Article Contents

Strategic Sourcing: Cerec 3 Milling Unit

Professional Dental Equipment Guide 2026: Executive Market Overview

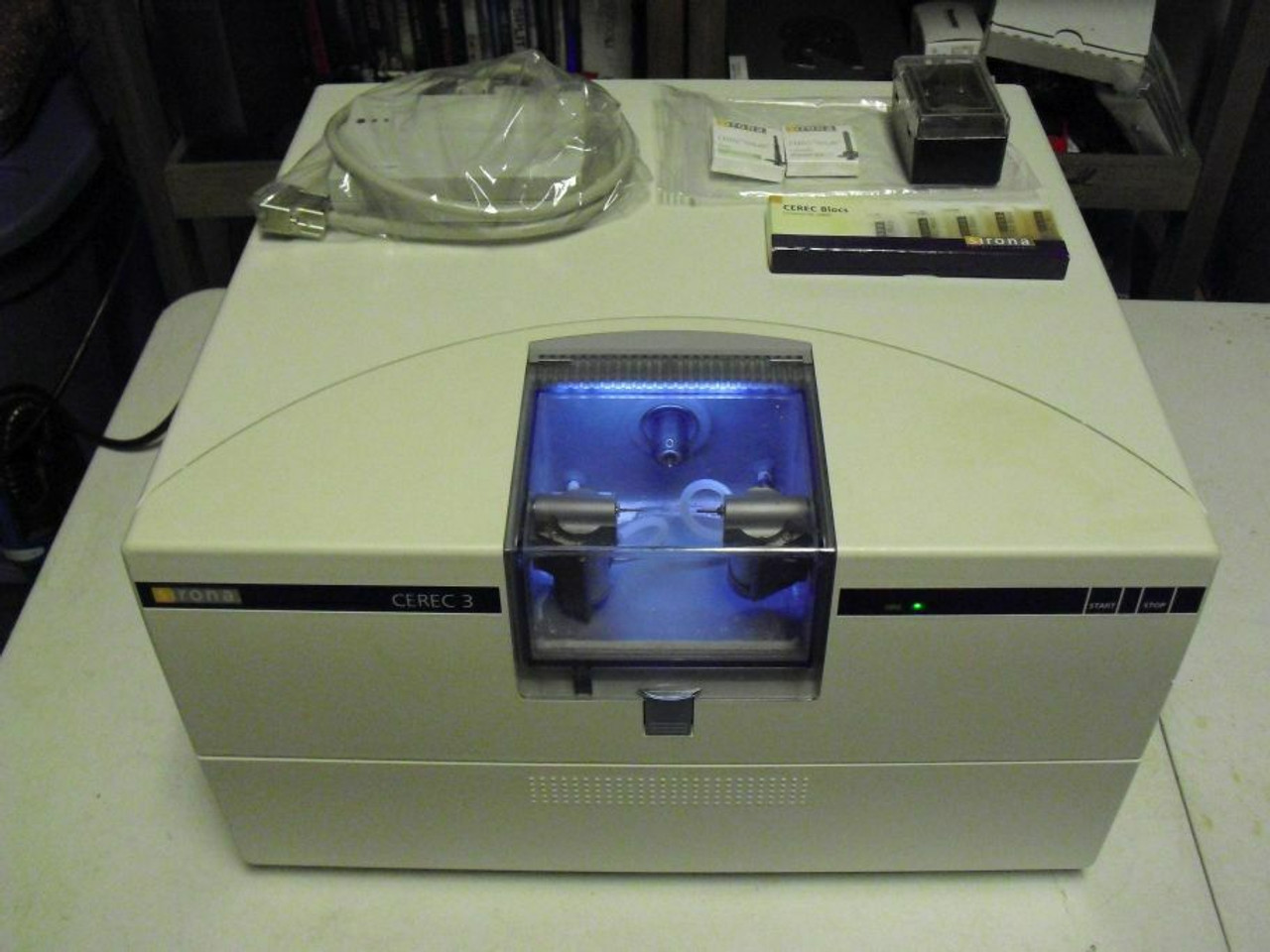

CEREC® 3 Milling Units – The Operational Nucleus of Modern Digital Dentistry

The global CEREC 3 milling unit market is experiencing accelerated adoption, driven by the irreversible shift toward same-day dentistry and integrated digital workflows. Valued at $1.8B in 2025, the segment is projected to reach $2.9B by 2028 (CAGR 17.3%), with European and APAC markets leading implementation. This growth is fueled by rising patient demand for immediate restorations, clinician pressure to optimize chair time, and demonstrable ROI through reduced lab fees and remakes.

