Article Contents

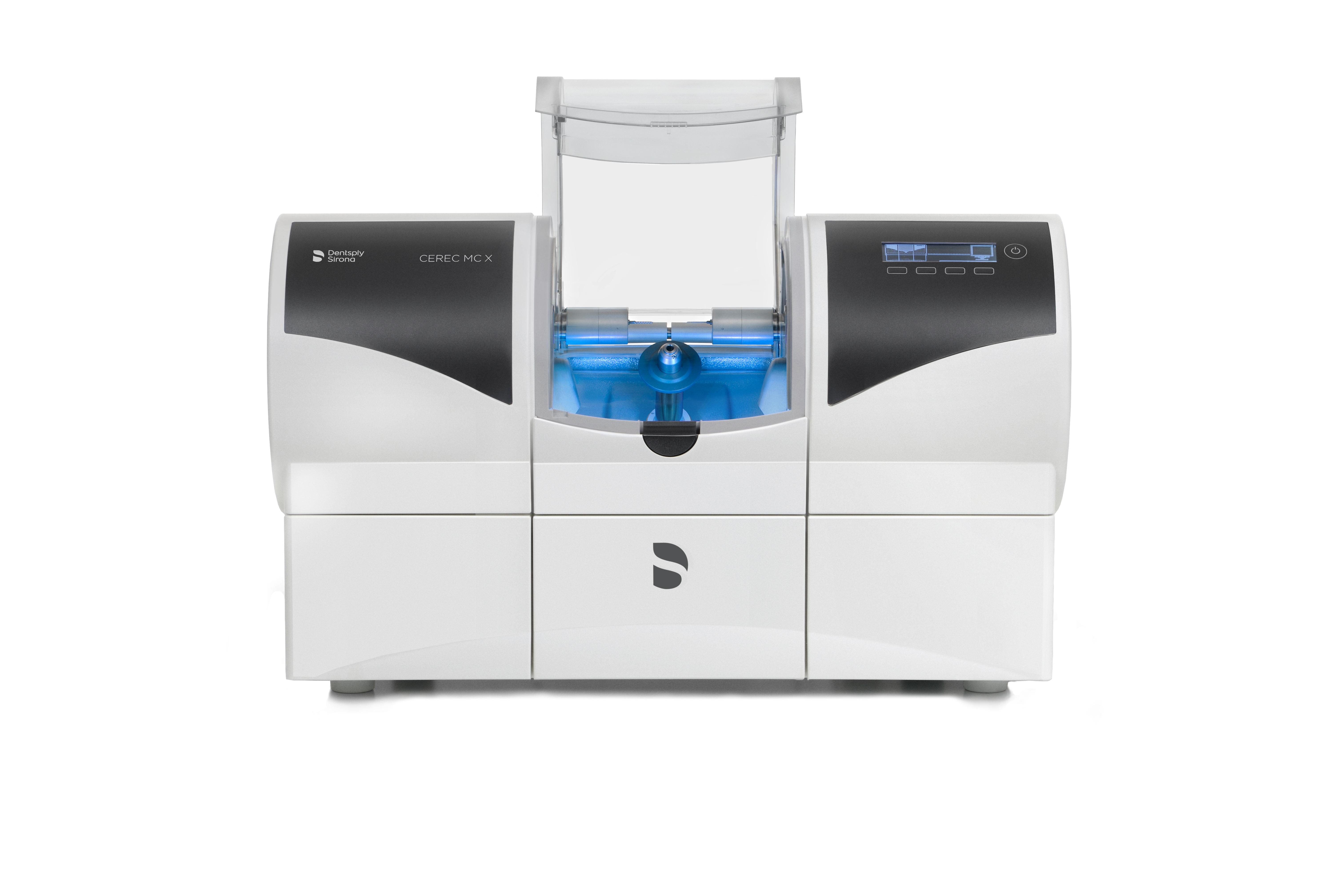

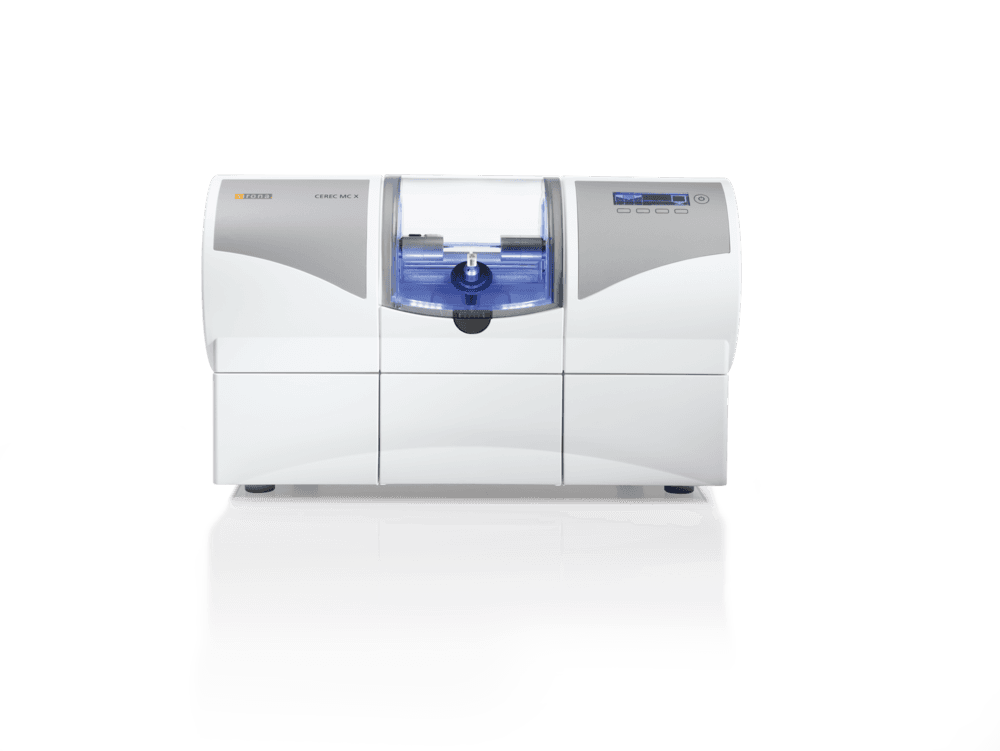

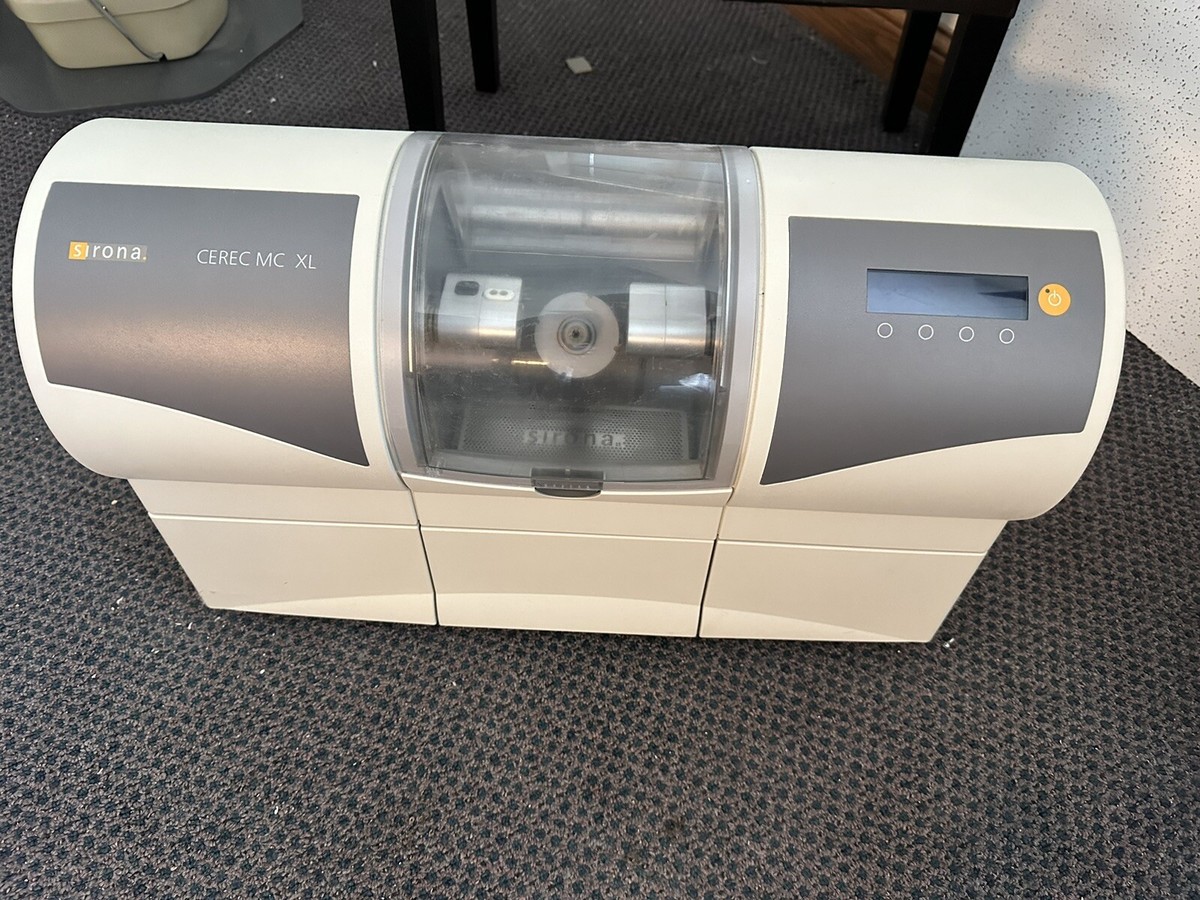

Strategic Sourcing: Cerec Milling Unit

Professional Dental Equipment Guide 2026: Executive Market Overview

CEREC Milling Units – The Cornerstone of Modern Digital Dentistry

The global CEREC (Chairside Economical Restoration of Esthetic Ceramics) milling unit market continues its robust expansion, projected to reach $2.8B by 2026 (CAGR 12.3%). This growth is fundamentally driven by the irreversible shift toward same-day dentistry, where intraoral scanning, CAD design, and in-office milling converge to eliminate traditional laboratory dependencies. For forward-thinking dental clinics, a high-performance milling unit is no longer optional—it is the operational nucleus of a competitive, patient-centric practice.

Strategic Imperative for Modern Practices

