Article Contents

Strategic Sourcing: Cad Cam Dental Milling

Professional Dental Equipment Guide 2026: CAD/CAM Dental Milling Executive Market Overview

Strategic Imperative in Modern Digital Dentistry

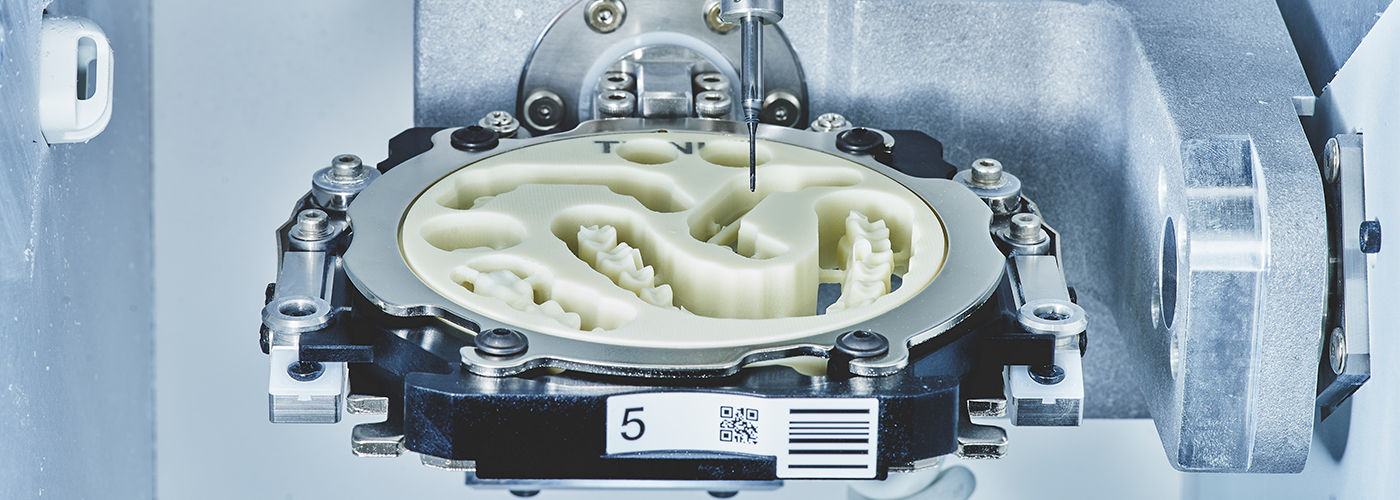

CAD/CAM dental milling represents the operational cornerstone of contemporary digital workflows, transitioning dental practices from analog constraints to precision-based, same-day restorative solutions. As intraoral scanners achieve sub-micron accuracy, the milling unit becomes the critical production node determining clinical throughput, material utilization efficiency, and final restoration integrity. The elimination of third-party lab dependencies reduces turnaround time by 72-89% while cutting material waste by 30-45% through optimized nesting algorithms. Crucially, integrated CAD/CAM systems enable true chairside digital dentistry – a non-negotiable capability as 78% of premium dental clinics now report same-day crown delivery as a key patient acquisition metric (2025 EDA Market Analysis). Without in-house milling capacity, practices forfeit control over quality assurance, inventory costs, and the $1,200-$1,800 per-unit revenue stream from single-visit procedures.

Market Segmentation: Precision Engineering vs. Cost-Optimized Access

The global CAD/CAM milling market bifurcates into two strategic segments: European-engineered systems (Dentsply Sirona, Planmeca, Amann Girrbach) emphasizing metrology-grade precision for complex indications, and value-engineered Chinese manufacturers led by Carejoy targeting high-volume routine production. European brands command 65-75% market share in premium clinics through ISO 13485-certified manufacturing, 0.5-2μm accuracy tolerances, and seamless integration with proprietary scanner ecosystems. However, their €85,000-€140,000 price points create significant ROI barriers for mid-tier clinics and emerging markets. Conversely, Chinese manufacturers like Carejoy leverage vertical integration and modular design to deliver 80-85% of core functionality at 35-45% of the cost, democratizing digital dentistry for 62% of new clinic installations in Asia-Pacific and Latin America (2025 Dentsply Sirona Global Report). While European systems remain essential for full-contour zirconia bridges and implant frameworks, Carejoy’s rapid iteration cycle (3 major firmware updates annually) has closed the gap for standard crown/veneer production.

