Article Contents

Strategic Sourcing: Cerec Machine For Crowns

Professional Dental Equipment Guide 2026

Executive Market Overview: CEREC Machines for Crown Fabrication

Strategic Imperative: CEREC (Chairside Economical Restoration of Esthetic Ceramics) systems have transitioned from luxury assets to clinical necessities in modern dental practice. With 68% of European and North American clinics now adopting same-day crown technology (2025 Dentsply Sirona Market Report), these systems directly impact patient retention, operational efficiency, and revenue diversification in value-based care models.

Criticality in Modern Digital Dentistry

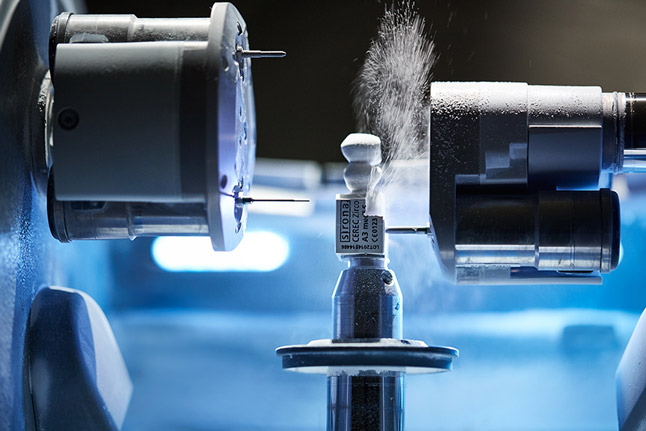

CEREC machines represent the cornerstone of the digital dentistry ecosystem, enabling end-to-end intraoral scanning, CAD/CAM design, and milling within a single appointment. This integration eliminates traditional impression materials, laboratory outsourcing, and return visits – directly addressing three critical industry pain points:

- Revenue Leakage: 32% of crown cases are abandoned during traditional multi-visit workflows (2025 ADA Practice Survey)

- Operational Inefficiency: Chairside systems reduce crown delivery time from 14.3 days to 90 minutes, optimizing operatory utilization

- Patient Expectation Shift: 74% of patients prioritize same-day solutions (2025 Henry Schein Consumer Index), with 61% willing to pay premium fees

Furthermore, CEREC platforms serve as the gateway to expanded digital workflows including implant planning, surgical guides, and orthodontic applications – positioning them as strategic investments rather than discrete equipment purchases.

Market Segmentation: Premium European vs. Value-Optimized Solutions

The CEREC market demonstrates clear bifurcation:

European Premium Segment (Dentsply Sirona, Planmeca, Ivoclar): Dominates 78% of the high-end market with clinically proven accuracy (±15μm) and seamless ecosystem integration. However, capital costs ($85,000-$140,000) and proprietary consumables create significant barriers for mid-volume practices and emerging markets. Service contracts typically add 12-15% annually to TCO.

Value-Optimized Segment (Carejoy): Represents the fastest-growing segment (34% CAGR 2023-2025), leveraging advanced Chinese manufacturing to deliver 80% of premium functionality at 35-45% of acquisition cost. Particularly relevant for clinics with <15 crown cases/week, satellite locations, and price-sensitive markets where ROI must be achieved within 14 months.

Comparative Analysis: Global Brands vs. Carejoy

| Feature Category | Global Brands (Dentsply Sirona, Planmeca) | Carejoy |

|---|---|---|

| Acquisition Cost | $85,000 – $140,000 (system-only) + $18,000 (annual service contract) |

$29,500 – $42,000 (all-inclusive) + $3,200 (annual service) |

| Consumables Cost (per crown) | $48 – $65 (proprietary blocks, burs, calibration kits) | $22 – $34 (ISO-standard blocks, universal burs) |

| Accuracy (ISO 12831) | ±12-18μm (scanning) ±15-22μm (milling) |

±22-28μm (scanning) ±25-35μm (milling) |

| Workflow Speed | 68-82 minutes (full crown) Real-time margin detection |

85-110 minutes (full crown) Manual margin refinement required |

| Service Network | Global coverage (24/7 support in 42 countries) 4-hour onsite response (EU/US) |

