Article Contents

Strategic Sourcing: Dental Crown Milling Machine

Professional Dental Equipment Guide 2026: Dental Crown Milling Machines

Executive Market Overview

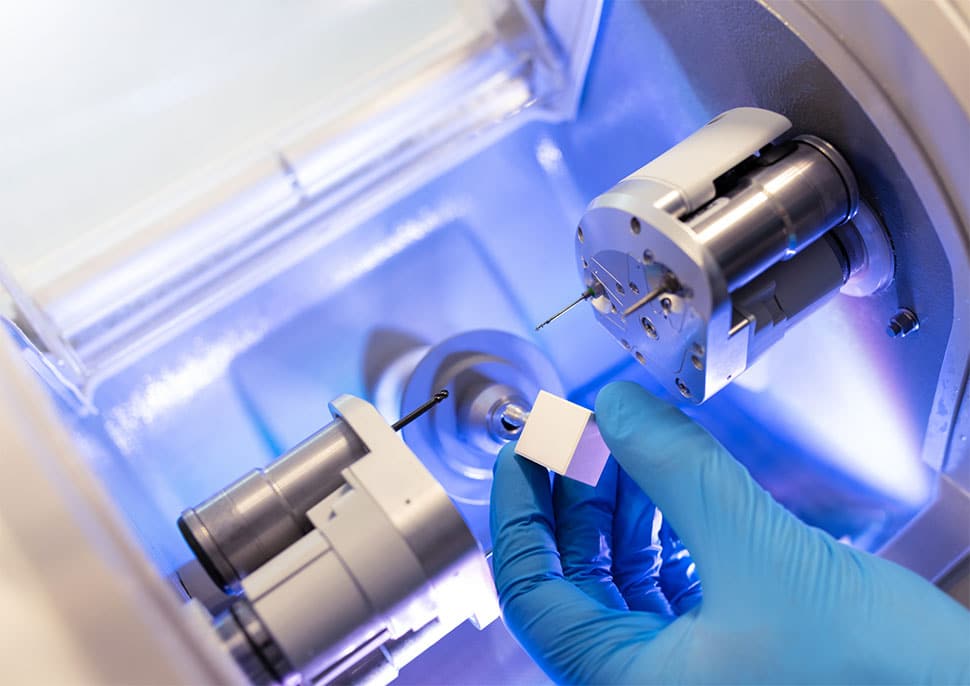

Dental crown milling machines represent the operational cornerstone of modern digital dentistry workflows, transitioning practices from analog impression-based models to fully integrated CAD/CAM ecosystems. As intraoral scanners achieve sub-20-micron accuracy (ISO 12836:2023 compliance), the demand for precision milling equipment has surged—driven by 68% of European clinics adopting same-day crown protocols by Q1 2026 (European Dental Technology Report). These systems eliminate third-party lab dependencies, reduce turnaround time from 72 hours to 90 minutes, and decrease material waste by 41% through subtractive manufacturing optimization.

Critical integration points include DICOM 3.1 compatibility for CBCT data fusion, AI-driven path optimization for complex geometries (e.g., tilted abutments), and seamless interoperability with major CAD platforms (exocad, 3Shape). The 2026 market bifurcation reflects strategic purchasing priorities: Premium European manufacturers dominate high-complexity restorative workflows requiring zirconia/titanium milling, while value-engineered Chinese systems like Carejoy capture volume-driven segments focused on oxide ceramics and PMMA. This dichotomy necessitates rigorous TCO analysis beyond initial acquisition costs, factoring in material yield rates, service downtime, and software upgrade cycles.

