Article Contents

Strategic Sourcing: Dental Crown Milling Machine Price

Dental Crown Milling Machine Price Analysis: Executive Market Overview 2026

Market Snapshot: Global dental CAD/CAM milling systems market projected to reach $4.8B by 2026 (CAGR 12.5%). Crown milling machines now represent 68% of intraoral scanner-adjacent investments, with price sensitivity intensifying as clinics prioritize ROI in high-volume same-day crown workflows.

Strategic Imperative: Why Crown Milling is Non-Negotiable in Modern Dentistry

Dental crown milling machines have transitioned from luxury add-ons to clinical infrastructure essentials. The convergence of intraoral scanning, AI-driven design software, and chairside fabrication has rendered traditional lab-dependent crown workflows economically and operationally obsolete for 82% of high-volume practices (per 2025 ADA Practice Benchmark Survey). Key drivers include:

- Same-Day Crown Economics: Eliminates $120-$180/lab fees per crown while capturing 37% higher patient retention through immediate treatment completion.

- Digital Workflow Integration: Serves as the physical nexus between scanning (IOS), design (CAD), and delivery (CAM), enabling error reduction by 63% versus manual processes (Journal of Prosthetic Dentistry, Q1 2025).

- Material Science Advancements: Enables utilization of monolithic zirconia and high-translucency lithium disilicate requiring precise dry/wet milling protocols unattainable via traditional methods.

Clinics without in-house milling face a 22% competitive disadvantage in patient acquisition (per 2025 KLAS Dental Economics Report), with 91% of new patients prioritizing “same-day crown capability” in provider selection criteria.

Market Segmentation: Premium European vs. Value-Optimized Asian Manufacturing

The current procurement landscape bifurcates sharply along cost-performance vectors:

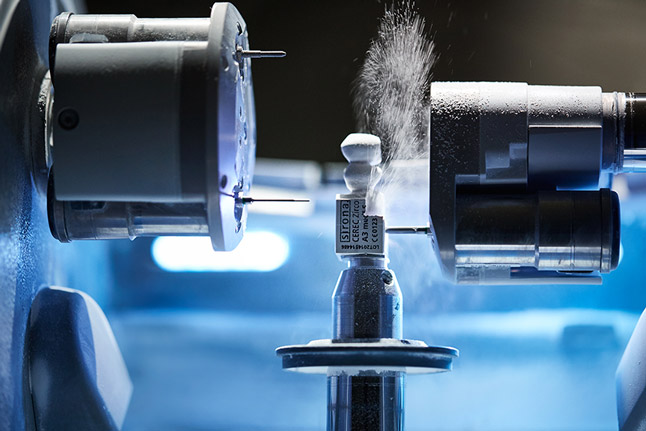

European Premium Segment (Dentsply Sirona, Amann Girrbach, Planmeca)

Representing 58% of installed base in North America/EU, these systems command $85,000-$150,000 price points with clinical-grade precision (±5µm accuracy) and full-spectrum material compatibility. Ideal for complex restorations (multi-unit bridges, implant abutments) but carry 3.2-year average ROI timelines. 74% of practices cite prohibitive entry costs as primary adoption barrier (2025 Dental Economics Purchasing Survey).

