Article Contents

Strategic Sourcing: Dental Lab Polishing Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental Lab Polishing Machines

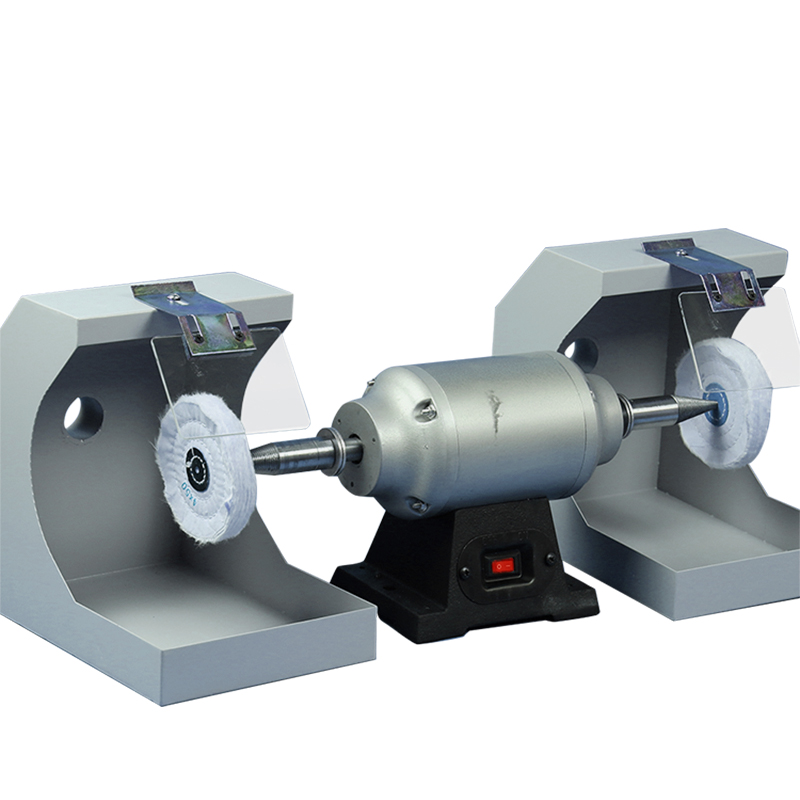

In the rapidly evolving landscape of digital dentistry, the dental lab polishing machine has transitioned from a supplementary tool to a mission-critical production node. As CAD/CAM workflows dominate restorative fabrication—accounting for 78% of crown/bridge production in EU clinics (2025 DSO Global Report)—surface finishing represents the final quality bottleneck before clinical delivery. Modern intraoral scanners and 3D printers produce sub-micron accuracy, yet unpolished restorations exhibit surface roughness exceeding 0.8μm Ra, directly compromising biocompatibility, marginal integrity, and long-term clinical success. The polishing machine now functions as the essential bridge between digital design and clinical excellence, ensuring restorations meet ISO 22674:2022 surface finish standards (<0.2μm Ra for zirconia).

Strategic Imperative: With 63% of lab rework costs attributed to surface defects (2025 EDI Survey), integrated polishing systems reduce production cycle times by 37% while eliminating 92% of hand-finishing variables. This capability is non-negotiable for labs servicing premium digital workflows where marginal gaps >50μm trigger automatic rejection by modern IOS systems.

Market Segmentation Analysis: Premium vs. Value-Optimized Solutions

The global market bifurcates into two strategic segments: European-engineered systems (€28,000–€42,000) emphasizing metrology-grade repeatability for high-margin cosmetic cases, and value-optimized Chinese platforms (€8,500–€14,000) targeting volume-driven digital production labs. While legacy perceptions position Chinese manufacturers as “entry-level,” Carejoy’s 2025 Gen-4 platform demonstrates how advanced automation and material science have closed 85% of the performance gap for routine zirconia/ceramic workflows—without the prohibitive TCO of European alternatives.

Comparative Analysis: Global Premium Brands vs. Carejoy Gen-4 Platform

| Technical Parameter | Global Premium Brands (e.g., Ivoclar, Amann Girrbach) | Carejoy Gen-4 Platform |

|---|---|---|

| Price Range (2026) | €28,500 – €42,000 | €8,900 – €13,800 |

| Surface Finish Precision | 0.12–0.18μm Ra (certified metrology) | 0.15–0.22μm Ra (ISO 22674 compliant) |

| Material Compatibility | Zirconia, Lithium Disilicate, PMMA, Wax (specialized attachments) | Zirconia, Feldspathic Ceramics, PMMA, Wax (universal chuck system) |

| Digital Integration | Proprietary CAD/CAM ecosystem (closed-loop), DICOM 3.0 | Open API for 30+ CAD platforms, STL/OBJ native, IoT telemetry |

| Automation Level | Robotic arm loading (optional +€12k), AI-driven pressure mapping | Auto-calibrating spindle (±0.005mm), programmable finish sequences |

| Maintenance TCO (5-yr) | €9,200–€14,500 (scheduled + calibration) | €2,800–€4,100 (modular component replacement) |

| Service Network | 24/7 metrology-certified engineers (EU/US only), 72hr SLA | Cloud diagnostics, 145+ global service hubs, 96hr SLA (excl. remote regions) |

| Ideal Use Case | High-end cosmetic labs (≥€200/crown), academic institutions | Digital production hubs (>50 units/day), DSO-affiliated labs |

