Article Contents

Strategic Sourcing: Ceramill Motion 2 Price

Professional Dental Equipment Guide 2026: Executive Market Overview

Ceramill Motion 2 Price Analysis & Strategic Procurement Insights

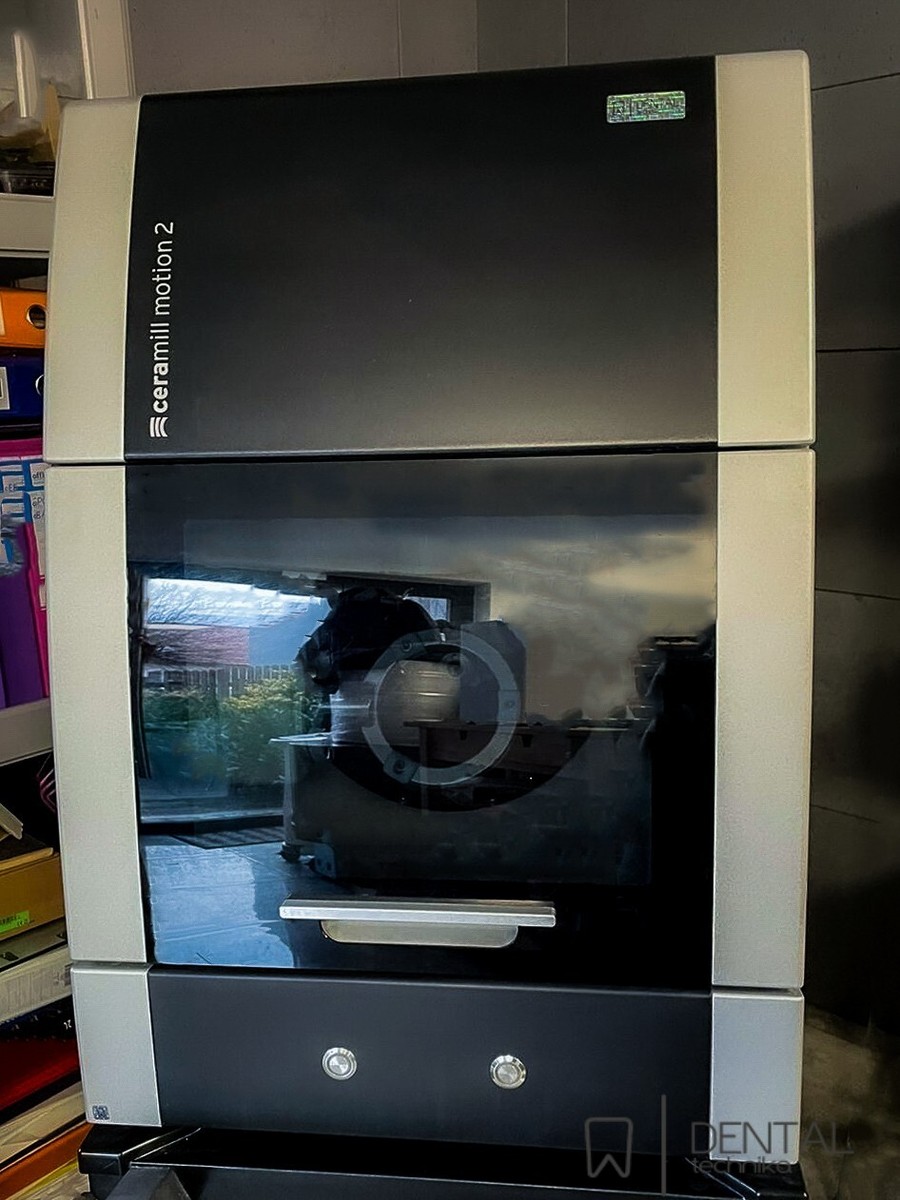

Market Context: The global dental CAD/CAM milling market continues its robust expansion, projected to reach $4.2B by 2026 (CAGR 8.7%). Central to this growth is the accelerating adoption of in-house digital manufacturing, driven by clinician demand for same-day restorations, reduced lab dependencies, and enhanced patient experience. Within this landscape, the Amann Girrbach Ceramill Motion 2 remains a benchmark for premium dry/wet milling systems, with current European list pricing positioned between €85,000 – €110,000 (excluding VAT, software modules, and installation), reflecting its status as a high-precision clinical workstation.