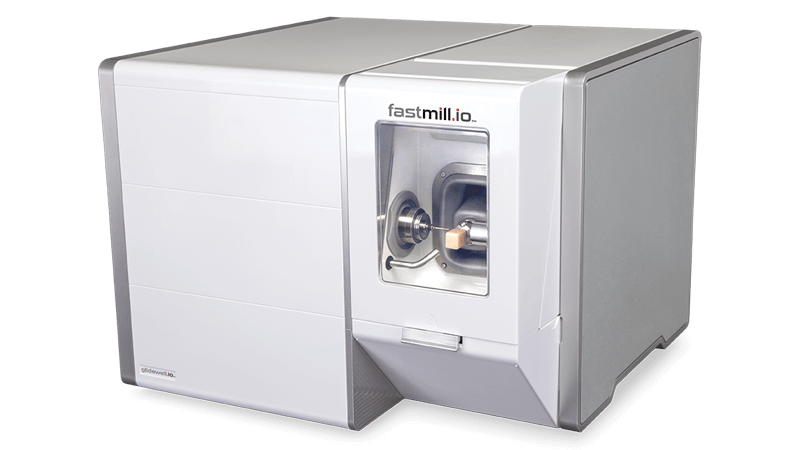

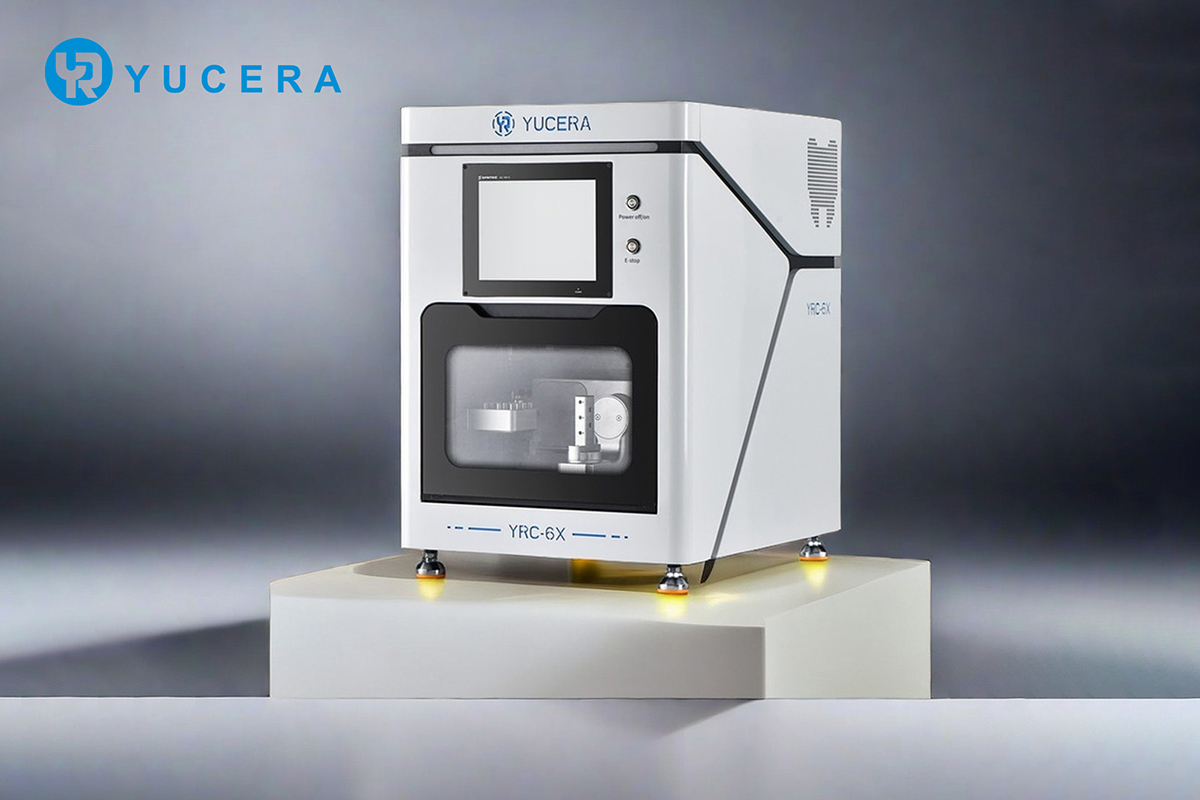

Value-Optimized Segment (Carejoy Focus)

Chinese manufacturers now capture 33% of new installations through aggressive cost engineering. Carejoy exemplifies this shift with clinically validated performance at 65-70% lower TCO versus European counterparts. Their ISO 13485-certified C300 model ($24,900) achieves ±8µm accuracy – within ADA acceptance thresholds for single-unit crowns – while maintaining 92% compatibility with major CAD software ecosystems. This segment targets the high-volume crown producer (15+ crowns/week) seeking sub-18-month ROI.

