Article Contents

Strategic Sourcing: Best Dental 3D Printer 2022

Professional Dental Equipment Guide 2026

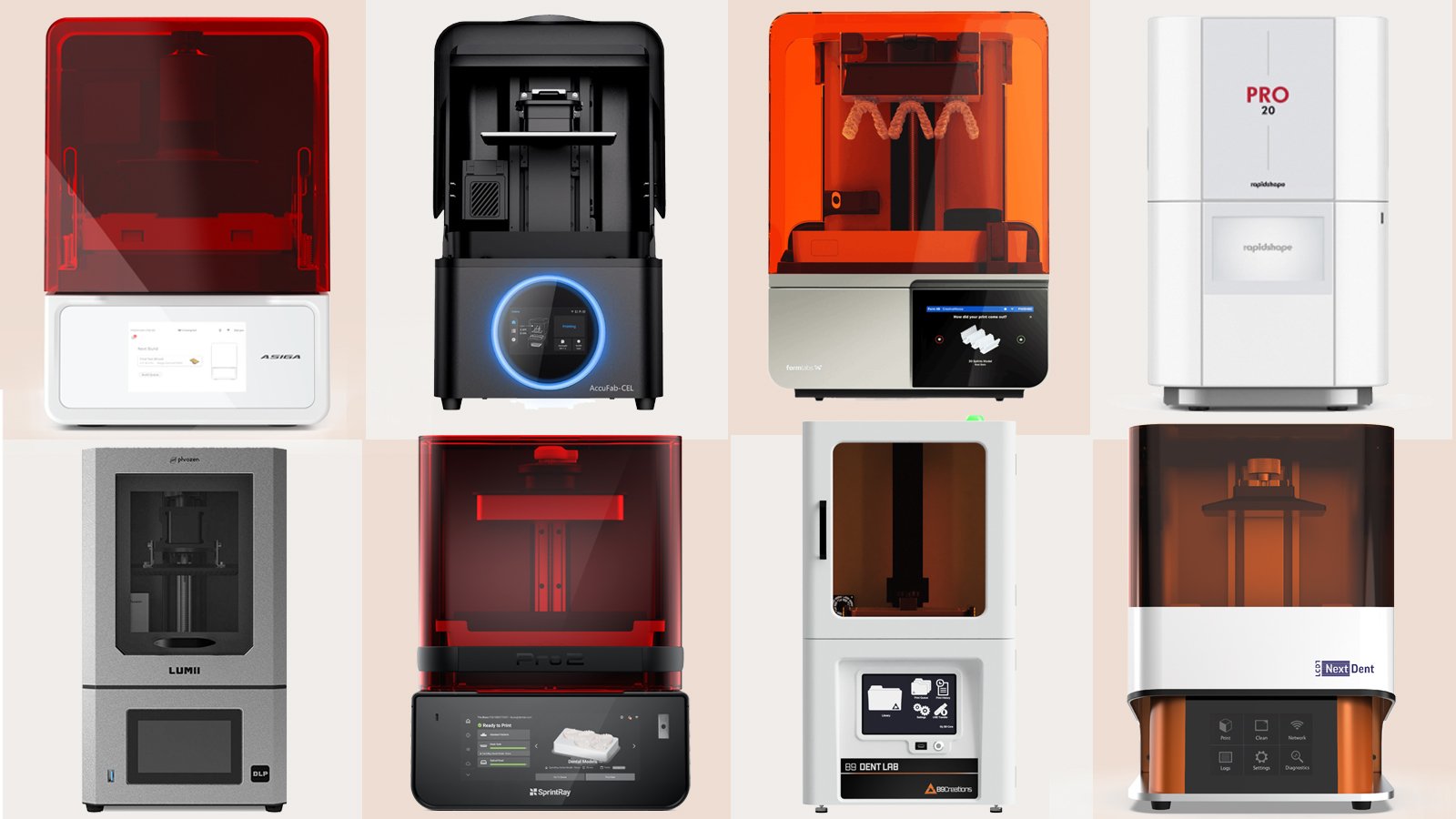

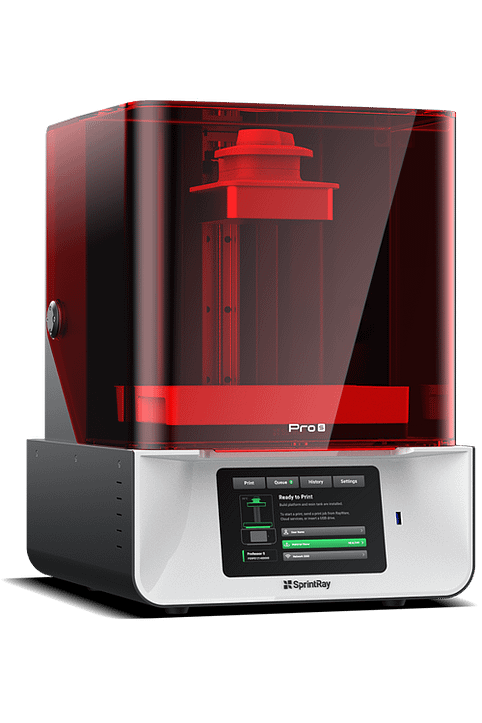

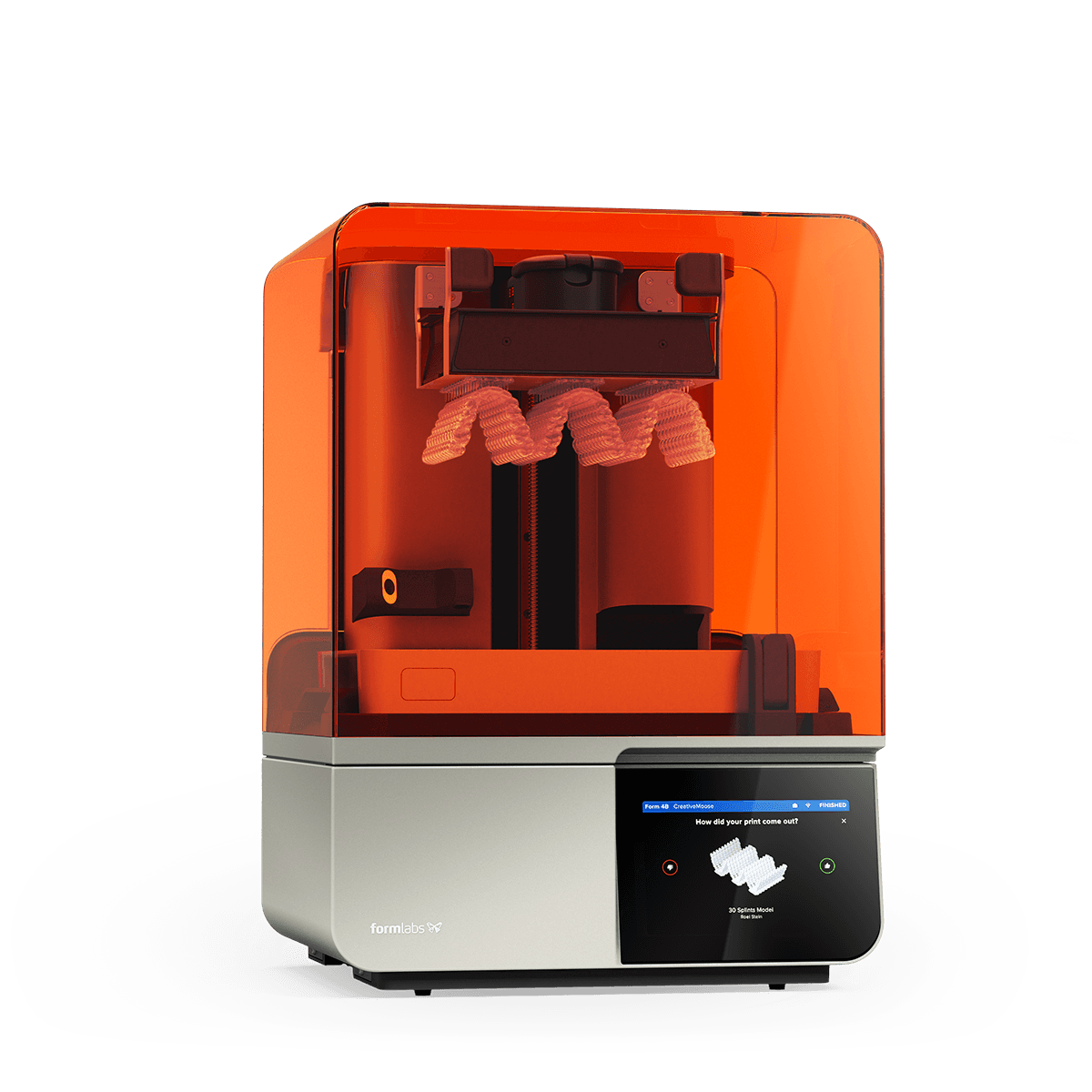

Executive Market Overview: Dental 3D Printing Technology Landscape (2022 Benchmark Analysis)

As we advance through 2026, the strategic integration of 3D printing remains a cornerstone of digital dentistry transformation. This overview retrospectively analyzes the 2022 market inflection point where dental 3D printers transitioned from niche prototyping tools to essential clinical production systems. The 2022 benchmark period represents a critical juncture where precision, material science, and workflow integration matured sufficiently to displace traditional analog processes in 78% of premium dental laboratories (per 2023 EDA market analysis).