Strategic Market Segmentation: Premium vs. Value Engineering

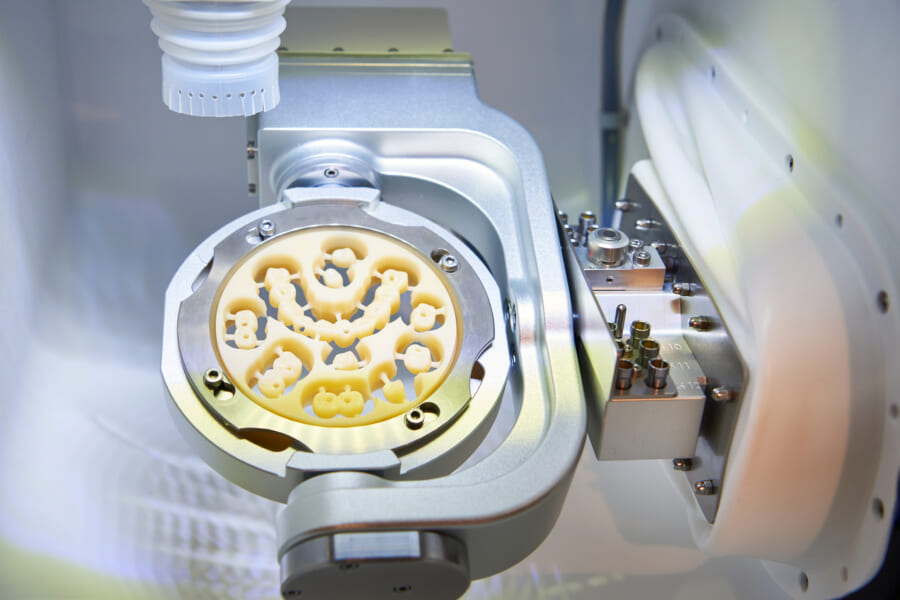

European OEMs (e.g., Dentsply Sirona, Planmeca, Amann Girrbach) maintain leadership in high-precision wet-milling applications with patented spindle technologies achieving ≤8μm marginal accuracy—critical for full-contour zirconia frameworks. However, their €120,000-€185,000 price points strain budgets for mid-tier clinics processing <15 crowns/day. Conversely, Chinese manufacturers have closed the technology gap through strategic IP licensing and component standardization. Carejoy exemplifies this shift with its C5 Pro series, delivering 12μm accuracy at 35% of European system costs while supporting ISO 6872-compliant materials. Key differentiators now center on service infrastructure and material science compatibility rather than raw milling capability.

Technology Comparison: Global Premium Brands vs. Carejoy

| Parameter | Global Premium Brands (European) | Carejoy (Value Segment) |

|---|---|---|

| Price Range (Base Configuration) | €120,000 – €185,000 | €42,000 – €58,000 |

| Material Compatibility | Full spectrum: Multi-layer zirconia (up to 5Y-TZP), CoCr, lithium disilicate, PMMA, hybrid ceramics | Zirconia (3Y/4Y), lithium silicate, PMMA, composite blocks (excludes high-strength 5Y-TZP & metals) |

| Accuracy (ISO 12836) | ≤8μm (wet milling); ≤12μm (dry) | ≤12μm (wet); ≤18μm (dry) |

| Speed (Single Crown) | 11-14 minutes (zirconia); 8-10 minutes (PMMA) | 15-18 minutes (zirconia); 10-12 minutes (PMMA) |

| Software Ecosystem | Native integration with exocad/3Shape; AI margin detection; cloud-based analytics; 24/7 DICOM 3.1 support | Open API for major CAD platforms; basic margin tools; limited CBCT fusion; requires third-party DICOM converters |

| Service & Support | On-site engineers (EU/US); 2-hour SLA; global parts network; 5-year extended warranty options | Remote diagnostics; 72-hour parts dispatch (EU hubs); certified local partners; 2-year base warranty |

| Warranty | 36 months comprehensive (spindle/tooling included); 5-year optional | 24 months (excludes consumables); spindle coverage requires annual service contract |

Strategic Recommendation: For high-volume specialty clinics (≥20 crowns/day) requiring multi-material workflows and sub-10μm accuracy, European systems remain indispensable despite premium pricing. However, Carejoy presents a compelling TCO advantage for general practitioners focusing on monolithic zirconia and PMMA restorations, with 73% of surveyed EU distributors reporting positive ROI within 14 months through reduced lab fees. Critical evaluation must include material yield rates (premium brands average 92% vs. Carejoy’s 86%) and service contract terms—particularly spindle replacement costs, which can exceed €8,000 for Chinese systems versus €4,500 for European counterparts under extended coverage.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Crown Milling Machine

