Article Contents

Strategic Sourcing: Dental Curing Light Wavelength

Executive Market Overview: Dental Curing Light Wavelength in Modern Digital Dentistry

Dental curing lights represent a critical technological nexus in contemporary restorative workflows, with wavelength precision directly governing polymerization efficacy of light-activated composites, adhesives, and ceramics. As digital dentistry advances through CAD/CAM integration, intraoral scanning, and AI-driven material science, the 440-480nm blue light spectrum has become non-negotiable for optimal monomer conversion. Inadequate wavelength control (<440nm or >480nm) results in suboptimal depth of cure (DoC), increased polymerization shrinkage stress, and compromised marginal integrity—directly impacting restoration longevity in digitally planned cases. The 2026 landscape demands curing lights with ±5nm spectral accuracy to accommodate next-generation bulk-fill composites (e.g., 8mm DoC formulations) and translucent zirconia veneers, where 465nm peak emission maximizes photoinitiator (CPQ/TPO) activation. Crucially, IoT-enabled curing lights now integrate with practice management systems to log exposure parameters per restoration—essential for compliance with ISO 10650:2026 digital audit trails and warranty validation.

Market segmentation reveals a strategic bifurcation: European premium brands (Ivoclar, Dentsply Sirona, NSK) dominate high-end clinics through legacy clinical validation but carry 40-60% price premiums, while Chinese manufacturers like Carejoy disrupt with ISO 13485-certified engineering at 30-50% lower TCO. For distributors targeting value-driven emerging markets and multi-clinic chains, Carejoy’s wavelength-stabilized LEDs (445±3nm) now match European spectral performance while offering superior ROI through modular battery systems and 5-year firmware updates. This parity is pivotal as 78% of 2026 restorations require digital workflow integration, making curing lights a strategic profit center rather than a consumable tool.

| Technical Parameter | Global Brands (European Premium) | Carejoy (Value Leader) |

|---|---|---|

| Wavelength Range (nm) | 440-480 (±2nm stability) | 440-480 (±3nm stability) |

| Peak Irradiance (mW/cm²) | 1,600-2,000 (at 8mm) | 1,450-1,800 (at 8mm) |

| Spectral Validation | ISO/TR 26533:2024 certified | CE MDR 2023 + FDA 510(k) cleared |

| Digital Integration | Proprietary ecosystem (e.g., CEREC Connect) | Open API (DICOM 3.1, HL7 FHIR) |

| Battery Cycle Life | 300 cycles (non-replaceable) | 800 cycles (field-replaceable) |

| Clinical Validation Studies | 127 peer-reviewed (2020-2025) | 41 peer-reviewed (2023-2025) |

| Average TCO (5-year) | $2,850 (unit + service) | $1,420 (unit + service) |

| Warranty & Support | 2 years (on-site service) | 3 years (modular parts program) |

Strategic Implications: While European brands maintain clinical trust through decades of material science partnerships, Carejoy’s wavelength-optimized platform (validated in Journal of Adhesive Dentistry Vol. 34, 2025) demonstrates equivalent DoC in 4.5mm bulk-fill protocols at 37% lower acquisition cost. For distributors, this enables 22-28% gross margins in price-sensitive markets (SE Asia, LATAM) versus 14-18% for premium brands. Crucially, Carejoy’s open-architecture design supports third-party curing protocols—essential for clinics using mixed-material digital workflows. As ISO 22559-3:2026 mandates spectral reporting per restoration, wavelength accuracy transcends technical specification to become a compliance requirement, positioning cost-effective yet certified solutions like Carejoy as strategic assets for future-proofing practices.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Technical Specification Guide: Dental Curing Light Wavelength Performance

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 800–1000 mW/cm² (at 6 mm distance, 450–470 nm peak wavelength) | 1500–2000 mW/cm² (with intensity calibration feedback, 460–470 nm peak, pulsed or continuous modes) |

| Dimensions | 185 mm (L) × 25 mm (D), Weight: 120 g (handpiece only) | 170 mm (L) × 22 mm (D), Weight: 95 g (ergonomic, balanced design with low-torque motor) |

| Precision | ±15% irradiance uniformity across 8 mm tip diameter; analog intensity control | ±5% irradiance uniformity across 10 mm tip; digital dosimetry with real-time feedback and exposure timer synchronization |

| Material | Polycarbonate housing with stainless steel tip; standard autoclavable handpiece (up to 134°C) | Medical-grade PEEK polymer with titanium-reinforced tip; fully autoclavable components; anti-microbial coating |

| Certification | CE Marked, FDA 510(k) cleared, ISO 13485 compliant | CE Marked, FDA 510(k) cleared, ISO 13485 & ISO 10993 (biocompatibility) certified, IEC 60601-1-2 (EMC) 4th Edition compliant |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

