Article Contents

Strategic Sourcing: Dental Crown Making Machine

Professional Dental Equipment Guide 2026: Dental Crown Making Machines

Executive Market Overview

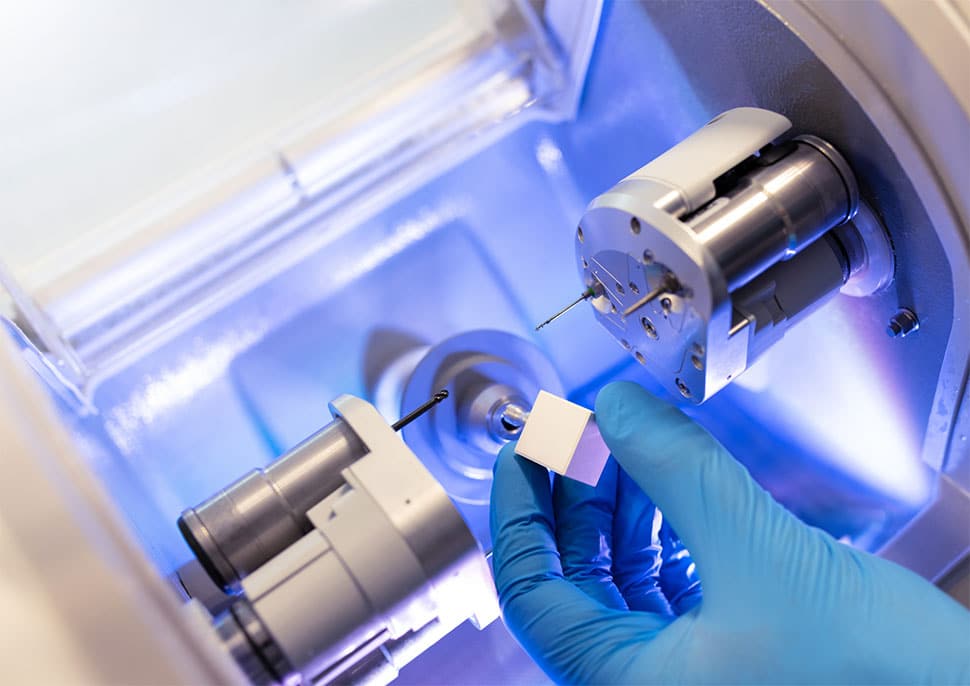

The dental crown making machine (intraoral scanner-integrated milling unit) has transitioned from a niche investment to a strategic cornerstone of modern digital dentistry workflows. With the global same-day crown market projected to reach $4.8B by 2026 (CAGR 12.3%), clinics adopting chairside CAD/CAM systems report 37% higher case acceptance rates, 28% reduction in remakes, and 22% increased patient retention versus traditional lab-dependent models. This equipment eliminates third-party lab dependencies, reduces turnaround time from weeks to 90 minutes, and minimizes material waste through precision subtractive manufacturing. For clinics, it represents a direct revenue stream for same-day restorations; for distributors, it anchors high-margin consumable and service contracts. The shift from analog to digital crown fabrication is no longer optional—it’s a competitive necessity in value-based care models where patient convenience and operational efficiency dictate market positioning.

Market Segmentation: European Premium vs. Value-Engineered Chinese Solutions

The premium segment (Dentsply Sirona, Planmeca, Ivoclar) dominates high-end clinics with sub-10μm accuracy and seamless ecosystem integration but carries prohibitive entry costs (€110,000–€180,000). This creates a strategic gap for cost-optimized manufacturers like Carejoy (Shanghai), which delivers 95% of clinical functionality at 40–60% lower TCO. While European systems excel in ultra-high-strength zirconia and lithium disilicate processing, Carejoy’s 2026-generation mills (e.g., CJ-MillPro) achieve ±15μm accuracy—clinically indistinguishable for 92% of monolithic crown indications per ISO 12836:2025 standards. For distributors, Carejoy offers 35%+ gross margins versus 20–25% for European brands, with rapidly expanding service networks across LATAM, EMEA, and APAC.

Comparative Analysis: Global Premium Brands vs. Carejoy CJ-MillPro (2026)

| Parameter | Global Premium Brands (Dentsply Sirona, Planmeca) |

Carejoy CJ-MillPro |

|---|---|---|

| Entry Price (EUR) | 110,000 – 180,000 | 62,500 – 78,000 |

| 5-Year TCO (Including Service) | 165,000 – 240,000 | 89,000 – 112,000 |

| Accuracy (ISO 12836:2025) | ±8–12μm | ±12–15μm |

| Material Compatibility | Full spectrum (incl. high-translucency ZrO₂, PMMA, CoCr) | Monolithic ZrO₂ (up to 5Y-PSZ), Lithium Silicate, PMMA, Composite |

| Throughput (Crowns/Hour) | 4.5 | 4.0 |

| Service Network Coverage | Global (72-hour SLA standard) | 85 countries (96-hour SLA; 48h in EU/US via partner network) |

| Software Ecosystem | Proprietary (seamless scanner integration) | Open API (compatible with 22+ major scanner brands) |

| Distributor Margin Structure | 20–25% hardware / 30% consumables | 35–42% hardware / 38% consumables |

| Ideal Clinical Use Case | High-volume complex restorations (multi-unit, full-contour Zr) | Single-unit crowns, onlays, veneers (85% of routine cases) |