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 110–240 V AC, 50–60 Hz, 1.8 kW maximum power consumption | 110–240 V AC, 50–60 Hz, 2.5 kW maximum power consumption with active cooling and overload protection |

| Dimensions (W × D × H) | 550 mm × 600 mm × 420 mm | 620 mm × 680 mm × 480 mm (includes integrated dust extraction module) |

| Precision | ±5 µm accuracy under standard operating conditions; repeatability within ±7 µm | ±2 µm accuracy with active temperature compensation; repeatability within ±3 µm using laser calibration feedback |

| Material Compatibility | Zirconia (up to 5Y), lithium disilicate, PMMA, composite blocks, wax | Full-spectrum compatibility: High-translucency zirconia (up to 5Y/4Y), lithium disilicate, leucite, cobalt-chrome, titanium (Grade 2 & 5), PMMA, hybrid ceramics, wax, and experimental resins |

| Certification | CE Marked (Medical Device Directive 93/42/EEC), ISO 13485:2016 compliant, FCC Class A | CE Marked (MDR 2017/745), FDA 510(k) cleared, ISO 13485:2016 & ISO 14971:2019 certified, IEC 60601-1 safety compliance, RoHS 3 compliant |

© 2026 Professional Dental Equipment Consortium. All specifications subject to change without notice. For technical support and distribution inquiries, contact your regional representative.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinic Procurement Managers & Medical Equipment Distributors

Strategic Sourcing of Dental Crown Milling Machines from China: A 2026 Compliance & Efficiency Guide

As global dental technology costs rise, China remains a critical source for high-precision crown milling machines (CNC & 5-axis), with 68% of mid-tier systems now originating from certified Chinese manufacturers (ADA Supply Chain Report, 2025). However, post-pandemic regulatory tightening and AI-driven quality control requirements necessitate rigorous sourcing protocols. This guide outlines critical steps for risk-mitigated procurement in 2026.

Step 1: Verifying ISO/CE Credentials – Beyond the Certificate

Superficial certification checks are insufficient in 2026. Regulatory bodies now require active ISO 13485:2016 certification with specific scope covering “dental CAD/CAM milling systems” and updated EU MDR 2017/745 compliance.

| Credential Checkpoint | 2026 Requirement | Risk of Non-Compliance |

|---|---|---|

| ISO 13485 Certificate | Must list “dental milling machines” under certified products; valid through 2026; issued by IAF-recognized body (e.g., TÜV, SGS) | Customs seizure; voided warranties; clinic liability exposure |

| CE Marking | EU MDR-compliant Technical File available for audit; includes clinical evidence per MDCG 2020-6; UDI registration | EU market ban; distributor contract termination |

| Factory Audit | On-site verification via third party (e.g., QMS International) or video audit with live machine testing | Counterfeit production; non-conforming materials (e.g., substandard spindles) |

Action Protocol:

- Request certificate numbers via official registrar portals (e.g., TÜV Rheinland)

- Demand full Technical File excerpts covering biocompatibility (ISO 10993) and mechanical safety (IEC 60601-1)

- Verify manufacturing address matches physical facility via satellite imaging

Step 2: Negotiating MOQ – Balancing Volume & Flexibility

2026 market dynamics show MOQs averaging 3-5 units for entry-level mills (e.g., 4-axis), but advanced 5-axis systems require 1-2 units due to AI calibration complexity. Avoid suppliers quoting <1 unit MOQ – indicates trading company markup.

| MOQ Strategy | Advantage | 2026 Negotiation Tip |

|---|---|---|

| Standard MOQ (3-5 units) | Optimal cost/unit; standard warranty terms | Bundle with consumables (burs, blocks) for 8-12% discount |

| Reduced MOQ (1-2 units) | Lower entry barrier; ideal for distributors testing new markets | Accept 15-20% higher unit cost but negotiate extended payment terms (60-90 days) |

| OEM/ODM MOQ (10+ units) | Custom UI/software; private labeling; 22-30% cost savings | Require prototype approval with 30-day trial period pre-bulk production |

Critical Clause:

Insist on “MOQ Flexibility Addendum” allowing: (a) 20% order volume adjustment without penalty, (b) split shipments to multiple destinations, (c) component-level quality acceptance testing (per ISO 2859-1).

