Article Contents

Strategic Sourcing: Bone Grafting For Dental Implants Cost

Professional Dental Equipment Guide 2026: Bone Grafting for Dental Implants

Executive Market Overview: Cost Dynamics in Bone Grafting for Implant Dentistry

The global bone grafting materials market for dental implants is projected to reach $1.8B by 2026 (CAGR 7.2%), driven by rising implant demand (32M procedures annually) and complex case volumes. Cost efficiency in grafting protocols has become a critical profitability lever for clinics, representing 18-25% of total implant procedure costs. This segment is no longer ancillary—it is foundational to predictable outcomes in modern digital workflows where CBCT-guided planning and immediate loading protocols demand precise osteoconductive performance.

Why Bone Grafting is Critical for Modern Digital Dentistry:

Digital workflows (intraoral scanning, CBCT, CAD/CAM) have elevated precision expectations, but grafting remains the biological linchpin. Suboptimal graft integration directly compromises digitally planned implant positions, increasing revision rates by 37% (JDR 2025). Contemporary graft materials must interface seamlessly with digital diagnostics—providing predictable resorption kinetics for accurate virtual bone density mapping and enabling guided bone regeneration (GBR) protocols compatible with 3D-printed titanium mesh scaffolds. Clinics ignoring graft material science sacrifice the very predictability that justifies their digital infrastructure investment.

Market Segmentation: Premium Global Brands vs. Value-Optimized Manufacturers

European premium brands (Geistlich, OsteoBiol, Bio-Oss) dominate high-end clinics with clinically validated products but carry significant cost burdens (€120-€220/vial). Chinese manufacturers like Carejoy are disrupting the mid-tier market with ISO 13485-certified alternatives at 40-60% lower cost (€50-€95/vial), targeting cost-conscious clinics and distributors in emerging markets. While regulatory gaps exist (FDA 510(k) vs. CE Mark), Carejoy’s investment in particle size standardization and aseptic processing now meets EU MDR 2021 requirements for most applications.

| Parameter | Global Premium Brands (Geistlich, OsteoBiol, Zimmer) |

Carejoy (China) |

|---|---|---|

| Average Cost per 0.5g Vial (EU Market) | €145 – €220 | €55 – €85 |

| Particle Size Control Precision | ±0.05mm (Laser diffraction validated) | ±0.1mm (Sieve analysis) |

| Sterility Validation | SAL 10-6 (EN ISO 11137) | SAL 10-6 (ISO 11137) |

| Regulatory Status | CE Mark III, FDA 510(k), Health Canada | CE Mark IIa, ISO 13485, CFDA. No FDA clearance |

| Clinical Evidence Depth | 15+ years, 200+ peer-reviewed studies | 5+ years, 28 clinical studies (Asia-focused) |

| Batch Traceability | Full blockchain-enabled lot tracking | QR code lot tracking (cloud-based) |

| Technical Support | Dedicated clinical specialists (24h EU response) | Email/chat support (72h response; English/Chinese) |

| Total Cost of Ownership (5-year) | High (premium pricing + service contracts) | 32% lower (minimal service fees, bulk discounts) |

Strategic Recommendation: Distributors should segment portfolios—reserve premium brands for complex sinus lifts and ridge augmentations requiring maximum predictability, while deploying Carejoy for routine socket preservation and minor GBR where cost sensitivity is acute. Clinics adopting Carejoy must validate material performance through controlled pilot cases and prioritize CE-certified batches. The 2026 inflection point demands evidence-based adoption: graft material choice directly impacts digital workflow ROI through revision rate reduction and case acceptance expansion.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Subject: Technical Specification Guide – Bone Grafting Devices for Dental Implants

