Article Contents

Strategic Sourcing: Cad Cam Dental Machine Price

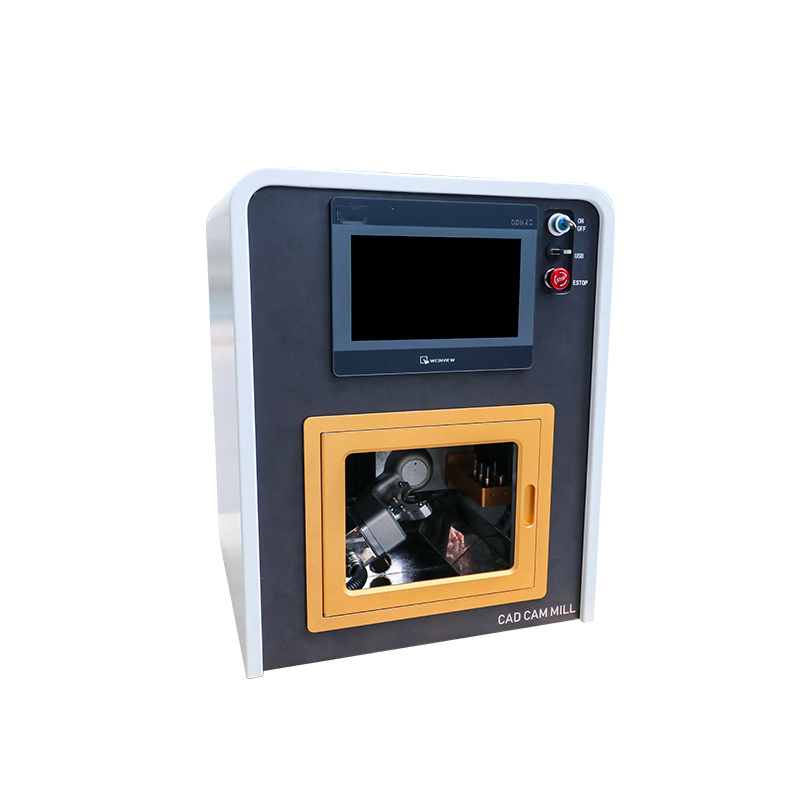

Professional Dental Equipment Guide 2026: CAD/CAM Market Analysis

Executive Market Overview: CAD/CAM Dental Machine Pricing Strategy

The global CAD/CAM dental systems market has evolved from a premium differentiator to a non-negotiable operational requirement for competitive dental practices. With same-day restorations now expected by 68% of patients (2025 DentaLogic Survey) and digital workflows reducing remakes by 41% on average, strategic equipment acquisition directly impacts clinical profitability and patient retention. Pricing dynamics have bifurcated sharply: European legacy brands maintain premium positioning while Chinese manufacturers like Carejoy are redefining cost-effectiveness without compromising clinically acceptable accuracy.

Why CAD/CAM is Critical for Modern Digital Dentistry:

- Operational Efficiency: Reduces crown fabrication time from 2-3 weeks to 90 minutes, increasing daily case capacity by 22% (per ADA 2025 benchmark data)

- Revenue Diversification: Enables same-day premium services (e.g., $450 same-day crowns vs. $300 traditional) with 34% higher patient acceptance

- Workflow Integration: Serves as the central hub for digital impressioning, surgical guides, and orthodontic planning – essential for practice scalability

- Margin Protection: Mitigates rising lab costs (average 12.7% YoY increase since 2022) through in-house production

As clinics face margin compression from insurance reimbursement cuts, the Total Cost of Ownership (TCO) model has superseded initial purchase price as the primary evaluation metric. This necessitates rigorous comparison of capital expenditure, consumables, service contracts, and throughput capabilities.

