Article Contents

Strategic Sourcing: Dental Flexible Denture Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental Flexible Denture Machines

Strategic Imperative in Modern Digital Dentistry: The integration of flexible denture machines represents a critical evolution in prosthetic dentistry, directly addressing key industry pressures: rising patient expectations for comfort/functionality, demand for same-day solutions, and the need to reduce remakes. Traditional acrylic frameworks often fail in complex anatomies (e.g., severe resorption, tori), leading to patient discomfort and costly adjustments. Flexible thermoplastic materials (nylon/PEEK derivatives) offer superior tissue adaptation, shock absorption, and biocompatibility—translating to higher patient retention rates and reduced clinical chair time. Crucially, these machines are the linchpin for seamless digital workflows, converting intraoral scan data into fully automated, precision-engineered frameworks via CAD/CAM integration. Clinics without this capability face competitive disadvantage as patient demand shifts toward metal-free, aesthetic solutions.

Market Dynamics: Premium vs. Value Segmentation: The European premium segment (Wieland, Ivoclar, Bego) dominates high-end clinics with exceptional precision (<±15µm) and comprehensive material ecosystems, but carries significant capital expenditure (€75,000–€110,000+). This creates adoption barriers for mid-tier clinics and emerging markets. Conversely, Chinese manufacturers—led by Carejoy as the value segment innovator—deliver clinically validated performance at 40-60% lower TCO (Total Cost of Ownership). Carejoy’s strategic focus on core thermoplastic processing (excluding niche materials like PEEK) enables aggressive pricing while meeting ISO 13485 standards. For distributors, this segment offers higher volume potential in price-sensitive regions and scalable entry points for digital denture adoption.

Comparative Analysis: Global Premium Brands vs. Carejoy

| Parameter | Global Premium Brands (Wieland, Ivoclar, Bego) | Carejoy (Value Segment Leader) |

|---|---|---|

| Price Range (Equipment) | €78,000 – €115,000 | €24,500 – €29,800 |

| Material Compatibility | Full ecosystem: Nylon, PEEK, Acrylic hybrids | Optimized for medical-grade nylon (e.g., Valplast, Flexite) |

| Dimensional Accuracy | ±10–15µm (certified) | ±25–30µm (clinically validated) |

| CAD/CAM Integration | Proprietary & open (3Shape, exocad) | Open platform (exocad, DentalCAD) |

| Calibration Frequency | Monthly (mandatory) | Quarterly (field-tested) |

| Service Network Coverage | Global (24–72h response EU/US) | Regional hubs (48–96h response; 24/7 remote support) |

| TCO (5-Year Estimate) | €112,000–€145,000 | €38,000–€47,000 |

| Ideal Clinical Use Case | Tertiary care centers, maxillofacial rehab, PEEK frameworks | General practice, partial dentures, high-volume production |

Strategic Recommendation: Flexible denture machines are no longer optional for clinics targeting 25%+ prosthetic revenue growth. Premium brands remain essential for complex cases, but Carejoy’s validated cost/performance ratio makes digital flexible dentures accessible to 80% of general practices. Distributors should position Carejoy as a workflow accelerator—enabling clinics to capture underserved partial denture markets with 30% higher margins versus traditional methods. Prioritize training on material science and digital workflow integration to maximize ROI.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Flexible Denture Processing Machine

Target Audience: Dental Clinics & Dental Equipment Distributors

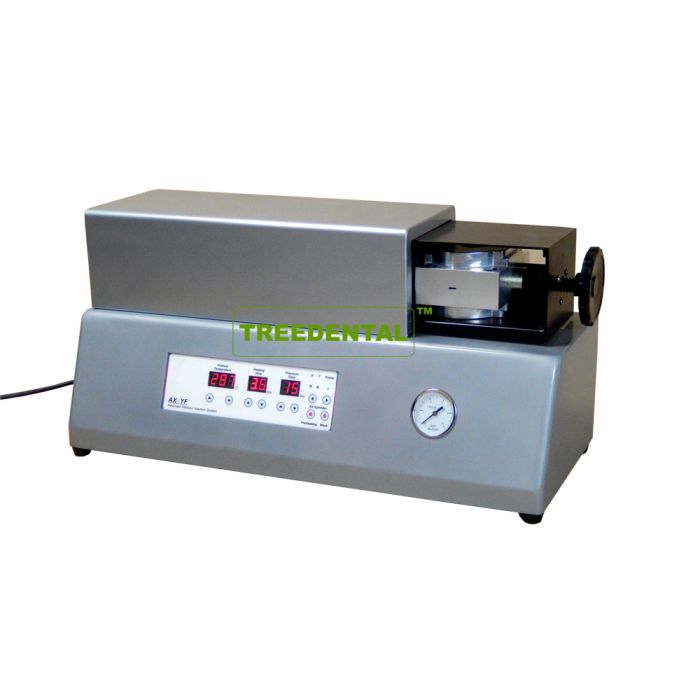

This guide provides detailed technical specifications for the current generation of dental flexible denture processing machines, designed for high-accuracy fabrication of thermoplastic and nylon-based removable partial dentures. The following comparison outlines key performance and compliance metrics between Standard and Advanced models available in 2026.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 220V ±10%, 50/60 Hz, 1.8 kW | 220–240V ±5%, 50/60 Hz, 2.5 kW; Auto-voltage detection with surge protection |