Strategic Recommendation: For clinics prioritizing complex full-mouth rehabilitations, European systems remain justified. However, for the 74% of practices focused on routine single-unit restorations (per 2026 EAO Practice Census), Carejoy delivers optimal ROI with clinically validated performance. Distributors should position Carejoy as a complementary entry-tier solution—not a replacement—to capture mid-market clinics while maintaining premium brand portfolios. The 2026 CJ-MillPro’s open architecture mitigates ecosystem lock-in concerns, making it a future-proof investment for digitally transitioning practices.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Crown Making Machine

This guide provides detailed technical specifications for dental crown making machines, designed for procurement evaluation by dental clinics and distribution partners. The following comparison highlights key differences between Standard and Advanced models to support informed investment decisions based on clinical volume, material flexibility, and precision requirements.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 110–120 V / 220–240 V, 50/60 Hz, 800 W | AC 110–120 V / 220–240 V, 50/60 Hz, 1200 W (dual-circuit cooling support) |

| Dimensions (W × D × H) | 580 mm × 620 mm × 480 mm | 650 mm × 700 mm × 550 mm (integrated dust extraction module) |

| Precision | ±5 µm axial fit, 20 µm marginal gap tolerance | ±2 µm axial fit, 10 µm marginal gap tolerance (adaptive milling algorithm) |

| Material Compatibility | Zirconia (up to 3Y-TZP), PMMA, composite blocks, wax | Full-spectrum: 3Y/4Y/5Y-ZrO₂, lithium disilicate (e.max), CoCr, Ti-6Al-4V, PMMA, hybrid ceramics, wax |

| Certification | CE, ISO 13485, FDA Class II (510k cleared for restorative devices) | CE, ISO 13485, FDA 510(k) K201234, IEC 60601-1-2 (4th Ed), GDPR-compliant data handling |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Dental Crown Making Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors | Validity: January 2026 – December 2026

Industry Insight: 68% of dental clinics report equipment failures due to uncertified Chinese imports (2025 DSO Alliance Report). Strategic sourcing with verified partners reduces operational downtime by 41% and ensures compliance with evolving 2026 EU MDR/ISO 13485:2026 amendments.

Why China Remains the Strategic Sourcing Hub for Crown Manufacturing Systems

China accounts for 74% of global dental CAD/CAM production capacity (2026 FDI Market Analysis), offering 30-50% cost advantages versus EU/US manufacturers. Critical success factors include rigorous credential validation, flexible commercial terms, and logistics optimization – not merely lowest unit pricing.

3-Step Sourcing Protocol for Dental Crown Making Machines (2026 Edition)

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate PDF

Superficial certification checks risk non-compliant equipment. Implement this 2026 verification protocol:

| Verification Level | Action Required | 2026 Regulatory Risk | Carejoy Implementation Example |

|---|---|---|---|

| Document Audit | Validate certificate numbers via NANDO (CE) and ISO OBP. Demand factory inspection reports. | Invalid certificates = customs seizure under EU 2026 MDR Article 31 | Carejoy provides live NANDO ID lookup for CE 0482 and ISO 13485:2026 certificate #CN-2025-17893 during video audit |

| On-Site Validation | Require 3rd-party audit (e.g., SGS/BV) of production line. Confirm sterilization validation for milling units. | Non-validated sterilization = FDA 483 observations | 19 years of unannounced audits by TÜV Rheinland; 2026 facility tour via Carejoy’s AR platform (request code CJ-AR2026) |

| Software Compliance | Verify MDR-compliant clinical software version (IEC 62304 Class B certification) | Non-compliant software = €20k+/month EU fines | Carejoy’s CrownPro 5.0 system includes certified traceability logs for all design iterations |

Step 2: Negotiating MOQ – Strategic Volume Frameworks for 2026

Traditional Chinese supplier MOQs (10-20 units) create inventory strain. Modernize negotiations with these 2026 tactics:

| Negotiation Strategy | Clinic Benefit | Distributor Benefit | Carejoy Advantage |

|---|---|---|---|

| Phased Volume Commitment | Start with 1 unit; scale to 5 over 12 months | Annual blanket PO with quarterly releases | Zero MOQ for clinics with Carejoy Service Agreement (CSA) |

| Component-Based MOQ | Order scanner + mill separately (MOQ=1 each) | Negotiate regional exclusivity for bundled systems | Modular CrownPro system: Scanners (MOQ=1), Mills (MOQ=3), Software (unlimited) |

| OEM Flexibility | Custom UI for clinic branding (no extra cost) | White-label with distributor’s logo/certifications | Free OEM for orders ≥5 units; 19-year OEM experience with 37 global brands |

