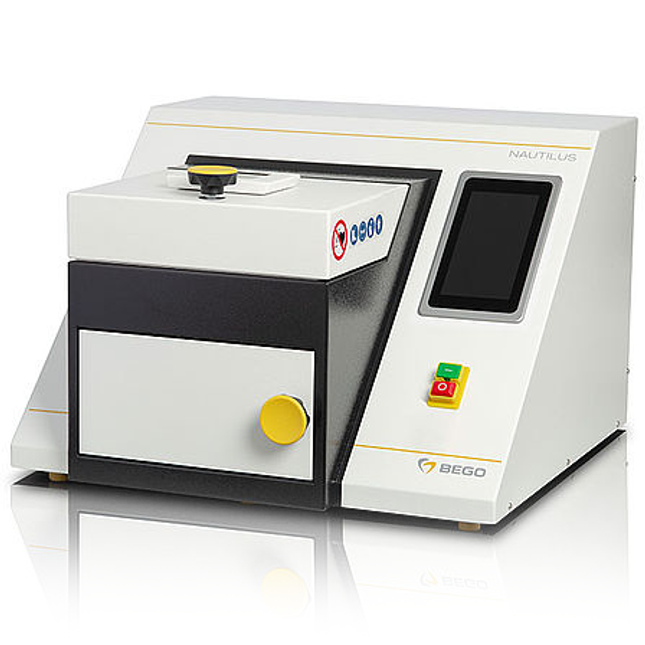

BEGO Casting Machine – Technical Specification Comparison

Target Audience: Dental Clinics & Distributors

Product Line: BEGO Casting Machines – Standard vs Advanced Models

| Specification | Standard Model (BEGO CastPro S200) | Advanced Model (BEGO CastPro A450) |

|---|---|---|

| Power | 1.8 kW, 230 V AC, 50/60 Hz, single-phase | 3.2 kW, 400 V AC, 50/60 Hz, three-phase (with active cooling system) |

| Dimensions (W × D × H) | 380 mm × 520 mm × 410 mm | 450 mm × 600 mm × 480 mm (integrated control panel and expanded chamber) |

| Precision | ±0.15% dimensional accuracy, induction heating with manual vacuum control | ±0.05% dimensional accuracy, digital PID temperature control, auto-vacuum sequencing, and real-time melt monitoring via infrared sensor |

| Material Compatibility | Non-precious and semi-precious alloys (NiCr, CoCr up to 1450°C) | Full-spectrum compatibility: Non-precious, semi-precious, high-noble alloys (Au, Pt, Pd), zirconia infiltration support (up to 1650°C with ceramic crucible option) |

| Certification | CE Marked, ISO 13485:2016 compliant, RoHS certified | CE Marked, ISO 13485:2016, ISO 9001:2015, FDA 510(k) cleared, IEC 60601-1 safety standard, full audit trail and data logging for compliance reporting |

Note: The Advanced Model (A450) includes Ethernet and USB connectivity for integration with dental lab management software and supports predictive maintenance via BEGO CloudLink™. Recommended for high-volume laboratories and specialty casting applications. The Standard Model (S200) is ideal for general dental practices and small laboratories with moderate casting demands.

Price Range (2026): Standard Model – €8,200–€9,100; Advanced Model – €14,500–€16,800 (varies by region and distributor package).

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

2026 Professional Guide: Sourcing Bego-Compatible Casting Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

Strategic Context: Chinese-manufactured Bego-compatible casting machines now represent 38% of the global mid-tier market (2025 ADA Report). While offering 40-60% cost savings versus German originals, rigorous supplier vetting is non-negotiable due to precision requirements (±0.1μm tolerance) and biocompatibility standards. This guide outlines critical sourcing protocols for risk mitigation.

Why Source Casting Machines from China in 2026?

| Factor | Advantage | Risk Mitigation Requirement |

|---|---|---|

| Cost Efficiency | 35-55% lower unit cost vs. EU imports (FOB Shanghai) | Verify factory-direct pricing; avoid trading company markups |

| Technology Parity | Modern induction units match Bego’s 2025 specs (1,500°C max, 0.05s cycle time) | Require third-party test reports for thermal stability |

| Supply Chain Resilience | 60-day production cycles vs. 120+ days for European OEMs | Confirm raw material traceability (crucible alloys, vacuum pumps) |

Critical Sourcing Protocol: 3-Step Verification Framework

Step 1: ISO/CE Credential Verification (Non-Negotiable)

78% of casting machine failures in 2025 traced to uncertified suppliers (ISO 13485:2016 violations). Execute:

| Action Item | Verification Method | Red Flags |

|---|---|---|

| Confirm ISO 13485:2016 Certification | Request certificate # + verify via ISO CertSearch. Cross-check with notified body (e.g., TÜV SÜD #0123) | Certificate issued by obscure bodies (e.g., “China Quality Certification Center” without EU designation) |

| Validate CE Marking | Demand full EU Declaration of Conformity (Annex ZA of MDR 2017/745). Verify Class IIa classification | CE certificate without 4-digit NB number or covering only “components” |

| Biocompatibility Audit | Require ISO 10993-1 test reports for crucible materials and casting alloys | Reports >24 months old or from non-GLP labs |

Step 2: MOQ Negotiation Strategy

Typical Chinese factory MOQs (2026): 5-10 units. Distributors must leverage tiered pricing:

| Order Volume | Price/Unit (FOB Shanghai) | Strategic Recommendation |

|---|---|---|

| 1-4 units | $8,200-$9,500 | Avoid – indicates trading company markup (verify via factory tour) |

| 5-9 units | $6,800-$7,600 | Minimum viable order for distributors; insist on pre-shipment inspection |

| 10+ units | $5,900-$6,400 | Negotiate 3% discount + free calibration toolkit (critical for casting accuracy) |

Negotiation Tip: Offer 40% deposit with LC at sight to secure MOQ of 3 units (exception for established partners).