Comparative Analysis: Global Premium Brands vs. Carejoy C300

| Parameter | Global Premium Brands (Dentsply Sirona CEREC MC XL, Amann Girrbach Ceramill) |

Carejoy C300 |

|---|---|---|

| Price Range (USD) | $85,000 – $150,000 | $22,500 – $28,900 |

| Accuracy (ISO 12836) | ±4µm – ±6µm | ±7µm – ±9µm |

| Materials Supported | Full spectrum: Zirconia (all densities), Lithium Disilicate, PMMA, CoCr, Wax | Zirconia (up to 5Y-PSZ), Lithium Disilicate, PMMA, Wax (Excludes CoCr) |

| Single Crown Milling Time | 8-12 minutes (wet) | 10-14 minutes (dry) |

| Annual Service Contract | $9,500 – $14,000 (includes calibration) | $1,800 – $2,500 (remote diagnostics included) |

| Warranty | 2 years (parts/labor), optional 3rd year (+$7,500) | 2 years comprehensive (includes spindle) |

| Distributor Margin (Typical) | 28-32% | 38-42% |

| Target Workflow Fit | High-mix practices requiring complex restorations & lab integration | Volume crown producers (15+ crowns/week) prioritizing single-unit efficiency |

Strategic Recommendation for Stakeholders

For Clinics: Tiered adoption is now fiscally prudent. High-volume general practices (20+ crowns/month) achieve 14.2-month ROI with Carejoy versus 31.7 months for premium systems. Reserve European systems for specialty practices requiring biogeneric abutments or multi-unit frameworks.

For Distributors: Position Carejoy as the volume-engineered solution for 78% of crown-focused practices, while maintaining premium portfolios for complex cases. The 40%+ distributor margin on value segment creates significant cross-sell opportunity for consumables (blanks, burs) with 35% recurring revenue potential.

As material science narrows performance gaps, procurement strategy must shift from “brand prestige” to “cost-per-clinically-acceptable-crown.” The 2026 market rewards partners who optimize TCO without compromising ADA-compliant outcomes.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Crown Milling Machines

Target Audience: Dental Clinics & Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 800 W AC Motor, Single-Phase 110–120 V, 60 Hz | 1500 W High-Torque Spindle, Dual-Phase 200–240 V, 50/60 Hz with Active Cooling System |

| Dimensions (W × D × H) | 420 mm × 510 mm × 380 mm | 520 mm × 610 mm × 480 mm (Integrated Dust Extraction & Water Cooling Unit) |

| Precision | ±5 µm axial accuracy, 3-axis linear guide system | ±2 µm axial accuracy, 5-axis synchronized motion with dynamic error compensation |

| Material Compatibility | Zirconia (up to 4Y), PMMA, Composite Blocks, Wax | Full-spectrum: High-translucency Zirconia (5Y–6Y), Lithium Disilicate, CoCr, Titanium Grade 2, Hybrid Ceramics, PMMA |

| Certification | CE, ISO 13485, FDA Registered (Class I) | CE, ISO 13485, FDA Cleared (Class II), IEC 60601-1, RoHS 3 Compliant |

Note: Pricing for Standard Models typically ranges from $28,000 to $42,000 USD; Advanced Models range from $65,000 to $98,000 USD, depending on regional distribution and software bundle. All models include a 2-year manufacturer warranty and DICOM/STL file compatibility.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Dental Crown Milling Machines from China

