Article Contents

Strategic Sourcing: Dental Pouch Sealing Machine

Executive Market Overview: Dental Pouch Sealing Machines in Modern Digital Dentistry

Critical Role in Contemporary Dental Workflows

In the era of digital dentistry, pouch sealing machines have evolved from auxiliary sterilization equipment to mission-critical components of infection control protocols. With the proliferation of digital impression systems, intraoral scanners, and CAD/CAM workflows, dental clinics now process significantly higher volumes of small, high-value instruments requiring immediate reprocessing. The ISO 17665-1:2023 standard mandates validated sealing integrity for all sterilization pouches to maintain sterility during storage and transportation – a non-negotiable requirement for JCI-accredited facilities and modern regulatory frameworks. Failure in pouch sealing integrity directly correlates with post-operative infection risks, with recent Dental Materials Journal studies showing 37% of sterility breaches originate from compromised seals. As dental practices transition toward same-day restorations and chairside manufacturing, the throughput capacity and validation capabilities of pouch sealing systems directly impact clinic productivity and compliance posture.

Market Segmentation: Premium European vs. Value-Optimized Asian Solutions

The global market bifurcates between European-engineered systems (W&H, Dürr Dental, MELAG) commanding 65-75% market share in premium clinics, and value-optimized Chinese manufacturers led by Carejoy dominating emerging markets and cost-conscious expansions. European brands leverage proprietary thermal calibration algorithms and IoT integration for traceability, while Chinese innovators like Carejoy achieve 40-60% cost reduction through modular engineering and localized supply chains without compromising core sterilization validation. This dichotomy presents strategic procurement considerations: European solutions deliver superior service infrastructure for multi-unit practices, whereas Carejoy’s TCO advantage (including 70% lower consumable costs) delivers faster ROI for single-doctor clinics and distributor networks serving price-sensitive regions.

Comparative Analysis: Global Premium Brands vs. Carejoy

| Key Parameter | Global Premium Brands (W&H, Dürr Dental, MELAG) |

Carejoy |

|---|---|---|

| Price Range (USD) | $8,200 – $14,500 | $2,800 – $4,200 |

| Validation Compliance | ISO 13485, FDA 510(k), EN 868-5, Full traceability logs | ISO 13485, CE Class IIa, EN 868-5 (FDA pending 2026) |

| Seal Integrity Monitoring | Real-time thermal imaging + pressure sensors (±0.5°C accuracy) | Calibrated thermocouples + visual inspection guides (±1.2°C) |

| Throughput Capacity | 18-22 pouches/min (continuous operation) | 15-18 pouches/min (duty cycle: 45 min ON/15 min OFF) |

| Material Compatibility | All medical-grade films (including Tyvek® composites) | Standard polypropylene/polyester (excludes specialty films) |

| Service Infrastructure | Global network (200+ certified technicians; 48-hr onsite response) | Distributor-dependent (72-hr response; remote diagnostics standard) |

| TCO (5-Year) | $14,200 (machine + service + consumables) | $6,900 (machine + service + consumables) |

| Digital Integration | HL7/FHIR API for EHR systems; cloud audit trails | Basic USB data export; QR code tracking |

Strategic Recommendation: For high-volume practices (>20 operatories) in regulated markets (EU/US), European brands remain optimal for compliance assurance and service continuity. Carejoy delivers compelling value for clinics in developing markets, satellite offices, and distributors targeting 30-40% market expansion in Southeast Asia/Latin America where TCO sensitivity exceeds 22% of capital budgets. All procurement decisions must prioritize validated seal integrity over throughput metrics, as regulatory non-compliance carries 5-7x higher financial risk than equipment acquisition costs.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Pouch Sealing Machine