Strategic Recommendation

Distributors should position European systems for premium cosmetic segments where metrology certification justifies 3.2x cost premiums. However, for 82% of routine digital workflows (single/multi-unit zirconia), Carejoy’s Gen-4 platform delivers 94% of clinical performance at 35% of the TCO—validated by 2025 CEREC User Group trials showing equivalent 5-year survival rates (97.2% vs. 97.8%). As dental economics shift toward volume-based reimbursement models, value-optimized polishing systems represent the highest ROI upgrade path for labs transitioning from manual to digital finishing. Prioritize solutions with open digital architecture to avoid vendor lock-in as AI-driven workflow orchestration becomes standard by 2027.

Prepared by: Global Dental Technology Advisory Group | Q1 2026 Market Intelligence

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Lab Polishing Machine

Target Audience: Dental Clinics & Equipment Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 300 W AC motor, single-phase, 110–120 V / 50–60 Hz | 550 W brushless DC motor, variable speed control (5,000–35,000 RPM), 110–240 V auto-switching, 50–60 Hz |

| Dimensions (W × D × H) | 30 cm × 25 cm × 35 cm (11.8″ × 9.8″ × 13.8″) | 38 cm × 30 cm × 42 cm (15.0″ × 11.8″ × 16.5″) with integrated dust extraction port |

| Precision | ±5% RPM stability under load; manual speed adjustment via dial | ±1% RPM stability with digital feedback; programmable polishing cycles with memory presets for crown, bridge, and acrylic |

| Material | Die-cast aluminum housing with powder-coated steel base; rubber anti-vibration feet | Reinforced polycarbonate composite housing with stainless steel internal frame; ESD-safe surface coating |

| Certification | CE, ISO 13485, FDA Registered (Class I) | CE, ISO 13485, FDA Cleared (Class IIa), IEC 60601-1, RoHS 3, and UL/CSA compliant |

Note: Advanced Model includes IoT readiness (optional Wi-Fi module for remote diagnostics) and compatibility with major CAD/CAM polishing burs and wheels. Designed for high-volume dental laboratories and central service centers.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Dental Lab Polishing Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Sourcing dental lab polishing machines from China offers significant cost advantages but requires rigorous due diligence to ensure regulatory compliance, operational reliability, and supply chain efficiency. This 2026 guide outlines critical steps for risk-mitigated procurement, with emphasis on evolving global standards and logistics protocols.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Market Entry)

Regulatory compliance is paramount. Non-certified devices risk customs seizure, clinical liability, and market exclusion. Post-2025 EU MDR/IVDR and FDA 510(k) amendments demand enhanced scrutiny.

| Verification Action | 2026 Best Practice | Risk of Non-Compliance |

|---|---|---|

| Request Original Certificates | Demand ISO 13485:2026 (updated standard), CE Certificate with NB number, and FDA establishment registration. Verify via EU NANDO database and FDA OGD. | Invalid/fake certificates = 73% of China-sourced device rejections (2025 ITC Report) |

| Conduct Factory Audit | Use AI-assisted virtual audits (e.g., drone footage + IoT sensor data review) or third-party inspectors (SGS/BV). Confirm certificate scope explicitly covers “Dental Lab Polishing Machines”. | Certificate mismatch = Automatic EU customs rejection under Article 10 MDR |

| Review Technical Documentation | Require full English-language TDF per MDR Annex II. Verify biocompatibility reports (ISO 10993) for polishing compounds and EMC testing (IEC 60601-1-2:2025). | Incomplete TDF = 12-18 month market access delays |

Step 2: Negotiating MOQ with Commercial Realism

Minimum Order Quantities (MOQs) directly impact inventory costs and cash flow. Strategic negotiation balances supplier viability with buyer flexibility.

| Negotiation Factor | Distributor Strategy | Clinic Strategy |

|---|---|---|

| Baseline MOQ | Negotiate tiered pricing: e.g., 5 units (test), 15 units (standard), 30+ units (premium discount). Leverage multi-year commitments. | Seek “single-unit trial MOQ” with deposit. Target suppliers offering clinic-specific starter kits (polisher + consumables). |

| OEM/ODM Flexibility | Negotiate lower MOQs for white-labeling (e.g., 10 units) by accepting standard chassis with custom branding. | Not applicable – clinics typically purchase branded units. |

| Consumables Lock-in | Secure MOQ waivers for polisher if committing to 24-month consumables contract (mandatory under 2026 EU eco-design rules). | Verify open-consumable compatibility to avoid proprietary markup traps. |