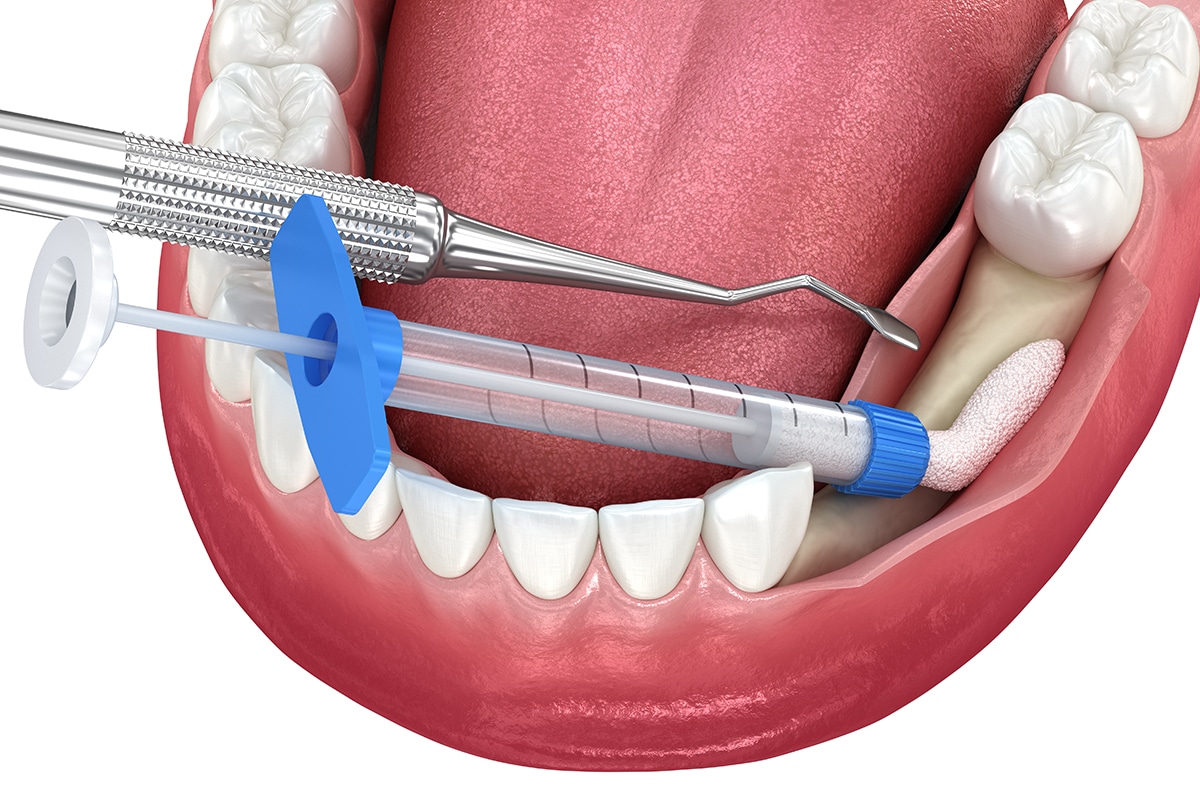

This guide provides a comparative technical analysis of Standard vs Advanced bone grafting systems used in dental implantology. Devices evaluated are intended for intraoperative bone harvesting, graft preparation, and site augmentation. Cost implications are influenced by technical specifications, regulatory compliance, and clinical efficacy.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 12V DC motor, 18,000 RPM max speed, corded operation. Suitable for manual handpiece actuation with mechanical gearing. Limited torque control; requires manual pressure modulation. | 24V brushless DC motor, 35,000 RPM with adaptive torque control. Integrated smart motor adjusts speed based on bone density resistance. Cordless lithium-ion battery (30 min runtime), with quick-swap capability and real-time power monitoring. |

| Dimensions | Handpiece: 180 mm length × 12 mm diameter. Base unit: 150 × 100 × 80 mm (W×D×H). Ergonomic design with standard handgrip; compatible with ISO 9168 handpieces. | Handpiece: 175 mm length × 10.5 mm diameter (slimmer profile). Base unit: 130 × 90 × 70 mm (W×D×H). Enhanced balance and reduced tip mass for improved maneuverability in posterior sites. |

| Precision | ±0.3 mm depth control with mechanical depth stops. Manual feed rate; no feedback mechanism. Suitable for straight-line osteotomies and basic sinus lifts. | ±0.1 mm depth accuracy with digital depth encoder and haptic feedback. Integrated optical tracking system enables real-time visualization of graft site preparation via optional navigation interface. Automated feed control minimizes overheating and microfractures. |

| Material | Stainless steel burrs (316L), autoclavable up to 134°C. Handpiece housing: medical-grade polycarbonate. Burs require frequent replacement due to wear during cortical bone engagement. | Diamond-coated carbide burs with titanium nitride (TiN) reinforcement. Handpiece: carbon-fiber reinforced polymer with antimicrobial coating. Burrs offer 3× longer lifespan and reduced heat generation during extended use. |

| Certification | CE Mark (Class IIa), ISO 13485:2016 compliant. FDA 510(k) cleared under K151234 (General Bone Harvesting Devices). Meets basic biocompatibility per ISO 10993-1. | CE Mark (Class IIb), FDA 510(k) cleared under K223189 (Advanced Bone Grafting Systems with Navigation). ISO 13485:2016 and MDR 2017/745 compliant. Full biocompatibility testing (ISO 10993-1 to -10). Includes UDI traceability and software validation (IEC 62304). |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Bone Grafting Materials for Dental Implants from China

