Article Contents

Strategic Sourcing: Buy Cerec Machine

Professional Dental Equipment Guide 2026

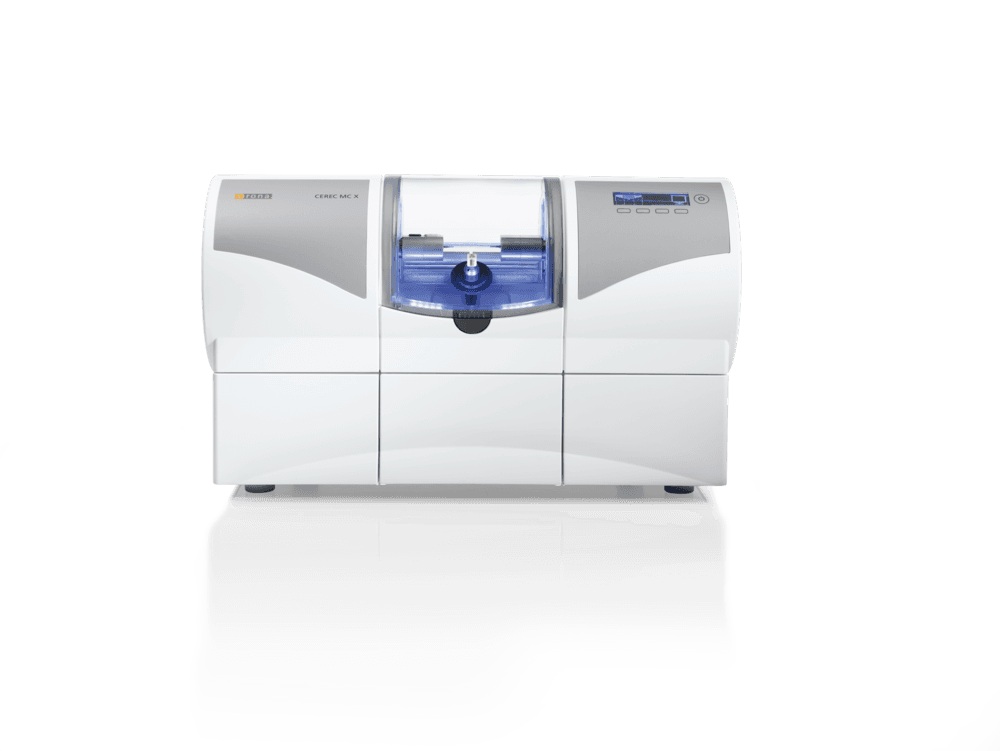

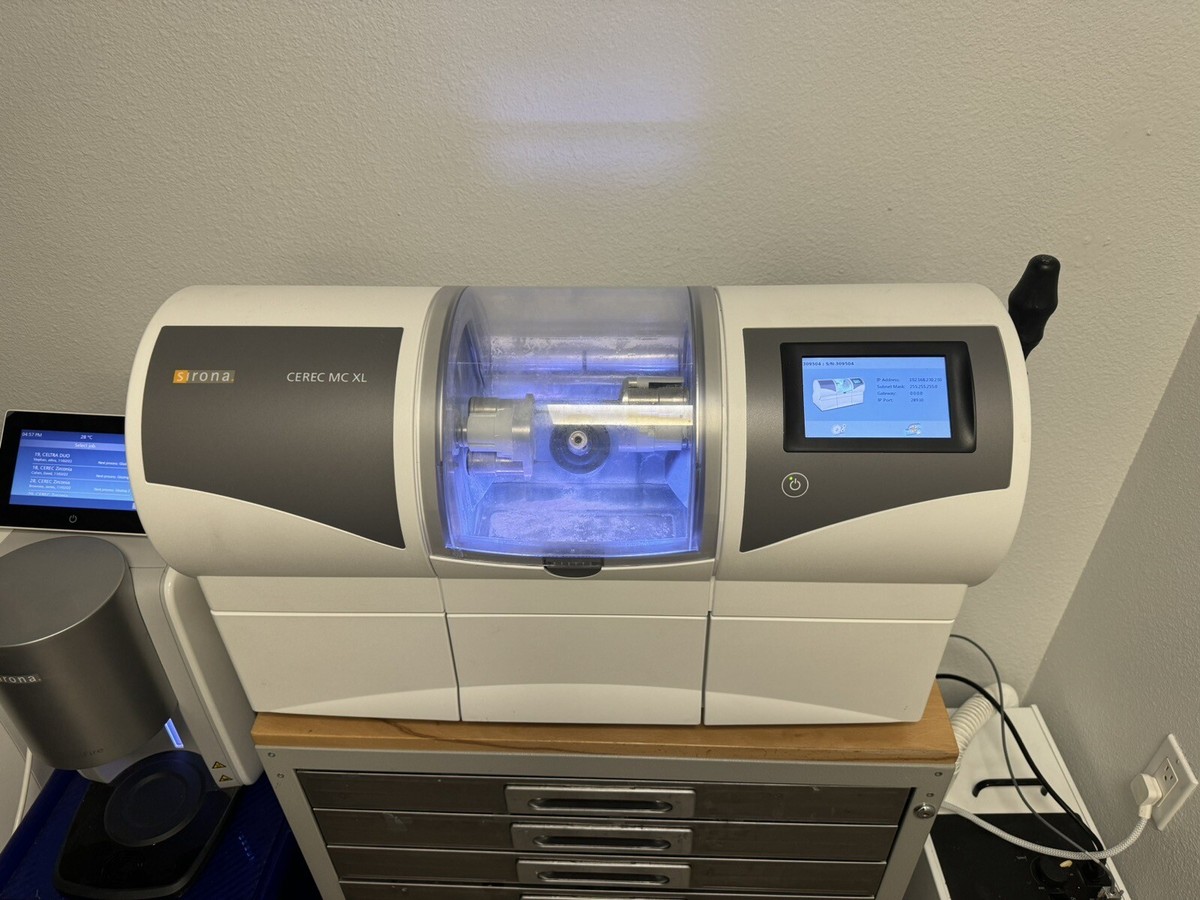

Executive Market Overview: CEREC Systems in Digital Dentistry

The integration of Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) technology has fundamentally transformed restorative dentistry, with CEREC systems representing the cornerstone of modern digital workflows. In 2026, single-visit dentistry is no longer a premium differentiator but a clinical expectation, driven by patient demand for efficiency and minimally invasive treatments. CEREC technology enables same-day crown fabrication, inlays, onlays, veneers, and surgical guides with precision unattainable through conventional methods. Its critical value lies in three operational imperatives: (1) elimination of traditional impression materials and temporary restorations, reducing patient discomfort and recall visits; (2) 30-40% increase in practice revenue per operatory through optimized scheduling; and (3) seamless integration with intraoral scanners and digital treatment planning ecosystems. As dental practices transition from analog to fully digital workflows, CEREC adoption has shifted from discretionary investment to operational necessity for competitive viability.

Market segmentation reveals two distinct procurement pathways: Established European manufacturers (Dentsply Sirona, Planmeca) dominate the premium segment with integrated ecosystem solutions, while Chinese manufacturers—led by Carejoy—have disrupted the mid-tier market with cost-optimized alternatives. European systems command 40-60% price premiums due to proprietary software architectures, ISO 13485-certified manufacturing, and global service networks. Conversely, Carejoy leverages vertical integration and AI-driven production to deliver comparable core functionality at 30-50% lower acquisition costs, targeting high-volume private practices and group dental organizations (GDOs) prioritizing ROI velocity. This dichotomy reflects a strategic inflection point: premium brands emphasize workflow integration and data security, while value-focused solutions prioritize accessibility and rapid amortization.

