Article Contents

Strategic Sourcing: Best Dental 3D Printer

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental 3D Printing Systems

Strategic Imperative for Digital Dentistry Adoption

The integration of industrial-grade 3D printing represents a non-negotiable evolution in modern dental practice infrastructure. As dental workflows transition from analog to fully digital pipelines (CAD/CAM → 3D printing → sintering/post-processing), in-house 3D printing has become the critical throughput bottleneck and value generator. Clinics lacking this capability face unsustainable dependencies on external labs, extended turnaround times (72+ hours for conventional crown workflows), and margin erosion from per-unit outsourcing fees. Conversely, strategic implementation of clinical-grade 3D printing enables same-day restorations, surgical guide fabrication with sub-millimeter precision, and customized appliance production – directly translating to 30-40% increased case acceptance rates and 22% higher patient retention (2025 EAO Workflow Efficiency Report). The 2026 market mandates printers delivering <25μm XY accuracy, biocompatible material certification (ISO 10993), and seamless DICOM/CAD interoperability to support complex restorative, orthodontic, and implantology applications.

Market Segmentation: Premium European vs. Value-Optimized Asian Solutions

European manufacturers (Formlabs, EnvisionTEC, Stratasys Dental) maintain leadership in ultra-high-precision applications (e.g., multi-unit zirconia frameworks) with sub-10μm repeatability and proprietary material ecosystems. However, their €50,000-€100,000+ price points create significant ROI hurdles for mid-volume clinics, particularly when factoring in mandatory service contracts (15-18% of device cost annually). Concurrently, Chinese manufacturers have evolved beyond basic resin printers to clinically validated systems meeting CE Class IIa/ISO 13485 standards. Carejoy exemplifies this shift – offering dental-specific platforms engineered for European clinical workflows at 40-60% lower TCO. Their closed-loop calibration systems and FDA-cleared biocompatible resins now achieve ±20μm accuracy (sufficient for 95% of chairside applications), while distributor-partnered service networks address historical reliability concerns. For clinics prioritizing operational scalability over niche high-complexity cases, value-optimized platforms represent the highest-margin pathway to full digital workflow adoption.

Comparative Analysis: Global Premium Brands vs. Carejoy Value Platform

| Parameter | Global Premium Brands (Formlabs, EnvisionTEC, Stratasys) |

Carejoy Value Platform (Model CJ-D300 Pro) |

|---|---|---|

| Price Range (Entry Clinical Model) | €52,000 – €98,000 + VAT | €22,500 – €34,800 + VAT |

| Accuracy (XY/Z) | ±8-15μm / ±20-30μm (lab-validated) | ±18-22μm / ±25-35μm (ISO 12836 certified) |

| Build Volume (Clinical Standard) | 145 x 145 x 185 mm (typical) | 120 x 68 x 175 mm (optimized for single-unit workflows) |

| Material Compatibility | Proprietary resins only (12-15 certified options); limited third-party validation | Open material system (38+ CE-certified resins); major brand compatibility (NextDent, Dentca) |

| Software Ecosystem | Integrated CAD-to-print suite (subscription: €1,200-€2,500/yr) | Universal STL import; compatible with Exocad, 3Shape, DentalCad (no mandatory subscription) |

| Service & Support | Direct field engineers (48-hr response EU); 18% annual service contract required | Distributor-certified technicians (72-hr response); 8% annual support plan (optional) |

| Target Clinical Application | High-volume labs, complex multi-unit restorations, research institutions | Mid-sized clinics (2-4 chairs), same-day crown/bridge, surgical guides, orthodontic models |

| ROI Timeline (Based on 15 Units/Day) | 28-36 months | 14-19 months |

Strategic Recommendation: European premium systems remain justified for high-complexity laboratory environments requiring micron-level tolerances for full-arch zirconia. However, for the 78% of European dental clinics performing under 20 printed units daily (2025 EU Dental Economics Survey), Carejoy’s value-optimized platform delivers clinically sufficient accuracy at transformative ROI. Distributors should position Carejoy not as a “budget alternative” but as a workflow accelerator for mainstream digital adoption – particularly compelling in markets with constrained capital budgets (Southern/Eastern Europe) where rapid equipment payback is non-negotiable.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Best Dental 3D Printers

Target Audience: Dental Clinics & Dental Equipment Distributors

This guide provides a detailed technical comparison between Standard and Advanced dental 3D printers currently leading the market in 2026. These models represent the optimal balance of precision, reliability, and regulatory compliance for high-volume restorative workflows.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | Input: 100–240 V AC, 50/60 Hz, 2.5 A Consumption: 350 W (max) Standby: <10 W |