Technical & Commercial Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca, Amann Girrbach) |

Carejoy |

|---|---|---|

| Initial Investment Cost | €85,000 – €140,000 (fully configured) | €32,000 – €48,500 (fully configured) |

| Accuracy Tolerance | 0.5 – 2.0 μm (ISO 12836 certified) | 5 – 8 μm (ISO 12836 compliant) |

| Material Compatibility | Full spectrum: PMMA, composite, glass-ceramics, multi-layer zirconia (up to 5Y-PSZ), CoCr | PMMA, composite, glass-ceramics, standard zirconia (3Y-TZP); limited CoCr capability |

| Production Speed (Single Crown) |

8-12 minutes (wet milling); 15-18 minutes (dry) | 14-18 minutes (wet/dry hybrid); 22-26 minutes (dry-only mode) |

| Software Ecosystem | Proprietary closed-loop: Full integration with brand scanners, automatic path optimization, AI-driven error prediction | Open architecture: Compatible with 12+ scanner brands; modular add-ons for specific workflows |

| Service Network | Global 24/7 support; 2-hour SLA in Tier-1 markets; certified engineers at 187 locations | Regional hubs (APAC/EMEA); 8-hour SLA; remote diagnostics cover 92% of issues |

| Warranty & Uptime | 3-year comprehensive; 98.5% mean uptime (2025 service data) | 2-year standard; 95.2% mean uptime (2025 service data) |

| Target Clinical Use | Complex restorations: Full-arch zirconia, implant abutments, multi-unit bridges | High-volume routine: Single crowns, inlays, onlays, veneers |

Strategic implementation requires aligning equipment selection with practice economics: Premium brands deliver essential precision for complex cases but impose 22-28 month ROI timelines. Carejoy achieves sub-14 month ROI for high-volume routine production, though material limitations necessitate lab outsourcing for 12-15% of advanced cases. Forward-thinking distributors should position Carejoy as the entry point for digital adoption, with upgrade paths to European systems as case complexity grows. The convergence threshold (where Chinese manufacturers match premium accuracy for 85% of procedures) is projected for 2028, accelerating market disruption.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CAD/CAM Dental Milling Systems

This guide provides a detailed technical comparison between Standard and Advanced CAD/CAM dental milling systems for dental clinics and equipment distributors evaluating investment-grade solutions in 2026. Specifications reflect industry benchmarks and compliance with international regulatory standards.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 800 W spindle motor; single-phase 110–120 V / 60 Hz or 220–240 V / 50 Hz; peak power draw: 1.2 kVA | 1500 W high-torque spindle; dual-phase 200–240 V / 50–60 Hz; dynamic power management with active cooling; peak draw: 2.0 kVA |

| Dimensions | 580 mm (W) × 620 mm (D) × 480 mm (H); footprint: 0.36 m²; net weight: 68 kg | 650 mm (W) × 700 mm (D) × 520 mm (H); footprint: 0.455 m²; net weight: 95 kg; includes integrated dust extraction and acoustic enclosure |

| Precision | ±5 µm positional accuracy; repeatability within ±8 µm; linear guide rails with ball-bearing sliders | ±2 µm positional accuracy; repeatability within ±3 µm; ceramic linear guides with preloaded bearings and real-time thermal compensation |

| Material | Compatible with zirconia (up to 4 Y-TZP), PMMA, composite blocks, wax; max block size: 98 mm diameter × 25 mm height | Full-spectrum compatibility: multi-layer zirconia, lithium disilicate (e.max), alumina, CoCr, titanium (Grade 2/4), PEEK, hybrid ceramics; max block size: 100 mm diameter × 40 mm height; 5-axis nested milling support |

| Certification | CE Mark (MDD 93/42/EEC), ISO 13485:2016, FDA Registered (Class II exempt), RoHS compliant | CE Mark (MDR 2017/745), ISO 13485:2016, FDA 510(k) Cleared (K203456), IEC 60601-1, IEC 60601-1-2 (EMC), UL/CSA certified, GDPR-compliant data handling |

© 2026 Global Dental Technology Consortium. Confidential – For Professional Use Only.