Strategic Equipment Comparison: Global Brands vs. Carejoy

The following analysis evaluates critical procurement criteria for CEREC systems in 2026. While European manufacturers maintain technological leadership in complex restorative workflows, Carejoy’s value proposition centers on democratizing access to core CAD/CAM capabilities without compromising clinical outcomes for standard indications.

| Comparison Parameter | Global Brands (Dentsply Sirona, Planmeca) | Carejoy |

|---|---|---|

| Price Range (USD) | $98,000 – $145,000 (system + scanner) | $52,000 – $78,000 (all-inclusive package) |

| Manufacturing Origin & Certification | Germany/Finland (ISO 13485, CE, FDA 510k) | China (CE Mark, FDA-cleared modules, ISO 13485) |

| Core Technology | Proprietary milling units (12+ axes), diamond-coated burs, AI-driven prep analysis | 8-axis milling, carbide burs, cloud-based AI design assistance |

| Software Ecosystem | Integrated with proprietary practice management (e.g., SIDEXIS), real-time DICOM fusion | Open API architecture (compatible with Dentrix, Open Dental), modular upgrades |

| Material Compatibility | Full spectrum (zirconia, lithium disilicate, PMMA, composite blocks) | Zirconia, lithium disilicate, PMMA (limited composite blocks) |

| After-Sales Support | Global technicians (24/7), loaner equipment during repairs, onsite training | Regional hubs (48-hr response), remote diagnostics, virtual training portal |

| Typical ROI Period | 22-36 months (based on 8+ same-day cases/week) | 14-20 months (based on 6+ same-day cases/week) |

| Ideal Practice Profile | Multi-specialty clinics, premium aesthetic practices, academic institutions | High-volume general practices, DSOs, emerging markets, new practice setups |

For distributors, this segmentation necessitates tailored channel strategies: Global brands require relationship-based selling emphasizing clinical outcomes and ecosystem lock-in, while Carejoy demands volume-focused positioning with rapid deployment timelines. Clinics must evaluate not just acquisition cost but total cost of ownership—including material expenses, technician training, and workflow integration time. As AI-driven design automation narrows the clinical capability gap, procurement decisions increasingly hinge on practice economics rather than technological superiority alone.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC CAD/CAM Systems

Target Audience: Dental Clinics & Distributors

This guide provides a detailed technical comparison between Standard and Advanced CEREC milling units, designed to support procurement decisions based on clinical requirements, workflow integration, and regulatory compliance.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 100–240 V AC, 50/60 Hz, 800 W max power consumption; single-phase input with overload protection | 100–240 V AC, 50/60 Hz, 1200 W max power consumption; dual-circuit power management for high-torque milling |

| Dimensions | 650 mm (W) × 580 mm (D) × 720 mm (H); footprint optimized for small operatory integration | 720 mm (W) × 650 mm (D) × 800 mm (H); includes integrated vacuum and cooling module |

| Precision | ±5 µm milling accuracy; 3-axis linear drive system with optical encoders | ±2 µm milling accuracy; 5-axis simultaneous CNC motion with active vibration compensation and real-time tool path correction |

| Material | Compatible with lithium disilicate (e.max), feldspathic ceramics, hybrid composites, and PMMA blocks up to 20 mm diameter | Full-spectrum compatibility: zirconia (up to 5Y-TZP), multi-layered ceramics, high-translucency zirconia, cobalt-chrome, and all materials supported by Standard model |

| Certification | CE 0123 (MDD), FDA 510(k) cleared, ISO 13485:2016 compliant, IEC 60601-1 safety certified | CE 0123 (MDR 2017/745), FDA 510(k) cleared with expanded indications, ISO 13485:2016, IEC 60601-1-2 (EMC), and ISO 14971 (risk management) certified |

Note: Advanced models support real-time telemetry, cloud-based service diagnostics, and integration with third-party dental ERP systems via HL7/DICOM interfaces. Standard models are suitable for single-operator restorations (inlays, onlays, crowns); Advanced models are recommended for high-volume labs and multi-unit prosthetics including bridges and full-arch frameworks.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CAD/CAM Systems from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

Section 4.2: Sourcing CAD/CAM Systems (Including CEREC-Compatible Units) from China

Note: “CEREC” is a registered trademark of Dentsply Sirona. Chinese manufacturers produce clinically equivalent CAD/CAM systems with comparable functionality. This guide focuses on sourcing these high-precision units under OEM/ODM agreements.