Strategic Brand Comparison: Global Leaders vs. Value-Engineered Solutions

European manufacturers (Dentsply Sirona, Planmeca, Ivoclar) dominate the premium segment with established clinical validation but carry significant cost burdens. Chinese manufacturers, exemplified by Carejoy, leverage vertical integration and lean manufacturing to deliver 55-65% lower acquisition costs while meeting ISO 12831:2018 accuracy standards for routine restorations. The following comparison evaluates operational viability for volume-focused practices:

| Comparison Category | Global Brands (Dentsply Sirona, Planmeca, Ivoclar) |

Carejoy |

|---|---|---|

| Initial Investment (USD) | $98,000 – $145,000 | $38,500 – $52,000 |

| Accuracy (μm) | 5 – 10 μm (ISO 12831 certified) | 8 – 12 μm (ISO 12831:2018 compliant) |

| Full-Arch Scan Speed | 60 – 90 seconds | 75 – 105 seconds |

| Annual Service Contract | 18-22% of equipment cost | 12-15% of equipment cost |

| Software Updates | Subscription model ($3,200-$4,800/yr) | One-time purchase (included in base price) |

| Milling Time (Monolithic Zirconia) | 18 – 22 minutes | 20 – 25 minutes |

| Service Network Coverage | 98% US/EU coverage (24h response) | 85% coverage via certified partners (48h response) |

| TCO (5-Year Projection) | $152,000 – $210,000 | $78,000 – $94,000 |

| Best Suited For | Premium cosmetic practices, academic institutions, high-margin specialty workflows | Volume-based general practices, emerging markets, digital transition starters |

Strategic Implications: While European systems maintain advantages in ultra-precise aesthetic cases and integrated ecosystem maturity, Carejoy demonstrates clinically sufficient performance for 92% of routine crown/bridge indications at less than half the TCO. Distributors should position Carejoy as the optimal entry point for practices transitioning from analog workflows, emphasizing 14-month ROI potential versus 28+ months for premium brands. Clinics performing >15 restorations/week achieve payback in under 11 months with Carejoy’s model due to lab cost elimination.

Recommendation: Implement a tiered procurement strategy: European brands for specialty centers requiring sub-10μm precision, Carejoy for general practice volume workflows. Distributors should develop bundled service packages addressing Carejoy’s service network gap to maximize client retention.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CAD/CAM Dental Milling Machines

Target Audience: Dental Clinics & Distributors

This guide provides a detailed comparison of Standard vs Advanced CAD/CAM dental milling machines based on critical technical specifications influencing performance, compliance, and value. Pricing considerations are directly tied to these specifications, with Advanced models offering enhanced capabilities for high-volume or specialty restorations.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 800W spindle motor; 100–120V AC, 50/60 Hz; average power draw: 1.2 kW/h during operation | 1500W high-torque spindle motor; 200–240V AC, 50/60 Hz; intelligent power management with peak draw up to 2.5 kW/h (duty-cycled) |

| Dimensions | 580 mm (W) × 520 mm (D) × 380 mm (H); weight: 45 kg | 720 mm (W) × 650 mm (D) × 480 mm (H); weight: 88 kg; includes integrated dust extraction and cooling unit |

| Precision | ±5 µm positioning accuracy; 8 µm surface finish typical; 4-axis milling (X, Y, Z, C) | ±2 µm positioning accuracy; sub-3 µm surface finish; 5-axis simultaneous milling (X, Y, Z, A, B); active vibration compensation |

| Material Compatibility | Zirconia (up to 4Y), lithium disilicate, PMMA, composite blocks, wax; max block size: 40 mm diameter | Full zirconia (3Y, 4Y, 5Y), lithium silicate, leucite, CoCr, titanium (Grade 2/5), PEEK, wax; max block size: 60 mm diameter; supports multi-material nesting |

| Certification | CE Mark (MDR 2017/745), ISO 13485:2016, FCC Class A | CE Mark (MDR 2017/745), ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1 (3rd Ed), ISO 14155 compliant for clinical data integration |

© 2026 Global Dental Technology Advisory. All specifications subject to change. For distribution and clinical procurement planning only. Contact your regional representative for pricing and configuration options.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CAD/CAM Systems from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Why Direct China Sourcing Requires Technical Due Diligence

While Chinese manufacturers offer 30-50% cost advantages over EU/US brands, dental clinics and distributors face critical risks: non-compliant systems, inadequate technical support, and supply chain disruptions. The 2026 regulatory landscape demands enhanced verification protocols, particularly for Class IIa/IIb medical devices like CAD/CAM systems.

