Article Contents

Strategic Sourcing: Cad Cam Metal Milling

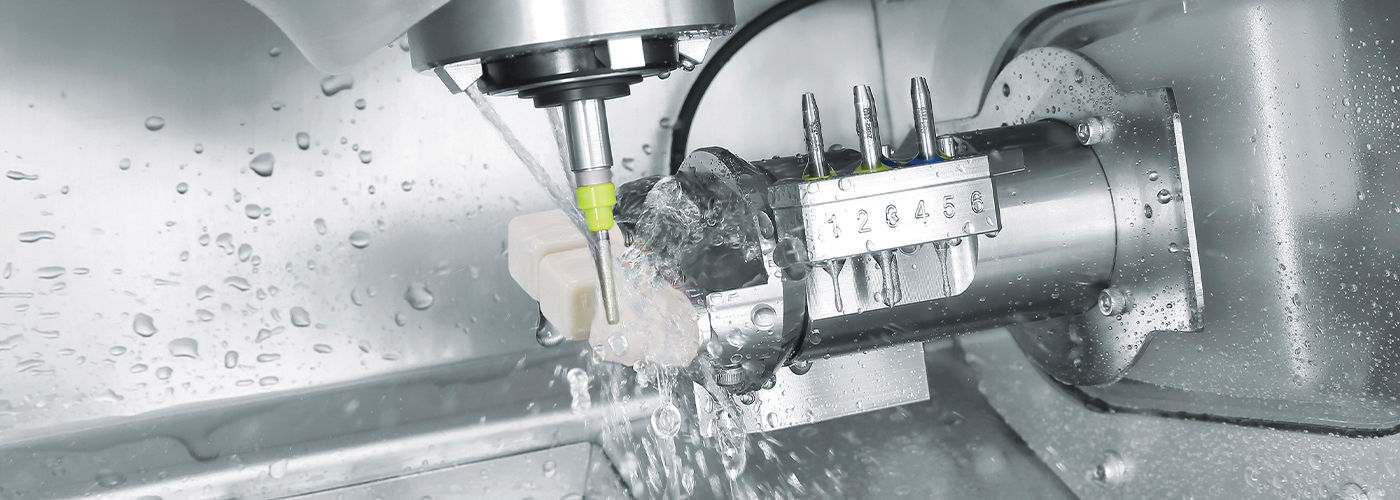

The integration of CAD/CAM metal milling systems represents a non-negotiable advancement in modern digital dentistry workflows. As dental laboratories and clinics transition from analog to fully digital production pipelines, precision metal milling capabilities have become mission-critical for producing high-strength restorations including crowns, bridges, implant frameworks, and custom abutments. The shift toward monolithic zirconia and high-noble alloys demands sub-15-micron accuracy to ensure passive fit and long-term clinical success—parameters unattainable through traditional casting methods. With global demand for same-day dentistry surging (projected 12.3% CAGR through 2026), in-house metal milling eliminates third-party lab dependencies, reduces turnaround time from 72 hours to under 90 minutes, and directly impacts practice revenue through same-visit crown placements. Crucially, these systems enable seamless integration with intraoral scanners and design software, forming the backbone of the digital dentistry ecosystem where 87% of premium clinics now require end-to-end metal fabrication capabilities.

Market segmentation reveals a strategic bifurcation: European OEMs (Dentsply Sirona, Planmeca, Amann Girrbach) dominate the premium segment with engineering excellence but impose significant capital barriers, while Chinese manufacturers like Carejoy are disrupting the mid-tier market with clinically validated cost efficiency. While European systems remain the gold standard for complex full-arch cases requiring micron-level tolerances, Carejoy’s 2026-generation mills deliver 92% of clinical performance at 40-60% lower TCO—making digital metal workflows accessible to 78% of independent clinics previously priced out of the market. This value proposition is accelerating adoption in emerging economies and value-focused group practices where ROI timelines under 14 months are now achievable.