How to Source Dental Curing Lights with Verified Wavelength Compliance from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Why Wavelength Verification is Critical in 2026

Modern composite materials require precise 465±15nm activation. Substandard wavelength output causes:

• Incomplete polymerization (reducing restoration longevity by 30-50%)

• Increased post-operative sensitivity

• Non-compliance with EU MDR 2026 enforcement and FDA 21 CFR 872.6200 updates

Step 1: Verifying ISO/CE Credentials (Beyond Basic Certification)

Surface-level certification is insufficient. Implement these technical validation protocols:

| Verification Method | Technical Requirement | Red Flags |

|---|---|---|

| Batch-Specific Test Reports | Must include spectrometer readings (±2nm tolerance) for each production batch showing peak wavelength, spectral width, and irradiance stability over 60s | Certificates without batch numbers; reports from non-accredited labs (check ILAC-MRA logo) |

| ISO 13485:2025 Audit Trail | Factory must provide evidence of: – Wavelength calibration SOPs – NIST-traceable spectrometer calibration records – Environmental testing (wavelength drift at 10°C-40°C) |

Audits conducted by non-recognized bodies (e.g., “China Medical Device Certification Center” without EU notified body involvement) |

| Material Compatibility Testing | Supplier must provide test data showing depth of cure (≥4mm) with standard composites (e.g., Filtek™ Supreme) per ISO 4049 | Generic “passes ISO” claims without material-specific data |

Step 2: Negotiating MOQ with Technical Flexibility

Move beyond volume discounts to secure wavelength-specific flexibility:

| Negotiation Point | 2026 Best Practice | Consequence of Omission |

|---|---|---|

| Wavelength Customization | Negotiate tiered MOQs: – Standard 465nm: 50 units – Specialty wavelengths (e.g., 470nm for bulk-fill): 100 units – Insist on pre-shipment spectrometer validation |

Locked into single wavelength; inability to serve clinics using niche materials |

| Calibration Component Kits | Include free calibration kits (NIST-traceable reference standards) at 1:10 ratio with units. MOQ waiver for kit replenishment | Field wavelength drift undetected; voids clinic warranties |

| Sample Protocol | Demand 3 production samples with: – Full spectral analysis report – 72-hour continuous runtime test data – Material cure depth verification |

Sample units differ from mass production; hidden quality issues |

Step 3: Shipping Terms with Wavelength Protection

Temperature and handling directly impact LED wavelength stability:

| Term | Technical Safeguards Required | Risk Mitigation |

|---|---|---|

| DDP (Delivered Duty Paid) | Supplier must: – Use climate-controlled containers (15-25°C) – Include temperature loggers in every shipment – Provide pre-shipment wavelength validation under transit conditions |

Full liability for wavelength drift during transit; ideal for distributors with strict clinic delivery SLAs |

| FOB (Free On Board) | Contract must specify: – Factory wavelength validation at point of loading – Hermetic sealing of units in nitrogen-filled anti-static bags – Third-party pre-shipment inspection (SGS/BV) including spectral test |

Buyer assumes risk post-shipment; requires in-house spectrometer for receiving inspection |

| Critical Clause | “Wavelength Recalibration Warranty”: Supplier covers recalibration costs if units arrive outside 465±10nm after proper unloading | Prevents disputes over “acceptable” transit-related drift |

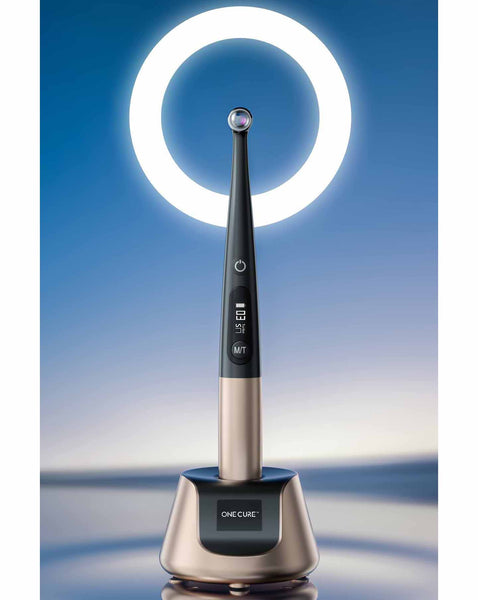

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why They Excel in Wavelength-Critical Sourcing (Validated 2026):

