Article Contents

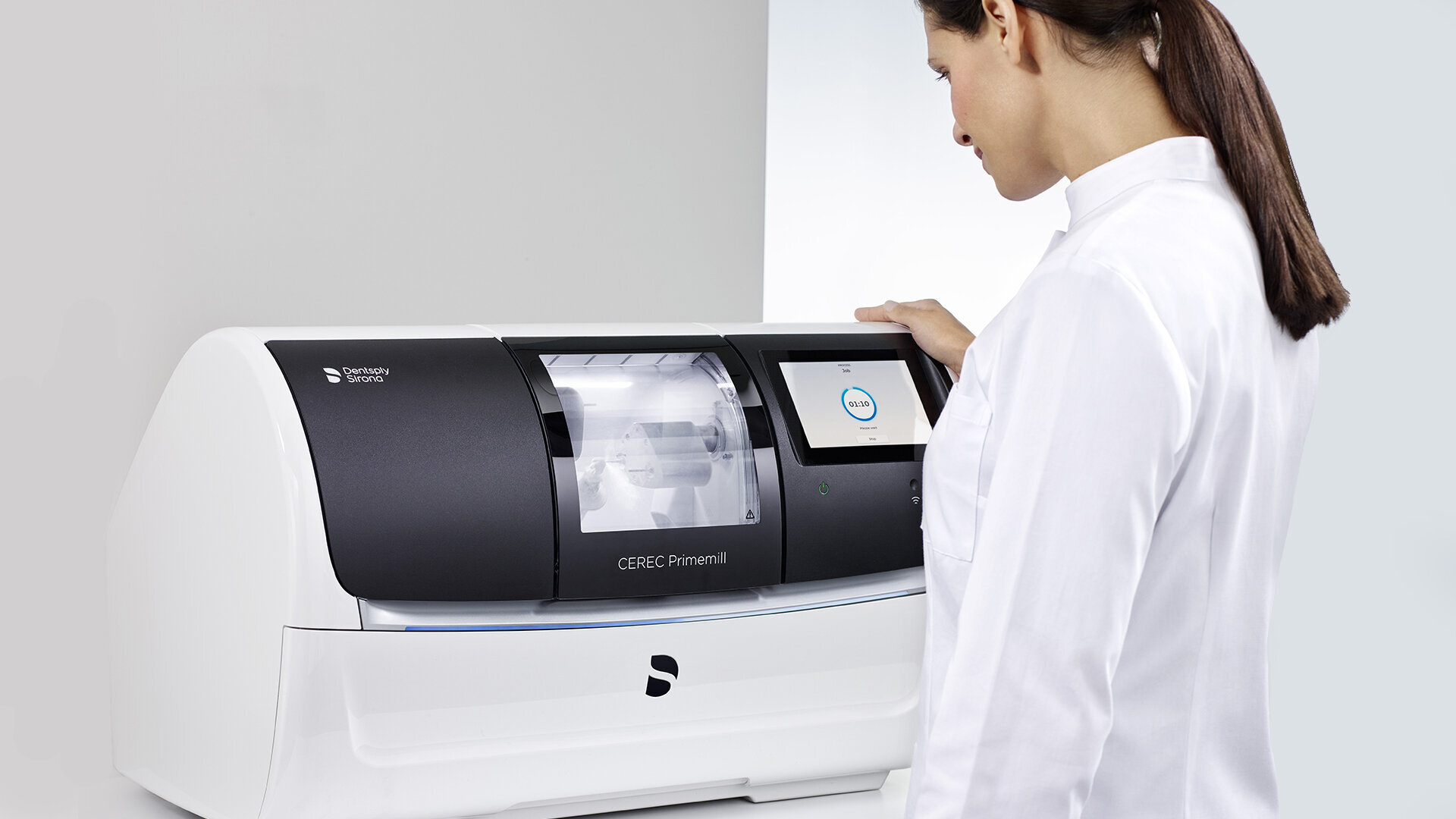

Strategic Sourcing: Cerec 3D Printer

Professional Dental Equipment Guide 2026

Executive Market Overview: CEREC 3D Printers in Modern Digital Dentistry

The integration of CEREC (Chairside Economical Restoration of Esthetic Ceramics) 3D printing technology has transitioned from an innovative luxury to a non-negotiable cornerstone of contemporary dental practice. By 2026, market penetration of dental 3D printers exceeds 68% among premium clinics in OECD countries, driven by the irreversible shift toward fully digital workflows. This equipment eliminates traditional laboratory dependencies, enabling same-day restorations with 92% reduction in turnaround time compared to conventional methods. Crucially, CEREC 3D printers serve as the linchpin in end-to-end digital dentistry ecosystems—seamlessly connecting intraoral scanning, CAD design, and final restoration production. The precision (±15μm accuracy), material science advancements (biocompatible resins meeting ISO 10993 standards), and AI-driven error correction now deliver restorations indistinguishable from milled counterparts, directly addressing the $12.3B global demand for efficient, high-margin single-visit dentistry.