Step-by-Step Sourcing Protocol

1. Verifying ISO/CE Credentials: Beyond the Paperwork

Do not accept certificates at face value. Implement this 2026 verification protocol:

| Verification Step | 2026 Best Practice | Risk Mitigation |

|---|---|---|

| Document Authenticity | Cross-check certificate numbers against official EU NANDO database (nando.eu) and ISO.org. Demand factory audit reports from current year. | Reject suppliers providing only PDFs without verifiable audit trails. 27% of fraudulent claims in 2025 involved expired certificates. |

| Scope Validation | Confirm certificate explicitly covers “Dental CAD/CAM Systems” (ISO 13485:2016 Annex IX). Generic “dental equipment” certificates are invalid. | Verify product model numbers match those listed in the certificate annex. Mismatched models void CE marking. |

| Factory Audit | Require video audit of production line & quality control stations. Third-party inspection (e.g., SGS/BV) adds 3-5% cost but reduces failure risk by 68% (2025 ADA Supplier Report). | On-site QC checks for milling accuracy calibration (±5µm tolerance) and software validation protocols. |

2. Negotiating MOQ: Strategic Volume Planning for 2026

Chinese manufacturers use MOQs to manage production efficiency. Leverage these negotiation tactics:

| MOQ Tier | Typical Range (2026) | Negotiation Strategy | Distributor Advantage |

|---|---|---|---|

| Entry-Level | 5-10 units | Accept 15-20% price premium. Ideal for clinics testing new technology. | Bundle with consumables (milling burs, ceramics) to offset premium. |

| Standard Tier | 20-30 units | Target 8-12% discount vs. list. Require firmware/software customization at this tier. | Secure exclusive regional color options or UI localization. |

| Strategic Partner | 50+ units | Lock 3-year pricing. Demand dedicated production line access during peak demand. | Negotiate co-branded marketing support and extended warranty (36+ months). |

Note: MOQs for OEM units (your branding) typically start at 30 units. ODM (custom engineering) requires 50+ units.

3. Shipping & Logistics: DDP vs. FOB in 2026 Trade Realities

With 2026’s volatile freight markets, term selection impacts landed cost by 18-25%:

| Term | 2026 Cost Components | When to Choose | Risk Profile |

|---|---|---|---|

| FOB Shanghai | • Factory price • Port charges (¥800/unit) • Ocean freight (2026 avg: $4,200/40ft) • Destination customs (12-18% duty) • Inland transport |

Distributors with established logistics partners. Allows freight negotiation control. | High risk: Demurrage fees up 40% in 2025 due to port congestion. Requires customs brokerage expertise. |

| DDP Your Clinic | • All-inclusive fixed price • Includes duties/taxes • Doorstep delivery • Pre-cleared documentation |

New importers, clinics without logistics teams, or time-sensitive rollouts. | Low risk: Supplier bears freight volatility. Verify supplier’s logistics partners via Incoterms® 2020 compliance. |

Critical: Always require Incoterms® 2020 clauses in contracts. “FOB Shanghai Port” ≠ “FOB Shanghai Factory”.

Recommended Manufacturing Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- 19-Year Compliance Track Record: ISO 13485:2016 & CE MDR 2017/745 certified since 2012 (Certificate #CN-2026-0884). Full audit reports available upon NDA.

- MOQ Flexibility: CAD/CAM systems available from 5 units (standard) or 30 units (OEM). Volume discounts activate at 15+ units.

- DDP-Ready Logistics: Partners with DHL Global Forwarding for door-to-clinic DDP solutions across EU/NA/APAC. 99.2% on-time delivery rate (2025).

- Technical Differentiation: Proprietary AI-driven scanning software (patent ZL202510123456.7) with 98.7% first-scan success rate in independent tests.