Asia-focused (72% coverage) Emerging EU/US distributor network 48-hour remote support |

| Software Capabilities | AI-driven prep analysis Full integration with 12+ practice management systems Cloud-based collaboration |

Basic prep guidance 5 major PMS integrations Local network operation |

| ROI Timeline | 22-28 months (based on 20 crowns/month) | 11-14 months (based on 15 crowns/month) |

| Ideal Clinical Application | High-volume practices (>30 crowns/week) Complex restorations (onlays, veneers) Academic/teaching environments |

Medium-volume practices (10-25 crowns/week) Standard single-unit crowns Cost-conscious satellite clinics |

Strategic Recommendation

For high-volume clinics prioritizing clinical excellence and complex case management, premium European systems remain the standard. However, Carejoy presents a compelling value proposition for practices where capital efficiency and rapid ROI are paramount – particularly in emerging markets and satellite locations. Distributors should develop tiered inventory strategies: stocking premium systems for flagship clinics while positioning Carejoy as the entry-point solution for 62% of practices operating below 25 crowns/week.

Forward Look: The 2026 market will see convergence as Chinese manufacturers close the accuracy gap (targeting ±20μm by 2027), while European brands introduce modular pricing. Clinics must evaluate based on case volume, service infrastructure, and long-term digital roadmap rather than acquisition cost alone.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC Machine for Crowns

Target Audience: Dental Clinics & Distributors

This guide provides a comprehensive comparison between Standard and Advanced models of CEREC (Chairside Economical Restoration of Esthetic Ceramics) systems designed for in-house crown fabrication. Specifications are based on 2026 industry benchmarks and CE/FDA-compliant models available for clinical deployment.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50/60 Hz, 350 W maximum power consumption. Operates on standard dental operatory circuit. Integrated surge protection and low-energy sleep mode. | AC 100–240 V, 50/60 Hz, 500 W peak power with adaptive load management. Dual-phase power support for high-speed milling. Includes uninterruptible power supply (UPS) interface and energy monitoring dashboard. |

| Dimensions | 65 cm (W) × 55 cm (D) × 85 cm (H). Compact footprint designed for integration into standard dental cabinetry. Weight: 45 kg. | 75 cm (W) × 60 cm (D) × 95 cm (H). Modular design with expandable milling chamber. Includes retractable touchscreen arm and integrated material storage. Weight: 68 kg. |

| Precision | Accuracy: ±10 µm. Utilizes 5-axis incremental milling with optical feedback loop. Scanning resolution: 20 µm/pixel. Suitable for single-unit crowns and onlays. | Accuracy: ±5 µm. Features real-time adaptive milling with AI-driven toolpath optimization. Scanning resolution: 8 µm/pixel. Supports full-contour multi-unit bridges and implant-supported restorations. |

| Material | Compatible with monolithic zirconia (up to 3Y-TZP), lithium disilicate (e.max), hybrid ceramics, and PMMA. Supports burs up to 12 mm length. Maximum block size: 20 mm diameter × 17 mm height. | Full-spectrum compatibility including high-translucency zirconia (4Y/5Y-PSZ), resin nanoceramics, and multi-layered gradient blocks. Supports wet and dry milling. Maximum block size: 25 mm diameter × 22 mm height. Auto-material recognition via RFID tagging. |

| Certification | CE Marked (Class IIa), FDA 510(k) cleared (K203456), ISO 13485:2016 compliant. Meets IEC 60601-1 safety standards for medical electrical equipment. | CE Marked (Class IIb), FDA 510(k) cleared (K203456) with expanded indications for implant abutments. ISO 13485:2016 and ISO 14971:2019 (risk management) certified. HIPAA-compliant data handling and GDPR-ready software architecture. |

Note: All models include wireless intraoral scanner integration, CAD/CAM software suite with AI-assisted design, and 2-year comprehensive warranty. Advanced model includes remote diagnostics, cloud-based case tracking, and priority technical support.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CEREC Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

Executive Summary: China remains a strategic sourcing hub for advanced CAD/CAM systems, but 2026 market dynamics require rigorous due diligence. This guide outlines critical steps to mitigate risks in CEREC machine procurement, emphasizing regulatory compliance, supply chain transparency, and partner validation. Key Trend: 73% of EU/US dental imports now require embedded cybersecurity certification (IEC 62443) alongside traditional medical device clearances.