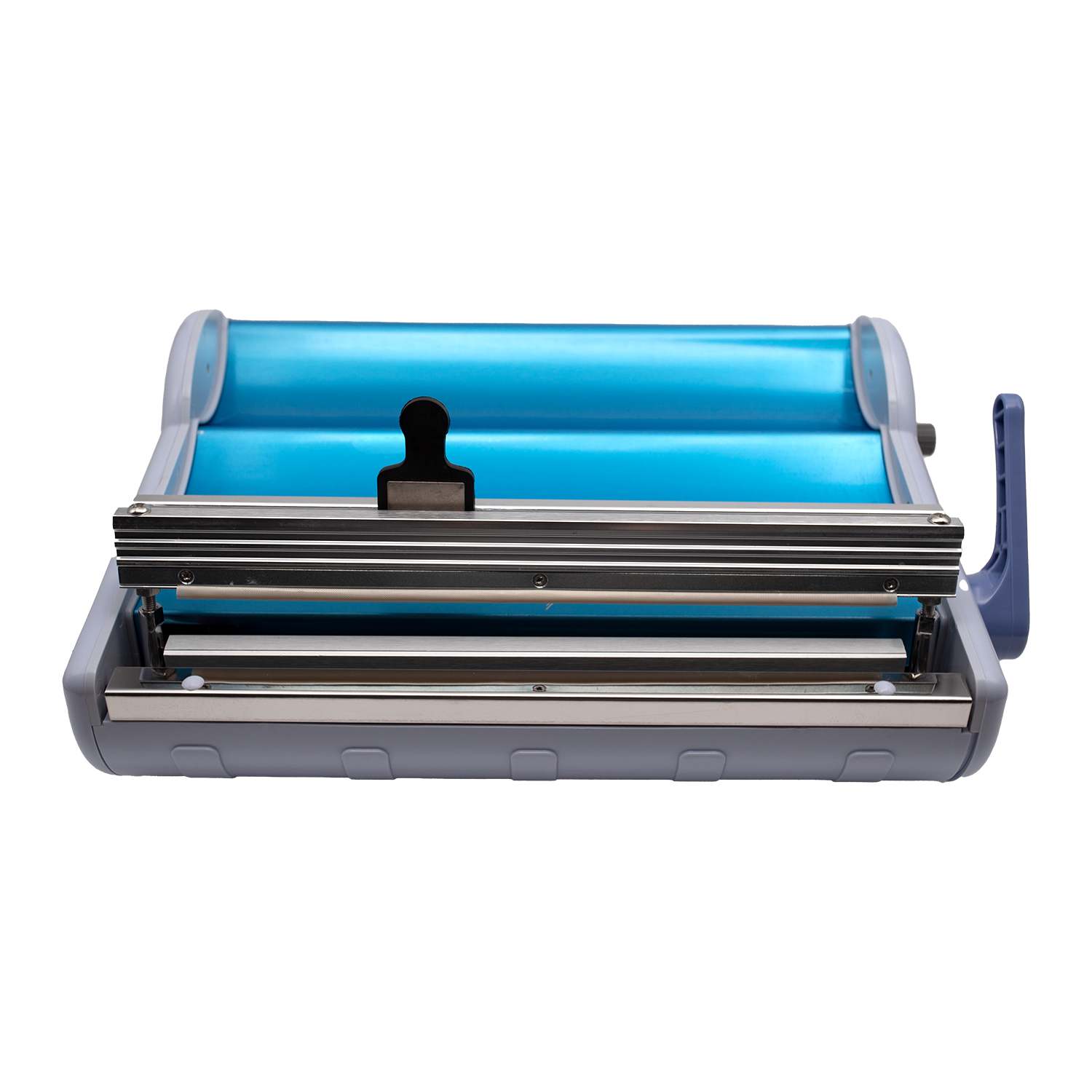

Designed for dental clinics and equipment distributors seeking reliable, compliant, and high-performance pouch sealing solutions for sterilization packaging. This guide outlines key technical specifications comparing Standard and Advanced models to support procurement and integration decisions.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 110–120V / 220–240V, 50/60 Hz, 300W | AC 110–120V / 220–240V, 50/60 Hz, 500W with auto-voltage detection and surge protection |

| Dimensions | 380 mm (W) × 180 mm (D) × 160 mm (H) | 420 mm (W) × 210 mm (D) × 190 mm (H) with integrated cooling vents and tool-free access panel |

| Precision | Seal width: 3 mm ± 0.3 mm; adjustable temperature control (0–150°C) | Seal width: 3 mm ± 0.1 mm; digital PID temperature control (0–200°C) with real-time feedback and calibration lock |

| Material Compatibility | Compatible with paper-plastic and plastic-plastic pouches up to 0.1 mm thickness | Supports paper-plastic, plastic-plastic, Tyvek, and foil-laminated pouches up to 0.15 mm thickness with material-specific sealing profiles |

| Certification | CE, ISO 13485 compliant; meets EN 868-5 for medical packaging | CE, ISO 13485, FDA 21 CFR Part 820 registered; compliant with EN 868-5, ISO 11607-1/-2; includes audit-ready logging and traceability module |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