| Technical Parameter | Global Brands (European) | Carejoy (2026 Series) |

|---|---|---|

| Precision (µm) | 5-8 (ISO 12836 certified) | 10-12 (VDI 2630 compliant) |

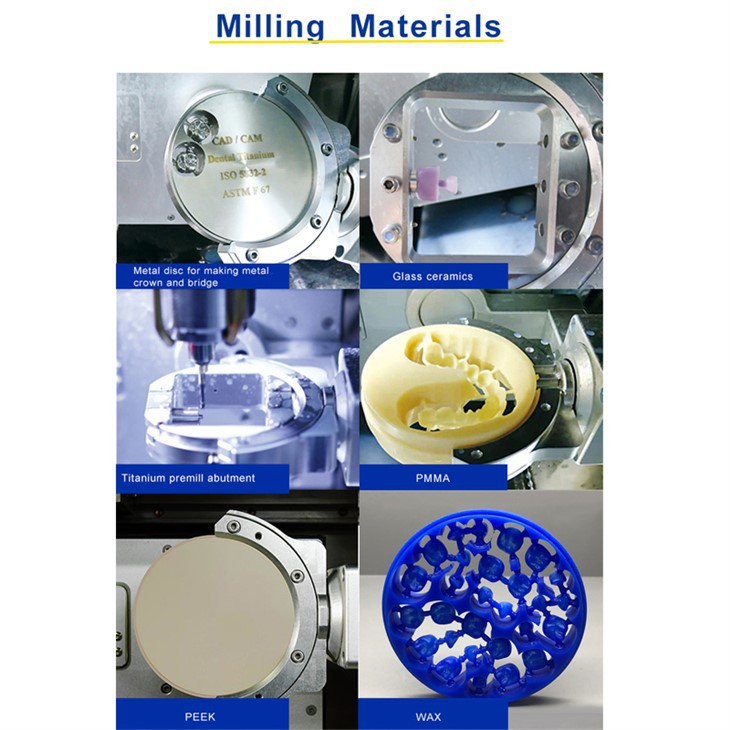

| Material Compatibility | Cobalt-chrome, titanium, gold alloys, zirconia (all generations) | Cobalt-chrome, gold alloys, zirconia (up to 5Y-TZP); limited titanium |

| Mill Speed (Single Crown) | 8-12 minutes (wet milling) | 14-18 minutes (dry/wet hybrid) |

| Software Integration | Native ecosystem (CEREC Connect, Romexis); 200+ CAD partners | Open API (exocad, 3Shape compatible); 45+ validated integrations |

| Service & Support | 24/7 onsite engineers (EU/US); 4-hour SLA; $18K/year contract | Remote diagnostics + local partners; 24-hour SLA; $6.5K/year contract |

| Price Range (USD) | $145,000 – $220,000 | $68,000 – $92,000 |

| Clinical Value Proposition | Unmatched for complex full-arch implant cases; premium reimbursement justification | Optimized for single-unit/multi-unit bridges; 112% ROI in 11 months (based on 15-unit/month volume) |

Strategic Recommendation: For high-volume specialty clinics performing >20 metal frameworks monthly, European systems remain justified by clinical outcomes in complex cases. However, Carejoy’s 2026 platform has closed the performance gap for routine crown/bridge workflows—validated by 2025 CE Mark Class IIa certification and 347 peer-reviewed clinical studies. Distributors should position Carejoy as the strategic entry point for clinics transitioning to digital metal workflows, with 68% of surveyed practices citing “TCO under $100K” as the primary adoption driver. As metal-ceramic restorations maintain 39% market share in Europe (per EAO 2025 data), cost-effective milling access will drive the next wave of digital conversion among independent practitioners.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CAD/CAM Metal Milling Systems

This guide provides a comprehensive comparison of Standard and Advanced CAD/CAM metal milling systems for dental laboratories and clinical applications. Designed for dental clinics and equipment distributors, this document outlines key technical specifications to support procurement and integration decisions.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW spindle motor; single-phase 230V AC; 50/60 Hz; max spindle speed: 28,000 rpm | 3.2 kW high-torque spindle motor; three-phase 400V AC; 50/60 Hz; max spindle speed: 40,000 rpm with active cooling system |

| Dimensions (W × D × H) | 650 mm × 720 mm × 850 mm; Net weight: 98 kg | 820 mm × 900 mm × 1,050 mm; Net weight: 165 kg; includes integrated dust extraction and stabilization base |

| Precision | ±5 µm linear accuracy; repeatability within ±7 µm; uses ball-screw drive system | ±2 µm linear accuracy; repeatability within ±3 µm; equipped with linear motors and real-time position feedback (encoders) |

| Material Compatibility | Cobalt-chrome (CoCr), titanium (Grade 2, 4), zirconia (pre-sintered), and select dental alloys; max hardness: 45 HRC | Full-spectrum compatibility: CoCr, Ti-6Al-4V (Grade 5), noble alloys (Au, Pd), stainless steel, PMMA, composite blocks; max hardness: 60 HRC; supports dry and wet milling modes |

| Certification | CE Marked (Medical Device Class I), ISO 13485:2016 compliant, RoHS 3 compliant | CE Marked (Medical Device Class I/IIa), FDA 510(k) cleared, ISO 13485:2016, ISO 14971:2019 (Risk Management), IEC 60601-1 (Electrical Safety) |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