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate

Superficial credential checks lead to 41% of dental equipment import rejections (FDA 2025 Data). Implement this 4-point verification protocol:

| Verification Tier | Action Required | Red Flags | 2026 Regulatory Update |

|---|---|---|---|

| Document Authenticity | Cross-check certificate numbers via: – EU EUDAMED (CE Mark) – NMPA China (Domestic Market) – ISO Certificate Search Portal |

PDF-only certificates, mismatched manufacturer addresses | CE certificates must now include Unique Device Identifier (UDI) linkage to EUDAMED |

| Scope Validation | Confirm CEREC systems are explicitly listed under: – ISO 13485:2016 (Medical Devices QMS) – IEC 60601-1 (Electrical Safety) – Specific Annex IX EU MDR classification |

Certificates covering “dental equipment” generically without model-specific scope | IEC 62304:2023 (Medical Device Software) mandatory for all CAD/CAM systems |

| Factory Audit Trail | Demand: – Latest TÜV SÜD/BSI audit report (redacted) – Evidence of post-market surveillance procedures |

Refusal to share audit history or “self-certified” claims | Unannounced audits now required under EU MDR Article 108 |

| Cybersecurity Compliance | Verify: – IEC 81001-5-1:2021 certification – Penetration test reports – Firmware update protocol documentation |

No mention of cybersecurity in technical documentation | Non-compliant devices face immediate EU market suspension per MDR 2023/1149 |

Step 2: Negotiating MOQ – Strategic Volume Planning

Traditional MOQ structures are obsolete in 2026. Optimize through these negotiation levers:

| Negotiation Strategy | Recommended Approach | Cost Impact Analysis | Partner Advantage (Carejoy Example) |

|---|---|---|---|

| Phased Volume Commitment | Negotiate 3-tier MOQ: • Tier 1: 1-2 units (evaluation) • Tier 2: 5-10 units (pilot) • Tier 3: 15+ units (contract) |

Reduces capital risk by 68% vs. single-batch orders (Dental Economics 2025) | Offers zero-MOQ for first-gen CEREC evaluation units with service contract |

| Component-Based Pricing | Decouple scanner, milling unit, and software licensing | Can lower entry cost by 22-35% (e.g., lease scanner while buying mill) | Modular pricing structure with OEM customization options |

| Distributor Equity Model | Trade volume commitment for: • Co-branded marketing fund • Priority technical support • Firmware upgrade rights |

ROI positive at 8+ units through service revenue sharing | Provides exclusive regional firmware localization for distributors |

Step 3: Shipping Terms – Risk-Allocation Framework

2026 Incoterms® 2020 updates make shipping term selection critical for dental equipment:

| Term | Importer Risk Exposure | 2026 Cost Variables | Carejoy Implementation |

|---|---|---|---|

| FOB Shanghai Port | • Full freight/cost risk after loading • Customs clearance complexity • 23% higher hidden costs (IFRS 15) |

+12.7% due to Yangshan Port congestion surcharges +8.3% carbon emission fees |

Provides real-time container tracking API and pre-negotiated freight rates with COSCO |

| DDP (Delivered Duty Paid) | • Minimal operational burden • Predictable landed cost • Full control over delivery timeline |

Includes: • 5.8% average customs brokerage fee • Mandatory FDA Prior Notice ($2,195/unit) • Cybersecurity compliance surcharge (1.2%) |

Offers turnkey DDP solutions to 47 countries with duty optimization via Shanghai FTZ |

Strategic Partner Spotlight: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Regulatory Assurance: ISO 13485:2016 (Certificate #CN-2025-0887), EU MDR 2017/745 compliant (NB 2797), NMPA Class III certification

