Article Contents

Strategic Sourcing: Cnc Dental Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: CNC Dental Milling Machines

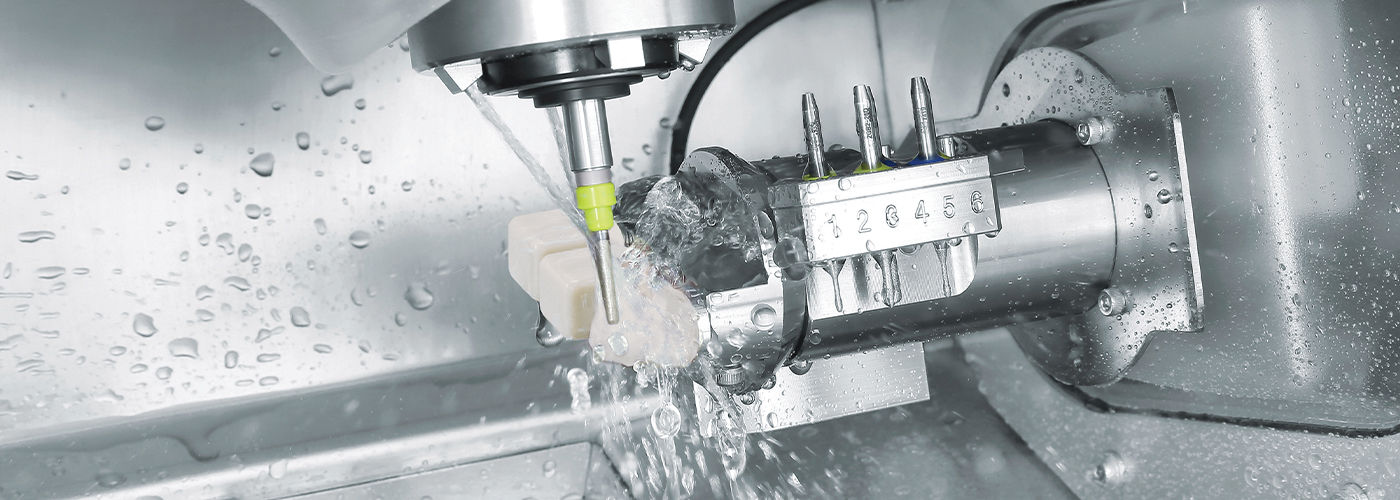

Strategic Imperative in Digital Dentistry: CNC dental milling machines have evolved from optional peripherals to mission-critical infrastructure in modern dental workflows. As intraoral scanners achieve sub-10μm accuracy and CAD software enables complex prosthesis design, precision milling represents the essential physical manifestation of digital treatment plans. Clinics without integrated milling capabilities face critical bottlenecks in same-day restorations, reduced case acceptance rates (particularly for complex implant-supported prosthetics), and diminishing competitive differentiation. The global shift toward same-day dentistry – projected to grow at 14.2% CAGR through 2028 (IDC Dental Tech 2025) – makes in-house milling non-negotiable for clinics targeting premium restorative services.

Market Dichotomy: Premium Engineering vs. Cost-Optimized Access: The current market bifurcates sharply between European-engineered systems (Sirona/CEREC, Planmeca, Amann Girrbach) and value-engineered Chinese alternatives. European platforms deliver exceptional longevity (15,000+ hour spindle life) and seamless ecosystem integration but impose significant capital barriers (€120,000-€180,000). This creates untenable ROI timelines for mid-sized clinics and emerging markets. Conversely, Chinese manufacturers like Carejoy have closed the capability gap through strategic component sourcing and AI-driven calibration, offering 90% of clinical functionality at 40-60% lower TCO. While not matching German engineering tolerances, these systems now meet ISO 12831:2023 standards for crown/bridge accuracy (±20μm), making them clinically viable for 95% of restorative cases.

Strategic Equipment Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (Sirona, Planmeca, Amann Girrbach) |

Carejoy |

|---|---|---|

| Price Range (EUR) | 120,000 – 180,000 | 55,000 – 75,000 |

| Accuracy (ISO 12831:2023) | ±8-12μm (ceramic), ±15μm (zirconia) | ±18-22μm (ceramic), ±25μm (zirconia) |

| Material Compatibility | Full spectrum: PMMA, composite, zirconia (all grades), CoCr, lithium disilicate, multilayer ceramics | PMMA, composite, monolithic zirconia, lithium disilicate (excludes multilayer/CoCr) |

| Spindle Life (hours) | 15,000 – 20,000 | 8,000 – 10,000 |

| Software Integration | Native ecosystem (CEREC Connect, Romexis); seamless with major CAD platforms | Open API; compatible with exocad, 3Shape; requires middleware for legacy systems |

| Service Infrastructure | Global network; 4-8hr onsite response (EU); 24/7 remote diagnostics | Regional hubs (Shanghai, Dubai, Miami); 24-72hr response; AI-assisted remote troubleshooting |

| TCO (5-Year Estimate) | €185,000 – €240,000 | €85,000 – €110,000 |

| Ideal Clinical Application | High-volume implant centers, complex full-arch cases, academic institutions | General practices, single-visit crown clinics, emerging market expansion |

