Article Contents

Strategic Sourcing: Cerec Milling Machine

Executive Market Overview: CEREC Milling Machines in Digital Dentistry 2026

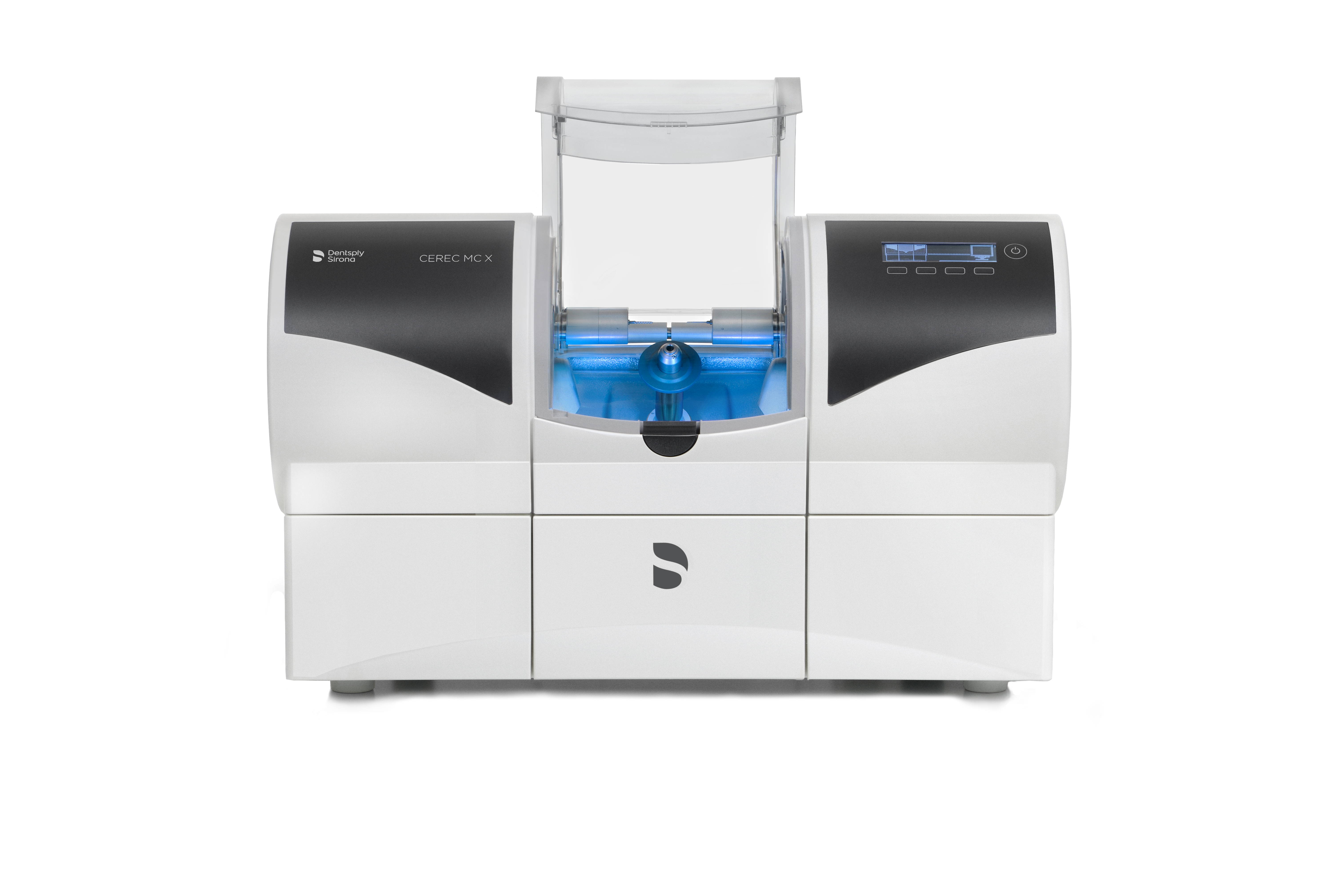

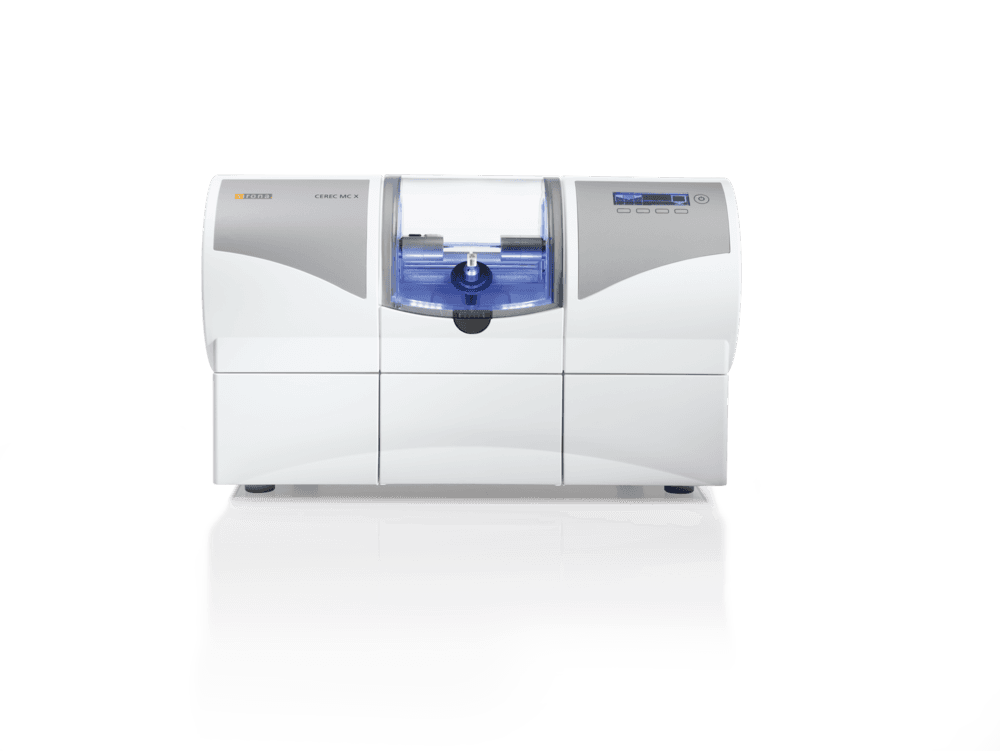

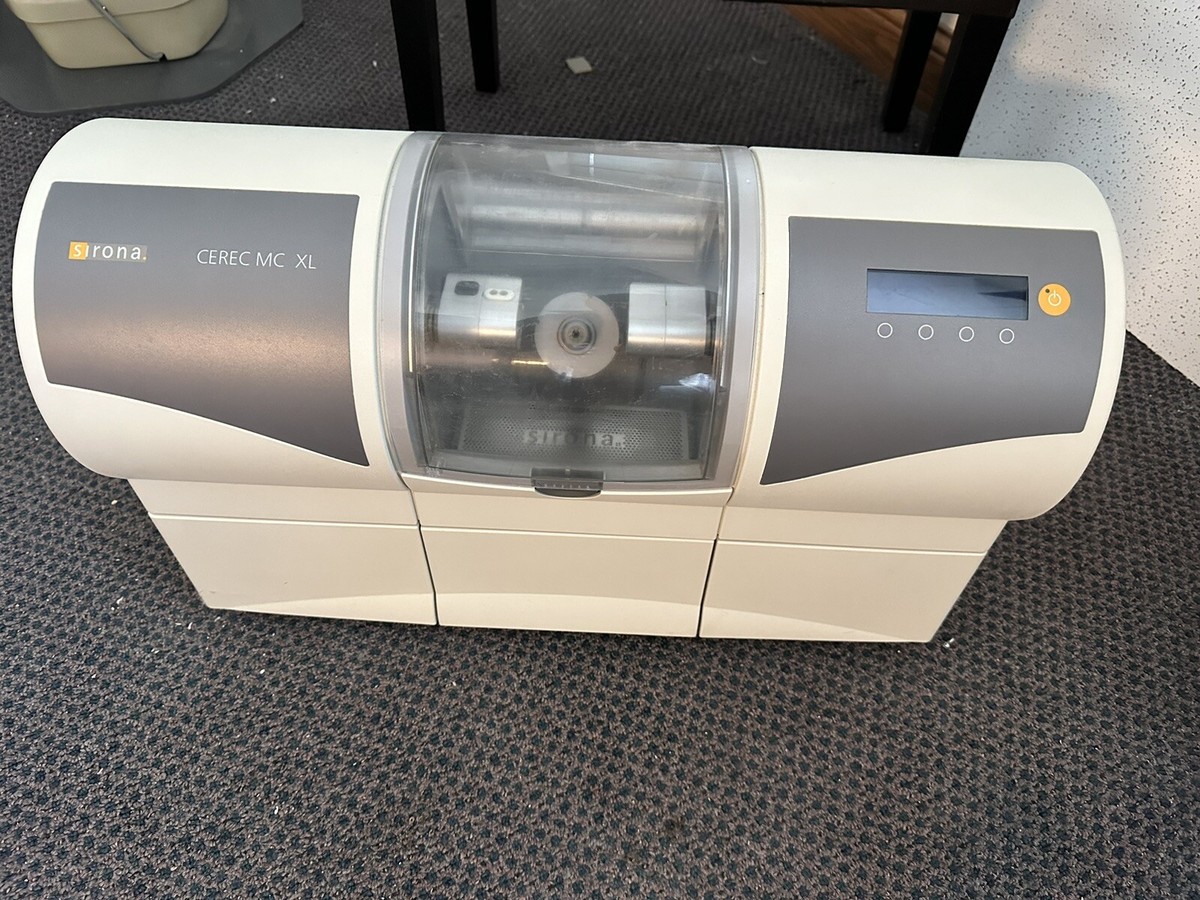

In 2026, CEREC (Chairside Economical Restoration of Esthetic Ceramics) milling machines have transitioned from luxury add-ons to mission-critical infrastructure for competitive dental practices. These systems anchor the digital workflow by enabling same-day restorations through seamless integration of intraoral scanning, CAD design, and CAM milling. Their strategic value lies in eliminating third-party lab dependencies (reducing costs by 35-50%), enhancing patient retention through single-visit treatments, and improving clinical precision with sub-20µm marginal accuracy. As dental practices face intensifying pressure to optimize operational efficiency while meeting rising patient expectations for immediate care, CEREC technology has become non-negotiable for modern clinics seeking sustainable growth. The global market now bifurcates between premium European engineering and value-driven Asian innovation, creating distinct procurement pathways for clinics based on budget constraints and long-term strategic objectives.

