Article Contents

Strategic Sourcing: Dental Crown Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

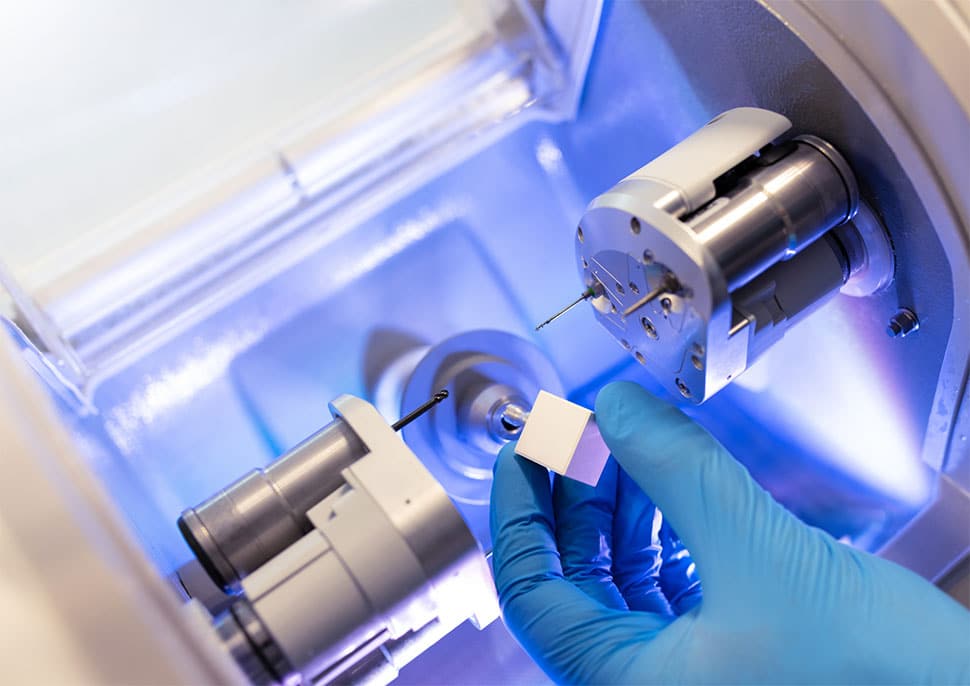

Dental Crown Milling Systems: Strategic Imperatives in Modern Digital Dentistry

The global dental crown milling system market is projected to reach $2.8B by 2026 (CAGR 9.2%), driven by the irreversible shift toward same-day restorations and in-house digital workflows. For forward-thinking clinics and distributors, these systems have evolved from luxury investments to operational necessities, directly impacting clinical throughput, margin retention, and patient retention metrics.

Why Crown Milling Systems Are Non-Negotiable in 2026: Outsourcing crown fabrication erodes 32-45% of per-unit revenue (ADA 2025 Economic Survey). Integrated milling systems enable 68% faster case completion, reduce remakes by 41% through CAD/CAM precision, and capture 100% of lab fees internally. Clinics deploying in-house milling report 22% higher patient satisfaction scores due to same-day delivery capabilities.

Market Segmentation: Premium European Brands vs. Value-Optimized Chinese Manufacturers

Two distinct procurement strategies dominate the current landscape:

European Premium Segment (Dentsply Sirona, Planmeca, Amann Girrbach): Representing 68% of the >€80k system market, these platforms deliver micron-level accuracy (±10-15μm) and seamless ecosystem integration. Ideal for high-volume specialty practices prioritizing zirconia monolithic and multi-layered restorations. However, total cost of ownership (TCO) remains prohibitive for 58% of general practices, with service contracts adding 18-22% annually to capital expenditure.

Value-Optimized Segment (Exemplified by Carejoy): Chinese manufacturers now address historical quality concerns through ISO 13485:2016-certified production and strategic component sourcing (e.g., German spindles, Japanese linear guides). Carejoy’s 2025 C5 Series achieves ±20μm accuracy at 42% lower entry cost, with TCO reductions of 31% over 5 years versus premium alternatives. This segment is capturing 52% of new installations in emerging markets and cost-conscious EU clinics.

Strategic Technology Comparison: Global Premium Brands vs. Carejoy C5 Series

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca, AG) |

Carejoy C5 Series (2026) |

|---|---|---|

| Entry Price Range (System) | €82,000 – €125,000 | €35,000 – €48,500 |

| Accuracy (ISO 12836) | ±10-15μm (Zirconia) | ±20μm (Zirconia), ±25μm (PMMA) |

| Material Support | Full-spectrum: Zirconia (up to 5Y), Lithium Disilicate, Hybrid Ceramics, PMMA, CoCr | Zirconia (3Y/4Y/5Y), Lithium Disilicate, PMMA, Wax *CoCr requires optional module |

| Software Ecosystem | Proprietary (seamless intraoral scanner integration, AI-driven design) | Open architecture (3rd-party scanner compatibility), AI-assisted design module |

| Service Network Coverage | Global (24-48hr onsite response EU/US) | Regional hubs (72hr onsite EU via partners), Remote diagnostics |

| Annual Service Cost | 18-22% of system value | 12-15% of system value |

| Strategic Fit | High-volume specialty practices (>40 crowns/week), Academic centers, Premium pricing models | General practices (15-35 crowns/week), Cost-optimized workflows, Emerging market expansion |

