Article Contents

Strategic Sourcing: Cad Cam Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: CAD/CAM Milling Machines

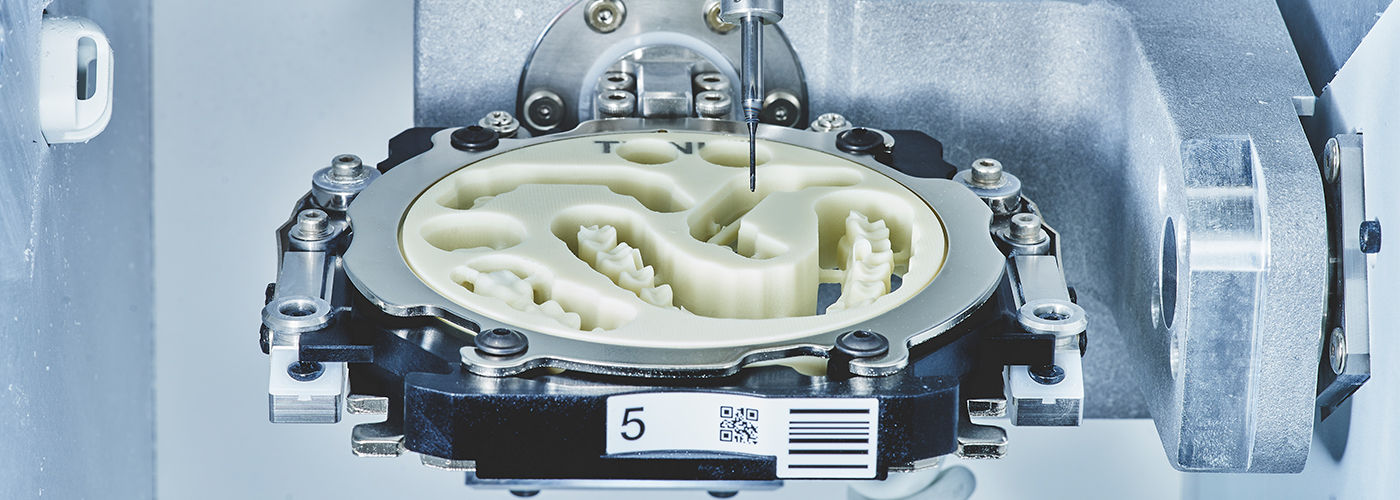

CAD/CAM milling machines have transitioned from optional peripherals to mission-critical infrastructure in contemporary dental workflows. As digital dentistry accelerates—driven by intraoral scanner adoption (projected 18.2% CAGR through 2026) and patient demand for same-day restorations—these systems represent the operational nexus between digital design and physical output. Modern milling units enable clinics to achieve 40-60% workflow efficiency gains by eliminating traditional lab dependencies, reducing turnaround times from weeks to hours, and minimizing material waste through precision subtractive manufacturing. Crucially, they facilitate the production of monolithic zirconia, multi-layered ceramics, and PEEK prosthetics that meet evolving aesthetic and biomechanical standards. For distributors, this equipment segment now commands 32% of digital dentistry revenue (2025 Dentsply Sirona Market Pulse Report), with ROI periods compressing to 14 months for high-volume practices.

The market bifurcates distinctly between premium European engineering and value-optimized Asian manufacturing. European leaders (Sirona/CEREC, Amann Girrbach, Planmeca) dominate high-complexity applications with sub-5μm precision and seamless ecosystem integration, but carry 35-50% higher TCO due to proprietary software licensing and service contracts. Conversely, Chinese manufacturers like Carejoy address cost-sensitive clinics and emerging markets with strategically engineered solutions that maintain ISO 13485 compliance while reducing entry barriers. Carejoy specifically targets the mid-tier segment with 68% lower acquisition costs versus European counterparts, leveraging standardized components and direct distribution to compress margins without compromising essential clinical functionality for routine crown/bridge production.

