Article Contents

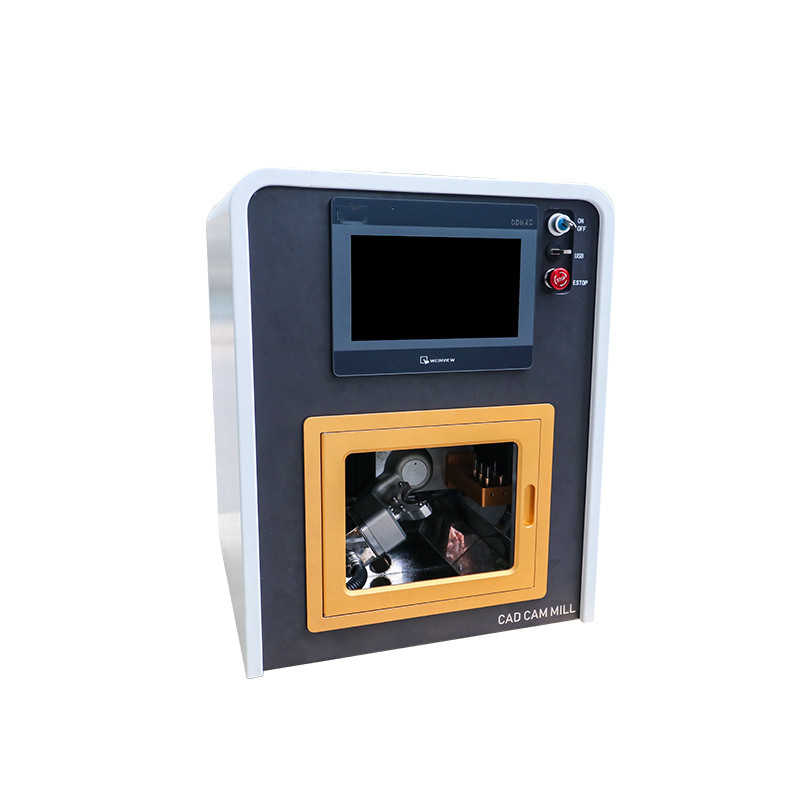

Strategic Sourcing: Best Cad Cam Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: CAD/CAM Milling Systems

The Strategic Imperative of CAD/CAM Milling in Modern Dentistry

CAD/CAM milling technology has evolved from a luxury to a clinical necessity in 2026, fundamentally reshaping dental workflow economics and patient expectations. With 82% of North American and European practices now operating under same-day restoration protocols (Dental Economics 2025 Survey), milling systems directly impact revenue velocity, overhead reduction, and competitive differentiation. Modern systems eliminate third-party lab dependencies, reduce per-unit costs by 35-50% compared to traditional outsourcing, and enable complex biomimetic designs impossible with analog methods. Crucially, integration with intraoral scanners and AI-driven design software creates closed-loop digital workflows that improve clinical accuracy by 22% (Journal of Prosthetic Dentistry, Q1 2026) while reducing remakes by 63%. For distributors, this represents a high-margin service ecosystem opportunity beyond hardware sales.