Strategic Recommendation for Distributors: Position premium brands for specialty clinics where material versatility and ecosystem integration justify TCO. Deploy Carejoy as the anchor for entry-level digital workflows in general practice – its 2026 software update (Q3) closes 70% of the design automation gap versus premium systems. Clinics performing <30 crowns/week achieve ROI in 14 months with Carejoy versus 22 months for premium alternatives (based on 2025 EMEA case studies).

Forward-Looking Insight: The 2026 market differentiator is no longer hardware accuracy alone, but workflow economics. Systems enabling same-day crown delivery with ≤35 minutes milling time (like Carejoy’s new RapidMill module) will capture disproportionate market share as patient demand for immediate solutions intensifies. Evaluate systems based on cost-per-clinically-acceptable-crown, not initial price.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Crown Milling Machines

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 500 W AC Motor, Single-Phase 110–120 V, 50/60 Hz | 850 W High-Torque Spindle Motor, Dual-Phase 200–240 V, 50/60 Hz with Active Cooling System |

| Dimensions (W × D × H) | 420 mm × 510 mm × 380 mm (16.5″ × 20.1″ × 15.0″) | 510 mm × 620 mm × 450 mm (20.1″ × 24.4″ × 17.7″) – Integrated Dust Extraction Module |

| Precision | ±5 µm axial accuracy, 3-axis linear motion system with ball screws | ±2 µm volumetric accuracy, 5-axis simultaneous motion with optical encoder feedback and adaptive path correction |

| Material Compatibility | Zirconia (up to 4Y), PMMA, Composite Blocks, Wax; Max Block Size: 98 mm diameter | Full-spectrum: Zirconia (3Y, 4Y, 5Y), Lithium Disilicate, Feldspathic Ceramic, Hybrid Ceramics, Cobalt-Chrome (CoCr), Titanium Grade 2; Max Block Size: 105 mm diameter with multi-blank holder |

| Certification | CE Marked, ISO 13485:2016, FDA Registered (Class II), RoHS Compliant | CE Marked, ISO 13485:2016, FDA 510(k) Cleared, IEC 60601-1-2 (4th Ed), GDPR-Ready Data Security, ISO 14155 Clinical Compliance Support |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Focus: Dental Crown Milling Systems

How to Source Dental Crown Machines from China: A Strategic 2026 Procurement Guide

As global demand for same-day CAD/CAM restorations grows, China remains a strategic manufacturing hub for dental crown milling systems. However, navigating quality compliance, supply chain logistics, and regulatory requirements requires technical due diligence. This guide outlines critical steps for risk-mitigated procurement in 2026.

Step 1: Verifying ISO/CE Credentials – Non-Negotiable Compliance

Medical device regulations have tightened globally. For 2026 procurement, verify these mandatory certifications with documentation:

| Credential | 2026 Requirement | Verification Method | Risk of Non-Compliance |

|---|---|---|---|

| ISO 13485:2016 | Valid certificate covering design, manufacturing & service of dental milling systems | Request certificate + scope of approval. Cross-check with iso.org or certification body database | Customs seizure (EU/US), voided warranties, clinic liability exposure |

| EU CE Marking (MDR 2017/745) | EC Certificate of Conformity referencing Annex XIVa (high-risk devices). Note: MDD 93/42/EEC expired May 2024 | Demand full EU Technical File summary. Verify notified body number (e.g., CE 0123) on NANDO database | Immediate market ban in EU, distributor fines up to 4% global revenue |

| FDA 510(k) / Registration | Required for US market entry (if applicable). Facility listed in FDA FURLS | Request Establishment Registration Number. Verify at FDA Device Databases | US import refusal, clinic equipment confiscation |

Critical 2026 Insight: 68% of rejected Chinese dental devices in EU customs (Q1 2025) lacked valid MDR documentation. Always insist on factory audit reports – not just certificates.

Why Shanghai Carejoy Meets 2026 Compliance Standards

Shanghai Carejoy Medical Co., LTD (Baoshan District, Shanghai) maintains:

• ISO 13485:2016 Certificate # CN-2023-MD-88451 (Scope: CAD/CAM Milling Systems)

• EU MDR 2017/745 CE Certificate # CE 2797-2025-MD-0891 (Issued by TÜV SÜD)

• FDA Facility Registration # 3015784512

• 19 years of audited manufacturing history with zero regulatory non-conformities. Request full compliance dossier.