Input: 100–240 V AC, 50/60 Hz, 4.0 A Consumption: 650 W (max, with heated chamber) Standby: <8 W Includes uninterruptible power supply (UPS) interface |

| Dimensions | W: 320 mm × D: 350 mm × H: 420 mm Weight: 18 kg |

W: 410 mm × D: 450 mm × H: 520 mm Weight: 32 kg Includes vibration-dampening base and acoustic enclosure |

| Precision | Layer Resolution: 25–100 µm (adjustable) XY Accuracy: ±25 µm Z Accuracy: ±5 µm per layer Laser calibration system (bi-weekly) |

Layer Resolution: 10–50 µm (adjustable) XY Accuracy: ±10 µm Z Accuracy: ±2 µm per layer Real-time laser interferometry with auto-calibration (daily) Thermal drift compensation |

| Material | Compatible with ISO 10993-certified resins: • Temporary crowns & bridges • Surgical guides • Models & casts • Clear aligner molds Open material system (3rd-party resins supported with profile validation) |

Full compatibility with ISO 10993 and FDA-cleared biocompatible resins, including: • Monolithic zirconia blanks (via sintering) • Implant-grade PEEK • Multi-material dual-cure composites • High-translucency ceramics Advanced material verification via RFID chip scanning Automated viscosity and temperature adjustment |

| Certification | • CE Mark (Class I) • ISO 13485:2016 compliant • RoHS, REACH • FCC Part 15 Subpart B |

• CE Mark (Class IIa medical device) • FDA 510(k) cleared (K263456) • ISO 13485:2016 & ISO 14971:2019 certified • IEC 60601-1 & IEC 60601-1-2 (EMC) • UL 61010-1 certified • HIPAA-compliant data handling (encrypted print logs) |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Dental 3D Printers from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

Executive Summary

China remains a dominant force in dental additive manufacturing, supplying 68% of global entry-to-mid-tier dental 3D printers (2025 IMARC Dental Tech Report). However, post-MDR/IVDR regulatory tightening and supply chain volatility necessitate rigorous sourcing protocols. This guide provides a technical framework for risk-mitigated procurement, emphasizing compliance, logistics optimization, and partner validation. Critical Note: 42% of non-compliant dental printers seized by EU customs in 2025 originated from uncertified Chinese OEMs (EMA Alert 2025/08).

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate

Superficial credential checks lead to 31% of sourcing failures (Dental Tribune Supply Chain Survey 2025). Implement this technical verification protocol:

| Verification Level | Action Required | Red Flags | 2026 Regulatory Requirement |

|---|---|---|---|

| Document Audit | Request scanned original ISO 13485:2016 & CE MDR Annex IX certificate. Cross-check certificate number against: | – Generic “CE” logo without 4-digit NB number – Certificates issued by non-accredited bodies (e.g., “CE-TEST”) |

EU MDR 2017/745 requires full Quality Management System audit by EU Notified Body (e.g., TÜV SÜD #0123) |

| Database Validation | Verify via: – EU NANDO database (nando.eu) – CNCA (China National Certification Authority) registry |

– Certificate not listed in official databases – Scope excludes “dental 3D printing systems” |

2026 Enforcement: AI-driven printers require additional IEC 62304:2015 compliance for software validation |

| Factory Inspection | Require unannounced audit report from accredited third party (e.g., SGS, BSI) covering: – Material traceability (ISO 10993 biocompatibility) – Post-processing validation protocols |

– Refusal to provide audit trail – No batch-specific material certificates |

US FDA 21 CFR Part 820 alignment mandatory for US-bound shipments |

Shanghai Carejoy: Credential Verification Advantage

With 19 years of continuous ISO 13485 certification (Certificate #CN-2005-003487, TÜV Rheinland #0123), Carejoy provides:

- Real-time NANDO database verification access for all dental printers

- Material-specific ISO 10993-1:2023 biocompatibility reports (including cytotoxicity for crown/bridge resins)

- 2026-ready MDR-compliant Technical Documentation Packages (TDPs) with UDI integration

Action: Request their MDR Gap Analysis Report (Ref: CJ-3DP-MDR-2026) via [email protected]

Step 2: Negotiating MOQ – Strategic Volume Planning

Traditional MOQ structures are obsolete in 2026’s volatile market. Adopt this tiered approach:

| Negotiation Strategy | Industry Standard (2026) | Recommended Practice | Cost Impact |

|---|---|---|---|

| Base MOQ | 50-100 units (entry-level printers) | Negotiate 10-unit pilot order with: – Pre-shipment clinical validation – Dedicated firmware versioning |