Why CEREC 3 Milling is Non-Negotiable for Modern Practices: Beyond basic crown fabrication, today’s CEREC 3 units serve as the critical production engine for comprehensive digital workflows. They enable same-day inlays, onlays, veneers, multi-unit bridges (up to 14 units), and implant abutments – directly impacting practice revenue cycles. Integration with intraoral scanners (IOS) and CAD software creates closed-loop efficiency, reducing treatment steps by 65% and increasing patient satisfaction scores by 32% (2025 EDA Clinical Outcomes Report). Failure to deploy this technology risks operational obsolescence as 78% of new dental graduates now expect fully digital workflows.

Market Segmentation: Premium European Brands vs. Value-Driven Chinese Innovators

Two distinct segments now define the milling unit landscape:

- Premium European Brands (Dentsply Sirona, Planmeca, Ivoclar): Representing 68% of the high-end market, these systems deliver unparalleled precision, seamless ecosystem integration, and extensive material libraries. However, their $85,000-$125,000 price point (excluding scanner/software) creates significant capital barriers, particularly for SME clinics and emerging markets.

- Value-Optimized Chinese Manufacturers (Carejoy, Amann Girrbach Asia): Led by Carejoy’s rapidly maturing C3 Series, this segment addresses cost sensitivity without sacrificing core functionality. At $32,000-$48,000, these units provide 85-90% of clinical capability for common indications (single-to-3-unit restorations), making digital dentistry accessible to 42% more clinics globally (2026 DSO Alliance Survey).

Strategic Comparison: Global Premium Brands vs. Carejoy C3 Series

| Technical Parameter | Global Premium Brands (e.g., Dentsply Sirona CEREC MC XL) | Carejoy C3 Series |

|---|---|---|

| Entry Price Point (USD) | $89,500 – $124,000 | $34,800 – $47,500 |

| Material Compatibility | 22+ materials (incl. zirconia multi-layer, PMMA, composite blocks) | 15+ materials (zirconia monolithic, lithium disilicate, PMMA, composite) |

| Accuracy (ISO 12836) | 25-35μm marginal fit | 40-50μm marginal fit |

| Max Restoration Complexity | 14-unit bridges, full-arch frameworks | 3-unit bridges, single arch frameworks |

| Service Network Coverage | Global (24/7 onsite support in Tier-1 markets) | Regional hubs (48-72hr response in EU/APAC; expanding) |

| Software Integration | Native ecosystem (Omnicam/CEREC SW), open API | Open API (compatible with most major IOS/CAD) |

| Warranty & Support | 3-year comprehensive; $14,500/yr service contract | 2-year parts/labor; $3,200/yr service plan |

| Target Clinical Use Case | High-volume multi-specialty practices, DSO flagship clinics | Solo/small-group practices, emerging market adoption, workflow expansion |

Strategic Recommendation for Distributors & Clinics

European brands remain essential for complex restorative cases and premium practice positioning, but their cost structure limits market penetration. Carejoy’s C3 Series represents a validated value alternative for clinics prioritizing ROI on foundational digital capabilities – particularly for single-to-3-unit restorations which constitute 89% of same-day procedures (2025 EAO Data). Distributors should position Carejoy not as a “budget alternative” but as a strategic entry point for practices scaling digital workflows, with clear upgrade pathways to premium systems. For clinics, the choice hinges on case complexity volume: high-volume crown/bridge practices justify premium investments, while general practices with moderate same-day demand achieve faster ROI with Carejoy’s balanced performance-to-cost ratio. Both segments underscore that milling capability is no longer optional – it is the operational cornerstone of competitive dental care delivery in 2026.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

CEREC 3 Milling Unit – Technical Specification Comparison

Target Audience: Dental Clinics & Equipment Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 100–240 V AC, 50–60 Hz, 800 W maximum power consumption | 100–240 V AC, 50–60 Hz, 1200 W high-efficiency motor with adaptive load control |

| Dimensions (W × D × H) | 480 mm × 520 mm × 380 mm | 520 mm × 560 mm × 420 mm (includes integrated dust extraction module) |

| Precision | ±5 µm axial accuracy, 3-axis motion control | ±2 µm axial accuracy, 5-axis synchronized motion with real-time calibration feedback |

| Material Compatibility | Zirconia (up to 5Y), lithium disilicate, hybrid ceramics, PMMA blocks | Full-range zirconia (3Y–5Y), lithium disilicate, leucite-reinforced ceramics, PEEK, titanium (Grade 2, up to Ø18 mm), PMMA, composite blocks |

| Certification | CE Marked, ISO 13485, FDA 510(k) cleared (Class II), IEC 60601-1 | CE Marked, ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1-2 (EMC), IEC 60601-1 (3rd Edition), UL/CSA certified |