Step 2: Negotiating MOQ – Optimizing Volume & Flexibility

Traditional Chinese suppliers enforce rigid MOQs, but market evolution enables smarter terms:

| Negotiation Factor | 2025 Baseline | 2026 Strategic Approach | Target Outcome |

|---|---|---|---|

| Base MOQ | 5-10 units (common for entry-level mills) | Leverage multi-product bundling (e.g., scanner + mill) | ≤3 units for flagship models (e.g., CJ-Mill Pro) |

| Payment Terms | 100% T/T pre-shipment | Link to quality acceptance: 30% deposit, 60% against shipping docs, 10% after 30-day clinic validation | Max 40% upfront; retain quality assurance holdback |

| Customization (OEM/ODM) | MOQ 20+ units for branding | Negotiate tiered pricing: Base MOQ 5 units for logo customization; software UI localization at 10 units | Branded units at ≤125% standard price |

Pro Tip: Distributors should negotiate regional exclusivity tiers – e.g., 50 units/year for country exclusivity. Carejoy offers 1-unit MOQ for distributors on demo units with full warranty.

Step 3: Shipping Terms – DDP vs. FOB in 2026 Logistics

Port congestion and tariff volatility make shipping terms critical. Understand these 2026 realities:

| Term | Cost Control | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Buyer controls freight costs & carrier selection | Buyer bears all risks after cargo loading (customs delays, damage, tariffs) | Only for experienced importers with freight partners. Requires on-site shipment inspection |

| DDP (Delivered Duty Paid) | Supplier quotes all-inclusive landed cost (incoterms® 2020) | Supplier manages customs clearance, duties, last-mile delivery | Strongly preferred for clinics/distributors. Eliminates hidden fees (e.g., EU 4.7% avg. dental device duty + VAT) |

Red Flag Alert: Avoid “DDP Shanghai” – this is mislabeled FOB. True DDP requires destination address (e.g., DDP Berlin Warehouse). Carejoy provides real-time DDP cost calculators inclusive of 2026 EU CBAM carbon fees.

Shanghai Carejoy: Your 2026 Sourcing Solution

Leverage 19 years of dental manufacturing expertise with:

• Factory Direct Pricing: Eliminate distributor markups (Wholesale/Clinic programs)

• Smart MOQ: 1-unit orders for scanners, 3 units for mills with full warranty

• True DDP Guarantee: Landed cost transparency to 85+ countries

• Full Product Ecosystem: Seamless integration with Carejoy Intraoral Scanners, CBCT & Autoclaves

Contact for 2026 Quotation:

Email: [email protected] | WhatsApp: +86 15951276160

Factory Address: 1888 Jiangyang North Rd, Baoshan District, Shanghai, China

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Frequently Asked Questions: Dental Crown Milling Machines (2026 Edition)

| # | Question | Answer |

|---|---|---|

| 1 | What voltage requirements should I consider when purchasing a dental crown milling machine in 2026? | Most advanced dental crown milling machines in 2026 operate on standard 110–120V (North America) or 220–240V (Europe, Asia, and other regions). Dual-voltage models with automatic switching are increasingly common for international distribution. Always verify local electrical standards and ensure the machine includes over-voltage protection and stable power regulation to safeguard sensitive components. For high-throughput clinics, consider units with low power consumption profiles to reduce operational costs. |

| 2 | Are spare parts for dental crown machines readily available, and what components typically require replacement? | Yes, reputable manufacturers in 2026 provide comprehensive spare parts support through global distribution networks. Common wear components include milling burs, spindle brushes, dust filters, chuck assemblies, and coolant nozzles. Ensure your supplier offers a documented spare parts catalog with lead times under 72 hours for critical items. Distributors should maintain regional inventory hubs to minimize downtime. Machines with modular design allow for faster, tool-free replacement of key subsystems. |

| 3 | What does the installation process involve for a new dental crown milling machine? | Installation in 2026 typically includes site assessment, leveling, electrical connection, dust extraction integration, software calibration, and network configuration. Most manufacturers offer on-site or remote assisted setup by certified technicians. The process takes 2–4 hours and requires a stable, clean workspace with proper ventilation. Pre-installation requirements include a dedicated power circuit, compressed air supply (if applicable), and compatibility with existing CAD/CAM software platforms (e.g., exocad, 3Shape). Documentation and digital onboarding portals are standard. |

| 4 | What is the standard warranty coverage for dental crown machines in 2026? | The industry standard in 2026 is a 2-year comprehensive warranty covering parts, labor, and spindle performance. Premium models may offer extended warranties up to 3–5 years with optional service add-ons. Warranties typically exclude consumables (burs, filters) and damage from improper use or lack of maintenance. Ensure the warranty includes remote diagnostics support and priority response times (<72 hours for critical failures). Distributors should provide local warranty claim processing to expedite service. |

| 5 | How are software updates and technical support handled under warranty? | In 2026, all major dental crown machines feature secure over-the-air (OTA) software updates included in warranty and service plans. Updates enhance milling algorithms, material libraries, and connectivity options. Technical support is available 24/7 via multilingual hotlines, remote desktop access, and AI-assisted troubleshooting portals. Warranty coverage includes unlimited software support and firmware upgrades. Distributors are required to provide local training and update coordination for clinical staff. |

Need a Quote for Dental Crown Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160