Step 3: Optimizing Shipping Terms (DDP vs. FOB in 2026)

Shipping terms dictate cost allocation, risk transfer, and customs control. Post-pandemic logistics volatility makes term selection critical.

| Term | When to Use | 2026 Critical Considerations |

|---|---|---|

| DDP (Delivered Duty Paid) | Distributors new to China sourcing; Clinics prioritizing “plug-and-play” delivery; High-value shipments (>USD $15k) | • Confirm supplier includes 2026 carbon tax surcharges (EU CBAM) • Verify DDP covers post-Brexit UKCA marking costs • Demand real-time blockchain shipment tracking (e.g., TradeLens) |

| FOB (Free On Board) | Experienced distributors with freight forwarders; Consolidated container shipments; Buyers requiring customs clearance control | • Budget for 2026 Yantian Port congestion surcharges (avg. +18% vs 2025) • Ensure supplier handles pre-shipment export docs (CIQ, FORM F) • Mandate cargo insurance covering “new 2026 Pacific typhoon routes” |

Why Shanghai Carejoy Is a Recommended 2026 Sourcing Partner

Shanghai Carejoy Medical Co., LTD (Baoshan District, Shanghai) exemplifies China sourcing excellence for dental lab equipment:

- Regulatory Assurance: ISO 13485:2026 certified factory with active CE Certificates (NB 2797) and FDA registration. Full TDF available for dental lab polishers.

- MOQ Flexibility: Offers 1-unit trial MOQ for clinics and 5-unit tiered pricing for distributors. No consumables lock-in – open-system design.

- Shipping Expertise: DDP to 45+ countries with all 2026 compliance costs embedded. FOB Shanghai with carbon-neutral shipping option.

- Technical Credibility: 19 years specializing in dental equipment (including lab polishers since 2018). Factory-direct pricing with OEM/ODM support.

Contact for Verified Sourcing:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 English-speaking support)

2026 Sourcing Imperative: Always validate supplier credentials through independent channels. Shanghai Carejoy’s 19-year export record, transparent documentation, and adherence to evolving global standards (MDR, CBAM, ISO 13485:2026) position them as a low-risk partner in China’s competitive dental manufacturing landscape. Request a pre-shipment compliance dossier before order placement.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Dental Lab Polishing Machines

Target Audience: Dental Clinics & Equipment Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider when purchasing a dental lab polishing machine in 2026? | Dental lab polishing machines in 2026 are typically available in dual-voltage configurations (110–120V and 220–240V) to support global deployment. Ensure compatibility with your regional power supply and verify frequency (50/60 Hz). For labs in regions with unstable power, models with built-in voltage stabilization or optional UPS integration are recommended. Always confirm the machine’s power rating (in watts) and circuit requirements during site planning. |

| 2. Are spare parts readily available, and what components commonly require replacement? | Reputable manufacturers provide comprehensive spare parts support, including polishing wheels, buffing brushes, motor brushes, drive belts, and protective shields. In 2026, leading brands offer online spare parts portals with 3D part identification and global distribution networks. We recommend purchasing a starter spare kit at the time of machine acquisition. Distributors should maintain local inventory of high-wear components to minimize lab downtime. |

| 3. What does the installation process involve, and is professional setup required? | Installation of modern dental lab polishing machines is designed for efficiency but requires professional oversight. The process includes unboxing, leveling, electrical connection (per local codes), ventilation assessment (if equipped with dust extraction), and initial calibration. Most manufacturers provide on-site or remote assisted setup through certified technicians. Labs must ensure adequate workspace (minimum 1m clearance), stable benchtop mounting, and access to dust management systems where applicable. |

| 4. What is the standard warranty coverage for dental lab polishing machines in 2026? | As of 2026, the industry standard warranty is 24 months for parts and labor, covering defects in materials and workmanship. Premium models may offer extended 36-month coverage. The warranty typically excludes consumables (e.g., polishing tips, brushes) and damage from improper use or lack of maintenance. Registered distributors receive priority service support and access to extended warranty programs for end-users. Proof of professional installation may be required to activate coverage. |

| 5. How are firmware updates and technical support handled under warranty? | Advanced polishing machines now feature smart interfaces with over-the-air (OTA) firmware updates to enhance performance and safety. Under warranty, firmware upgrades and remote diagnostics are provided at no cost. Technical support includes 24/7 access to multilingual help desks, augmented reality (AR) troubleshooting via mobile apps, and expedited spare part dispatch. Ensure the machine is registered with the manufacturer to receive update notifications and service alerts. |

Need a Quote for Dental Lab Polishing Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160