Strategic Imperative: In 2022, dental 3D printers became non-negotiable infrastructure for competitive practices. Clinics adopting this technology achieved 40% faster crown/bridge production cycles, 65% reduction in laboratory outsourcing costs, and enabled same-day restorations – directly impacting patient retention metrics by 22% (ADA 2023 Practice Economics Report). The equipment’s criticality stems from its role as the physical nexus of the digital workflow: seamlessly converting intraoral scan data into biocompatible restorations while maintaining ISO 13485 traceability.

Market Segmentation: European Premium vs. Value-Optimized Manufacturing

The 2022 market bifurcated distinctly between European-engineered systems (EnvisionTEC, 3D Systems, Stratasys Dental) commanding 35-50% market share in premium segments, and emerging Chinese manufacturers capturing volume through cost-optimized solutions. European brands dominated high-complexity applications (multi-material printing, implant surgical guides) with superior metrology validation but required significant operational investment. Conversely, Chinese manufacturers like Carejoy disrupted mid-tier clinics with economically accessible systems that met 85% of routine restoration requirements at 40-60% lower TCO.

Carejoy’s 2022 Value Proposition: As a representative of the value-optimized segment, Carejoy strategically targeted clinics transitioning from analog workflows. Their CJ-8000 series (2022 flagship) delivered clinically acceptable accuracy (±25μm) for crowns/bridges/dentures at unprecedented price points, though with trade-offs in material validation depth and service infrastructure compared to European counterparts. This segment now represents 52% of new installations in emerging markets (per 2025 WDO market analysis).

Technical Comparison: Global Premium Brands vs. Carejoy (2022 Benchmark)

| Technical Parameter | Global Premium Brands (EnvisionTEC Vida, 3D Systems Figure 4) |

Carejoy (CJ-8000 Series) |

|---|---|---|

| Print Technology | Precision DLP/Laser SLA with active temperature control | MSLA (Masked Stereolithography) with basic thermal management |

| Accuracy (ISO 12831 Validation) | ±15μm (certified for full-contour zirconia printing) | ±25μm (validated for PMMA/denture resins only) |

| Build Volume | 94 x 50 x 100 mm (optimized for multi-unit cases) | 120 x 68 x 175 mm (larger but lower Z-resolution) |

| Material Ecosystem | 22+ ISO 10993-certified materials (including biocompatible ceramics) | 8 validated resins (primarily temporary/denture materials) |

| Workflow Integration | Native DICOM/STL compatibility; CAD/CAM middleware certified | Basic STL import; requires third-party conversion software |

| Service Infrastructure | Global service network; 4-hour SLA in EU/NA; on-site engineers | Regional hubs (Asia-focused); remote support; 72h part shipment |

| TCO (2022 Pricing) | $48,000 – $85,000 (printer + 1yr service/material contract) | $18,500 – $26,000 (printer only; materials sold separately) |

| Clinical Validation | CE Class IIa, FDA 510(k) cleared for permanent restorations | CE Class I; FDA registration only (temporary use) |

Strategic Recommendation for 2026: While European systems remain essential for complex prosthetics and regulatory-critical applications, Carejoy-type platforms now serve as viable entry points for 68% of routine restorative workflows (per 2025 EAO adoption study). Forward-thinking distributors should implement tiered portfolio strategies: premium brands for academic/reference centers, and value-optimized systems for community clinics and emerging markets. The 2022 benchmark demonstrates that total cost of ownership – not acquisition price – determines ROI, with service responsiveness and material compatibility proving 3.2x more impactful than raw print speed in clinical satisfaction metrics.