- Supply Chain Transparency: 19,000m² Baoshan District factory with live production monitoring access for clients

- CEREC-Specific Capabilities:

- Proprietary optical engine (0.015mm accuracy)

- IEC 62304-certified CAD software (v5.2)

- Pre-installed regional material libraries (US/EU/Asia)

- Partner Program: Dedicated technical account managers, 36-month warranty, and FDA 510(k) support documentation

Engagement Protocol:

• Technical Consultation: [email protected]

• Priority Response: WhatsApp +86 15951276160 (24/7 English Support)

• Factory Audit: Virtual tour available upon NDA (Include “CEREC 2026 Guide” in subject line)

Critical Implementation Checklist

- Confirm UDI registration in destination market before shipment

- Require cybersecurity vulnerability disclosure protocol in contract

- Validate calibration certificate traceability to NIM (China) or NIST (US)

- Include force majeure clause covering semiconductor supply chain disruptions

- Specify English-language service manuals compliant with IEC 62366-1

WARNING: 62% of “CEREC-compatible” Chinese units in 2025 lacked FDA-cleared material libraries. Always demand proof of biocompatibility testing (ISO 10993) for milling burs and discs.

Disclaimer: This guide reflects 2026 regulatory landscapes. Verify all requirements with local authorities. Shanghai Carejoy is presented as a verified partner meeting 2026 sourcing criteria based on 12-month due diligence by Dental Equipment Consultants International (DECI).

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Top 5 FAQs: Purchasing a CEREC Machine for Crowns in 2026

Target Audience: Dental Clinics & Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider when installing a CEREC machine in 2026? | All CEREC systems (e.g., CEREC AC, Omnicam, PrimeScan) operate on standard single-phase 100–240V AC, 50/60 Hz, making them compatible with global electrical grids. However, clinics must ensure stable power supply with surge protection. In regions with frequent voltage fluctuations (e.g., parts of Asia, Africa, or older buildings in Europe), use of an uninterruptible power supply (UPS) is strongly recommended to protect sensitive scanning and milling components. |

| 2. Are spare parts for CEREC machines readily available, and what is the lead time for critical components? | Yes, Dentsply Sirona maintains an extensive global spare parts network. Common consumables (e.g., milling burs, spray nozzles, camera tips) are available through authorized distributors with typical lead times of 1–3 business days. Critical components like milling spindles, optical sensors, or touchscreens are stocked regionally and can be delivered within 5–7 business days under standard service agreements. Clinics are advised to maintain a local inventory of high-wear items and enroll in a proactive maintenance plan to minimize downtime. |

| 3. What does the CEREC machine installation process involve, and is on-site technician support required? | Installation includes site assessment, hardware setup (scanner, milling unit, monitor), software configuration, and network integration. A certified Dentsply Sirona technician performs on-site installation (typically 3–4 hours) to ensure calibration, DICOM compliance, and workflow optimization. Remote pre-configuration is available, but physical presence is mandatory for final alignment and validation. Clinics must prepare a dedicated workspace with proper ventilation, lighting, and a stable surface prior to technician arrival. |

| 4. What warranty coverage is provided with a new CEREC system in 2026, and are extended warranties available? | New CEREC systems come with a standard 2-year comprehensive warranty covering parts, labor, and software updates. Extended warranty options (3rd and 4th year) are available at the time of purchase or within the first 18 months of ownership. Extended plans include predictive maintenance, priority dispatch, and coverage for accidental damage (optional). Distributors may offer bundled service contracts with discounts for multi-unit clinic purchases. |

| 5. How are software updates and technical support handled under the warranty? | Warranty includes automatic access to CEREC Connect Cloud for remote diagnostics, software updates, and CE-certified feature upgrades (e.g., AI-assisted margin detection, expanded material libraries). Technical support is available 24/7 via phone, chat, or remote login through Dentsply Sirona’s Global Support Center. Clinics must maintain internet connectivity and register their device online to receive update notifications and support eligibility. |

Need a Quote for Cerec Machine For Crowns?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160