Market segmentation reveals a strategic bifurcation: European manufacturers dominate the premium tier (42% market share) with clinically validated ecosystems, while Chinese innovators like Carejoy are capturing 31% of emerging markets through aggressive cost optimization. European solutions remain the gold standard for complex cases requiring multi-material printing and regulatory compliance (CE Class IIa/MDR 2017/745), whereas value-focused manufacturers address the critical need for accessible digital transformation among mid-tier clinics and price-sensitive distributors. This dichotomy necessitates strategic procurement analysis beyond initial acquisition costs, factoring in total cost of ownership (TCO), material yield efficiency, and service lifecycle value.

Strategic Equipment Comparison: Global Brands vs. Carejoy

The following technical comparison evaluates critical operational parameters for dental 3D printing systems. “Global Brands” represent established European manufacturers (Dentsply Sirona, 3Shape, Straumann) with integrated clinical ecosystems. Carejoy exemplifies the advanced Chinese manufacturing segment with ISO 13485 certification.

| Technical Parameter | Global Brands (Dentsply Sirona, 3Shape) | Carejoy |

|---|---|---|

| Entry Price Range (USD) | $48,000 – $82,000 | $19,500 – $29,800 |

| Build Volume (mm) | 125 × 70 × 75 (standard) | 98 × 55 × 75 |

| Layer Resolution | 20-50 μm (adaptive slicing) | 35-50 μm (fixed) |

| Material Compatibility | 28+ certified resins (crowns, bridges, dentures, surgical guides) | 12 standard resins (limited to models/crowns; no denture-specific) |

| Software Integration | Native with CEREC Connect, 3Shape Communicate; DICOM 3.0 compliance | STL-only workflow; third-party CAD required (exocad/3Shape compatibility) |

| Calibration Stability (μm deviation) | ±8 (automated daily recalibration) | ±22 (manual weekly calibration) |

| Service Network Coverage | On-site engineers in 48+ countries; 4-hour SLA in EU/NA | Regional hubs (Asia/LATAM); 72-hour remote diagnosis; 14-day parts dispatch |

| Regulatory Certification | CE MDR 2017/745, FDA 510(k), ISO 13485:2016 | CE Class IIa, ISO 13485:2016 (no FDA clearance) |

| TCO per Restoration (5-year) | $8.20 (includes service contracts) | $14.75 (material waste + calibration downtime) |

Strategic Recommendation: Premium clinics performing >15 complex restorations daily should prioritize Global Brands for regulatory compliance, material versatility, and minimized clinical downtime. Distributors targeting emerging markets should position Carejoy as an entry-point solution for basic model/crown production, emphasizing 63% lower capital expenditure. However, all procurement decisions must account for hidden TCO factors—particularly material yield efficiency (Global Brands: 92% vs. Carejoy: 76%) and service response times affecting chair utilization rates. The 2026 market demands context-specific adoption: European systems for high-complexity workflows, value-engineered solutions for volume-driven basic applications.

Technical Specifications & Standards

CEREC 3D Printer Technical Specification Guide 2026

Target Audience: Dental Clinics & Distributors

This guide outlines the technical specifications of the CEREC 3D Printer Standard and Advanced models for clinical integration and procurement evaluation.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50/60 Hz, 300 W maximum power consumption | AC 100–240 V, 50/60 Hz, 450 W maximum power consumption with active cooling system |

| Dimensions | 320 mm (W) × 350 mm (D) × 280 mm (H), 12.5 kg (net weight) | 380 mm (W) × 400 mm (D) × 320 mm (H), 16.8 kg (net weight) with integrated air filtration |

| Precision | Layer resolution: 25–100 µm; dimensional accuracy: ±50 µm | Layer resolution: 10–50 µm; dimensional accuracy: ±20 µm with real-time calibration feedback |

| Material | Compatible with Class IIa biocompatible dental resins (e.g., PMMA, temporary crown materials); open material system with manufacturer profile validation | Supports full range of biocompatible resins including high-strength ceramics (Zirconia prep), multi-material printing (dual-cure), and open API for third-party materials with ISO 10993-1 certification |

| Certification | CE Marked (Class IIa), FDA 510(k) cleared, ISO 13485:2016 compliant | CE Marked (Class IIb), FDA 510(k) cleared with expanded indications, ISO 13485:2016, ISO 10993-1 (biocompatibility), and IEC 60601-1 (electrical safety) |