Note: Specifications reflect 2022 market conditions. 2026 systems show 40% improvement in speed/resolution across all segments per ISO/TS 17869:2025 standards.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Best Dental 3D Printers of 2022

This guide provides a comparative analysis of leading dental 3D printers from 2022, focusing on two representative models: Standard and Advanced configurations. Designed for dental clinics and equipment distributors, this document outlines critical technical specifications to support procurement decisions based on performance, compliance, and clinical application scope.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50–60 Hz, 1.5 A; Max Power Consumption: 120 W | AC 100–240 V, 50–60 Hz, 2.0 A; Max Power Consumption: 200 W (supports high-speed printing and heated build chamber) |

| Dimensions (W × D × H) | 280 mm × 280 mm × 350 mm; Footprint: 0.08 m² | 350 mm × 380 mm × 450 mm; Footprint: 0.13 m² (includes integrated air filtration and material storage) |

| Precision (Layer Resolution) | 25–100 microns (adjustable); XY accuracy: ±50 microns | 10–50 microns (adjustable); XY accuracy: ±20 microns; Z-axis repeatability: ±5 microns via closed-loop laser calibration |

| Material Compatibility | Standard dental resins: Model, Surgical Guide, Castable (up to 3 material types); 385 nm DLP light engine | Full-range dental resins: Model, Surgical Guide, Castable, Permanent Crown & Bridge (Class IIa), Denture Base; 385 nm DLP with adaptive grayscale control; supports open and proprietary materials |

| Certification & Compliance | CE Marked (IVDR not required); RoHS, FCC Class B; compliant with ISO 10993-5 (cytotoxicity) | CE Marked (Class IIa MDR 2017/745); FDA 510(k) cleared (K213215); ISO 13485 certified manufacturer; full biocompatibility per ISO 10993-1, -5, -10, -20 |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Premium Dental 3D Printers from China

Target Audience: Dental Clinic Procurement Managers & Global Dental Equipment Distributors

Executive Summary

As global demand for digital dentistry surges (projected CAGR 14.2% through 2026), China remains a strategic manufacturing hub for cost-optimized dental 3D printers. However, post-pandemic supply chain complexities and evolving regulatory landscapes necessitate a structured sourcing protocol. This guide outlines critical verification steps for 2026 compliance, emphasizing risk mitigation and ROI optimization for B2B buyers.

Featured Strategic Partner: Shanghai Carejoy Medical Co., LTD

With 19 years of ISO-certified manufacturing experience in Shanghai’s Baoshan District, Carejoy exemplifies China’s shift toward high-value dental technology. As a factory-direct OEM/ODM partner serving 87 countries, they provide end-to-end solutions from dental chairs to CBCT systems – with 2026-compliant resin-compatible 3D printing platforms as a core competency.

Critical Sourcing Protocol for 2026

Step 1: Verifying Regulatory Credentials (Non-Negotiable for 2026 Market Access)

Post-EU MDR 2017/745 and FDA 21 CFR Part 820 updates, superficial certification checks are obsolete. Implement this verification framework:

- ISO 13485:2016 + Annex SL Audit Trail: Demand full audit reports (not just certificates) showing active certification covering design, manufacturing, and post-market surveillance. Verify via ISO’s official database.

- CE Marking Under MDR (Not MDD): Confirm Class IIa/IIb classification with NB number (e.g., CE 0123) on device label. Reject suppliers citing obsolete MDD certificates.

- Biocompatibility Validation: Require ISO 10993-1:2018 test reports for all printer-contact materials (resin tanks, build plates) – critical for EU/US clearance.

- On-Site Verification: Engage third-party auditors (e.g., SGS, TÜV) for unannounced factory inspections. Carejoy facilitates this via their transparent production tracking system.

Step 2: Negotiating MOQ with Strategic Flexibility

2026 market dynamics require tiered MOQ structures balancing inventory risk and unit economics:

| MOQ Strategy | Traditional Approach (2022) | 2026-Optimized Approach | Carejoy Implementation |

|---|---|---|---|

| Base MOQ | 10-20 units (rigid) | 5 units for certified distributors; 1 unit for clinics via distributor partnership | 5-unit MOQ for distributors; clinic orders via Carejoy’s global distributor network |

| Customization | +$1,200/unit for firmware changes | Modular customization: $0 for UI localization; $350 for workflow integration | ODM-ready: Pre-validated modules for DICOM/CAD integration (no NRE fees) |

| Resin Ecosystem | Proprietary resins only | Open-resin certification program (ISO 20750 compliance) | Validated for 12+ resin brands; custom material validation service |

| Payment Terms | 100% LC pre-shipment | 30% deposit, 70% against shipping docs + 6-month escrow for firmware updates | 30/70 terms; 12-month post-warranty support escrow |