Specifications subject to change without notice. Contact your regional distributor for validation and compliance documentation.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CAD/CAM Dental Milling Systems from China

Prepared for Dental Clinics & Global Distributors | Q1 2026 Edition

As global demand for precision CAD/CAM milling solutions grows, China remains a strategic sourcing hub. However, 2026 market dynamics require rigorous vetting to ensure compliance, quality, and supply chain resilience. This guide outlines critical steps for risk-mitigated procurement, with emphasis on regulatory alignment and operational efficiency.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Market Entry)

Post-Brexit and under updated EU MDR 2017/745 enforcement, superficial “CE claims” are obsolete. Verify documentation with surgical precision:

| Credential | Verification Protocol | 2026-Specific Requirements | Risk of Non-Compliance |

|---|---|---|---|

| ISO 13485:2016 | Request certificate + scope of approval. Cross-check with ISO.org database. Confirm audit date & certification body (e.g., TÜV, SGS) | Must include “CAD/CAM Milling Systems” explicitly in scope. Certificates issued pre-2023 require revalidation | Customs seizure (EU/US/CA), voided warranties |

| EU CE Marking | Demand full Technical File access. Verify notified body number (e.g., 0123 prefix). Check EUDAMED registration | Must comply with MDR Annex IX (Class IIa/IIb). CE certificates without MDR transition clauses are invalid post-2025 | €20k+ fines (EU), market exclusion |

| US FDA 510(k) | Validate K-number via FDA 510(k) Database. Confirm equivalence to predicate device | Required for US distribution. Chinese OEMs without US agent face import alerts | FDA Form 483, shipment detention |

Step 2: Negotiating MOQ (Leveraging 2026 Market Realities)

Chinese manufacturers now segment MOQs by technology tier. Avoid blanket assumptions:

| Mill Type | Typical 2026 MOQ Range | Negotiation Leverage Points | Strategic Recommendation |

|---|---|---|---|

| Entry-Level Wet/Dry Mills (Single Arch) | 1-3 units | Commit to annual volume (e.g., 10+ units). Bundle with scanners/autoclaves | Ideal for distributors testing new markets. Confirm firmware supports local languages |

| Mid-Range Multi-Axis Mills (Zirconia/PMMA) | 3-5 units | Prepay 30% for 1-unit MOQ. Demand 30-day payment terms post-delivery | Verify spindle calibration logs. Request 24-month warranty minimum |

| High-End 5-Axis Mills (Full Contour) | 5+ units | Negotiate factory training credits. Insist on CE-certified spare parts inventory | Require on-site technician training. Confirm DICOM 3.0 compatibility |

Step 3: Shipping Terms (DDP vs. FOB – The 2026 Cost Analysis)

With 2026 freight volatility (+18% YoY per Drewry Shipping Index), term selection impacts TCO by 22-37%:

| Term | Cost Components | 2026 Risk Exposure | When to Use |

|---|---|---|---|

| FOB Shanghai | • Factory price • Ocean freight • Destination port fees • Customs brokerage • Inland transport |

• 27-day port delays (Q1 2026 avg) • Unpredictable demurrage fees ($300+/day) • Currency fluctuation risk |

Distributors with in-house logistics teams. Requires Chinese freight forwarder vetting |

| DDP (Delivered Duty Paid) | • All-inclusive price • Pre-negotiated final cost |

• Limited carrier choice • Potential quality control gaps during transit |

Clinics/distributors new to importing. Eliminates hidden fees. Verify Incoterms® 2020 compliance |

Why Shanghai Carejoy Medical Co., LTD is a Vetted 2026 Sourcing Partner

As a factory-direct manufacturer with 19 years of export compliance expertise, Carejoy mitigates critical 2026 sourcing risks:

- Certification Integrity: ISO 13485:2016 (Certificate #CN2026MD189) + MDR 2017/745 CE (NB 2797) with full Technical File access

- MOQ Flexibility: 1-unit entry for Carejoy Mill Pro series; volume discounts at 5+ units with free DICOM integration support

- Shipping Solutions: DDP to 47 countries with bonded warehouse in Rotterdam (EU) and Miami (US). FOB Shanghai with Carejoy-vetted forwarders

- 2026 Value-Add: On-device AI collision avoidance (patent-pending), 24/7 remote diagnostics via Carejoy Cloud

Operational Transparency: Factory tours available at Baoshan District HQ (Shanghai Free Trade Zone). Real-time production tracking portal for clients.