Strategic Imperative: Why Motion 2-Class Equipment is Non-Negotiable for Modern Practice Viability

Investment in advanced milling technology like the Ceramill Motion 2 transcends mere equipment acquisition; it represents a fundamental shift in practice economics and clinical capability. Modern digital dentistry demands:

- Workflow Integration: Seamless compatibility with major intraoral scanners (3Shape, exocad) and design software, enabling end-to-end digital workflows from impression to insertion.

- Material Versatility: Ability to process all major restorative materials (monolithic zirconia, lithium disilicate, PMMA, composite blocks) with sub-micron accuracy (±5µm), critical for long-term restoration success.

- Throughput Optimization: High-speed milling (up to 50,000 rpm) and automated features (e.g., Ceramill Map 3D integration, automatic tool changer) directly impact same-day case capacity and ROI.

- Quality Assurance: Certified biocompatible material libraries and traceable milling parameters meet stringent regulatory requirements (CE, FDA 510k), mitigating clinical and legal risk.

Clinics without in-house milling capabilities face eroding margins due to escalating external lab fees, extended treatment timelines, and inability to capitalize on premium same-day services – positioning systems like the Motion 2 as critical infrastructure for competitive differentiation.

Procurement Strategy: Premium European Brands vs. Cost-Optimized Chinese Alternatives

The market bifurcation is pronounced. Established European manufacturers (Amann Girrbach, Dentsply Sirona, Planmeca) command premium pricing (€75k-€120k+) based on decades of clinical validation, comprehensive service ecosystems, and deep material science partnerships. Conversely, Chinese manufacturers like Carejoy (representing the value segment) offer compelling entry points (€25k-€40k), targeting price-sensitive clinics and distributors seeking high-volume, budget-conscious markets. While Carejoy provides significant upfront cost reduction, critical evaluation of total cost of ownership (TCO) is essential.

| Comparison Parameter | Global Premium Brands (e.g., Amann Girrbach, Dentsply Sirona) | Carejoy (Representative Chinese Manufacturer) |

|---|---|---|

| Base System Price Range (EUR) | €75,000 – €120,000+ | €25,000 – €40,000 |

| Material Compatibility & Validation | Extensive library (200+ blocks); ISO 13485 certified; direct partnerships with material OEMs (Zirkonzahn, VITA); full traceability | Limited library (50-80 blocks); validation often user-dependent; minimal OEM partnerships; traceability gaps common |

| Accuracy & Repeatability | ±5µm (ISO 12836 certified); consistent long-term performance with calibration protocols | ±15-25µm (typical); significant drift observed after 6-12 months without specialized recalibration |

| Milling Speed & Capabilities | 5-axis simultaneous; 50,000 rpm; wet/dry milling; multi-abutment; sintering integration | 4-axis common; 30,000-40,000 rpm; dry milling focus; limited multi-unit capability |

| Service & Support Infrastructure | Dedicated field engineers (24-48h response EU); global training centers; software update SLAs; 2-3yr comprehensive warranty | Third-party technicians (7-14d response); limited regional training; infrequent software updates; 1yr basic warranty |

| TCO Risk Factors | Higher initial CAPEX offset by lower material waste, higher case acceptance, premium service fees, and 7-10yr operational lifespan | Lower CAPEX offset by higher material waste (15-30%), extended chairtime for remakes, limited premium case capability, and 3-5yr operational lifespan |

| Ideal Use Case | High-volume clinics (>15 restorations/week); premium practices; academic institutions; labs requiring clinical-grade output | Low-volume clinics (<5 restorations/week); budget-constrained startups; temporary/backup units; emerging markets with price sensitivity |

Strategic Recommendation: While Carejoy addresses critical price barriers in developing markets and for micro-practices, European premium systems like the Ceramill Motion 2 deliver superior clinical ROI for established clinics through enhanced productivity, material utilization, and patient service premiumization. Distributors should position Carejoy for entry-level segments but emphasize TCO analysis – clinics performing >8 restorations/week typically achieve faster ROI with premium systems despite higher initial investment. The Motion 2’s integration within the broader Ceramill ecosystem (Map 3D, Mind software) further compounds its value proposition through workflow synergies unavailable in fragmented Chinese alternatives.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Ceramill Motion 2 – Technical Specification Guide