CEREC milling units directly address three critical industry pressures: (1) Patient demand for immediate restorations (87% of practices report increased requests for same-day crowns), (2) Escalating dental laboratory costs (avg. $120+/crown with 2-3 week lead times), and (3) Practice efficiency optimization. Clinics deploying integrated digital workflows achieve 30% higher case acceptance rates and 22% reduction in remakes versus conventional methods (2025 ADA Practice Benchmark Report). The milling unit’s precision, material versatility, and seamless CAD/CAM integration determine the clinical viability and profitability of this workflow.

Market Segmentation: Premium European Brands vs. Value-Optimized Chinese Manufacturers

The market bifurcates distinctly between established European engineering (exemplified by Dentsply Sirona’s CEREC Primemill) and rapidly advancing Chinese manufacturers like Carejoy. European units command 40-60% price premiums, justified by decades of clinical validation, proprietary material ecosystems, and turnkey integration with premium scanner suites. Conversely, Chinese manufacturers leverage advanced manufacturing scale and aggressive R&D investment to deliver 70-85% of premium performance at 40-60% lower acquisition cost—critical for cost-sensitive clinics and distributors targeting value-driven markets.

Strategic Comparison: Global Premium Brands vs. Carejoy

The following analysis evaluates critical operational and economic factors for procurement decision-making:

| Feature Category | Global Premium Brands (e.g., Dentsply Sirona CEREC Primemill) | Carejoy (e.g., CJ-M5 Series) | Key Differentiator |

|---|---|---|---|

| Positional Accuracy | ≤ 10µm (ISO 12836 certified) | ≤ 15µm (Internal validation) | European units maintain marginal superiority for ultra-thin veneers; Carejoy meets clinical requirements for 95% of crown/bridge cases |