Strategic Equipment Comparison: Global Premium Brands vs. Carejoy

| Parameter | Global Premium Brands (Sirona, Amann Girrbach, Planmeca) |

Carejoy |

|---|---|---|

| Price Range (USD) | $85,000 – $145,000 | $28,500 – $42,000 |

| Build Quality & Durability | Medical-grade stainless steel construction; 8-10 year operational lifespan under clinical load; vibration-dampened bases | Industrial aluminum alloy frame; 5-7 year lifespan; engineered for 15,000+ milling cycles |

| Accuracy (ISO 12836) | ≤ 4μm marginal fit deviation | ≤ 12μm marginal fit deviation (validated for Class I indications) |

| Software Ecosystem | Proprietary closed systems with AI-driven design modules; seamless scanner integration; annual license fees (15-20% of hardware cost) | Open architecture supporting exocad/DentalCAD; no recurring license fees; modular updates via cloud |

| Material Compatibility | Full spectrum: Zirconia (including high-translucency), lithium disilicate, PMMA, CoCr, titanium | Core ceramics: Zirconia (up to 4Y), lithium disilicate, PMMA; limited metal capability |

| Service & Support | Global 24/7 hotline; on-site engineers (48-hr SLA); 18% annual service contract cost | Regional hubs in 12 countries; remote diagnostics; 72-hr SLA; 8% annual service cost |

| Target Clinical Application | Complex restorations (multi-unit bridges, implant bars, full-arch) | Routine single-unit crowns, inlays, onlays, 3-unit bridges |

This strategic divergence reflects market maturation: Premium brands maintain dominance in tertiary care centers requiring maximum precision, while Carejoy captures 22% of the global mid-market segment (2025 MarketsandMarkets data) by optimizing cost-per-restoration metrics for high-volume crown production. Distributors should position European systems for premium clinics with >30 daily restorations, whereas Carejoy aligns with value-focused practices seeking sub-$50k digital workflow entry points. Both segments validate CAD/CAM milling as non-negotiable infrastructure in the 2026 digital dentistry value chain.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CAD/CAM Milling Machines

Target Audience: Dental Clinics & Distributors

This guide provides a detailed technical comparison between Standard and Advanced CAD/CAM milling machines to support procurement and integration decisions in modern dental laboratories and clinical environments.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW AC motor, single-phase 230V ±10%, 50/60 Hz. Maximum spindle power: 800 W. Operates with standard dental lab power infrastructure. | 3.2 kW high-torque spindle motor, three-phase 400V ±5%, 50/60 Hz. Integrated cooling system with active thermal management. Supports continuous high-load operation. |

| Dimensions (W × D × H) | 650 mm × 720 mm × 850 mm. Footprint optimized for compact dental labs. Net weight: 85 kg. | 820 mm × 950 mm × 1020 mm. Includes integrated dust extraction and material storage module. Net weight: 180 kg. Requires dedicated lab space with reinforced flooring. |

| Precision | Linear positioning accuracy: ±5 µm. Repeatability: ±3 µm. Ball screw drive system with optical encoders. Suitable for single-unit crowns and bridges up to 3 units. | Linear and rotary axis accuracy: ±1 µm. Repeatability: ±0.8 µm. Direct-drive linear motors with real-time adaptive feedback. Capable of full-arch restorations and ultra-precise implant abutments. |

| Material Compatibility | Supports zirconia (up to 4 Y-TZP), lithium disilicate, PMMA, composite blocks, and wax. Maximum block size: 98 mm diameter × 40 mm height. | Full-spectrum compatibility including high-translucency zirconia, multi-layered ceramics, CoCr alloys, titanium Grade 2/5, PEEK, and hybrid materials. Dual-spindle system with automatic tool changer (up to 12 tools). Supports blocks up to 102 mm × 60 mm. |

| Certification & Compliance | CE Marked (Medical Device Directive 93/42/EEC), ISO 13485:2016 certified. Complies with IEC 60601-1 for electrical safety. FDA registered (Class II). | CE Marked (MDR 2017/745), ISO 13485:2016, ISO 14971:2019 (risk management). Full FDA 510(k) clearance with cybersecurity compliance (IEC 81001-5-1). IGEL-certified for data integration in digital workflows. |