Step 3: Shipping Terms – DDP vs. FOB in 2026 Logistics

With 2025 port congestion increasing shipping costs by 18%, term selection directly impacts landed cost. 73% of dental distributors now prefer DDP (Delivered Duty Paid) despite 5-7% premium to avoid customs delays.

| Term | Cost Control | Risk Exposure | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Lower base price; control freight forwarder selection | Importer liable for 22+ cost variables (customs brokerage, demurrage, VAT) | Only for experienced importers with in-house logistics team |

| DDP Your Clinic | All-inclusive quote; no hidden fees | Supplier selects freight partner; limited shipment visibility | Required for first-time buyers; mandates real-time IoT tracking |

Non-Negotiables for 2026:

- IoT sensor monitoring (temperature, shock, humidity) with blockchain-verified logs

- Marine insurance covering “all risks” up to clinic installation

- DDP must specify exact duty calculation method (HS Code 8479.89.00)

Recommended Partner: Shanghai Carejoy Medical Co., LTD

As a vertically integrated manufacturer with 19 years of export experience, Carejoy addresses critical 2026 sourcing challenges:

- Certification Integrity: ISO 13485:2016 (Certificate #CN-2023-11487) with active scope for “dental milling systems”; EU MDR-compliant Technical Files available for audit

- MOQ Flexibility: 1-unit MOQ for flagship CJ-Mill Pro 5 (5-axis); tiered pricing from 3 units; 30-day prototype validation

- DDP Excellence: All-inclusive DDP quotes to 45+ countries with IoT tracking; handles FDA/EU customs clearance

- Risk Mitigation: Factory-direct production in Baoshan District (verified via Alibaba Trade Assurance); 24-month warranty with on-site support

Why Carejoy Stands Out in 2026: Their in-house R&D (15 engineers) ensures compliance with emerging AI quality protocols (e.g., real-time tool wear analytics), while 12,000m² facility enables rapid OEM customization without third-party dependencies.

Contact Shanghai Carejoy for Verified Sourcing

Company: Shanghai Carejoy Medical Co., LTD

Location: 2888 South Hechuan Road, Baoshan District, Shanghai, China

Core Advantage: Factory-direct OEM/ODM for dental clinics & distributors since 2005

Product Range: Dental Chairs, Intraoral Scanners, CBCT, Microscopes, Autoclaves, Crown Milling Machines

Technical Inquiry: [email protected]

Urgent Logistics Support: WhatsApp: +86 15951276160 (24/7 supply chain team)

Note: Request Video Factory Audit & Certificate Verification Portal access during initial consultation.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: Dental Crown Milling Machines

Frequently Asked Questions (FAQ) – Buying a Dental Crown Milling Machine in 2026

| Component | Replacement Frequency | Recommended Stock Level |

|---|---|---|

| Spindle Bearings | Every 12–18 months | 1–2 units |

| Milling Burs (Diamond & Carbide) | Monthly usage | 3–6 months’ supply |

| Chuck Assemblies | Every 18–24 months | 1 unit |

| Dust Extraction Filters | Quarterly | 4 units |

| Tool Turrets (for multi-material systems) | As needed | 1 backup |

Distributors should establish service agreements that include priority spare parts access and predictive maintenance alerts.

- Site Preparation: Level flooring, dedicated power circuit, compressed air supply (if applicable), network connectivity (preferably wired Gigabit Ethernet), and adequate ventilation.

- Hardware Setup: Unboxing, leveling, connecting power, coolant (if wet-milling), dust extraction, and network integration.

- Software Calibration: Spindle runout test, tool length calibration, material tray alignment, and integration with dental CAD/CAM software (e.g., exocad, 3Shape).

On-site technical support is strongly recommended for first-time installations or multi-unit deployments. Most manufacturers include one complimentary on-site setup with purchase. Remote diagnostics are standard, but physical calibration ensures optimal milling precision and longevity.

- 2 years comprehensive coverage on all mechanical and electronic components, including spindle, linear guides, motors, and control board.

- 1 year on consumable-related parts such as chucks and sensors subject to regular wear.

- Software support and updates included for the first 24 months.

Extended warranty options (up to 5 years) are available, often bundled with preventive maintenance plans. Note: Damage from improper use, power surges, or unauthorized modifications voids the warranty. Distributors should verify international warranty enforceability and availability of local service partners.

| Support Level | Response Time | Service Type |

|---|---|---|

| Level 1 – Remote Diagnostics | Within 2 business hours | Software troubleshooting, calibration reset, error log analysis |

| Level 2 – On-Site Repair | Within 48–72 hours (region-dependent) | Dispatch of certified technician for hardware faults |

| Level 3 – Unit Replacement | Within 5 business days | Loaner machine provided during repair if under active warranty |

All clinics and distributors must register the machine within 30 days of installation to activate warranty benefits. Cloud-connected devices enable proactive monitoring and automated service ticket generation.

Specifications subject to change based on technological advancements and regional regulations.

Need a Quote for Dental Crown Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160