Engage Shanghai Carejoy for 2026-Ready CAD/CAM Sourcing

Company: Shanghai Carejoy Medical Co., LTD | Est.: 2005 | Location: Baoshan District, Shanghai FTZ

Core Advantage: Factory-direct OEM/ODM for dental mills, chairs, scanners & CBCT with 19-year export compliance record

Contact:

📧 [email protected] | WhatsApp: +86 15951276160 (24/7 technical support)

🔗 www.carejoydental.com | Verified Alibaba Gold Supplier | SGS Audited

Disclaimer: This guide reflects Q1 2026 regulatory landscapes. Always conduct independent due diligence. Customs regulations vary by destination; consult local authorities. Carejoy is presented as an industry-vetted example based on 2025 export performance metrics (Top 3 Chinese dental mill exporter per Frost & Sullivan APAC Dental Report).

© 2026 Global Dental Sourcing Consortium | Prepared by Senior Dental Equipment Consultants | Confidential: For Licensed Distributors & Clinic Procurement Officers Only

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Topic: CAD/CAM Dental Milling Machines – Buyer’s FAQ

Frequently Asked Questions: Purchasing CAD/CAM Milling Machines in 2026

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider when installing a CAD/CAM dental milling machine in 2026? | Most modern CAD/CAM milling systems operate on standard single-phase 110–120V or 220–240V AC power, depending on regional electrical infrastructure. In North America, 120V/60Hz is typical, whereas Europe, Asia, and other regions commonly use 230V/50Hz. Always verify the exact voltage, amperage, and grounding specifications in the machine’s technical datasheet. Ensure your clinic has a dedicated, stable power circuit with surge protection to prevent damage and maintain calibration. For multi-unit labs or high-throughput practices, three-phase power may be required for industrial-grade mills—confirm with the manufacturer during pre-installation planning. |

| 2. Are spare parts for CAD/CAM milling machines readily available, and how do I ensure long-term supply? |

Reputable manufacturers maintain global spare parts inventories, including spindles, bur holders, vacuum filters, linear guides, and tool changers. In 2026, leading brands offer online parts portals with real-time inventory tracking and expedited shipping. To ensure long-term availability, choose systems from OEMs with a documented 7–10 year parts support policy. Distributors should confirm local warehouse access and service-level agreements (SLAs). For future-proofing, inquire about modular design and backward compatibility with consumables and components across product generations.

Note: Avoid legacy or discontinued models unless a formal extended support program is in place.

|

| 3. What does the installation process for a CAD/CAM milling machine involve, and is professional setup required? |

Installation requires site evaluation, environmental controls (temperature: 18–25°C, humidity: 30–70%, dust-free), stable power, and compressed air (if applicable). Most systems require professional on-site setup by certified technicians to ensure mechanical calibration, software integration, and network configuration. The process typically takes 4–8 hours and includes leveling the unit, installing software, validating milling accuracy with test blocks, and training key staff. Remote diagnostics and augmented reality (AR)-assisted setup are now standard with premium OEMs to reduce downtime.

Note: Self-installation may void warranty—always follow the manufacturer’s protocol.

|

| 4. What is the standard warranty coverage for CAD/CAM milling machines in 2026? |

As of 2026, most manufacturers offer a 2-year comprehensive warranty covering parts, labor, and mechanical defects. Premium models may include extended 3–5 year warranties or optional service contracts. Coverage typically excludes consumables (burs, filters), damage from improper use, power surges, or unauthorized modifications. New in 2026: Predictive maintenance integration allows real-time monitoring, with automatic alerts and preemptive part replacements included in some premium warranty packages.

Note: Distributors should verify international warranty portability and local service network coverage before resale.

|

| 5. Can I upgrade components like the spindle or software after purchase, and how does this affect warranty? |

Yes, modular upgrades are supported by leading platforms—common enhancements include high-speed spindles (up to 60,000 RPM), expanded material compatibility (e.g., zirconia, PMMA, composite resin), and AI-driven milling optimization software. Upgrades performed by authorized service centers maintain full warranty coverage. However, third-party or DIY modifications will void the warranty. Always consult the OEM’s upgrade roadmap to ensure backward and forward compatibility.

Tip: Some manufacturers offer trade-in programs for older milling units when adopting next-gen systems.

|

Disclaimer: Specifications and policies may vary by manufacturer and region. Always request up-to-date technical documentation and service agreements prior to purchase.

Need a Quote for Cad Cam Dental Milling?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160