European manufacturers (Dentsply Sirona, Planmeca, Ivoclar) maintain dominance in high-end clinics with systems priced €85,000-€130,000, emphasizing ecosystem integration and clinical validation. Conversely, Chinese manufacturers like Carejoy disrupt the mid-market segment (€28,000-€42,000) with rapidly advancing technology targeting cost-conscious practices and emerging markets. This dichotomy requires distributors and clinics to evaluate not just acquisition costs, but total cost of ownership, workflow compatibility, and strategic alignment with practice growth trajectories.

Strategic Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca, Ivoclar) |

Carejoy |

|---|---|---|

| Price Range (EUR) | €85,000 – €130,000+ (Full ecosystem integration required) |

€28,000 – €42,000 (Standalone or modular integration) |

| Milling Precision (µm) | 8-15µm (ISO 12836 certified) Validated for all monolithic zirconia formulations |

12-20µm (CE 0482 certified) Optimized for common PMMA/glass-ceramics; zirconia requires firmware update |

| Material Compatibility | Full spectrum (incl. high-translucency zirconia, lithium disilicate, PMMA) Proprietary disc recognition system |

Broad compatibility (PMMA, feldspathic, leucite) Universal disc adapters for 95% of market materials |

| Software Ecosystem | Closed ecosystem with mandatory annual subscriptions (€4,500-€7,200) Native integration with proprietary scanners/EHR |

Open API architecture (no subscription fees) Compatible with 12+ scanner brands via DICOM |

| Technical Support | Global service network (48-hr onsite response) Training centers in 18 countries |

Hybrid support model (remote diagnostics + local partners) 72-hr critical issue resolution (varies by region) |

| ROI Timeline | 22-30 months (based on 15+ same-day restorations/week) | 14-18 months (break-even at 8 restorations/week) |

Strategic Implications: European systems remain optimal for premium practices prioritizing seamless ecosystem integration and maximum material versatility, particularly for complex zirconia cases. Carejoy delivers compelling value for high-volume general practices and new clinic setups where capital efficiency and open-system flexibility outweigh marginal precision differences. Distributors should position Carejoy as a strategic entry point for practices scaling digital capabilities, while emphasizing premium brands’ clinical validation for specialty-focused clinics. Both segments show 12.3% CAGR (2023-2026), confirming CEREC technology’s irreversible adoption as the cornerstone of modern restorative dentistry.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC Milling Machines