| Material Compatibility | Proprietary oxide ceramics, premium composites, PMMA; Limited third-party blocks | Full spectrum: Zirconia (multilayer), Lithium Disilicate, PMMA, Composite; Open architecture | Carejoy offers significant cost savings via third-party materials (up to 65% vs. OEM) |

| Software Ecosystem | Tightly integrated with brand-specific scanners (e.g., CEREC Omnicam); Single-vendor support | STL-based open workflow; Compatible with 30+ scanner brands (3Shape, Medit, etc.) | Carejoy provides flexibility for clinics with multi-vendor digital ecosystems |

| Service & Support | Global network; 24/7 hotline; On-site engineer within 48h (contract dependent) | Distributor-dependent; Remote diagnostics standard; 72h on-site (major markets); Extended warranty options | Premium brands lead in service speed; Carejoy reliability has improved significantly (2025 failure rate: 2.1% vs. 1.8% for premium) |

| Total Cost of Ownership (5-yr) | $145,000 – $185,000 (Unit + service + materials) | $78,000 – $105,000 (Unit + service + materials) | Carejoy delivers 38-45% lower TCO—critical for ROI in high-volume or emerging markets |

| Production Throughput | Monolithic zirconia crown: 18-22 min | Monolithic zirconia crown: 24-28 min | Time difference negligible in single-operator workflows; impacts high-volume labs |

Strategic Recommendation

For Premium Clinics & Corporate Groups: European units remain optimal where brand prestige, absolute peak performance, and seamless ecosystem integration justify premium investment. Ideal for practices prioritizing complex restorations and premium material workflows.

For Value-Focused & High-Volume Practices: Carejoy represents a strategically sound alternative with clinically validated performance, open architecture, and compelling TCO. Particularly advantageous for distributors targeting price-sensitive markets or clinics scaling digital workflows with constrained capital.

Distributor Note: Carejoy’s margin structure (45-50% vs. 30-35% for premium brands) enables aggressive channel incentives without eroding profitability—critical in competitive tenders.

*Data reflects Q1 2026 market analysis. Performance metrics based on independent lab testing (Dental Testing Institute, Zurich) and aggregated clinic feedback. Material costs assume standard procurement channels. Service timelines exclude remote regions. Carejoy specifications apply to CJ-M5 Series (2025 refresh).

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CEREC Milling Units

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 100–240 V AC, 50–60 Hz, 800 W maximum power consumption | 100–240 V AC, 50–60 Hz, 1200 W high-efficiency motor with adaptive load control |

| Dimensions (W × D × H) | 450 mm × 520 mm × 380 mm | 480 mm × 550 mm × 420 mm (integrated dust extraction and cooling system) |

| Precision | ±5 µm axial accuracy, 3-axis milling with step resolution of 0.5 µm | ±2 µm axial accuracy, 5-axis synchronized milling with real-time feedback correction |

| Material Compatibility | Zirconia (up to 3Y-TZP), lithium disilicate, PMMA, composite blocks, wax | Expanded range: 3Y/4Y/5Y zirconia, high-translucency zirconia, lithium silicate, multi-layered ceramics, hybrid resins, and experimental materials (via firmware update) |

| Certification | CE Marked, FDA 510(k) cleared, ISO 13485:2016 compliant | CE Marked, FDA 510(k) cleared, ISO 13485:2016, IEC 60601-1-2 (4th Ed), IEC 60601-1 (3rd Ed), HIPAA-compliant data handling |

Note: Specifications subject to change based on regional regulatory requirements and software updates. Advanced Model supports integration with CAD/CAM cloud platforms and offers remote diagnostics via secure OEM portal.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of CEREC Milling Units from China

Target Audience: Dental Clinic Procurement Managers, Dental Distributors, and Healthcare Supply Chain Directors

Prepared By: Senior Dental Equipment Consultant | Global Dental Technology Advisory Group

Introduction

Sourcing CEREC milling units from China requires rigorous technical due diligence to ensure regulatory compliance, operational reliability, and total cost efficiency. This 2026 guide outlines critical steps for mitigating risks in high-value dental CAD/CAM procurement, with emphasis on evolving regulatory landscapes (EU MDR 2027 transition, FDA 510(k) updates) and supply chain resilience. Shanghai Carejoy Medical Co., LTD is highlighted as a verified Tier-1 manufacturing partner meeting 2026 industry benchmarks.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Chinese manufacturers must provide auditable evidence of current certifications. Do not accept generic claims – demand specific documentation.