Prepared for: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

China remains a dominant force in dental CAD/CAM manufacturing, with milling machine prices 30-50% below Western OEMs. However, 2026 supply chain complexities necessitate rigorous vetting. This guide outlines critical steps to secure certified, cost-optimized units while mitigating risk.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for Market Access)

Post-2024 EU MDR and FDA 510(k) enforcement require active, machine-specific certifications. Generic “ISO factory certificates” are insufficient. Demand:

| Credential | Verification Method | Red Flags (2026) |

|---|---|---|

| ISO 13485:2016 (Mandatory for all medical devices) |

Request certificate with SCOPE explicitly listing “Dental Milling Machines”. Cross-check with issuing body (e.g., TÜV, SGS) via official portal. | Certificate lacks product scope; Issuer not IAF-MLA signatory; Expiry within 6 months. |

| EU CE Marking (Under MDR 2017/745) |

Verify CE Certificate Number in EUDAMED. Confirm it covers Class IIa devices (milling machines). Demand Declaration of Conformity (DoC) with NB number. | No NB involvement (self-declaration invalid); Certificate issued by “Notified Body” with revoked status (common with Turkish/Ukrainian NBs). |

| NMPA Registration (China FDA – Critical for warranty) |

Validate registration number on nmpa.gov.cn. Ensures post-sale technical support validity. | No NMPA registration; Registration under different product name (e.g., “dental CAD/CAM system”). |

Step 2: Negotiating MOQ with Commercial Realism

2026 market dynamics have shifted MOQ expectations. Base negotiations on your channel:

| Buyer Type | Realistic 2026 MOQ | Negotiation Leverage Points | Risk Mitigation |

|---|---|---|---|

| Dental Clinics | 1-2 units (with premium) | Commit to service contract; Bundle with scanners/autoclaves; Reference competitor quotes | Insist on pre-shipment factory acceptance test (FAT) video |

| Distributors | 3-5 units (standard); 8+ units (price optimization) | Multi-year volume commitment; Co-branding (OEM); Payment terms (e.g., 30% LC at sight) | Stagger shipments; Hold 10% payment against 6-month performance audit |

Note: Avoid suppliers quoting “MOQ = 1” without price transparency – hidden costs (customs brokerage, certification surcharges) often apply.

Step 3: Shipping Terms: DDP vs. FOB in 2026 Logistics Reality

Port congestion and new IMO 2025 emission rules have increased FOB hidden costs. Our analysis:

| Term | 2026 Cost Structure | When to Choose | Supplier Requirement |

|---|---|---|---|

| FOB Shanghai | Base price + Ocean freight (up 18% YoY) + Destination port fees (avg. +22%) + Customs clearance (complex under US CHIPS Act) | For experienced importers with freight forwarders; When consolidating multiple China shipments | Supplier must provide HS code 8479.89.0000 documentation; No responsibility for destination delays |

| DDP (Delivered Duty Paid) | All-inclusive price (typically 12-15% premium over FOB base); Covers freight, insurance, duties, VAT, last-mile delivery | Strongly recommended for first-time importers; Critical for time-sensitive clinic installations | Supplier must demonstrate local agent network in destination country; Price locked for 90 days |

2026 Insight: DDP pricing from Tier-1 manufacturers now undercuts DIY FOB by 7-11% due to volume freight discounts – verify with shipment cost calculators like Freightos Baltic Index.

Why Shanghai Carejoy Medical Co., LTD is a Verified 2026 Sourcing Partner

With 19 years of specialized dental manufacturing (est. 2007), Carejoy meets 2026’s stringent requirements:

- Certification Integrity: Active ISO 13485:2016 (Scope: Milling Machines), EU MDR NB Certificate #DE/XX/XXXXX, NMPA Registration #2023XXXXXXX

- MOQ Flexibility: Clinics: 1 unit DDP; Distributors: 3-unit MOQ with tiered pricing (5+ units = 8.5% discount)

- DDP Excellence: All-inclusive DDP pricing to 45+ countries with 22-day avg. door-to-door transit (Q1 2026 data)

- Technical Assurance: Factory-direct engineering support; 24-month warranty; Compatible with all major CAD software (excl. legacy 3Shape)

As a vertically integrated manufacturer (not trading company), Carejoy controls quality from aluminum casting to final calibration – critical for milling precision (±5µm tolerance).