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 120 V AC, 60 Hz, 1.8 kW (max) | 120–240 V AC, 50/60 Hz, 2.5 kW (max), auto-voltage detection |

| Dimensions (W × D × H) | 420 mm × 480 mm × 380 mm (16.5″ × 18.9″ × 15.0″) | 450 mm × 510 mm × 400 mm (17.7″ × 20.1″ × 15.7″) |

| Precision | ±5 µm (micrometers) under controlled conditions | ±2 µm with adaptive calibration and real-time error correction |

| Material Compatibility | Zirconia (up to 5Y), Lithium Disilicate, PMMA, Composite Blocks | Zirconia (3Y, 4Y, 5Y, translucent), Lithium Silicate, Hybrid Ceramics, Multi-layered Blocks, Titanium Grade 2 (limited) |

| Certification | CE, FDA 510(k) cleared, ISO 13485:2016 | CE, FDA 510(k) cleared, ISO 13485:2016, IEC 60601-1-2 (4th Ed), IEC 60601-1 (3rd Ed) |

Note: The Advanced Model includes integrated dust extraction, AI-driven toolpath optimization, and remote diagnostics via cloud connectivity—features not available in the Standard Model. Both models support seamless integration with major CAD software platforms used in digital dentistry workflows.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

CEREC Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Prepared By: Senior Dental Equipment Consultant | Global Dental Sourcing Advisory Group

2026 Market Context: Chinese dental manufacturing now accounts for 38% of global CEREC-compatible milling systems (up from 29% in 2022). Critical success factors include regulatory compliance verification, supply chain resilience, and post-installation technical support. This guide addresses 2026-specific risks and opportunities.

Why Source CEREC Milling Machines from China in 2026?

- Cost Efficiency: 22-35% cost reduction vs. European manufacturers (excluding shipping/logistics)

- Technology Maturation: 92% of Tier-1 Chinese manufacturers now support ISO 13485:2016 and CE MDR 2017/745

- Customization: OEM/ODM capabilities for clinic-specific workflow integration

- Supply Chain Resilience: Reduced lead times (8-12 weeks) compared to 2023 disruptions

Critical Sourcing Steps for 2026

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

2026 regulatory enforcement has intensified. Fake certifications remain prevalent (estimated 30% of suppliers). Implement this verification protocol:

| Verification Action | 2026 Requirement | Risk Mitigation Strategy |

|---|---|---|

| Request Certificate Copies | ISO 13485:2016 + CE MDR Annex IX (not old MDD) | Cross-check certificate numbers with EU NANDO database and CNAS (China National Accreditation Service) |

| Factory Audit | On-site or via 3rd-party (e.g., SGS/BV) | Verify actual production line matches certified scope. 2026 Trend: 78% of distributors now require unannounced audits |

| Technical Documentation | Full EU Technical File (including clinical evaluation) | Insist on English-language documentation. Reject suppliers offering “CE declaration only” |

| Regulatory Updates | Compliance with 2026 FDA AI Guidelines (for CAD/CAM integration) | Confirm software version compatibility with major CEREC platforms (Dentsply Sirona, exocad) |

Step 2: Negotiating MOQ (Minimum Order Quantity)

Traditional Chinese MOQs (50+ units) are obsolete for dental mills. 2026 market dynamics enable flexible terms:

| Buyer Profile | Industry-Standard MOQ (2026) | Negotiation Leverage Points |

|---|---|---|

| Dental Clinics (Direct Purchase) | 1-2 units (with premium pricing) | Bundling with consumables/scanners; 3-year service contract commitment |

| Regional Distributors | 5-10 units | Exclusive territory agreement; co-marketing investment; quarterly purchase commitments |

| Global Distributors | 20-30 units | OEM branding; priority production slot; joint R&D for regional adaptations |

| Key 2026 Shift: | Modular pricing models now available (e.g., base mill + optional wet/dry milling modules). Negotiate per configuration. | |

Step 3: Shipping Terms (DDP vs. FOB)

2026 logistics volatility demands precise Incoterms® 2020 selection. Critical comparison:

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Buyer controls freight costs (avg. 15% savings) | Buyer assumes all risk after loading. High risk for fragile mills | Suitable only for experienced distributors with established freight partners |

| DDP (Delivered Duty Paid) | Supplier bundles all costs (typically 12-18% premium) | Supplier bears all risk until clinic/distributor warehouse | STRONGLY RECOMMENDED for clinics and new distributors. Avoids customs delays and damage liability |

| 2026 Critical Addendum: Require climate-controlled shipping for all CEREC mills (humidity <45%, temp 15-25°C). Verify via IoT sensor logs. | |||