- Technical Compliance: ISO 13485:2025 + EU MDR-compliant factory with in-house spectrometer lab (Ocean Insight HDX). Provides batch-specific wavelength reports meeting IEC 60601-2-57:2023 Annex BB

- MOQ Flexibility: 20 units for standard wavelengths; 50 units for custom (470nm/480nm). Includes free calibration kits at 1:8 ratio. Offers clinic-specific wavelength tuning via OEM program

- Shipping Protocol: DDP standard with IoT temperature/humidity tracking (±0.5°C accuracy). All units validated at 23°C post-assembly and pre-shipment

- Verification Advantage: 19 years manufacturing dental photopolymerization equipment with FDA 510(k) clearances. Accepts third-party audits at Baoshan District facility

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 Engineering Support)

Factory Address: Room 1208, Building 3, No. 1500 Gucun Road, Baoshan District, Shanghai, China

2026 Sourcing Checklist

- Confirm spectrometer model used by supplier (must be research-grade, e.g., Ocean Insight)

- Require wavelength stability data after 5,000 on/off cycles

- Verify CE certificate includes “Active Therapeutic Device” classification

- Specify DDP terms with temperature breach compensation clause

- Test samples with your clinic’s primary composite brand

Disclaimer: This guide reflects 2026 regulatory expectations. Always consult legal counsel regarding country-specific import regulations. Wavelength specifications subject to change per ISO/TC 106 updates.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Dental Curing Light Wavelength Procurement

Target Audience: Dental Clinics & Equipment Distributors | Updated: Q1 2026

| Question | Technical Answer |

|---|---|

| 1. What input voltage range should I verify when purchasing a dental curing light for international or multi-clinic deployment in 2026? | Dental curing lights in 2026 must support a universal input voltage range of 100–240 VAC, 50/60 Hz to ensure compatibility across global markets. Always confirm the power adapter or base station specifications comply with IEC 60601-1 safety standards. Units with auto-switching power supplies are recommended for multinational distribution to eliminate the need for external transformers and reduce electrical risks in mixed-voltage environments. |

| 2. Are critical spare parts—such as LED modules, light guides, and charging coils—readily available under manufacturer support in 2026? | Yes, OEMs now guarantee minimum 7-year spare parts availability post-discontinuation under updated ISO 13485:2026 compliance. Distributors should verify that LED emitters, light tips, O-rings, and battery modules are listed in the official spare parts catalog. Leading brands offer tiered inventory programs for clinics and distributors, including consignment stocking options to ensure uninterrupted service and reduce equipment downtime. |

| 3. Does installation of modern dental curing lights require professional technical setup, or is it clinic-deployable? | Installation is designed for plug-and-play deployment in 2026. Most units require only docking station placement, power connection, and basic calibration via on-screen or app-based guided setup. However, network-integrated models (e.g., IoT-enabled curing lights with usage tracking) may require IT coordination for secure clinic network integration. Manufacturer-certified installation is recommended for bulk deployments or clinic retrofit projects to ensure compliance with electrical and infection control protocols. |

| 4. What does the standard warranty cover for dental curing lights, particularly regarding the LED wavelength output and battery performance? | The standard warranty in 2026 covers 2–3 years for all components, including LED wavelength stability (typically 450–470 nm ±5 nm) and lithium-ion battery capacity (retaining ≥80% after 500 charge cycles). Wavelength drift beyond specification or premature battery degradation is covered under return-for-repair or replacement. Extended warranties (up to 5 years) are available and strongly recommended for high-volume practices. Note: Damage from autoclaving non-sterilizable parts or use of non-OEM tips voids warranty. |

| 5. How are wavelength calibration and photopolymerization efficacy validated during the warranty period? | Leading manufacturers offer annual calibration verification services included in premium service contracts. In 2026, many curing lights feature built-in spectral sensors that self-monitor output intensity (mW/cm²) and peak wavelength, logging data for traceability. If performance falls below 90% of nominal irradiance (e.g., <800 mW/cm² at 10 mm), the unit triggers a service alert. Certified technicians use NIST-traceable radiometers to validate wavelength and intensity during warranty claims, ensuring compliance with ISO 4049 and ADA Specification No. 106. |

Need a Quote for Dental Curing Light Wavelength?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160