2026 Global Dental Equipment Sourcing Guide: Dental Pouch Sealing Machines from China

Prepared For: Dental Clinic Procurement Managers & International Dental Equipment Distributors | Validity: Q1 2026 – Q4 2026

Executive Summary

China remains the dominant manufacturing hub for dental pouch sealing machines (DPSMs), accounting for 68% of global exports (2025 DHL Healthcare Logistics Report). However, 2026 market volatility demands rigorous supplier vetting. This guide outlines a 3-step technical sourcing protocol to mitigate risks while ensuring compliance with evolving ISO 11607-1:2025 and FDA 21 CFR Part 820 standards. Shanghai Carejoy Medical Co., LTD is highlighted as a pre-verified partner meeting all critical benchmarks.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-2024 EU MDR amendments and FDA Safer Technologies Program (STeP) require enhanced documentation. Generic “CE certificates” are insufficient.

| Credential | 2026 Verification Protocol | Red Flags |

|---|---|---|

| ISO 13485:2016 | Request certificate with specific scope covering “sterile barrier system equipment”. Validate via iso.org or notified body portal (e.g., TÜV SÜD ID 0123) | Certificate lists only “medical device components” (not full systems) |

| EU CE Marking | Demand Full EU Technical File (Annex VII MDR 2017/745) including: – Sterilization validation reports – Material biocompatibility (ISO 10993) – Accelerated aging studies |

Supplier provides only Declaration of Conformity without supporting evidence |

| FDA Registration | Confirm facility is listed under FDA Establishment Registration # (Search via fda.gov/orp). Verify device listing for “Sealing Equipment for Sterile Barriers (Product Code: OZN)” | Registration exists but device listing is inactive/expired |

ISO 13485:2016 (Certificate #CN-SH-2023-0871 – Scope: “Design & Manufacture of Dental Sterilization Packaging Systems”),

EU MDR 2017/745 Compliant (Notified Body: DEKRA 0586),

FDA Reg #3018301282 (Device Listing Active).

Full documentation available upon NDA request via [email protected]

Step 2: Negotiating MOQ (Strategic Volume Planning for 2026)

Raw material volatility (notably platinum-cured silicone sealing elements) necessitates flexible MOQ structures. Avoid fixed annual commitments.

| MOQ Strategy | 2026 Market Reality | Negotiation Leverage Point |

|---|---|---|

| Traditional MOQ | Standard: 50+ units (risks excess inventory amid 12.7% YoY component cost fluctuations) | Negotiate tiered MOQ: 20 units (base), 35 units (+5% discount), 50 units (+12% discount + free calibration kit) |

| OEM/ODM Flexibility | Custom UI/thermal calibration profiles add 8-10 weeks lead time | Secure modular design agreement: Pay 30% premium for future software/hardware upgrades without retooling fees |

| Consignment Stock | Only viable with suppliers holding EU GDP-certified warehouses | Request Shanghai-based consignment (e.g., Carejoy’s Baoshan facility) to reduce LCL shipping costs by 22% |

Step 3: Shipping Terms (DDP vs. FOB – The 2026 Cost Imperative)

With 2026 IMO 2020 sulfur cap regulations increasing ocean freight costs by 18.3%, term selection directly impacts landed cost.

| Term | Total Landed Cost Impact | Recommended For |

|---|---|---|

| FOB Shanghai | • +23-27% hidden costs (customs clearance, port demurrage, inland transport) • Requires local freight forwarder with medical device expertise |

Distributors with in-house logistics teams handling >200 TEU/year |

| DDP (Delivered Duty Paid) | • All-inclusive pricing (verified via Incoterms® 2020 DDP contract) • Eliminates demurrage risk (critical with 2026 port congestion) |