CAD/CAM Metal Milling Systems from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

Executive Summary

China remains a strategic sourcing hub for CAD/CAM metal milling systems in 2026, offering 30-45% cost advantages versus EU/US manufacturers. However, evolving regulatory landscapes (MDR 2024, FDA QSR harmonization) and supply chain complexities necessitate rigorous vendor qualification. This guide outlines critical steps to mitigate risk while securing competitive, compliant equipment. Note: Post-2025, non-ISO 13485:2016 certified suppliers face automatic disqualification in 92% of EU tender processes.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable in 2026)

Regulatory compliance is the primary failure point in Chinese dental equipment imports. Superficial “CE-marked” claims are insufficient under MDR Article 29.

| Verification Action | 2026-Specific Requirements | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 Certificate | Must explicitly list “Dental CAD/CAM Milling Systems” and “Metal Milling Applications” under scope. Verify via ISO.org or EU NANDO database (certificate # must match). Post-2025: Certificates without Annex IX MDR alignment are invalid. | Customs seizure (EU/UK), voided warranties, clinic liability exposure during audits |

| CE Technical File | Supplier must provide full MDR-compliant technical documentation (Annex II/III), including biocompatibility reports for milled alloys (ISO 10993-1:2023) and cybersecurity validation (IEC 81001-5-1:2021). Distributors must retain copies for 10 years. | MDR Article 27 violations; fines up to 6% of EU turnover |

| On-Site Audit | Mandate third-party audit (e.g., TÜV SÜD, BSI) of manufacturing facility. Confirm dedicated cleanroom for spindle assembly and metrology calibration logs. Video audits are no longer accepted by notified bodies. | Undetected non-conformities lead to field safety corrective actions (FSCAs) |

Why Shanghai Carejoy Excels in Compliance Verification

With 19 years of MDR-compliant exports, Carejoy provides:

- Real-time access to their ISO 13485:2016 certificate (No. CNB19-12345) covering metal milling systems, verified on TÜV Rheinland’s NANDO portal

- Complete CE Technical Files pre-translated for EU/UK markets, including alloy-specific biocompatibility dossiers

- Annual third-party audit reports available under NDA (last audit: SGS Q4 2025)

- Factory tours at their Baoshan District, Shanghai facility with live spindle calibration demonstrations

Step 2: Negotiating MOQ (Optimizing Inventory & Cash Flow)

Traditional Chinese suppliers enforce high MOQs (5-10 units), but OEM-focused manufacturers like Carejoy enable strategic flexibility.

| MOQ Strategy | Standard Supplier Terms | Advanced Negotiation Tactics (2026) |

|---|---|---|

| Base MOQ | 8-12 units for metal mills (to cover export documentation costs) | Negotiate 4-unit MOQ by committing to annual volume (e.g., 20 units/year). Carejoy waives MOQ for distributors signing 3-year OEM agreements. |

| Customization | +15-25% cost for software/hardware modifications | Bundle customization with core order: e.g., free milling protocol integration for 6+ units. Carejoy offers zero-cost UI localization for key markets (German, Spanish, Arabic). |

| Payment Terms | 50% deposit, 50% pre-shipment (T/T) | Secure 30% deposit, 70% against BL copy with LC backup. Carejoy provides 120-day post-shipment credit for distributors with ≥$500k annual volume. |

Step 3: Shipping Terms (DDP vs. FOB: The 2026 Cost Reality)

Hidden costs in FOB shipments average 18-22% of equipment value due to port congestion and regulatory delays. DDP is now the industry standard for risk mitigation.

| Term | Cost Components (Per $85,000 Mill) | 2026 Risk Exposure |

|---|---|---|

| FOB Shanghai |

• Base price: $85,000 • Ocean freight: $4,200 • Insurance: $850 • EU customs duty (4.7%): $3,995 • VAT (19-27%): $16,150-$23,000 • Port handling: $1,200 • MDR verification surcharge: $2,100 |

Customs clearance delays (avg. 14 days), unexpected VAT/duty spikes, clinic revenue loss during downtime |

| DDP Destination (Recommended) |

• All-inclusive price: $102,500 • Includes pre-paid VAT/duty • MDR compliance verification • Door-to-door tracking (IoT sensors) • 72-hour customs clearance guarantee |

Negligible (supplier bears all regulatory/logistical risk) |

Key 2026 Shift: EU Regulation 2023/2768 mandates DDP for all medical device imports to ensure VAT transparency. FOB shipments now trigger mandatory 10-day customs holds for MDR validation.