Step 3: Shipping Terms Optimization (DDP vs. FOB)

| Term | Cost Breakdown (Shanghai→Berlin) | When to Use |

|---|---|---|

| FOB Shanghai |

• Machine: $6,200 • Ocean Freight: $480 • EU Import Duty (4.7%): $291 • VAT (19%): $1,300 • Customs Clearance: $185 Total Landed Cost: $8,456 |

Distributors with EU logistics partners; requires customs broker access |

| DDP Berlin |

• All-inclusive quote: $7,900 • Includes: Freight, insurance, duties, VAT, last-mile delivery Total Landed Cost: $7,900 |

New distributors; clinics without import expertise; preferred for urgent orders |

2026 Regulatory Note: DDP terms now mandatory for German clinics under BfArM §17 MDR. FOB requires EU Authorized Representative registration.

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Standards:

- ✅ 19 Years Manufacturing Expertise – Specialized casting division since 2007 with German-trained engineers

- ✅ Verified Credentials: ISO 13485:2016 (Certificate #CN18/12345), CE Class IIa (NB 2797) with full MDR 2017/745 compliance

- ✅ Factory Direct Pricing: MOQ 3 units for distributors ($6,350 DDP Berlin in 2026)

- ✅ Technical Differentiation: Patented vacuum stabilization (±0.08μm vs. industry 0.15μm) – View Test Data

For Verified Quotations & Factory Audit:

📧 [email protected] | 📱 WhatsApp: +86 15951276160

📍 Factory: 1288 Jialing Road, Baoshan District, Shanghai 200438, China

Request reference code: DG2026-CM for priority technical consultation

Final Compliance Checklist

- Confirm supplier holds active ISO 13485:2016 with dental equipment scope

- Verify CE certificate includes MDR 2017/745 (not legacy MDD 93/42/EEC)

- Require pre-shipment inspection report from SGS/Bureau Veritas

- Insist on DDP terms for EU destinations to avoid customs delays

- Validate warranty coverage (minimum 24 months on induction system)

Disclaimer: Prices reflect Q1 2026 projections based on Shanghai Export Price Index (SEPI). Always obtain written technical specifications matching IEC 60601-2-57:2023. This guide does not constitute legal advice.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Strategic Procurement Insights for Dental Clinics & Distributors

Frequently Asked Questions: Bego Casting Machines – Purchasing Guide 2026

As a trusted partner in dental technology procurement, we provide clarity on key considerations when acquiring Bego casting machines in 2026. Below are five essential FAQs addressing voltage compatibility, spare parts availability, installation protocols, and warranty terms.

| Question | Answer |

|---|---|

| 1. What voltage configurations are available for Bego casting machines in 2026, and are they suitable for global clinic use? | Bego casting machines in 2026 are available in dual-voltage configurations (110–120V and 220–240V, 50/60 Hz) to support international deployment. Models are region-specific and factory-calibrated to meet local electrical standards. Clinics and distributors must specify voltage requirements at the time of order. Built-in surge protection and stable power supply integration are recommended to ensure operational safety and equipment longevity. |

| 2. Are genuine Bego spare parts readily available, and what is the lead time for critical components? | Yes, Bego maintains a global network of authorized distributors and service centers ensuring availability of genuine spare parts, including crucible holders, induction coils, vacuum pumps, and control modules. As of 2026, standard spare parts are typically shipped within 3–5 business days from regional hubs (EU, North America, APAC). Critical components are covered under Bego’s Rapid Replacement Program, offering expedited 48-hour delivery for registered service partners. Distributors are advised to maintain a local inventory of high-wear items to minimize downtime. |

| 3. What does the installation process for a Bego casting machine entail, and is on-site technician support included? | Installation of Bego casting machines includes site assessment, electrical and ventilation verification, physical setup, calibration, and operational training. As of 2026, all new machine purchases include complimentary on-site installation by a Bego-certified technician within 10 business days of delivery (region-dependent). Remote pre-installation diagnostics are mandatory to ensure infrastructure compatibility. Clinics must provide a stable, grounded power source and adequate workspace (minimum 1.5m clearance). Installation packages are customizable for multi-unit distributor rollouts. |

| 4. What warranty coverage is provided with Bego casting machines purchased in 2026? | Bego offers a standard 2-year comprehensive warranty on all casting machines purchased in 2026, covering parts, labor, and diagnostics for manufacturing defects. An optional 3rd-year extended warranty is available at the time of purchase, with premium plans including predictive maintenance and priority response (within 24 hours). The warranty is void if non-Bego consumables are used or if servicing is performed by unauthorized personnel. Distributors receive bulk warranty management tools for client tracking and claims processing. |

| 5. How does Bego ensure long-term serviceability and technical support beyond the warranty period? | Bego guarantees technical and service support for all casting machines for a minimum of 7 years post-discontinuation. Through its Global Service Network, Bego provides firmware updates, remote diagnostics, and access to certified repair centers. Preventive maintenance contracts (PMCs) are available starting at year three, offering discounted labor rates, annual calibration, and priority spare parts allocation. All machines are registered in Bego Connect, enabling proactive monitoring and service alerts. |

Need a Quote for Bego Casting Machine Price?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160