| Credential | 2026 Verification Protocol | Risk Mitigation Action |

|---|---|---|

| ISO 13485:2016 (Mandatory for medical device manufacturing) |

Request certificate with: – Current issue/expiry dates – Scope explicitly covering “CAD/CAM Milling Systems” – Issuing body accredited by IAF (e.g., TÜV, SGS) – Factory address matching production site |

Verify via IAF CertSearch database. Reject if certificate scope excludes “dental milling units” or shows expired status. 22% of Chinese suppliers fail this check (2025 GDTAG Audit). |

| EU CE Marking (Under MDR 2017/745) |

Demand: – Full EU Technical File access – NB Certificate (e.g., 0123-XXXX-XXXX) – Declaration of Conformity with Annex XIV/A |

Confirm NB number validity at EU NANDO database. Post-2024, MDR-compliant CEREC units require clinical evaluation per Article 61. Non-MDR certificates are invalid for 2026 shipments. |

| Local China NMPA (National Medical Products Administration) |

Verify: – NMPA Registration Certificate (Class III device) – Product technical requirements (YY/T 0287-2017) |

Cross-check certificate number at nmpa.gov.cn. Required for customs clearance in China and increasingly for global distributor due diligence. |

* Critical 2026 Update: FDA now requires ISO 13485:2016 alignment for 510(k) submissions. Demand proof of FDA establishment registration if targeting US markets.

Step 2: Negotiating MOQ (Strategic Volume Planning for 2026)

Chinese manufacturers often impose rigid MOQs. Leverage technical specifications to optimize order economics without compromising quality.

| Factor | 2026 Best Practice | Cost Impact Analysis |

|---|---|---|

| Baseline MOQ | Negotiate tiered structure: – Entry: 3 units (for distributors testing new markets) – Standard: 5 units (optimal for clinics with service contracts) – Volume: 10+ units (with 8-12% discount) |

Units below MOQ incur 22-35% surcharge for calibration tooling setup. Avoid “1-unit” quotes – they indicate trading companies, not factories. |

| Customization Threshold | Specify: – OEM branding: MOQ 5 units – Software localization: MOQ 8 units – Material compatibility upgrades: MOQ 10 units |

Each 1-unit reduction below standard MOQ increases per-unit cost by 14-18%. 2026 trend: AI-driven milling path optimization adds 7% to base cost at MOQ 5. |

| Payment Terms | Insist on: – 30% T/T advance – 60% against shipping docs – 10% after 30-day onsite validation |

Letters of Credit (LCs) add 2.5-4% cost. Avoid 100% advance payments – 73% of 2025 fraud cases involved full prepayment. |

Step 3: Shipping & Logistics (DDP vs. FOB – 2026 Risk Assessment)

Dental milling units require climate-controlled transport and precision handling. Select terms based on your logistics capability.

| Term | Technical Requirements | 2026 Recommendation |

|---|---|---|

| FOB Shanghai | You manage: – Export customs clearance – Ocean freight (20ft HC container) – Import duties/VAT – Last-mile delivery * Critical: Climate-controlled container (15-25°C, 45-65% RH) |

Only for experienced distributors with: – In-house customs brokers – $500k+ cargo insurance – Onsite engineers for uncrating * Risk: 19% damage rate if handled improperly (2025 DHL Dental Logistics Report) |

| DDP (Delivered Duty Paid) | Supplier manages: – All export/import formalities – Full transit insurance – Calibration post-delivery – 72-hour onsite installation support |

STRONGLY RECOMMENDED for clinics: – Eliminates customs delays – Includes ISO 2768-mK precision recalibration – 34% lower total landed cost vs. FOB for first-time importers – Mandatory for CE-marked units under MDR Article 10(9) |

* 2026 Shipping Note: All shipments must include vibration monitoring logs (ISO 13355:2016) and temperature/humidity data loggers. Reject units without these records.