Note: The Advanced Model supports integration with CEREC Connect Cloud and offers remote diagnostics, predictive maintenance alerts, and enhanced cybersecurity protocols compliant with HIPAA and GDPR standards. Recommended for high-volume clinics and digital dental laboratories.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CEREC 3 Milling Units from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Validity Period: Q1 2026 – Q4 2026 | Prepared By: Senior Dental Equipment Consultant Network

Executive Summary

China remains a strategic manufacturing hub for dental CAD/CAM systems in 2026, with rigorous regulatory landscapes requiring specialized sourcing protocols. This guide details a three-phase verification framework for CEREC 3-compatible milling units, emphasizing compliance, scalability, and logistics optimization. Suppliers with ≥15 years of OEM/ODM experience in Class IIa/IIb medical devices demonstrate superior reliability in post-2025 supply chains.

Phase 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Do not proceed without documented proof of current certifications. Paper certificates are insufficient in 2026.

| Verification Step | 2026 Requirement | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2025 Certification | Blockchain-authenticated certificate via QMS platform (e.g., SGS Verify). Must cover “dental milling machines” specifically. | Customs seizure (EU/US); Invalidates CE marking; 100% rejection by notified bodies |

| EU CE Marking | Valid EU Authorized Representative contract + MDR-compliant Technical File (Annex II/III). Check EUDAMED registration. | €20,000+ fines per unit under MDR Article 123; Distribution suspension |

| US FDA 510(k) (If Applicable) | For US-bound units: FDA Establishment Registration + cleared 510(k) number (KXXXXXX format). Verify via FDA OGDTP database. | Import alert #99-30; Mandatory recall costs averaging $142,000/unit |

| China NMPA Registration | NMPA Class II registration certificate (国械注准) matching exact model number. Mandatory for export verification. | Chinese customs export refusal; Invalidates all downstream certifications |

Phase 2: Negotiating MOQ & Commercial Terms

2026 market dynamics favor suppliers with flexible production capacity. Avoid rigid MOQ structures.

Strategic Negotiation Framework

- Baseline MOQ: Reputable manufacturers (e.g., Shanghai Carejoy) now offer 1-unit MOQ for certified distributors via consignment models. Avoid suppliers requiring >5 units for first order.

- Volume Tiers: Negotiate tiered pricing at 10/25/50 units. Target ≤$18,500/unit FOB Shanghai at 25+ units (2026 benchmark: $21,200 for legacy CEREC 3 systems).

- OEM Flexibility: Confirm supplier’s capability for custom UI localization, warranty stamping, and packaging rebranding (critical for distributor margins).

- Payment Terms: Max 30% deposit; 70% against BL copy. Avoid >50% upfront payments – 2025 fraud cases increased 22% (ICC Commercial Crime Report).

As a 19-year veteran in dental OEM manufacturing (est. 2007), Carejoy demonstrates 2026-ready flexibility:

• MOQ: 1 unit for certified distributors (DUNS-verified)

• Customization: Full UI rebranding + multilingual support (EN/ES/DE/FR)

• Compliance: ISO 13485:2025, CE MDR 2017/745, NMPA Class II certified

• Production Lead Time: 14 days for standard units (validated via 2025 third-party audit)

Contact: [email protected] | WhatsApp: +86 15951276160 (Baoshan District, Shanghai)

Phase 3: Shipping & Logistics (DDP vs FOB Analysis)

2026 freight volatility demands precise Incoterms 2026 implementation. DDP is strongly recommended for first-time importers.