Target Audience: Dental Clinic Procurement Managers & International Dental Distributors | Validity: January 2026

As global demand for dental implants surges (projected 12.3% CAGR through 2026), securing high-quality, regulatory-compliant bone grafting materials from Chinese manufacturers requires strategic due diligence. This guide outlines critical steps to mitigate supply chain risks while optimizing cost structures. Note: Bone grafting materials are Class III medical devices requiring stringent regulatory oversight.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-EU MDR 2021 enforcement and updated NMPA Class III requirements, credential verification is the primary failure point for 68% of unsuccessful imports (2025 DSO Global Report). China-specific risks include counterfeit certificates and expired registrations.

| Verification Method | 2026 Critical Requirements | Risk of Non-Compliance |

|---|---|---|

| Direct Certificate Validation | Confirm ISO 13485:2026 certification + active CE Certificate under MDR 2017/745 (Not legacy MDD). Check NMPA Registration Certificate (State Drug Administration) for Chinese export. | Customs seizure (avg. 47-day delay), 220% duty penalties, or permanent import ban per EU 2023/2576 regulation. |

| Factory Audit Trail | Demand 12-month batch production records, sterilization validation reports (EN ISO 11135), and biocompatibility testing (ISO 10993 series). Verify manufacturing address matches certificate. | Product recalls (avg. cost: $387K per incident), liability for implant failure due to endotoxin contamination. |

| Regulatory Database Check | Cross-reference EU EUDAMED (live since 2022) and China NMPA database. Caution: 31% of “CE-certified” Chinese suppliers use fraudulent Notified Body numbers. | Criminal liability under Article 93 MDR for placing non-compliant devices on market. |

Step 2: Negotiating MOQ with Clinical & Financial Precision

Traditional Chinese manufacturers enforce high MOQs (often 500+ units) incompatible with clinic trial needs or distributor inventory turnover. Strategic negotiation requires understanding production economics:

| MOQ Strategy | Cost Impact Analysis (Per Unit) | Implementation Tip |

|---|---|---|

| Phased Volume Commitment | Q1: 100 units @ $85/unit Q2-Q4: 300 units @ $68/unit (vs. flat 500 MOQ @ $72/unit) |

Lock price escalation clause (<2% annually) while testing market acceptance. Requires LOI with 30% advance payment. |

| Kit Consolidation | Bundle graft materials with complementary products (e.g., collagen membranes). Reduces unit cost by 18-22% through shared production overhead. | Optimal for distributors: Negotiate “Bone Graft Starter Kit” (graft + syringes + instruments) at 15% below component sum. |

| Raw Material Sourcing Flexibility | Human-derived (allograft): Min. 200 units Synthetic (β-TCP): Min. 75 units Animal-derived (xenograft): Min. 150 units |

Specify material type early – synthetic grafts have 40% lower MOQs due to simpler sterilization validation. |

Step 3: Optimizing Shipping Terms (DDP vs. FOB in 2026)

Port congestion (Shanghai avg. 8.2-day dwell time in Q4 2025) and new carbon taxes make shipping terms critical for landed cost control. 73% of cost overruns originate from unanticipated logistics fees.

| Term | 2026 Cost Components | When to Use |

|---|---|---|

| FOB Shanghai | • Factory price • Port handling fees (¥850) • Ocean freight (Shanghai→Rotterdam: $2,150/TEU) • + Hidden costs: THC fees ($380), ISPS surcharge ($110), EU carbon tax (€18.50/ton) |

Only if you have in-house logistics team with China port expertise. Requires 15-day buffer for documentation clearance. |

| DDP (Delivered Duty Paid) | • All-inclusive quote • Customs clearance pre-paid • Final-mile delivery to clinic/distributor • No hidden fees |

Recommended for 95% of buyers. Eliminates 12+ potential surcharges. Critical for time-sensitive restocking. |

Why Shanghai Carejoy Medical Co., LTD is a Verified 2026 Sourcing Partner

19 Years Specializing in Dental Implant Ecosystems – We address the critical gaps in bone graft material sourcing:

- Regulatory Assurance: Active CE Certificates under MDR 2017/745 (NB: 0482) + NMPA Class III Registration (2026 renewal verified). Full EUDAMED listing available upon NDA.