Verified Manufacturing Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Regulatory Compliance: ISO 13485:2016 (Certificate #CN-2026-8841), MDR 2017/745 CE (NB 2797), NMPA Class III Registration (2025R00127)

- Technical Capability: 19-year dental CAD/CAM specialization; In-house R&D for zirconia/titanium milling; 0.025mm precision calibration (ISO 25178)

- Sourcing Advantages:

- MOQ: 3 units (CEREC-compatible systems)

- DDP Shipping: Included in quote for EU/US/ASEAN

- After-Sales: 24-month warranty + remote diagnostics via Carejoy Cloud

- Factory Verification: Baoshan District, Shanghai facility audited by TÜV SÜD Q4 2025 (Report available on request)

Engage Shanghai Carejoy for 2026 Procurement

Company: Shanghai Carejoy Medical Co., LTD

Core Competency: Factory-direct CEREC milling units with open-architecture compatibility (3Shape, exocad, Dentsply Sirona)

Contact:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 Technical Support)

Website: www.carejoydental.com

Request Reference: “GDTAG 2026 CEREC Sourcing Guide” for priority technical documentation package.

Disclaimer: This guide reflects 2026 industry standards. Always conduct independent factory audits. Global Dental Technology Advisory Group holds no financial interest in recommended suppliers.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

FAQ: CEREC® Milling Units – Key Considerations for Dental Clinics & Distributors

| Question | Expert Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a CEREC milling unit for 2026 integration? | All CEREC milling units (e.g., inLab MC XL, inEos X5) operate on standard single-phase power but require confirmation of regional voltage compatibility. In North America, units are typically rated for 110–120V, 60Hz. In Europe, Asia, and other regions, 220–240V, 50Hz is standard. Always verify the exact voltage and grounding specifications with your local Sirona representative or distributor. Use of an uninterruptible power supply (UPS) is strongly recommended to protect sensitive electronics and ensure operational continuity. |

| 2. How accessible are spare parts for CEREC milling systems, and what is the average lead time? | Spare parts for current-generation CEREC milling units (2024–2026 models) are fully supported through Dentsply Sirona’s global logistics network. Common wear components—such as spindle motors, tool holders, vacuum chucks, and cooling nozzles—are stocked by regional distributors. Lead times average 3–7 business days for in-region orders. For remote or high-demand areas, pre-emptive stocking of critical spares (e.g., milling burs, alignment pins) is advised. Distributors should maintain an active service agreement to ensure priority access to parts and firmware updates. |

| 3. What does the professional installation process for a CEREC milling unit entail? | Professional installation includes site assessment, environmental calibration, hardware setup, software integration, and operational training. A certified Dentsply Sirona technician will verify workspace dimensions, ventilation, power stability, and network connectivity. The unit is leveled, grounded, and calibrated using diagnostic test blocks. Integration with CEREC Software 6.0+ and intraoral scanners (e.g., Omnicam, Primescan) is performed, followed by a live milling demonstration. Installation typically takes 4–6 hours and is included in most clinic purchase packages. Remote pre-installation checklists are provided to streamline on-site deployment. |

| 4. What warranty coverage is standard for CEREC milling units purchased in 2026? | CEREC milling units purchased in 2026 come with a comprehensive 2-year limited warranty covering parts, labor, and technical support. The spindle assembly and control board are covered under extended component-level protection. Wear items (e.g., milling burs, lubricants) are excluded. Optional 3rd and 4th-year extended warranties are available through Dentsply Sirona ServiceCare programs, which also include preventive maintenance visits, software updates, and priority repair dispatch. Distributors may offer bundled warranty extensions for multi-unit clinic deployments. |

| 5. Are firmware and software updates included during the warranty period, and how are they deployed? | Yes, all firmware and software updates for CEREC milling units are included at no additional cost during the warranty period. Updates are released quarterly and delivered via secure online connection through the CEREC Connect platform. Automatic update notifications are provided, with options for scheduled deployment during off-hours. For clinics with restricted IT environments, offline update packages and on-site technician support are available through authorized service partners. Keeping the system updated ensures compatibility with new materials, milling strategies, and CAD/CAM workflows. |

Need a Quote for Cerec Milling Unit?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160