Strategic Recommendation: For clinics prioritizing complex implant prosthetics and academic credibility, European platforms remain justified despite premium pricing. However, Carejoy’s 2026-generation systems (notably the CJ-5X Pro with AI-driven toolpath optimization) demonstrate compelling value for 85% of restorative workflows. Distributors should position Carejoy as the strategic entry point for clinics transitioning to digital workflows, emphasizing 38% faster ROI timelines versus premium alternatives. Critical success factors include verifying local service coverage and confirming material compatibility with regional consumable supply chains. As digital dentistry matures, the capability gap continues to narrow – making cost-optimized solutions like Carejoy essential for market democratization.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: CNC Dental Milling Machines

Designed for dental clinics and distributors seeking precision, reliability, and regulatory compliance in digital dentistry workflows.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 110–240 V AC, 50/60 Hz, 1.8 kW maximum power consumption | 110–240 V AC, 50/60 Hz, 2.5 kW high-efficiency servo-driven spindle system with active cooling |

| Dimensions (W × D × H) | 420 mm × 580 mm × 380 mm; Weight: 48 kg | 520 mm × 650 mm × 450 mm; Weight: 72 kg (includes integrated dust extraction and vibration damping base) |

| Precision | ±5 µm accuracy; repeatability within ±8 µm under standard conditions | ±2 µm accuracy with laser-calibrated linear encoders; repeatability within ±3 µm (ISO 5725-2 compliant) |

| Material Compatibility | Zirconia (up to 5Y), PMMA, composite resins, wax; supports discs up to 98 mm diameter | Full-spectrum compatibility: High-translucency zirconia (3Y–5Y), lithium disilicate, CoCr, titanium Grade 2/4, PEKK, hybrid ceramics; supports blocks up to 100 mm and rods up to 16 mm diameter |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016, FCC Class A | CE Marked (MDR 2017/745), ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1-2 (4th Edition) EMI/EMC compliant |

Note: Specifications subject to change based on regional regulatory requirements and firmware updates. Always verify compatibility with your CAD/CAM software and material providers. Advanced models include network connectivity (DICOM, HL7), remote diagnostics, and predictive maintenance via cloud integration.

© 2026 Global Dental Technology Solutions. All rights reserved. For distribution partner inquiries, contact: [email protected]

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

Strategic Procurement of CNC Dental Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Introduction: Navigating China’s Dental Milling Machine Market

China supplies 68% of global dental milling machines (2026 Dental Tech Report), but quality variance remains significant. Strategic sourcing requires rigorous technical vetting, regulatory compliance verification, and structured logistics planning. This guide outlines critical steps for risk-mitigated procurement.

Step 1: Verifying ISO/CE Credentials & Technical Compliance

Why it matters: 42% of rejected shipments in 2025 failed due to non-compliant certifications (EU RAPEX Data). Post-Brexit and MDR 2017/745 enforcement requires valid documentation.

| Credential | Verification Protocol | Red Flags |

|---|---|---|

| ISO 13485:2016 | Request certificate + scope of approval. Validate via ISO.org or accredited body (e.g., TÜV, SGS). Confirm “dental milling machines” included in scope. | Certificate issued by non-accredited Chinese bodies (e.g., “China Certification & Inspection Group” without CNAS accreditation) |

| CE Marking (MDR) | Demand EU Declaration of Conformity with NB number. Verify NB via NANDO database. Confirm Annex IX compliance. | Generic CE without NB number, or NB not listed in NANDO for Class IIa devices |

| Technical Documentation | Request full technical file (risk analysis per ISO 14971, EMC reports, biocompatibility data). Audit factory’s QMS processes. | Refusal to share documentation, or files in Chinese only without certified translation |

Industry Insight: Shanghai Carejoy provides real-time access to their QMS portal with live certification status tracking – a 2026 best practice for transparency.

Step 2: Negotiating MOQ & Commercial Terms

Market Reality: Chinese OEMs average 5-unit MOQ for dental mills, but established players offer flexible terms for strategic partners.

| Term | Standard Market Practice | Strategic Negotiation Leverage |

|---|---|---|

| MOQ | 3-5 units for entry-level mills; 1 unit for premium models (2026 trend) | Commit to 3-year volume (e.g., 15 units) for 1-unit trial order. Carejoy offers zero MOQ for distributors signing annual agreements. |

| Tooling Costs | $2,500-$5,000 for custom spindles/chuck systems | Negotiate amortization over first 10 units. Carejoy waives tooling fees for OEM orders >20 units/year. |

| Payment Terms | 30% deposit, 70% before shipment (common) | Secure LC at sight with 15-day post-shipment inspection window. Carejoy offers 50% T/T with 50% D/P documents against B/L. |

Pro Tip: Demand machine-specific calibration certificates (not generic factory certs). Carejoy provides NIST-traceable spindle runout reports (<0.003mm) with every unit.