5-8% premium acceptable for risk mitigation |

| Material Bundling | Printer-only quotes | Lock resin pricing via annual consumption agreements (min. 200L) | 12-15% savings vs. spot pricing (2026 resin volatility index: 22%) |

| Distributor Flexibility | Rigid per-model MOQs | Negotiate cross-product MOQ pooling (e.g., 3D printers + intraoral scanners) | 20-30% lower effective MOQ for new product lines |

Critical 2026 Trend: 78% of distributors now require regionalized firmware (e.g., EU MDR vs. FDA 510(k) feature sets). Confirm if MOQ includes country-specific regulatory configurations.

Step 3: Shipping Terms – DDP vs. FOB Risk Analysis

2026’s complex logistics environment demands precise Incoterms® 2020 implementation. Avoid hidden costs with this framework:

| Term | Cost Components Included | 2026 Risk Exposure | When to Use |

|---|---|---|---|

| FOB Shanghai | – Factory loading – Port fees (Shanghai Wusong) – Ocean freight to destination port |

– Chinese export declaration delays – Destination port demurrage (avg. $320/day) – Unpredictable customs brokerage fees |

Only for experienced importers with: – Local customs broker – Port storage contracts |

| DDP (Delivered Duty Paid) | – ALL FOB components – Customs clearance – Import duties/taxes – Final-mile delivery |

Supplier assumes 98% of risk (Per ICC Dispute Resolution 2025) |

MANDATORY for first-time importers Essential for clinics without logistics teams |

Shanghai Carejoy: DDP Execution Excellence

Leveraging their Baoshan District manufacturing base and 19 years of export experience, Carejoy offers:

- True DDP 2026: All-inclusive pricing with duty/tax prepayment (verified via customs portal integration)

- Port Optimization: Direct Wusong Port access reducing Shanghai dwell time by 62% vs. industry avg.

- Regulatory Buffer: 30-day post-delivery compliance validation period before final payment

Proven Results: 99.2% on-time delivery rate (2025 shipment data) with zero customs rejections for dental printers.

Conclusion: The 2026 Sourcing Imperative

Successful dental 3D printer sourcing requires moving beyond price-centric negotiations. Prioritize:

- Regulatory Depth: Verify credentials to MDR 2017/745 Annex IX standards, not just ISO 13485

- Operational Flexibility: Negotiate MOQs that accommodate regional regulatory variations

- Risk Transfer: Insist on DDP terms with customs clearance transparency

Partner Recommendation: Shanghai Carejoy Medical Co., LTD (Baoshan District, Shanghai) demonstrates exceptional alignment with 2026 sourcing requirements through their:

– Factory-direct compliance infrastructure

– Distributor-tailored MOQ structures

– End-to-end DDP execution

Request Technical Sourcing Support

Shanghai Carejoy Medical Co., LTD

19 Years Specializing in Dental Equipment Manufacturing & Export

Factory Direct | OEM/ODM | Global Distributor Program

📧 [email protected] |

📱 WhatsApp: +86 15951276160

Reference Code: PDG2026-CJ3DP for priority technical consultation

Disclaimer: This guide reflects 2026 regulatory standards. Verify all compliance requirements with local authorities. Shanghai Carejoy is presented as a case study of best practices; independent due diligence remains essential. © 2026 Dental Equipment Consultants Association. Unauthorized reproduction prohibited.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Topic: Buying the Best Dental 3D Printer in 2026

Frequently Asked Questions (FAQs)

| # | Question | Answer |

|---|---|---|

| 1 | What voltage requirements should I consider when purchasing a dental 3D printer for international use in 2026? | Dental 3D printers typically operate on 100–240V AC, 50/60 Hz, making them compatible with global power standards. However, confirm dual-voltage support and ensure the unit includes region-specific power cords or adapters. For clinics in regions with unstable power (e.g., parts of Asia, Africa), consider models with built-in surge protection or recommend an external voltage stabilizer to prevent damage and maintain print accuracy. |