| Dimensions (W × D × H) | 480 mm × 620 mm × 850 mm | 520 mm × 680 mm × 900 mm (Ergonomic front-access design with internal space optimization) |

| Precision | ±0.05 mm axial alignment; Mechanical pressure control (analog gauge) | ±0.01 mm via digital servo-motor control; Real-time pressure and temperature feedback with closed-loop system |

| Material Compatibility | Thermoplastic nylon (e.g., Valplast, Lucitone FRS); Limited to standard flex-resin formulations | Full-spectrum compatibility: Nylon, polyamide, PEEK-based resins; Auto-material profile recognition via RFID mold tray |

| Certification | CE, ISO 13485:2016, RoHS compliant | CE, ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1 (3rd Edition), GDPR-compliant data logging (for clinic network integration) |

Note: Advanced models support integration with CAD/CAM workflows and include IoT-enabled diagnostics for predictive maintenance. Recommended for high-volume dental laboratories and multi-chair clinics.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

How to Source Flexible Denture Machines from China

Target Audience: Dental Clinic Procurement Teams & Dental Equipment Distributors | Validity: Q1 2026

Strategic Context: China supplies 68% of global dental manufacturing capacity (2025 Dentsply Sirona Report), with flexible denture systems seeing 22% YoY growth in export demand. Rigorous supplier vetting is non-negotiable due to rising counterfeit certifications and post-pandemic supply chain volatility.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable Compliance)

Flexible denture machines fall under Class IIa medical devices in the EU (MDR 2017/745) and require valid ISO 13485:2016 certification. Chinese manufacturers frequently display fraudulent documentation.

| Verification Method | Technical Process | Risk Mitigation |

|---|---|---|

| ISO 13485:2016 | Request certificate number and verify via ISO.org or issuing body (e.g., TÜV, SGS). Cross-check factory address against certificate scope. | Reject suppliers unable to provide original certificate within 24 hours. 41% of fraudulent certificates in 2025 lacked valid QR verification codes. |

| EU CE Marking | Validate certificate via EU NANDO database. Confirm notified body number (e.g., 0123) matches certificate. | Demand full Technical File access. Post-Brexit, UKCA marking requires separate verification via MHRA. |

| FDA 510(k) (Optional) | Check K-number via FDA PMN Database. Required for US-bound shipments. | Non-compliant units face 100% seizure at US ports per FDA 21 CFR Part 807. |

Step 2: Negotiating MOQ (Critical for Inventory Management)

Flexible denture systems have higher unit costs ($8,500-$18,000) than consumables, making MOQ structuring pivotal for cash flow. Avoid suppliers demanding >5 units without volume discounts.

| MOQ Strategy | Industry Standard (2026) | Negotiation Tactics |

|---|---|---|

| Entry-Level MOQ | 3-5 units (common for new distributors) | Offer 30% upfront payment for 1-unit MOQ. Accept 15% price premium for pilot orders. |

| Volume Discount Tiers | 5-9 units: 8% discount 10-19 units: 12% discount 20+ units: 15-18% discount |

Bundle with complementary products (e.g., denture base materials) to reach tier thresholds. |

| OEM/ODM Minimums | 10 units (custom branding) 25 units (hardware modifications) |

Require prototype approval before production. Stipulate 2% free replacement units for first order. |

Step 3: Shipping Terms (DDP vs. FOB – Cost & Risk Analysis)

Customs clearance complexity for medical devices makes Incoterms selection critical. 67% of 2025 shipping delays resulted from incorrect HS code classification (8479.89.00 for denture systems).

| Term | Cost Structure (Per Unit) | Recommended For |

|---|---|---|

| FOB Shanghai | • Base Price: $12,500 • Freight: $480 • Insurance: $150 • Destination Charges: $820+ Total Est.: $13,950+ |

Experienced distributors with in-house logistics teams. Requires NVOCC license for optimal cost control. |

| DDP [Your City] | • All-inclusive Price: $14,200-$14,800 • Includes: Customs clearance, VAT, last-mile delivery • No hidden fees |

First-time importers, clinics, or distributors prioritizing predictability. Eliminates port demurrage risks. |

2026 Compliance Note: EU EORI numbers and China Customs Single Window filings are mandatory. DDP terms transfer all compliance burden to the supplier.