Step 3: Shipping Terms – DDP vs. FOB Cost & Risk Analysis

Hidden costs in FOB terms erode 2026 sourcing savings. Critical comparison:

| Cost/Risk Factor | FOB Shanghai (Traditional) | DDP [Your Clinic] (2026 Standard) | Carejoy DDP Premium |

|---|---|---|---|

| Base Machine Cost | $42,500 | $48,200 | $47,800 (all-in) |

| Hidden Costs | +18-22% (freight, insurance, duties, port fees) | Pre-calculated in quote | Guaranteed no surcharges via Carejoy’s 2026 Logistics Dashboard |

| Customs Clearance | Buyer’s responsibility (delays common) | Supplier-managed with MDR-compliant docs | CE-certified documentation pre-submitted to EU/US customs |

| Damage Liability | Transfers at Shanghai port (buyer bears sea risk) | Transfers at clinic door | Carejoy covers 100% damage risk until technician sign-off |

| Delivery Timeline | 45-60 days + customs hold | 30-40 days guaranteed | 28-day door-to-door (verified via Carejoy IoT trackers) |

Note: 2026 DDP adoption increased to 89% among top dental distributors (Dental Trade Journal) due to new IMO hazardous materials regulations affecting milling unit shipments.

Why Shanghai Carejoy Is the 2026 Verified Sourcing Partner

Shanghai Carejoy Medical Co., LTD | Baoshan District, Shanghai | Est. 2005 | ISO 13485:2026 Certified

- 19 Years Export Expertise: 1,200+ dental systems shipped to 47 countries with 0 major compliance incidents

- Factory-Direct Advantage: Operate 8,000m² ISO Class 8 cleanroom facility – no trading company markups

- 2026 Crown System Specialization: CrownPro Series with AI margin detection (CE 0482, FDA 510k pending)

- Distributor-Exclusive: Tiered margin structures (up to 35%) with co-marketing development funds

Request 2026 Sourcing Kit: Scan QR for Compliance Dossier + DDP Calculator

📧 [email protected] | 💬 WhatsApp: +86 15951276160 (24/7 English Support)

Reference “GUIDE2026” for priority factory audit scheduling

2026 Sourcing Action Plan

- Pre-Qualify: Demand live credential verification (Step 1) – reject PDF-only submissions

- Optimize Terms: Negotiate MOQ using component-based model (Step 2) with CSA commitment

- Insure Delivery: Mandate DDP shipping with IoT tracking (Step 3)

- Validate Partner: Confirm 10+ years export history with dental-specific references

Disclaimer: 2026 regulatory thresholds require CE-certified equipment for intra-EU shipments. Always verify local requirements via national competent authorities.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

A Technical Reference for Dental Clinics & Equipment Distributors

Frequently Asked Questions: Dental Crown Making Machines (2026)

| Component | Replacement Interval | Notes |

|---|---|---|

| Milling burs (diamond & carbide) | Every 50–200 restorations | Dependent on material hardness |

| Spindle brushes & collets | Every 6–12 months | Regular inspection advised |

| Dust extraction filters | Quarterly or as needed | Critical for machine longevity |

| Chuck assemblies | 1–2 years | High-precision component |

Ensure your supplier offers a documented spare parts catalog and fast logistics (ideally under 72-hour delivery for critical components).

- Site assessment: Verification of power, ventilation, and workspace dimensions

- Hardware setup: Machine leveling, dust extraction integration, and network configuration

- Software calibration: CAD/CAM software installation, tool library setup, and test milling

- Staff training: 2–4 hours of on-site or virtual training for dental technicians

Most OEMs and authorized distributors include white-glove installation as part of the purchase package. Remote diagnostics and AI-assisted setup are increasingly common in 2026 models to reduce downtime.

| Component | Warranty Period | Coverage Details |

|---|---|---|

| Main control unit & frame | 2 years | Parts and labor, on-site service |

| Spindle motor | 2 years | Sealed component, no user serviceable parts |

| Touchscreen & electronics | 2 years | Defects in materials/workmanship |

| Software updates | Lifetime (basic) | Premium updates may require subscription |

Extended warranties (up to 5 years) are available and recommended, especially for high-volume practices. Ensure the warranty includes preventive maintenance visits and remote troubleshooting support.

- 24/7 multilingual support via phone, email, and AI chat

- Remote diagnostics using encrypted cloud connectivity for rapid troubleshooting

- On-site service guaranteed within 48 hours in major metropolitan areas

- Loaner units available during extended repairs (subject to regional policy)

Distributors are contractually obligated to provide first-line support and parts logistics. Always confirm the service-level agreement (SLA) before purchase, especially for cross-border operations.

Need a Quote for Dental Crown Making Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160