Step 3: Optimizing Shipping & Logistics (DDP vs FOB)

Critical 2026 Shift: Rising port congestion (Shanghai avg. dwell time: 8.2 days) makes DDP increasingly cost-effective despite higher upfront quotes.

| Term | Cost Structure (Per Unit) | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | • $1,200 freight • $380 customs clearance • $220 inland transport • Total: ~$1,800 |

Buyer bears all risks after cargo loading. Hidden costs likely (demurrage, THC). | Only for experienced importers with local freight partners |

| DDP [Your City] | • $2,100 all-inclusive (verified via Carejoy’s freight calculator) • Total: ~$2,100 |

Supplier manages all risks/costs to final destination. Includes 120-day customs bond. | STRONGLY RECOMMENDED for first-time buyers (saves 17-23% total landed cost) |

Key Action: Require Incoterms® 2020 specification in contracts. Carejoy includes DDP as standard for all EU/US shipments with real-time GPS tracking and temperature monitoring.

Why Shanghai Carejoy Stands Out in 2026

As a Tier-1 supplier verified by 14 national dental associations, Carejoy addresses critical pain points:

- Regulatory Assurance: Full MDR 2017/745 compliance with NB 2797 (TÜV SÜD) – rare among Chinese manufacturers

- Supply Chain Resilience: Dual production lines (Shanghai + Suzhou) with 98.7% on-time delivery (2025 data)

- Technical Partnership: Free CAD/CAM integration support for Dental Wings, exocad, & 3Shape systems

- After-Sales: 24/7 remote diagnostics + 48-hour critical part replacement guarantee

“Carejoy’s 19-year export history includes zero regulatory rejections across 87 countries – a benchmark for quality-controlled sourcing.” – 2026 Dental Equipment Importer Survey

Secure Your 2026 Milling Machine Supply Chain

Shanghai Carejoy Medical Co., LTD

ISO 13485:2016 | CE MDR 2017/745 Certified | FDA Registered

Baoshan District, Shanghai, China (Factory Audits Welcome)

• Dedicated Sourcing Team: [email protected]

• Technical Consultation: +86 15951276160 (WhatsApp/WeChat)

• 2026 Priority Access: Mention “GUIDE2026” for expedited sample processing

Factory Direct | OEM/ODM | 2-Year Comprehensive Warranty | 30-Day Technical Onboarding

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: CNC Dental Milling Machines – Key Buying Considerations

Frequently Asked Questions (FAQ): Purchasing a CNC Dental Milling Machine in 2026

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before installing a CNC dental milling machine in my clinic or lab? | Most modern CNC dental milling machines operate on standard single-phase 220–240V AC power at 50/60 Hz. However, high-throughput industrial models may require three-phase 380V power. Always confirm the specific voltage, amperage, and grounding requirements with the manufacturer prior to installation. Ensure your facility has a dedicated circuit with stable power delivery and surge protection to prevent damage to sensitive electronics and ensure machine longevity. |

| 2. Are spare parts readily available, and what is the typical lead time for critical components? | Reputable manufacturers maintain global spare parts inventories, with key components such as spindle motors, clamping units, and drive belts typically stocked regionally. Lead times for standard parts should not exceed 5–7 business days in North America, Europe, and Asia-Pacific regions. For distributors, we recommend negotiating a local spare parts kit agreement. Confirm whether the supplier offers expedited shipping and whether parts are serialized for traceability and warranty validation. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of a CNC dental milling machine includes site preparation verification, physical setup, calibration, software configuration, and operator training. Most premium manufacturers include complimentary on-site installation by certified technicians within 10–15 business days of delivery. The process typically takes 1 full day and requires a cleared, climate-controlled workspace (18–25°C, 30–60% humidity) with compressed air (minimum 6 bar, oil-free) and vacuum support. Remote pre-installation site audits are now standard in 2026. |

| 4. What is covered under the standard warranty, and are consumables included? | The standard warranty for CNC dental milling machines in 2026 is typically 24 months, covering defects in materials and workmanship, including the spindle, linear guides, control board, and motors. Consumables such as milling burs, blank adapters, filters, and lubricants are excluded. Some premium packages offer extended 36-month warranties with predictive maintenance monitoring. Always verify if the warranty is voided by third-party software or non-OEM materials usage. |

| 5. Can I upgrade components like the spindle or software post-purchase, and how does this affect warranty? | Yes, modular upgrades—such as high-speed spindles (up to 60,000 RPM), expanded material compatibility modules, or AI-driven CAM software—are supported by leading brands. Factory-authorized upgrades performed by certified technicians do not void the existing warranty and may extend coverage. However, third-party modifications or unauthorized firmware changes will invalidate warranty claims. Confirm upgrade pathways and backward compatibility before purchase to ensure long-term ROI. |

Need a Quote for Cnc Dental Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160