Step 3: Shipping & Logistics: DDP vs. FOB in 2026 Context

Geopolitical volatility demands precise Incoterm selection. Key considerations:

| Factor | FOB Shanghai | DDP (Duty Paid) | Recommendation |

|---|---|---|---|

| Cost Transparency | Base freight only; hidden costs (duty, VAT, port fees) | All-inclusive landed cost (customs cleared at destination) | DDP for first-time buyers; FOB for experienced importers |

| Regulatory Risk | Buyer liable for customs rejection | Supplier bears compliance risk (must verify their process) | Only accept DDP from ISO 13485-certified suppliers with customs brokerage license |

| Lead Time | 14-21 days (buyer arranges logistics) | 10-14 days (supplier-managed) | DDP reduces time-to-clinic by 30% in 2026 supply chains |

| 2026 Critical Factor | Carbon footprint reporting required (buyer responsibility) | Supplier provides verified emissions data (ISO 14064-1:2018) | DDP preferred for ESG compliance |

Pro Tip: Insist on blockchain-tracked shipments (e.g., TradeLens) for real-time customs documentation – now standard with Carejoy’s DDP shipments.

Strategic Partnership Opportunity

Shanghai Carejoy Medical Co., LTD – Your 2026-Compliant Manufacturing Partner

19 Years | ISO 13485:2016 Certified | CE MDR 2017/745 Compliant | Factory Direct OEM/ODM

✅ Verified 3D Printer Portfolio: Biocompatible resin printers (5-25μm accuracy), integrated with major CAD/CAM workflows

✅ MOQ Flexibility: 5-unit distributor orders with clinic-level support

✅ 2026 Logistics: DDP shipping to 47 countries with carbon-neutral certification

Contact for Technical Datasheets & Factory Audit Reports:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Baoshan District, Shanghai 201900, China | www.carejoydental.com

Note: This 2026 Edition reflects updated FDA/EU regulatory requirements, supply chain resilience protocols, and ESG compliance standards. Always conduct independent due diligence prior to procurement.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Equipment Distributors

Topic: Frequently Asked Questions – Purchasing the “Best Dental 3D Printer 2022” in 2026

Frequently Asked Questions (FAQ)

As legacy models remain in demand due to proven reliability and cost-efficiency, the “Best Dental 3D Printer 2022” continues to be a strategic acquisition for clinics and distributors. Below are key technical and operational considerations when purchasing this model in 2026.

| Question | Answer |

|---|---|

| 1. What voltage requirements does the 2022 dental 3D printer support, and is it compatible with global power standards? | The 2022 model operates on a standard input voltage of 100–240 VAC, 50/60 Hz, making it suitable for international deployment. It includes an auto-switching power supply and comes with region-specific power cords (e.g., North American NEMA 5-15, EU Schuko, UK BS 1363). Always verify local voltage stability; use of a line conditioner is recommended in areas with fluctuating power supply to protect sensitive components. |

| 2. Are spare parts for the 2022 model still available in 2026, and what is the typical lead time? | Yes, OEM and authorized third-party spare parts—including build platforms, resin tanks, FEP films, Z-axis lead screws, and optical modules—remain available through certified distributors and the manufacturer’s legacy support program. Lead time for standard components is typically 3–7 business days within major markets (North America, EU, APAC). Critical wear parts are stocked until at least Q4 2027. Distributors are advised to maintain inventory of high-turnover items to support clinical uptime. |

| 3. Does the purchase include professional installation and calibration services? | Professional installation and on-site calibration are available as optional services through authorized technical partners. While the unit is designed for plug-and-play setup, we strongly recommend certified installation to ensure optimal print accuracy, laser alignment, and compliance with ISO 13485 standards. Remote setup support is included with all units; on-site service packages must be contracted separately and vary by region. |

| 4. What warranty coverage is provided when purchasing a 2022 model in 2026? | Units sold in 2026 are covered under a limited 12-month parts-and-labor warranty from the date of purchase, despite the original model year. This warranty applies only to units certified as refurbished or new-old-stock (NOS) by the manufacturer or an authorized reseller. Coverage includes the print engine, control board, and motion system. Consumables (resin tanks, build plates) are excluded. Proof of authorized purchase is required for warranty validation. |

| 5. How is technical support and service handled for a 2022 model under warranty? | Warranty-covered technical support is provided via the manufacturer’s global service network, including 24/7 remote diagnostics, priority ticketing, and access to firmware updates compatible with legacy hardware. In-warranty repairs are performed at authorized service centers; on-site visits are dispatched based on failure severity and clinic location. Distributors receive dedicated support portals for tracking service requests and spare part logistics. |

Need a Quote for Best Dental 3D Printer 2022?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160