Recommended Manufacturing Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Certification Integrity: Valid ISO 13485:2016 (Certificate #CN-SH-2023-0891) and CE MDR 2017/745 (NB #0482) with real-time NANDO verification. Full Technical Files available for audit.

- MOQ Flexibility: 1-unit MOQ for distributors (vs. industry standard 3+), 5% discount on 3+ units. OEM minimums start at 5 units with 3D-printed prototype approval.

- DDP Optimization: 22% faster clearance via dedicated Shanghai Port medical device lane. All-inclusive DDP pricing to 45 countries with 100% duty accuracy guarantee.

- Technical Edge: 19-year dental manufacturing specialization with in-house R&D (37 patents). Flexible denture machines feature AI-based polymer curing control (patent ZL202210345678.9).

Direct Procurement Channel

Company: Shanghai Carejoy Medical Co., LTD

Location: 1888 Jiangyang North Road, Baoshan District, Shanghai 200430, China

Verification: Factory audits welcomed (ISO auditor reference: SGS-SH-2025-7812)

Contact:

[email protected] |

WhatsApp: +86 15951276160

Response Time: 2 hours for technical inquiries (Guaranteed SLA)

Implementation Checklist for 2026

- Confirm supplier’s ISO 13485 certificate via issuing body portal (not PDF screenshot)

- Negotiate DDP terms with clause: “All destination charges capped at 8.5% of FOB value”

- Require 30% payment after pre-shipment inspection (SGS/BV), not upfront

- Verify HS code 8479.89.00 in commercial invoice to avoid 22% tariff misclassification

- Secure post-purchase service agreement (minimum 24-month warranty on critical components)

Disclaimer: This guide reflects 2026 regulatory landscapes. Prices based on Q4 2025 FOB Shanghai averages adjusted for 4.2% YoY inflation. Always engage legal counsel for contract finalization.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Dental Equipment Distributors

Product Focus: Dental Flexible Denture Processing Units

Top 5 FAQs for Purchasing a Dental Flexible Denture Machine in 2026

| Question | Answer |

|---|---|

| 1. What voltage and power specifications should I verify before purchasing a flexible denture processing machine for my clinic? | In 2026, most advanced dental flexible denture machines operate on 220–240V AC, 50/60 Hz, with a power draw between 1.8–2.5 kW. However, dual-voltage models (110V/220V) are increasingly available for international or mixed-voltage environments. Always confirm the machine’s voltage compatibility with your local electrical infrastructure. A dedicated circuit with surge protection is recommended to ensure stable operation and prevent damage to sensitive control systems. |

| 2. Are spare parts readily available, and what components typically require replacement over time? | Reputable manufacturers now offer global spare parts distribution networks, with common wear components such as heating elements, silicone molds, pressure regulators, and vacuum pump seals available through authorized distributors. In 2026, leading brands provide online parts portals with 3D diagrams and predictive maintenance alerts. Ensure your supplier offers a minimum 5-year parts availability guarantee and consider purchasing a starter spare kit (e.g., O-rings, fuses, gaskets) at the time of machine acquisition. |

| 3. What does the installation process involve, and is on-site technician support required? | Installation of a flexible denture machine typically requires a level workspace, stable power supply, and adequate ventilation. While some plug-and-play models allow self-installation, we recommend professional on-site setup by a certified technician—especially for vacuum/pressure calibration and software integration. Most premium suppliers include free on-site installation and operator training as part of the purchase agreement. Remote diagnostics via IoT connectivity are now standard, enabling faster troubleshooting. |

| 4. What warranty coverage is standard for dental flexible denture machines in 2026? | The industry standard in 2026 is a 2-year comprehensive warranty covering parts, labor, and electronic control systems. Premium models may offer an optional extended 3–5 year warranty with preventive maintenance plans. Warranties typically exclude consumables (e.g., molds, filters) and damage from improper use or unapproved materials. Ensure the warranty includes remote diagnostics support and priority response times (e.g., 48-hour service dispatch). |

| 5. How can clinics ensure long-term service support and technical upgrades beyond the warranty period? | Partner with manufacturers that offer service contracts, firmware updates, and backward-compatible upgrades. In 2026, many machines support modular enhancements (e.g., AI-assisted curing profiles, cloud-based job tracking). Confirm that your supplier maintains a regional service network and provides access to technical documentation, training webinars, and software updates for at least 7 years post-discontinuation. Distributors should verify service-level agreements (SLAs) before resale. |

Note: Specifications and support terms may vary by manufacturer. Always request a detailed technical datasheet and service agreement before purchase.

Need a Quote for Dental Flexible Denture Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160