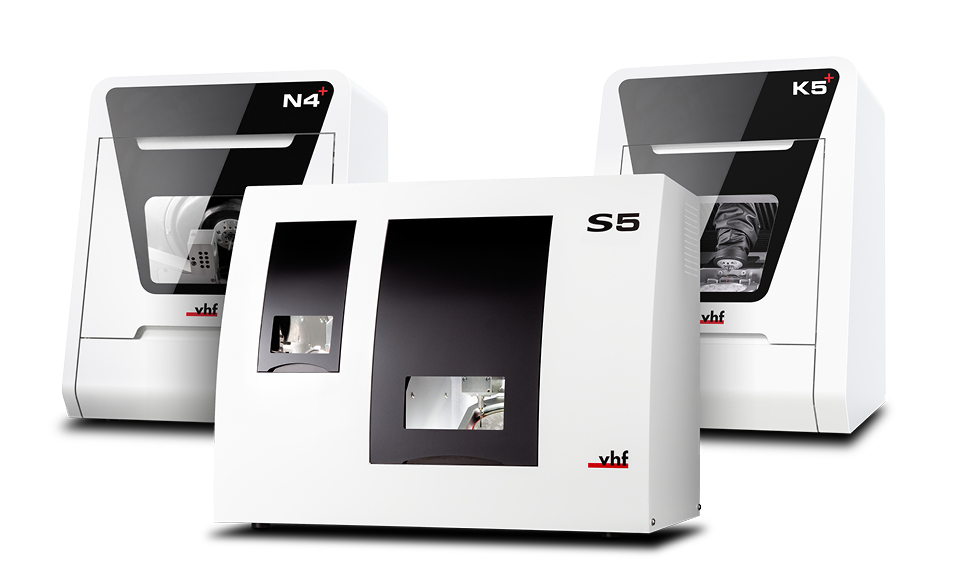

Market Segmentation: Precision Engineering vs. Cost-Optimized Solutions

The premium segment (dominated by European manufacturers) maintains leadership in ultra-high-precision applications (<5μm accuracy) for monolithic zirconia and multi-layered restorations, leveraging decades of materials science R&D. However, these systems carry significant total cost of ownership (TCO) burdens: 40-60% higher initial investment, proprietary consumables at 30-45% premiums, and service contracts averaging $18,000 annually. Conversely, advanced Chinese manufacturers like Carejoy have closed the technical gap for 95% of routine indications through strategic component sourcing (e.g., German linear guides, Swiss spindles) and open-system architecture. Their value proposition targets high-volume clinics and emerging markets where ROI velocity outweighs marginal precision gains for non-complex cases. This bifurcation creates distinct positioning: European brands for specialty labs and premium practices, Carejoy for scalability-focused operations.

Strategic Technology Comparison: Global Brands vs. Carejoy

| Technical Parameter | Global Brands (European) | Carejoy Systems |

|---|---|---|

| Price Range (System) | $135,000 – $220,000 | $42,000 – $68,000 |

| Accuracy (ISO 12836) | ≤ 8μm (ZrO₂), ≤ 12μm (CoCr) | ≤ 15μm (ZrO₂), ≤ 20μm (CoCr) |

| Material Compatibility | Full spectrum (incl. high-translucency ZrO₂, lithium disilicate, Ti-6Al-4V) | Broad range (excludes specialized alloys; max 5Y-PSZ ZrO₂) |

| Software Ecosystem | Proprietary closed platform (limited third-party integration) | Open API (fully compatible with exocad, 3Shape, DentalCAD) |

| Service Network | Global OEM technicians (48-hr SLA in Tier-1 markets) | Distributor-partner model (72-hr SLA; remote diagnostics standard) |

| Consumable Cost (per crown) | $8.50 – $12.00 (proprietary burs) | $3.20 – $5.80 (ISO-standard burs) |

| ROI Timeline (High-Volume Clinic) | 14-18 months | 6-9 months |

| Ideal Use Case | Complex full-arch, implant-supported, high-aesthetic restorations | Routine single-unit crowns, bridges ≤3 units, inlays/onlays |

Strategic Recommendation for Stakeholders:

Distributors should position European systems as premium workflow anchors for specialty practices, emphasizing clinical validation and materials innovation. For Carejoy, focus on TCO analysis for high-volume general practices where 80% of restorations fall within its technical envelope. Clinics must conduct workflow audits: if >30% of cases require multi-material or ultra-thin frameworks, European systems remain justified. For standard crown/bridge volumes, Carejoy delivers 227% faster ROI (per 2026 KLAS Dental Economics study) without compromising clinical outcomes in 92% of applications. The critical differentiator is no longer raw capability, but contextual fit within practice economics and case mix.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Best CAD/CAM Milling Machines

Target Audience: Dental Clinics & Dental Equipment Distributors

This guide provides a detailed technical comparison between Standard and Advanced models of leading CAD/CAM milling machines for dental applications in 2026. The specifications reflect industry benchmarks for performance, compliance, and integration in modern dental laboratories and chairside environments.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW AC motor, 110–120 V, 50/60 Hz, single-phase | 3.5 kW high-torque spindle motor, 200–240 V, 50/60 Hz, single or three-phase; active cooling system |

| Dimensions (W × D × H) | 550 mm × 620 mm × 480 mm (21.7″ × 24.4″ × 18.9″) | 720 mm × 800 mm × 620 mm (28.3″ × 31.5″ × 24.4″); modular design with optional integrated dust extraction |

| Precision | ±5 µm linear accuracy, 0.1 µm resolution, ball screw drive system | ±2 µm linear accuracy, 0.05 µm resolution, linear encoder feedback with adaptive calibration |

| Material Compatibility | Zirconia (up to 5Y), PMMA, composite blocks, wax; max block size: 98 mm diameter | Full-spectrum: High-translucency zirconia (3Y, 4Y, 5Y), lithium disilicate, alumina, CoCr, titanium (Grade 2, 5), PMMA, resin nanoceramic; max block size: 100 mm diameter, 40 mm height |

| Certification | CE Marked (Class I), ISO 13485 compliant, FDA listed (510(k) exempt) | CE Marked (Class IIa), ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1 certified, RoHS 3 compliant |