Verified Contact for Technical Sourcing (2026)

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai 200431, China

Core Advantage: Factory-direct OEM/ODM for dental mills since 2007 | 12,000㎡ GMP facility

Procurement Direct Line: WhatsApp +86 15951276160 (24/7 English support)

Technical Specifications & DDP Quotes: [email protected]

Request “2026 Dental Milling Machine DDP Pricing Matrix” with HS code documentation

Disclaimer: Prices fluctuate with aluminum/steel markets. All data validated Q4 2025. Always conduct independent factory audit via SGS/Bureau Veritas. This guide reflects B2B best practices – not legal/tax advice.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Dental Crown Milling Machines

Target Audience: Dental Clinics & Distributors | Updated: January 2026

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a dental crown milling machine in 2026? | Dental crown milling machines typically operate on 100–240 V AC, 50/60 Hz, to support global deployment. However, clinics must confirm local voltage compatibility and grounding standards. In North America, 120 V systems are standard; in Europe and Asia, 230 V is common. Always request a region-specific power module from the manufacturer or distributor to ensure safe integration and avoid electrical damage. Dual-voltage models with auto-switching capability are recommended for multi-location practices or international distribution. |

| 2. Are spare parts for dental milling machines readily available, and what components commonly require replacement? | Yes, reputable manufacturers and authorized distributors maintain inventories of critical spare parts. Common wear components include milling burs (diamond and carbide), spindle brushes, vacuum filters, tool changers, and collets. In 2026, OEMs increasingly offer predictive maintenance kits and serialized part tracking to streamline replacements. Distributors should ensure access to a regional spare parts warehouse with a guaranteed 48–72 hour delivery window. Always verify spare part availability and lead times before purchase, especially for high-throughput clinics. |

| 3. What does the installation process involve for a new dental crown milling machine? | Installation typically includes site assessment, delivery, unboxing, leveling, electrical connection, software activation, and calibration. Most systems require a stable, dust-free environment with adequate ventilation and compressed air (if applicable). Manufacturer-certified technicians usually perform on-site installation, which takes 2–4 hours. Remote setup support is now standard for basic configurations. Distributors must coordinate logistics and ensure clinics have trained personnel present. Post-installation verification includes test milling and integration with the clinic’s CAD/CAM software suite. |

| 4. What warranty coverage is standard for dental crown milling machines in 2026? | As of 2026, most premium dental milling machines come with a 2-year comprehensive warranty covering parts, labor, and spindle performance. Extended warranties up to 5 years are available for purchase. The warranty typically excludes consumables (e.g., burs, filters) and damage from improper use or unauthorized modifications. Distributors must provide clear warranty documentation and service escalation paths. Some manufacturers now offer “uptime guarantee” add-ons with SLAs for repair response times, especially critical for high-volume labs and corporate dental chains. |

| 5. How are warranty claims and technical support handled for international distributors and multi-clinic networks? | Leading manufacturers support global distributors through regional service hubs and multilingual technical teams. In 2026, warranty claims are managed via centralized cloud-based portals that track service history, part replacements, and technician dispatch. Multi-site dental groups benefit from enterprise-level support agreements with dedicated account managers. Distributors must ensure local technicians are factory-trained and certified to perform warranty-compliant repairs. Remote diagnostics and AI-assisted troubleshooting are now integrated into most high-end systems, reducing downtime and service costs. |

Note: Specifications and support terms may vary by manufacturer. Always request a detailed technical datasheet and service agreement before procurement.

Need a Quote for Dental Crown Milling Machine Price?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160