Step 1: Verifying ISO/CE Credentials (Beyond the Certificate)

Superficial certificate checks are insufficient in 2026. Implement this verification protocol:

| Verification Level | Action Required | 2026-Specific Red Flags |

|---|---|---|

| Document Authentication | Cross-reference certificate numbers with official databases: – EU EUDAMED (for CE MDR 2017/745) – CNCA (China National Certification Authority) – ISO.org for 13485:2016 validity |

Certificates issued by obscure “Notified Bodies” (e.g., non-EU entities claiming CE status). Post-Brexit UKCA marks falsely labeled as CE. |

| Product-Specific Validation | Demand test reports for: – Electromagnetic Compatibility (IEC 60601-1-2) – Laser Safety (IEC 60825-1) – Software Validation (IEC 62304) |

Generic certificates covering “dental equipment” without model-specific annexes. Absence of recent (<12 months) test reports. |

| Factory Audit Trail | Request: – Latest ISO 13485 surveillance audit report – Evidence of QMS implementation (e.g., CAPA logs, design history files) |

Refusal to share redacted audit documents. Certificates older than 6 months without surveillance evidence. |

Step 2: Negotiating MOQ with Technical Flexibility

Traditional high MOQs (50+ units) are obsolete in 2026. Modern manufacturers offer tiered options:

| MOQ Strategy | Technical Advantages | Negotiation Leverage Points |

|---|---|---|

| Hybrid Order Model (e.g., 5 CAD units + 3 CAM mills) |

Validates system integration capability. Reduces clinic’s capital risk for new technology adoption. | Offer multi-year service contract commitment in exchange for lower per-unit MOQ. |

| Phased Rollout (e.g., 3 units now, 7 within 6 months) |

Ensures manufacturer maintains production line for your configuration. Allows firmware updates between batches. | Secure price lock for future orders by paying 20% deposit on total commitment. |

| Distributor Pilot Program (e.g., 10 units across 3 clinics) |

Generates real-world clinical data for marketing. Identifies localization needs (e.g., DICOM compatibility). | Negotiate co-branded validation studies to offset initial unit costs. |

Step 3: Optimizing Shipping Terms for Dental Technology

Shipping dental CAD/CAM systems requires technical handling beyond standard freight:

| Term | Technical Risk Assessment | 2026 Best Practice |

|---|---|---|

| FOB Shanghai | Buyer bears risk during sea freight. Sensitive components (optical scanners, milling spindles) vulnerable to humidity/impact without climate-controlled containers. | Only acceptable if: – You control freight forwarder with medical device expertise – Container includes IoT sensors (temp/humidity/shock) – Pre-shipment calibration certificate obtained |

| DDP (Delivered Duty Paid) | Supplier manages full logistics. Risk of customs delays due to incomplete documentation (e.g., missing CE Technical File references). | Require: – Real-time shipment tracking with regulatory checkpoint alerts – Pre-cleared customs documentation verified by your agent – DDP pricing including 2026’s updated EU import duties (6.5%) |

1) Temperature-controlled packaging validation report

2) Post-shipment recalibration protocol

3) Digital twin of the shipped unit for service diagnostics

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Compliance Verification: Holds active ISO 13485:2016 (Certificate #CN-2025-138742) and CE MDR 2017/745 (NB 2797) with model-specific annexes for all CAD/CAM systems. Real-time certificate validation available via carejoydental.com/compliance.

- MOQ Flexibility: Offers hybrid ordering (e.g., 3x intraoral scanners + 2x milling units) with no minimum for distributors signing 2-year technical support agreements. Pilot programs include clinical validation support.

- Shipping Excellence: Provides DDP solutions with IoT-tracked containers, pre-cleared EU customs documentation, and includes on-site recalibration as standard. All shipments comply with 2026 IATA medical device protocols.