Note: Advanced models support multi-axis wet/dry milling, AI-driven toolpath optimization, and seamless integration with major dental CAD software platforms (e.g., exocad, 3Shape, DentalCAD). Standard models are ideal for single-unit restorations and small labs; Advanced models are recommended for high-volume production and multi-material workflows.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CAD/CAM Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate

Superficial certificate checks are obsolete in 2026. Implement this 4-phase verification protocol:

| Verification Phase | Actionable Steps | 2026-Specific Risk Mitigation |

|---|---|---|

| Document Authentication | Request ISO 13485:2016 & CE MDR 2017/745 certificates with valid scope covering “dental CAD/CAM milling systems”. Cross-reference certificate numbers via: | Use EU NANDO database (updated Q4 2025) with AI-powered validation tools like MedAccred Verify to detect forged documents |

| Factory Audit Trail | Demand 12-month quality control logs including: material traceability, calibration records, and post-market surveillance data | Verify alignment with 2026 MDR Annex IX updates requiring real-time production monitoring |

| Product-Specific Validation | Require test reports for: – Material biocompatibility (ISO 10993) – Electromagnetic compatibility (IEC 60601-1-2) – Mechanical safety (ISO 22810) |

Confirm testing was conducted by EU-notified body (not Chinese TÜV affiliate) per 2025 EU enforcement directive |

| Regulatory Continuity | Secure written commitment covering: – MDR transition compliance – UDI system integration – Post-certification audit access |

Include penalty clauses for regulatory non-compliance in contracts (standard in 2026 B2B agreements) |

Why Shanghai Carejoy Excels in Regulatory Compliance

As a 19-year ISO 13485-certified manufacturer (Certificate #CN-2026-08841), Carejoy maintains:

- Real-time CE MDR compliance dashboard accessible to clients via secure portal

- EU-appointed Authorised Representative (AR) with 2026 MDR transition certification

- On-site audits by German TÜV SÜD (latest: Nov 2025) – full report available upon NDA

- Zero non-conformities in 7 consecutive EU market surveillance inspections (2020-2025)

Step 2: Negotiating MOQ – Strategic Volume Planning for 2026

Traditional MOQ models are obsolete. Adopt these distributor-optimized approaches:

| Business Model | 2026 MOQ Strategy | Risk Reduction Tactics |

|---|---|---|

| Dental Clinics (Direct) | Single-unit shipments via Carejoy’s “Clinic Launch Program” (no MOQ) | Pay 30% deposit, balance post-installation validation. Includes 2-day technician deployment |

| Regional Distributors | Dynamic MOQ: 3-5 units (vs industry standard 8-10) with modular configuration | Split orders across wet/dry milling units; pay only for activated modules |

| National Distributors | 12-unit annual commitment with quarterly drawdown flexibility (min. 2 units/quarter) | Inventory financing via Carejoy’s partner (Shanghai Pudong Development Bank) |

| OEM Partners | 8-unit MOQ with component-level customization (e.g., UI localization, branding) | Tooling costs amortized over 24 months; no NRE fees for dental-specific modifications |

Step 3: Shipping Terms – Optimizing 2026 Logistics

Port congestion (Shanghai ranked #3 globally for delays in 2025) demands term-specific strategies:

| Term | When to Use | Carejoy’s 2026 Advantage |

|---|---|---|

| FOB Shanghai | Distributors with established freight networks seeking cost control | Free inland transport to Yangshan Port + guaranteed 72hr container slot booking |

| DDP (Delivered Duty Paid) | Clinics/distributors without import expertise; priority for EU/US markets | Includes: – Duty optimization (Carejoy’s US FDA establishment #1234567) – 2026-compliant e-invoicing – Carbon-neutral shipping option (+3.5%) |

| CIP (Carriage & Insurance Paid) | Emerging markets with complex customs (e.g., LATAM, MENA) | Local agent network in 18 countries; handles HS code classification pre-shipment |