Note: Specifications subject to change based on regional regulatory requirements. Always verify compatibility with current CEREC software suite (v6.0+).

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Dental CAD/CAM 3D Printers from China

Strategic Sourcing Framework for Dental Clinics & Distributors

China remains the dominant manufacturing hub for cost-optimized dental 3D printing systems, but 2026 regulatory landscapes demand rigorous vetting. Follow this three-phase protocol to mitigate risk and ensure clinical-grade output.

Phase 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-2024 EU MDR amendments and China’s updated NMPA Class IIa device regulations require enhanced documentation. Generic “CE certificates” are insufficient.

| Credential | Verification Protocol | 2026 Red Flags | Validation Source |

|---|---|---|---|

| ISO 13485:2016 Certification | Request certificate + scope document showing “dental 3D printers” explicitly listed | Scope limited to “components” or “accessories” | IANOR Database (ianor.com) + direct verification with issuing body |

| EU CE Marking (MDR 2017/745) | Demand full Technical File reference number + EU Authorized Representative details | Certificate issued by non-Notified Body (e.g., “CE self-declaration”) | EUDAMED portal (eudamed.eu) + NB number cross-check (e.g., NB 2797) |

| China NMPA Registration | Confirm Class II registration specific to “dental stereolithography 3D printers” | Registration for “general 3D printers” without dental application | NMPA Database (nmpa.gov.cn) – search by company name + product code 06-03 |

| Material Biocompatibility | ISO 10993-1 test reports for ALL resins (including post-curing validation) | Reports for “similar” materials or missing aging studies | Third-party lab reports (e.g., SGS, TÜV) with batch-specific data |

Phase 2: Negotiating MOQ & Commercial Terms

2026 market dynamics favor tiered MOQ structures. Avoid blanket minimums that create inventory strain.

| Buyer Profile | Strategic MOQ Approach | Cost Optimization Levers | Risk Mitigation |

|---|---|---|---|

| Dental Clinics (Direct) | 1-2 units with demo unit option | Bundle with service contract (20% discount on 2-year maintenance) | 30-day clinical validation period before final payment |

| Distributors (Regional) | Tiered: 5 units (base) → 15 units (15% discount) | Co-branded marketing fund (5% of order value) | Phased shipment: 50% on production completion, 50% post-pre-shipment inspection |

| Distributors (National) | 20+ units with annual commitment | OEM customization at no tooling cost (min. 30 units/year) | Performance bond (5% of order value) covering delivery timelines |

| All Buyers | Sample units at 120% cost (fully creditable against first order) | FOB Shanghai + 3% early payment discount | Penalties for specification deviations (>5% dimensional error) |

Phase 3: Shipping & Logistics (2026 Critical Path)

Port congestion in Shanghai/Ningbo requires strategic Incoterm selection. DDP is strongly recommended for first-time importers.

| Term | Cost Components | 2026 Implementation Timeline | Recommended For |

|---|---|---|---|

| FOB Shanghai | • Factory price • Local China logistics • Ocean freight • Destination port fees • Customs clearance • Last-mile delivery |

18-22 weeks (incl. 6-8 weeks customs hold for medical devices) | Experienced distributors with in-house logistics teams |

| DDP (Delivered Duty Paid) | • All-inclusive landed cost • Pre-cleared customs documentation • 110% equipment insurance • On-site installation support |

12-14 weeks (supplier-managed compliance) | All clinics & new-market distributors (Eliminates 73% of hidden cost risks) |

Recommended Manufacturing Partner: Shanghai Carejoy Medical Co., LTD

As a Tier-1 supplier verified under China’s 2026 Dental Equipment Export Compliance Program, Carejoy provides turnkey solutions with risk-mitigated sourcing:

- 19-Year Regulatory Expertise: Full ISO 13485:2016 certification (Certificate #CN-2026-0887) with dental 3D printer-specific scope. Validated EU MDR NB 0123 Technical File #TF-2026-DP11

- MOQ Flexibility: Clinic demo units available; Distributor tiered pricing starting at 3 units (OEM at 10 units)

- DDP Optimization: Shanghai port expedited clearance via NMPA “Green Channel” partnership (avg. 10-day shipment-to-installation)

- Technical Alignment: Seamless integration with major intraoral scanners (3Shape, Medit) via open STL/DICOM protocols

📧 [email protected] | 📱 WhatsApp: +86 15951276160

🏭 Factory: 2888 Youyi Road, Baoshan District, Shanghai 200940, China

Request reference dossier: “CEREC-3DP-2026-Compliance-Pack”

Implementation Checklist

- Obtain factory-audited ISO 13485 scope document (not website screenshot)

- Require DDP quote with itemized landed cost breakdown

- Conduct remote factory audit via Teams (verify cleanroom Class 8+ for resin handling)

- Secure sample unit for clinical validation with your materials

- Confirm post-warranty service network in your region

Disclaimer: This guide reflects 2026 regulatory standards. Verify all claims through independent channels. Shanghai Carejoy is presented as a case-study compliant supplier; inclusion does not constitute endorsement by this publication.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: CEREC 3D Printer Acquisition

Target Audience: Dental Clinics & Dental Equipment Distributors

Focus: Sirona CEREC 3D Printing Systems – Technical & Operational Readiness (2026)

| # | Question | Professional Answer |

|---|---|---|

| 1 | What voltage and power requirements does the CEREC 3D printer support for global deployment in 2026? | The 2026 CEREC 3D printer models (e.g., CEREC SpeedFire, CEREC Print Pro) are engineered for international use with auto-switching power supplies supporting 100–240 V AC, 50/60 Hz. Units are supplied with region-specific power cords (e.g., EU Schuko, UK BS 1363, US NEMA 5-15). A dedicated 15A circuit with stable power output and surge protection is recommended to ensure print accuracy and prevent thermal fluctuations during extended operations. |

| 2 | Are critical spare parts (e.g., print cores, laser modules, build platform) available through local distributors, and what is the lead time? | Yes. Sirona maintains a global network of certified distributors with regional logistics hubs stocking high-turnover spare components. Critical parts including print cores (resin dispensing), galvanometer scanners, and heated build platforms are available under SKU-level inventory tracking. Standard lead time for in-stock items is 1–3 business days within North America, EMEA, and APAC regions. Extended warranties include priority spare parts allocation (24-hour dispatch). Distributors are required to maintain a minimum 90-day operational buffer for clinics with active service contracts. |

| 3 | What does the professional installation process entail, and is on-site calibration included? | Installation is performed by Sirona-certified biomedical engineers and includes: physical setup, utility connection verification, network integration (DICOM/CDM compatibility), and full system diagnostics. On-site optical and thermal calibration is mandatory and performed using ISO 17025-traceable test patterns to validate layer accuracy (±10 µm) and dimensional stability. Installation concludes with a validation print and operator training session (2–3 hours). Remote pre-checks are conducted prior to dispatch to minimize on-site time. |

| 4 | What is the standard warranty coverage for the CEREC 3D printer in 2026, and are there extended service options? | The base warranty covers 24 months for parts and labor, including laser subsystems, motion components, and control electronics. Exclusions include consumables (resin tanks, filters) and damage from non-compliant materials. Extended Service Agreements (ESA) are available in 12-month increments up to 60 months total, offering predictive maintenance, priority response (<4 business hours), remote diagnostics, and annual performance recertification. Premium ESA includes automatic spare part upgrades for obsolescence mitigation. |

| 5 | How are firmware updates and technical support integrated post-installation? | Firmware updates are delivered securely via Sirona Connect™, with automated notifications and scheduled deployment options to minimize clinical disruption. Updates are backward-compatible and validated under ISO 13485. Technical support is available 24/7 through regional help desks with tiered escalation to engineering teams. All CEREC 3D printers include embedded telemetry (opt-in) for proactive fault detection, enabling remote troubleshooting and reduced mean time to repair (MTTR). |

Note: Specifications subject to change based on regional regulatory approvals and product revisions. Contact your authorized Sirona distributor for site-specific compliance documentation.

Need a Quote for Cerec 3D Printer?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160