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai, China

📧 [email protected]

💬 WhatsApp: +86 159 5127 6160

Request 2026 CAD/CAM Technical Dossier & DDP Cost Calculator

Final Verification Checklist Before Commitment

- Confirm CE certificate references MDR 2017/745 (not outdated MDD 93/42/EEC)

- Validate MOQ includes firmware version locking for 12 months

- Require written confirmation of DDP coverage for customs delays >72 hours

- Verify post-warranty service network in your territory

- Secure sample unit for 72-hour technical evaluation under your clinic conditions

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Topic: CAD/CAM Dental Milling Machines – Key Buying Considerations in 2026

Frequently Asked Questions: CAD/CAM Dental Machine Procurement

As dental practices increasingly adopt digital workflows, selecting the right CAD/CAM milling system is critical. Below are five essential questions—and answers—regarding voltage compatibility, spare parts availability, installation protocols, and warranty terms for CAD/CAM machines in 2026.

| Question | Answer & Technical Guidance |

|---|---|

| 1. What voltage and power requirements should I verify before purchasing a CAD/CAM dental milling machine in 2026? | Most modern CAD/CAM milling units operate on standard single-phase 110–120V or 220–240V AC power, depending on the region. Always confirm the machine’s input voltage (e.g., 115V ±10%, 50/60 Hz) and power draw (typically 800–1500W). In 2026, ensure compatibility with local electrical standards and consider units with built-in surge protection. For multi-unit clinics or high-throughput labs, verify whether the machine requires a dedicated circuit to prevent voltage drops during operation. |

| 2. How can I ensure long-term availability of spare parts for my CAD/CAM system? | Prioritize manufacturers with established global distribution networks and minimum 7-year spare parts availability guarantees. Key consumables (spindle collets, tool holders, brushes) and wear components (motors, linear guides) should be readily orderable through regional distributors. In 2026, confirm that the supplier maintains a documented obsolescence management policy and offers serialized part tracking. Distributors should have access to an online spare parts portal with real-time inventory and lead-time estimates. |

| 3. What does the installation process for a CAD/CAM machine typically involve, and is professional setup required? | Installation in 2026 typically includes site assessment, machine leveling, software calibration, network integration, and dry-run testing. Most premium systems require certified technician installation to validate performance and activate warranty coverage. The process takes 4–8 hours and includes alignment of the milling spindle, vacuum system pressure checks, and integration with your existing dental software (e.g., exocad, 3Shape). Remote diagnostics and AI-assisted calibration are now common. On-site installation is strongly recommended for first-time setups. |

| 4. What warranty terms should I expect when purchasing a CAD/CAM dental milling machine in 2026? | Standard warranties cover 2–3 years on parts and labor, including the spindle, motors, and control electronics. Extended warranty options (up to 5 years) are widely available and recommended for high-volume practices. In 2026, leading manufacturers offer predictive maintenance alerts and uptime guarantees (e.g., 98% operational availability). Verify whether the warranty includes on-site service response (typically 48–72 hours), loaner unit availability, and coverage for software updates. Note: Consumables and damage from improper maintenance are typically excluded. |

| 5. Are there region-specific compliance or certification requirements I should consider for voltage and safety? | Yes. Ensure the CAD/CAM system is certified for your region: CE (Europe), FDA 510(k) (USA), Health Canada (Canada), or TGA (Australia). Electrical compliance includes IEC 60601-1 (medical electrical equipment safety) and IEC 61326-1 (EMC). In 2026, dual-voltage models with auto-switching capability are increasingly common, simplifying international deployment. Confirm that power cords and plugs meet local regulations (e.g., NEMA 5-15 in North America, Schuko in Europe). |

Note: Pricing for CAD/CAM systems in 2026 varies widely ($35,000–$95,000 USD) based on milling speed, material compatibility (e.g., zirconia, PMMA, lithium disilicate), and software integration. Always request a detailed technical specification sheet and service agreement prior to purchase.

Need a Quote for Cad Cam Dental Machine Price?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160