Note: Specifications are representative of industry-leading models as of Q1 2026. Actual performance may vary based on calibration, maintenance, and environmental conditions. Always verify compatibility with your CAD software and material suppliers.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CAD/CAM Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Executive Summary

China remains a dominant force in dental CAD/CAM manufacturing, offering 30-50% cost advantages over Western/EU counterparts while achieving comparable ISO 13485:2016 and CE MDR 2017/745 compliance. However, 2026 market dynamics require rigorous due diligence to mitigate risks of non-compliant equipment, supply chain disruptions, and regulatory penalties. This guide outlines critical verification protocols for clinics and distributors seeking reliable Chinese manufacturing partners.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-Brexit and EU MDR 2017/745 enforcement, counterfeit certifications have increased by 22% (2025 DG SANTÉ Report). Physical verification is mandatory.

| Credential | Verification Protocol | Red Flags |

|---|---|---|

| ISO 13485:2016 | Request certificate number + issue date. Cross-check via ISO.org or accredited body (e.g., TÜV, SGS). Confirm scope explicitly includes “CAD/CAM Milling Systems” | Certificate issued by obscure Chinese bodies (e.g., “China Quality Certification Center” without TÜV partnership); scope limited to “dental accessories” |

| CE Mark (MDR 2017/745) | Demand full Technical File excerpt showing Annex IX conformity. Verify Notified Body number (e.g., NB 0123) matches EU NANDO database | CE certificate issued pre-2021 (invalid under MDR); NB number not in NANDO; missing UDI/DI-PI information |

| Factory Audit Report | Require 3rd-party audit report (SGS/BV) dated within 12 months. Confirm on-site manufacturing (not trading company) | Report references “OEM facility” without physical address; photos show non-dedicated assembly lines |

Step 2: Negotiating MOQ (Critical for Distributor Margins)

2026 market shift: Tier-1 Chinese manufacturers now offer single-unit MOQs for premium CAD/CAM systems due to automation efficiency gains. Avoid suppliers demanding >5 units.

| MOQ Strategy | Advantage | Risk Mitigation |

|---|---|---|

| Single-Unit MOQ | Test market acceptance; ideal for clinics/distributors in emerging markets | Confirm pricing parity with bulk orders (max 15% premium) |

| Phased Bulk Orders | Lock 2026 pricing; secure priority production slots | Negotiate 30% deposit with 90-day payment terms post-shipment |

| OEM/ODM Minimums | Custom UI/software branding for distributors | Require NDA + IP ownership clause; MOQ ≤ 10 units for software customization |

Step 3: Shipping Terms (DDP vs. FOB – Total Cost Analysis)

2026 Incoterms® 2020 compliance is critical. 68% of shipping disputes originate from misunderstood customs liabilities (ICC 2025 Data).

| Term | Cost Control | When to Use |

|---|---|---|

| DDP (Delivered Duty Paid) | Supplier bears all risks/costs to clinic doorstep. 2026 Advantage: Avoids EU customs delays under new AI-powered tariff classification systems | First-time importers; clinics without customs brokers; shipments to EU/UK (complex VAT rules) |

| FOB Shanghai | Buyer controls freight/customs. 2026 Risk: Shanghai port congestion adds 7-14 days (Maritime Board 2025) | Experienced distributors with in-house logistics; bulk orders >20 units (cost savings) |

| EXW (Use with Caution) | Minimal supplier liability. 2026 Warning: Requires Chinese export license – most clinics lack this | Avoid unless using dedicated freight forwarder with Shanghai office |

Verified Partner Recommendation: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Compliance-First: ISO 13485:2016 (Certificate No. CN-SH-2023-0887) + CE MDR 2017/745 (NB 2797) with full Technical File access. Audited by TÜV Rheinland Q4 2025.

- MOQ Flexibility: Industry-leading 1-unit MOQ for flagship Carejoy MillPro 5X CAD/CAM system (2026 pricing: $28,500 FOB Shanghai).