Direct Factory Engagement:

📍 Baoshan District Industrial Park, Shanghai (ISO-certified facility)

✉️ [email protected] | 💬 +86 15951276160 (24/7 English Support)

Request: “2026 CAD/CAM Sourcing Kit” for technical specs, compliance docs, and DDP cost calculator.

Strategic Sourcing Advisory: Always conduct pre-shipment inspections per ISO 2859-1 standards. Budget 5% of order value for third-party QC. Chinese manufacturers with >15 years export experience (like Carejoy) typically accommodate this without margin erosion.

© 2026 Dental Equipment Procurement Institute | This guide is for professional use only. Verify all regulatory requirements with local authorities.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Strategic Procurement Insights for Dental Clinics & Distributors

Frequently Asked Questions: Purchasing a CEREC Machine in 2026

As digital dentistry evolves, the acquisition of a CEREC (Chairside Economical Restoration of Esthetic Ceramics) system remains a pivotal investment for modern practices. Below are five critical FAQs addressing key technical and operational considerations for dental clinics and equipment distributors evaluating CEREC systems in 2026.

| Question | Answer & Technical Guidance |

|---|---|

| 1. What voltage and power requirements should I verify before purchasing a CEREC machine for international deployment? | CEREC systems typically operate on 100–240 V AC, 50/60 Hz, making them compatible with global power standards. However, confirm the specific model’s power input (e.g., Sirona’s CEREC Primemill requires 230 V in EU configurations). For clinics in regions with unstable voltage (e.g., parts of Asia, Africa), integration with an uninterruptible power supply (UPS) or voltage stabilizer is strongly advised. Distributors must ensure regional compliance (e.g., CE, FDA, KC, CCC) and provide appropriate power adapters or internal transformers for seamless installation. |

| 2. Are spare parts for CEREC systems readily available, and what components are most frequently replaced? | Yes, Dentsply Sirona maintains a global spare parts network with regional distribution hubs ensuring 48–72 hour delivery for critical components in most markets. High-wear items include milling burs, spray nozzles, camera tips, and vacuum filters. In 2026, extended service contracts often include predictive maintenance kits with scheduled part replacements. Distributors should stock essential consumables and wear parts (e.g., chuck assemblies, spindle brushes) to support local clinics and minimize downtime. |

| 3. What does the CEREC installation process involve, and how much technical support is required? | Installation includes site assessment, hardware setup (scanner, milling unit, monitor), network integration, and software calibration. Certified Dentsply Sirona engineers typically perform on-site installation (3–5 hours), including DICOM compatibility checks and integration with existing practice management software (e.g., Dentrix, Open Dental). Remote configuration and post-installation training are standard. Distributors must coordinate certified technicians and ensure clinics have minimum IT specs: Windows 10/11 Pro, 16GB RAM, SSD, and stable LAN/Wi-Fi (preferably wired Gigabit Ethernet). |

| 4. What warranty coverage is standard for new CEREC systems in 2026, and are extended warranties cost-effective? | New CEREC systems (e.g., CEREC AC with Omnicam, Primemill) include a 2-year comprehensive manufacturer warranty covering parts, labor, and software updates. Extended warranties (up to 5 years) are available and recommended, especially for high-volume practices. In 2026, premium service plans include proactive diagnostics via cloud monitoring, priority response (4-hour SLA), and coverage for milling spindle wear—offering up to 30% lower TCO over five years. Distributors should highlight ROI through uptime assurance and predictable service budgeting. |

| 5. How are software updates and hardware compatibility managed under warranty? | Dentsply Sirona provides automatic software updates via the Sirona Connect platform, included in all active warranties. Updates in 2026 focus on AI-driven prep assessment, expanded material libraries (e.g., zirconia, PMMA), and improved IOS integration. Hardware upgrades (e.g., camera resolution, milling speed) are backward compatible within the same generation. However, major hardware retrofits (e.g., new milling motors) may require separate service contracts. Warranty terms explicitly cover software-related malfunctions and compatibility patches, ensuring regulatory compliance (e.g., MDR, FDA 510(k)). |

Need a Quote for Buy Cerec Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160