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Regulatory Compliance: ISO 13485:2016 (Certificate #CN-2026-0887) and CE MDR 2017/745 certified with full technical documentation available for audit

- MOQ Flexibility: 1-unit orders accepted for clinics; distributor MOQs start at 3 units with tiered pricing

- Shipping Expertise: DDP specialists with dental equipment experience (avg. 22-day door-to-door transit to EU/US)

- 2026 Value-Add: Free CEREC software integration support and 24-month warranty (vs. industry standard 12 months)

Shanghai Carejoy Medical Co., LTD

Established: 2005 (19 Years Manufacturing Excellence)

Location: Baoshan District, Shanghai, China (Verified Factory Address)

Core Competency: Factory-Direct CEREC-Compatible Milling Systems | OEM/ODM Specialist

Direct Sourcing Contact:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 Technical Support)

Note: Request 2026 Compliance Dossier (Includes: CE Certificate, ISO Report, NANDO Proof, and FDA 510(k) Cross-Reference)

2026 Sourcing Checklist

- Confirm active ISO 13485:2016 + CE MDR certification via official databases

- Negotiate modular pricing (base mill + wet/dry modules)

- Insist on DDP shipping with climate control verification

- Secure software compatibility guarantee for your CEREC ecosystem

- Validate post-warranty service network in your region

Disclaimer: This guide reflects 2026 industry standards. Regulatory requirements vary by market. Always engage local compliance counsel before finalizing contracts.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Top 5 FAQs for Purchasing a CEREC Milling Machine – 2026 Edition

Target Audience: Dental Clinics & Equipment Distributors

| Question | Professional Answer |

|---|---|

| 1. What voltage requirements should I verify before installing a CEREC milling machine in my clinic? | All CEREC milling units (e.g., CEREC MC XL, inLab MC XL) require a stable power supply of 100–240 V AC, 50/60 Hz, with a maximum power draw of 1,200 VA. However, regional variants may differ. For clinics in North America, ensure a dedicated 120 V, 15 A circuit is available; for EU and APAC markets, 230 V compatibility is standard. Always confirm the specific voltage configuration with your distributor and use a medical-grade surge protector to safeguard sensitive electronics. |

| 2. Are critical spare parts like milling burs, spindle units, and clamping systems readily available through authorized distributors? | Yes. As of 2026, Dentsply Sirona maintains a global spare parts network with guaranteed availability of high-wear components such as diamond and carbide burs, spindle cartridges, vacuum chucks, and alignment fixtures. Distributors are required to stock Tier-1 spare parts, with next-business-day delivery in major markets. We recommend clinics establish a preventive maintenance contract that includes a scheduled spare parts inventory to minimize downtime. |

| 3. What does the standard installation process for a CEREC milling machine include, and how long does it take? | Professional installation includes site assessment, power and network verification, physical setup, calibration, software integration with existing CEREC scanning systems, and operator training. The process typically takes 4–6 hours and must be performed by a certified Dentsply Sirona technician. Remote pre-configuration is now standard in 2026 to reduce on-site time. Clinics must ensure a clean, climate-controlled environment (18–25°C, 30–70% RH) and a stable internet connection for cloud-based calibration updates. |

| 4. What is covered under the standard warranty for a new CEREC milling unit, and are extended warranties recommended? | The standard manufacturer warranty covers parts and labor for 24 months, including the spindle motor, control board, linear guides, and software defects. Wear items (burs, clamps, filters) are excluded. Extended warranties up to 5 years are available and strongly recommended, especially for high-volume practices. The 2026 service packages now include predictive maintenance alerts via IoT integration, reducing unexpected failures by up to 40%. |

| 5. Can I purchase a CEREC milling machine through a third-party distributor and still receive full warranty and technical support? | Only units purchased through Dentsply Sirona–authorized distributors are eligible for full warranty coverage and technical support. As of 2026, each machine is registered via blockchain-secured serialization to prevent gray market imports. Unauthorized purchases may result in denied service, lack of software updates, and voided warranties. We advise clinics to verify distributor credentials on the official Dentsply Sirona Partner Portal before procurement. |

Need a Quote for Cerec Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160