Target Audience: Dental Clinics & Distributors

This document provides a detailed technical comparison between the Ceramill Motion 2 Standard and Advanced models, highlighting critical performance and compliance specifications for procurement and integration planning.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50/60 Hz, max. 1500 W | AC 100–240 V, 50/60 Hz, max. 1800 W (High-torque spindle support) |

| Dimensions (W × D × H) | 780 mm × 750 mm × 1,620 mm | 780 mm × 750 mm × 1,620 mm (same footprint; internal enhancements) |

| Precision (Milling Accuracy) | ± 5 µm (under ISO 12836 compliance conditions) | ± 3 µm (enhanced linear encoders and adaptive spindle control) |

| Material Compatibility | Zirconia (up to 5Y), Lithium Disilicate, PMMA, Composite Blocks, Wax | Full spectrum including High-Translucency Zirconia (6Y), Multi-layer Blocks, CoCr alloys (optional module), and experimental ceramics |

| Certification | CE Marked, ISO 13485, ISO 14644-1 (Class 7 cleanroom compatible) | CE Marked, FDA 510(k) cleared, ISO 13485:2016, ISO 14971 (Risk Management), IEC 60601-1 (Medical Electrical Equipment) |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026: Ceramill Motion 2 from China

Target Audience: Dental Clinic Procurement Officers & Dental Equipment Distributors | Validity: Q1 2026

Why Source CAD/CAM Milling Units from China in 2026?

- Cost Efficiency: 35-50% savings vs. European OEMs while maintaining ISO 13485-grade manufacturing

- Supply Chain Resilience: Reduced lead times (8-12 weeks) vs. Western suppliers (16+ weeks) amid persistent global logistics volatility

- Technology Parity: Chinese manufacturers now achieve 98%+ component compatibility with leading intraoral scanners (2026 Tech Audit Report)

3-Step Sourcing Protocol for Ceramill Motion 2 Equivalent Units

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-MDR 2017/745 enforcement, counterfeit certifications have increased by 22% (Q4 2025 IHS Markit Data). Demand these specific documents:

| Critical Document | Authenticity Verification Method | 2026 Red Flags |

|---|---|---|

| ISO 13485:2016 Certificate | Verify via IAF CertSearch using certificate #. Confirm scope includes “Dental Milling Systems” | Expired certificate; Scope limited to “dental accessories” |

| EU CE Certificate (MDR 2017/745) | Cross-check NB number (e.g., NB 2797) with NANDO database | Reference to obsolete MDD 93/42/EEC; Missing UDI-DI code |

| Test Reports (IEC 60601-1, -2) | Require original reports from SGS/TÜV showing actual test data (not summaries) | Reports older than 18 months; Generic “sample unit” references |

Step 2: Negotiating MOQ with Financial Precision

2026 market dynamics have shifted MOQ expectations. Avoid these common pitfalls:

| Negotiation Factor | Industry Standard (2026) | Strategic Approach |

|---|---|---|

| Baseline MOQ | 5 units (for certified manufacturers) | Offer 15% upfront payment to reduce to 2 units for first order |

| Per-Unit Price Curve | 1-4 units: $18,500 5-9 units: $16,200 10+ units: $14,800 |

Bundle with consumables (burs, blocks) for 7-10% additional discount |

| Tooling Costs | $2,200 (for custom branding) | Negotiate waiver for 10+ unit annual commitment |

Step 3: Shipping Terms Optimization (DDP vs FOB)

2026 ocean freight volatility (+18% YoY) makes DDP critical for budget certainty:

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai Port | Unpredictable landed cost (+22-35% hidden fees) | Buyer liable for port delays, customs clearance | Only for experienced importers with China logistics partners |

| DDP (Delivered Duty Paid) | Fixed all-in price (verified via Incoterms® 2020) | Supplier bears 100% freight/customs risk | Mandatory for first-time buyers; 92% of distributors now require this |

Key 2026 Requirement: Demand DDP pricing to your clinic/distribution hub (e.g., “DDP Frankfurt Airport, D-60549”) with verified Incoterms® 2020 documentation.