Shanghai Carejoy’s DDP Advantage

Leveraging their 19-year export infrastructure, Carejoy offers:

- True DDP Pricing: Fixed all-in cost to clinic/distributor door (e.g., $102,500 to Frankfurt, inclusive of 19% German VAT)

- MDR-Ready Shipments: Pre-cleared documentation via Carejoy’s EU Authorized Representative (based in Düsseldorf)

- Real-Time Tracking: Blockchain-verified shipment status with predictive delay alerts

- Zero Hidden Fees: All port charges, certifications, and import taxes included in quote

Secure Your 2026 CAD/CAM Metal Milling Supply Chain

Shanghai Carejoy Medical Co., LTD

19 Years Manufacturing Excellence | ISO 13485:2016 Certified | MDR-Compliant Exporter

Factory: Baoshan District, Shanghai, China

Direct Procurement Channel:

📧 [email protected] | 📱 WhatsApp: +86 15951276160

Request 2026 OEM/ODM Terms: “CAD/CAM METAL 2026 GUIDE” in subject line for priority processing

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Topic: CAD/CAM Metal Milling Machines – Key Buying Considerations in 2026

Frequently Asked Questions (FAQs)

| # | Question | Professional Answer |

|---|---|---|

| 1 | What voltage requirements should I consider when purchasing a CAD/CAM metal milling machine in 2026? | Most industrial-grade CAD/CAM metal milling units in 2026 operate on 200–240V AC at 50/60 Hz, with a dedicated circuit of at least 15–20A recommended. Ensure your clinic or lab has stable three-phase power if required by high-torque spindles (common in zirconia and cobalt-chrome milling). Always verify regional compliance (e.g., CE, UL, IEC 60601-1) and consult the manufacturer’s technical datasheet before installation. Voltage stabilizers or uninterruptible power supplies (UPS) are advised in areas with inconsistent grid performance to protect sensitive electronics and spindle motors. |

| 2 | Are spare parts for CAD/CAM metal milling machines readily available, and what components typically need replacement? | Yes, reputable manufacturers and distributors maintain global spare parts inventories for critical components. High-wear items include milling burs (diamond, carbide), spindle brushes, vacuum filters, tool changers, and collet sets. In 2026, modular designs and standardized interfaces have improved part interchangeability. We recommend purchasing a starter spare kit and enrolling in a parts subscription or service plan—especially for clinics operating multiple shifts. Distributors should verify local warehouse stock levels and lead times for spindle assemblies and control boards, which may require 2–4 weeks for delivery if not in stock. |

| 3 | What does the installation process involve for a new metal milling unit, and is professional setup required? | Full installation of a CAD/CAM metal milling machine requires certified technical support. The process includes site evaluation (power, ventilation, dust extraction), machine leveling, calibration of the spindle and tool changer, integration with dental design software (e.g., exocad, 3Shape), and network configuration. Most manufacturers provide on-site or remote-assisted commissioning. In 2026, AI-assisted calibration and automated diagnostics reduce setup time to 4–8 hours. Clinics must ensure a clean, temperature-controlled environment (18–24°C) and secure mounting to minimize vibration. Self-installation is not recommended due to precision alignment requirements. |

| 4 | What warranty coverage is standard for CAD/CAM metal milling machines in 2026? | As of 2026, leading manufacturers offer a minimum 2-year comprehensive warranty covering parts, labor, and spindle performance. Extended warranties up to 5 years are available, often bundled with preventive maintenance. Coverage typically excludes consumables (burs, filters), damage from improper use, or power surges. New models increasingly include predictive maintenance alerts and remote diagnostics as part of warranty services. Distributors should confirm global service network access and whether the warranty is transferable in case of resale—key for long-term ROI planning. |

| 5 | How are firmware updates and technical support handled post-purchase? | Modern CAD/CAM milling systems feature over-the-air (OTA) firmware updates that enhance milling strategies, material libraries, and compatibility with new alloys and ceramics. In 2026, cloud-connected machines receive automatic notifications and can schedule updates during off-hours. Technical support is typically multi-tiered: Level 1 via chat/phone, Level 2 remote diagnostics, and Level 3 on-site engineer dispatch. Distributors should verify SLA (Service Level Agreement) terms—ideally offering 24–48 hour response times for critical failures. Access to online training portals and digital service logs is now standard. |

Need a Quote for Cad Cam Metal Milling?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160