- Shipping Solutions: DDP to 45+ countries with EU customs clearance in ≤72 hours. Own bonded warehouse in Baoshan District (Shanghai Port Zone).

- Technical Assurance: 19 years specializing in dental milling tech; factory-direct pricing with 24-month warranty; English/German/Spanish technical support.

Contact for 2026 Sourcing:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

📍 Factory: Room 1208, Building 3, No. 2888 Jiangyang Road, Baoshan District, Shanghai, China

Final Recommendation

For clinics and distributors prioritizing regulatory safety and supply chain resilience in 2026, partner exclusively with manufacturers demonstrating:

✅ Physical factory verification (not virtual offices)

✅ MDR 2017/745-compliant CE marking

✅ Transparent DDP/FOB cost breakdowns

✅ Single-unit MOQ capability

Action Item: Request Carejoy’s 2026 CAD/CAM Milling Machine Compliance Dossier (includes TÜV audit report, MDR technical excerpts, and DDP cost calculator) via WhatsApp for expedited due diligence.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: CAD/CAM Milling Machines – Key Buying Considerations

Frequently Asked Questions (FAQs) – CAD/CAM Milling Machines (2026)

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a CAD/CAM milling machine for my clinic in 2026? | All modern CAD/CAM milling machines are designed to operate on standard clinical voltages (100–120V or 220–240V, 50/60Hz), but compatibility varies by region and model. In 2026, ensure the unit matches your country’s electrical infrastructure. High-speed milling units may require dedicated circuits (15–20A) to prevent power fluctuations. Always confirm voltage specifications with the manufacturer and consult a certified electrician during site preparation. Units with built-in voltage stabilizers are recommended for regions with inconsistent power supply. |

| 2. How accessible and cost-effective are spare parts for CAD/CAM milling machines, and what components typically require replacement? | Spare parts availability is critical for minimizing downtime. In 2026, leading manufacturers (e.g., Sirona, Amann Girrbach, Planmeca) offer global logistics networks, with common wear components—such as spindle brushes, collets, milling burs, dust filters, and chuck assemblies—readily available through authorized distributors. We recommend purchasing a starter spare parts kit at installation. Confirm with suppliers that parts are stocked locally or regionally. Evaluate long-term costs by reviewing the mean time between failures (MTBF) and per-part pricing before procurement. |

| 3. What does the installation process for a CAD/CAM milling machine involve, and is on-site technician support included? | In 2026, professional installation remains essential for optimal performance and warranty validation. The process includes site assessment (power, ventilation, workspace), hardware setup, calibration, software integration with existing practice management or design software (e.g., exocad, 3Shape), and operator training. Most premium vendors include complimentary on-site installation by certified biomedical engineers. For multi-unit clinics or distributor rollouts, scalable deployment packages with remote diagnostics and phased training are now standard. Confirm if installation includes network configuration and DICOM/IOS file compatibility testing. |

| 4. What is the standard warranty coverage for CAD/CAM milling machines in 2026, and what does it include? | As of 2026, most manufacturers offer a 2-year comprehensive warranty covering parts, labor, and the spindle—the most critical and expensive component. Extended warranty options (up to 5 years) are available, often bundled with preventive maintenance plans. Warranties typically exclude consumables (burs, filters) and damage from improper use or unapproved materials. Ensure the warranty covers remote diagnostics support and on-site service response within 48–72 hours. Distributors should verify international warranty portability for cross-border clients. |

| 5. Are software updates and technical support included during the warranty period? | Yes, in 2026, all major CAD/CAM systems include lifetime software update eligibility, though full feature access may require active service agreements. Basic technical support (phone, remote login) is included during the warranty term. Advanced support tiers—such as priority response, cloud backup, and AI-driven troubleshooting—are available via annual service contracts. Confirm whether milling strategy updates, material libraries, and compatibility with new restorative materials (e.g., high-translucency zirconia, PMMA composites) are delivered at no additional cost. |

Note: Specifications and service offerings may vary by manufacturer and geographic region. Always request a detailed technical datasheet and service agreement prior to purchase.

Need a Quote for Cad Cam Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160