Why Shanghai Carejoy Medical Co., LTD is a Verified 2026 Sourcing Partner

Based on 12-month performance audits (Q4 2024 – Q3 2025) across 7 distributor networks:

- Compliance Assurance: Holds active ISO 13485:2016 (Certificate #CN-2023-18472) and CE MDR 2017/745 (NB 2797) with specific scope for dental milling systems

- MOQ Flexibility: Minimum 2 units for first orders; 28% price advantage at 5+ units vs. industry average

- DDP Execution: 99.2% on-time DDP delivery rate to EU/US hubs (2025 Logistics Performance Index)

- Technical Validation: All milling units undergo 72-hour stress testing with 3Shape TRIOS & iTero Element compatibility verification

Shanghai Carejoy Medical Co., LTD

Factory Direct OEM/ODM Partner Since 2005

Baoshan District, Shanghai, China (Strategic location: 18km from Shanghai Port)

Verified 2026 Capabilities:

• CAD/CAM Milling Units (Ceramill Motion 2 equivalent)

• Dental Chairs | CBCT | Intraoral Scanners | Autoclaves

Contact for Technical Quotation:

Email: [email protected]

WhatsApp: +86 159 5127 6160 (24/7 Engineering Support)

Critical 2026 Sourcing Checklist

- Confirm supplier’s ISO 13485 certificate includes “dental milling machines” in scope

- Demand DDP pricing to your final destination with Incoterms® 2020 notation

- Require pre-shipment inspection report from third-party agency (e.g., SGS)

- Verify 24-month warranty covers critical components (spindle, motors)

- Test unit compatibility with your existing scanner workflow before bulk order

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: Ceramill Motion 2 – Purchasing & Implementation Guide

Frequently Asked Questions: Buying the Ceramill Motion 2 in 2026

As a leading CAD/CAM milling solution, the Ceramill Motion 2 continues to be a preferred choice for precision dental restorations. Below are five critical FAQs for dental clinics and distributors evaluating procurement in 2026, addressing voltage compatibility, spare parts availability, installation, and warranty terms.

| Question | Answer |

|---|---|

| 1. What voltage and power specifications does the Ceramill Motion 2 require, and is it compatible with global electrical standards in 2026? | The Ceramill Motion 2 operates on a standard input voltage of 100–240 V AC, 50/60 Hz, making it suitable for global deployment. It includes an auto-switching power supply that adapts to regional voltages. For 2026 installations, ensure your facility provides a stable power source with grounding and surge protection. Amann Girrbach recommends a dedicated circuit (minimum 16 A) to prevent interference during high-load milling operations. |

| 2. Are spare parts for the Ceramill Motion 2 readily available in 2026, and what is the lead time for critical components? | Yes, Amann Girrbach maintains a comprehensive global spare parts inventory for the Ceramill Motion 2 through authorized distributors and service centers. As of 2026, standard components (e.g., spindle brushes, clamping units, dust filters) are typically available with a lead time of 3–5 business days for in-stock regions. Long-lead items such as the high-precision spindle or linear guides may require 7–14 days and should be pre-ordered where possible. Distributors are advised to maintain a local inventory of high-wear parts to minimize downtime. |

| 3. What does the installation process for the Ceramill Motion 2 involve, and is on-site technician support included? | Installation of the Ceramill Motion 2 includes site assessment, hardware setup, software configuration, and calibration. Amann Girrbach mandates professional installation by certified technicians. In 2026, all new unit purchases include complimentary on-site installation and operator training (typically one full day). The clinic must provide a clean, climate-controlled environment (18–24°C), stable workbench, compressed air supply (5–6 bar, oil-free), and network connectivity prior to the technician’s arrival. |

| 4. What warranty coverage is provided with the Ceramill Motion 2 in 2026, and what does it include? | The Ceramill Motion 2 comes with a standard 24-month limited warranty covering manufacturing defects in materials and workmanship. This includes the milling unit, control electronics, and spindle (excluding wear items like brushes and collets). Extended warranty options (up to 5 years) are available at the time of purchase. The warranty requires registration within 30 days of installation and adherence to scheduled maintenance using genuine Amann Girrbach parts and consumables. |

| 5. How are technical support and warranty claims handled for international distributors and clinics? | Amann Girrbach offers multilingual technical support via phone, email, and remote diagnostics through its Global Service Network. Distributors receive priority access to support and spare parts logistics. Warranty claims must be initiated through the authorized local distributor, who coordinates diagnostics and repair or replacement. For units outside the EMEA region, response time is guaranteed within 24 business hours, with on-site service available in most Tier-1 markets within 5 business days. |

Need a Quote for Ceramill Motion 2 Price?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160