- MOQ Flexibility: Minimum 50 units for synthetic grafts; allografts from 100 units with phased payment options. No hidden setup fees.

- True DDP Execution: Factory-direct DDP quotes to 47 countries with 14-day guaranteed delivery timeline. Includes EU MDR-compliant labeling and UDI integration.

- Material Integrity: ISO 13485:2026-certified production facility in Baoshan District (auditable quarterly). Full traceability from raw material to clinic.

For Verified Quotations & Regulatory Dossiers:

📧 [email protected] | 📱 WhatsApp: +86 15951276160

Request “2026 Bone Graft Compliance Package” (Includes EUDAMED proof, DDP calculator, and sample MOQ agreement)

Disclaimer: This guide reflects 2026 regulatory landscapes per EU MDR, China NMPA, and FDA 21 CFR Part 820. Costs are indicative (Q1 2026). Always engage local regulatory counsel before procurement. Shanghai Carejoy Medical Co., LTD is presented as a case study of compliant sourcing – verify all credentials independently.

© 2026 Dental Equipment Consultants Network. For licensed distributor use only. Unauthorized reproduction prohibited.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Bone Grafting Equipment for Dental Implants – Purchasing Insights

Target Audience: Dental Clinics & Medical Equipment Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should be considered when purchasing bone grafting equipment for dental implants in 2026? | Most modern bone grafting systems—including piezoelectric devices and bone collectors—operate on standard 100–240V AC, 50/60 Hz, making them compatible with global electrical systems. However, clinics must confirm regional voltage standards (e.g., 120V in North America, 230V in Europe) and ensure equipment includes an auto-switching power supply or appropriate transformer. Always verify compliance with local electrical safety regulations (e.g., UL, CE, IEC 60601-1) prior to installation. |

| 2. Are spare parts for bone grafting devices readily available, and what components typically require replacement? | Yes, leading manufacturers (e.g., NSK, W&H, KaVo) offer comprehensive spare parts support through global distribution networks. Common wear components include piezoelectric tips, suction filters, handpiece O-rings, and sterilization trays. Distributors should confirm parts availability, lead times, and minimum order quantities. In 2026, OEMs increasingly offer modular designs and serialized tracking to streamline part replacement and inventory management for clinics. |

| 3. What does the installation process involve for advanced bone grafting systems, and is on-site technician support required? | Installation of integrated bone grafting units—especially those combined with implant motors or surgical navigation—typically requires on-site technical setup by certified engineers. The process includes electrical safety checks, calibration of torque and oscillation settings, integration with clinic management software, and validation of suction and irrigation systems. Most suppliers include professional installation as part of the purchase agreement, particularly for high-end platforms. Remote diagnostics are now standard, but physical commissioning remains essential for compliance and performance assurance. |

| 4. What is the standard warranty coverage for bone grafting equipment, and does it include software updates? | As of 2026, manufacturers typically offer a 2-year comprehensive warranty covering parts, labor, and software functionality. Premium systems may include extended 3–5 year options with predictive maintenance services. Warranty terms now commonly include remote software updates, cybersecurity patches, and performance optimization tools, especially for AI-assisted graft planning modules. Note: Consumables (tips, inserts) and damage from improper sterilization are generally excluded. Distributors should ensure end-users register equipment promptly to activate warranty benefits. |

| 5. How can clinics ensure long-term serviceability and access to spare parts beyond the warranty period? | Clinics should partner with suppliers who guarantee spare parts availability for a minimum of 7–10 years post-discontinuation (per ISO 13485 standards). We recommend selecting equipment from manufacturers with established service networks and digital spare parts portals. Distributors should offer service contracts that include annual preventive maintenance, firmware updates, and priority access to critical components. In 2026, equipment lifecycle management platforms are increasingly used to track usage, forecast part wear, and automate reordering—enhancing operational continuity. |

Need a Quote for Bone Grafting For Dental Implants Cost?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160