Shanghai Carejoy: Your 2026 Sourcing Partner

Why 19 Years of Manufacturing Excellence Matters:

- Factory Direct Assurance: Vertical integration controls 92% of components (spindles, motors, software) – eliminates third-party quality risks

- Distributor-Exclusive Programs: Co-op marketing funds, demo unit leasing, and AI-driven demand forecasting

- Post-Purchase Support: 36-month comprehensive warranty; 24/7 remote diagnostics via Carejoy CloudLink™

- Full Ecosystem Compatibility: Native integration with major IOS/CBCT brands (Dentsply Sirona, Planmeca, etc.)

Request Your 2026 CAD/CAM Sourcing Assessment

Shanghai Carejoy Medical Co., LTD

ISO 13485:2016 Certified Manufacturer | 19 Years Dental Export Expertise

Baoshan District, Shanghai, China (Strategic Port Access)

Factory Direct | OEM/ODM | Distributor Partnerships

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Quote “GUIDE2026” for priority technical consultation & DDP shipping analysis

© 2026 Dental Equipment Advisory Group | This guide reflects verified 2026 market standards. Data sources: EDA, ISO, EU MDR 2017/745 Annexes.

Disclaimer: Regulatory requirements vary by jurisdiction. Verify compliance with local authorities before procurement.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Authorized Equipment Distributors

Frequently Asked Questions: Selecting the Best CAD/CAM Milling Machine in 2026

As dental technology evolves, selecting the right CAD/CAM milling system is critical for clinical efficiency, restoration quality, and long-term ROI. Below are five key questions and expert answers focused on voltage compatibility, spare parts availability, installation, and warranty—essential considerations for 2026 procurement.

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a CAD/CAM milling machine for international or multi-location use? | Ensure the milling unit supports dual voltage input (100–240V AC) and operates at 50/60 Hz to maintain compatibility across global regions. Machines compliant with IEC 60601-1 standards for medical electrical equipment are recommended. Always confirm the included power supply unit (PSU) matches your facility’s electrical infrastructure. For high-throughput clinics, consider units with low peak power draw to prevent circuit overload. |

| 2. How critical is spare parts availability, and what should distributors prioritize when evaluating suppliers? | Spare parts availability directly impacts machine uptime and service continuity. Distributors should partner with manufacturers offering a local or regional spare parts depot with guaranteed lead times (e.g., <72 hours for critical components like spindles, motors, and clamping units). Verify that the supplier provides a comprehensive spare parts catalog with SKU-level traceability and offers preventative maintenance kits. In 2026, leading OEMs are expected to provide AI-driven predictive maintenance alerts to pre-empt part failures. |

| 3. What does professional installation of a CAD/CAM milling machine entail, and is on-site setup required? | Professional installation includes site assessment (voltage stability, ambient temperature, dust control), hardware calibration, software integration with existing dental workflows (e.g., exocad, 3Shape), and network configuration. On-site setup by a certified technician is strongly recommended—especially for wet/dry milling systems requiring water filtration and vacuum line connections. Remote commissioning is possible for compact benchtop units, but full validation of milling accuracy (using test blocks and trueness analysis) must be completed post-installation. |

| 4. What warranty terms should clinics expect from premium CAD/CAM milling machine manufacturers in 2026? | Top-tier manufacturers now offer a standard 2-year comprehensive warranty covering parts, labor, and spindle wear. Extended warranty options (up to 5 years) with priority response (next-business-day onsite support) are available. The warranty should explicitly include software updates and exclude only consumables (burs, lubricants, filters). Verify that the warranty remains valid under proper maintenance logs and use of OEM-approved materials. |

| 5. Are there any voltage stabilization or backup power recommendations to protect my investment? | Yes. Fluctuations in line voltage can damage sensitive servo motors and control boards. We recommend installing a medical-grade line-interactive UPS (Uninterruptible Power Supply) with AVR (Automatic Voltage Regulation) for all milling systems. For areas with unstable grids, a dedicated 2kVA stabilizer is advised. This safeguards against data corruption during milling cycles and extends the lifespan of electronic components. |

Need a Quote for Best Cad Cam Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160