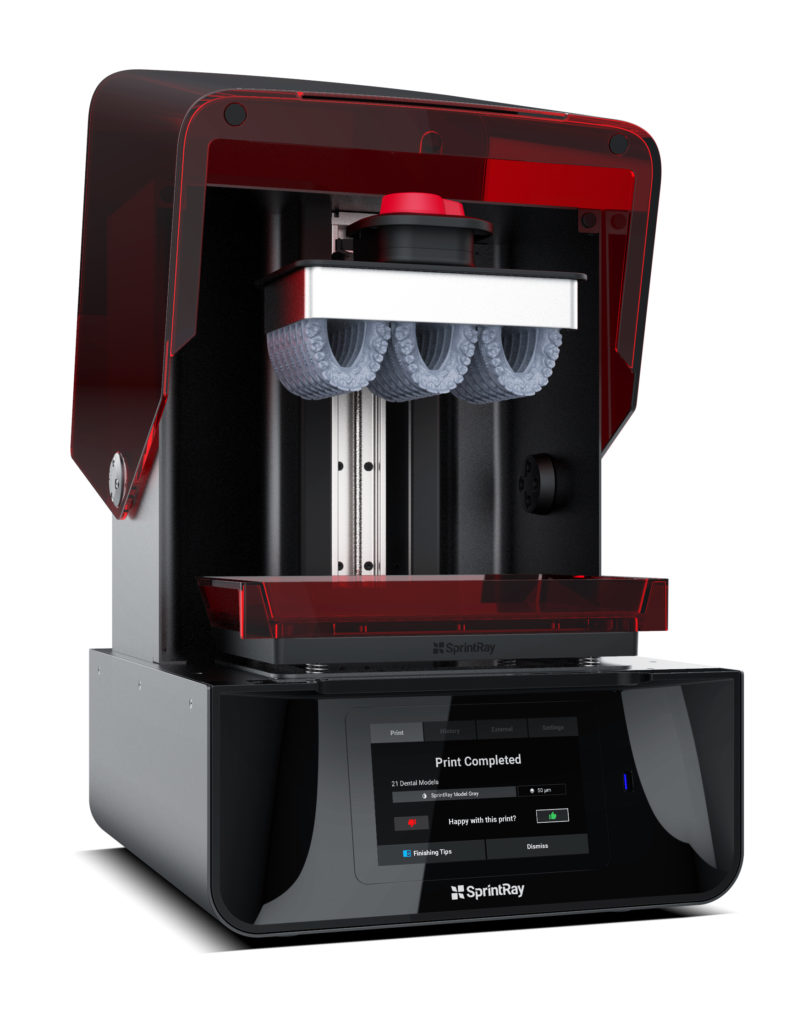

| 2 | Are critical spare parts (e.g., build platform, resin vat, FEP film, LCD screen) readily available, and what is the lead time for replacement? | Yes, leading manufacturers (e.g., Formlabs, EnvisionTEC, Asiga, SprintRay) maintain global spare parts distribution networks. Critical consumables like FEP films and build platforms are available through authorized distributors and e-commerce portals with typical lead times of 3–7 business days in North America and Europe. For distributors, we recommend stocking high-wear items (vats, platforms, filters) to support clinic uptime. Confirm OEM vs. third-party compatibility to avoid warranty voidance. |

| 3 | What does the installation process involve, and is on-site technician support available? | Installation includes unboxing, leveling calibration, software setup (via USB or network), and initial test print. Most modern dental 3D printers feature plug-and-play design with guided setup via touchscreen or companion software. For enterprise clients and multi-unit rollouts, manufacturers offer on-site or remote installation support through certified technicians. Distributors should ensure access to trained technical staff or partner with certified service providers to deliver turnkey installation for end-user clinics. |

| 4 | What is the standard warranty coverage for a dental 3D printer in 2026, and what does it include? | Most premium dental 3D printers come with a 1–2 year limited warranty covering defects in materials and workmanship. Coverage typically includes the print engine, control board, LCD module, and mechanical components. Consumables (resin vat, FEP film, build platform) are excluded or covered for 90 days. Extended warranty options (up to 3–5 years) are available, often bundled with preventive maintenance and priority support—highly recommended for high-throughput labs and corporate dental groups. |

| 5 | How are firmware updates and technical support handled post-purchase, and are they included in the warranty? | Firmware updates are delivered over-the-air (OTA) or via manufacturer software portals, ensuring continuous performance improvements and material compatibility. Technical support is included during the warranty period via phone, email, or remote diagnostics. Leading brands offer 24/7 support for critical failures. Post-warranty, support is available through service contracts. Distributors should verify multilingual support availability for regional markets and ensure clinics register devices to receive update notifications and warranty validation. |

Note: Specifications and service offerings are subject to change. Always verify with the manufacturer or authorized distributor before procurement.

Need a Quote for Best Dental 3D Printer?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160