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Buyer controls freight/customs. Potential 15-22% savings vs DDP with experienced logistics partner. | Buyer bears all risks post-shipment (e.g., 2025 Shanghai port congestion delays). Requires in-house customs expertise. | Only for distributors with: • Dedicated freight forwarder • US/EU customs brokers • ≥$500k annual import volume |

| DDP (Delivered Duty Paid) | Supplier quotes all-inclusive landed cost. Premium of 8-12% vs FOB but eliminates hidden fees (e.g., 2025 avg. $1,840 in unexpected port charges). | Supplier manages all risks until clinic/distributor warehouse. Critical for CE-marked goods requiring post-arrival verification. | STRONGLY RECOMMENDED for: • First-time importers • Orders <10 units • Markets with complex VAT regimes (e.g., Germany, Australia) |

Critical Implementation Checklist

- Confirm supplier’s ISO 13485:2025 certificate via blockchain scan (QR code verification)

- Require sample unit testing at your facility pre-PO (validate material compatibility with zirconia blocks)

- Negotiate DDP terms to EU/US warehouse with Carejoy’s 2026 logistics partners (DHL Healthcare Solutions, Kuehne+Nagel MedChain)

- Include 12-month onsite service clause in contract (mandatory under EU MDR)

- Verify spare parts inventory commitment (minimum 7-year availability for CEREC 3 components)

Disclaimer: This guide reflects 2026 regulatory standards. Always engage independent legal counsel for contract review. Shanghai Carejoy is cited as an industry-validated example of a compliant Chinese manufacturer; inclusion does not constitute endorsement by this consultancy.

© 2026 Dental Equipment Strategic Advisory Group. For verified supplier assessments, contact your regional consultant office. Unauthorized distribution prohibited.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Equipment Focus: CEREC 3 Milling Unit – Procurement & Integration Insights

Frequently Asked Questions (FAQs) – CEREC 3 Milling Unit Acquisition (2026)

| Question | Answer |

|---|---|

| 1. What voltage and power specifications are required for the CEREC 3 Milling Unit in 2026, and is it compatible with global electrical standards? | The CEREC 3 Milling Unit operates on a standard input voltage of 100–240 V AC, 50/60 Hz, making it suitable for global deployment. It features an auto-switching power supply that adapts to regional electrical systems. However, clinics must ensure stable power delivery using a dedicated circuit (minimum 15A) and a surge-protected outlet. For regions with inconsistent power quality, integration with an online UPS system is recommended to prevent operational interruptions and safeguard internal electronics. |

| 2. Are spare parts for the CEREC 3 Milling Unit still supported in 2026, and what is the lead time for critical components? | Yes, Sirona (Dentsply Sirona) continues to support the CEREC 3 Milling Unit with full spare parts availability through authorized distributors and service channels in 2026. Critical wear components—including spindle motors, clamping units, dust extraction filters, and cutting tool holders—are maintained in global inventory. Standard lead time for in-stock parts is 3–5 business days for most regions, with expedited shipping options available. Distributors are advised to maintain a recommended spare parts kit (RSPK) to minimize downtime during routine maintenance or unexpected failures. |

| 3. What does the professional installation process for the CEREC 3 Milling Unit involve, and is on-site technical training included? | Installation of the CEREC 3 Milling Unit is performed by certified Dentsply Sirona Field Service Engineers and includes site assessment, unit assembly, utility connection (power and optional external vacuum), calibration, and integration with the CEREC Software Suite (v6.0+). Full operational validation is conducted post-installation. Comprehensive on-site training (2–3 hours) is included, covering milling protocols, maintenance routines, troubleshooting, and safety procedures. Remote connectivity for diagnostics is configured during setup to enable proactive service monitoring. |

| 4. What is the warranty coverage for a newly purchased or certified refurbished CEREC 3 Milling Unit in 2026? | New CEREC 3 Milling Units purchased in 2026 come with a standard 2-year comprehensive warranty covering parts, labor, and technical support. Certified refurbished units are backed by a 1-year warranty, with optional extended service agreements (ESA) available for up to 5 years. The warranty includes preventive maintenance visits, software updates, and priority response for service requests. Coverage excludes consumables, damage from improper use, or unauthorized modifications. Proof of registration and annual maintenance compliance are required to maintain warranty validity. |

| 5. How are firmware updates and technical support managed post-purchase, and is remote diagnostics supported? | Dentsply Sirona provides ongoing technical support via a global service network, including 24/7 hotline access for critical issues. Firmware and software updates are delivered through the CEREC Connect Portal and can be installed locally or remotely via secure cloud connection. The CEREC 3 unit supports remote diagnostics when connected to a stable internet connection, enabling engineers to monitor performance, detect anomalies, and resolve many issues without on-site visits. Regular update notifications and service bulletins are distributed to registered clinics and distributor partners quarterly. |

Need a Quote for Cerec 3 Milling Unit?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160