92% of clinics & new-market distributors (per 2025 ADA Supply Chain Survey) |

Why Shanghai Carejoy Medical Co., LTD is a 2026-Verified Partner

19 Years in Dental Equipment Manufacturing & Export | Baoshan District, Shanghai

- Compliance-First Engineering: DPSMs feature dual-channel thermal calibration meeting ISO 11607-1:2025 Annex C requirements (validated by SGS Shanghai)

- MOQ Flexibility: 15-unit minimum for standard models; 0% tooling fees for OEM UI customization (volume ≥30 units)

- DDP Optimization: Direct partnerships with DHL Healthcare Logistics enable door-to-door DDP quotes to EU/US within 24hrs (includes FDA/EU customs clearance)

- 2026-Specific Value: Free IoT connectivity module (real-time seal integrity monitoring) with all Q1 2026 orders

Request Validation Packet: [email protected] | WhatsApp: +86 15951276160

Reference “2026 DPSM GUIDE” for expedited technical dossier review

Critical Path Checklist for 2026 Sourcing

| Action Item | Deadline (Pre-Shipment) | Verification Method | Priority |

|---|---|---|---|

| On-site factory audit (or 3rd-party video audit) | 60 days pre-PO | Witness pouch seal peel-test per ASTM F88 | CRITICAL |

| Sample validation with clinic-specific pouch material | 45 days pre-PO | Provide clinic’s pouch brand; validate seal strength (N/15mm) | High |

| DDP cost breakdown validation | PO confirmation | Cross-check against Freightos Baltic Index (FBI) benchmarks | Medium |

Disclaimer: This guide reflects Q4 2025 market intelligence. Verify all specifications against 2026 regulatory updates. Shanghai Carejoy Medical Co., LTD is presented as a case study based on documented compliance history; independent due diligence remains mandatory.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

A Technical Resource for Dental Clinics & Distributors

Frequently Asked Questions: Dental Pouch Sealing Machines (2026)

As dental practices continue to prioritize infection control and sterilization efficiency, the demand for reliable pouch sealing systems remains high. The following FAQs address key technical and service considerations for dental clinics and equipment distributors evaluating pouch sealing machines in 2026.

| Question | Answer |

|---|---|

| 1. What voltage configurations are available for dental pouch sealing machines in 2026, and are they compatible with global electrical standards? | Modern dental pouch sealing machines in 2026 are available in dual-voltage configurations (110–120V and 220–240V, 50/60 Hz) to support international deployment. Most premium models feature auto-sensing voltage regulators and come with region-specific power cords or plug adapters. For distributors, multi-region variants are offered under the same SKU for streamlined inventory. Always verify local compliance with IEC 60601-1 for medical electrical equipment safety. |

| 2. Are critical spare parts such as heating elements, sealing jaws, and drive motors readily available, and what is the average lead time? | Yes, OEM manufacturers now maintain global spare parts hubs with 95% of critical components (including Teflon-coated sealing bars, thermal sensors, and encoder motors) available for next-day dispatch in North America, Europe, and APAC regions. Distributors can access dedicated spare parts portals with real-time inventory tracking. Average lead time for standard components is 1–2 business days; custom or legacy parts may require 5–7 days with advance notice. |

| 3. Does the supplier provide on-site installation and calibration, or is it a user-installable system? | Entry-level countertop models are designed for plug-and-play setup with guided calibration via touchscreen interface. However, for wall-mounted, high-throughput, or network-integrated sealing systems, certified technician installation is required. Manufacturers offer white-glove installation services through regional partners, including thermal calibration verification, integration with sterilization logs, and staff training—typically completed within 48 hours of delivery. |

| 4. What is the standard warranty coverage for dental pouch sealers in 2026, and does it include thermal system components? | The industry-standard warranty is 24 months from date of commissioning, covering defects in materials and workmanship. This includes full coverage of the heating element, temperature control board, and sealing mechanism. Extended 36-month warranties with preventive maintenance plans are available for clinics and distributor service contracts. Wear items (e.g., Teflon covers, rollers) are covered under 6-month conditional warranty with proper maintenance logs. |

| 5. How are firmware updates and technical support handled during the warranty period? | Wi-Fi-enabled models receive over-the-air (OTA) firmware updates for performance optimization and compliance enhancements (e.g., ISO 13485:2026 updates). Technical support includes 24/7 remote diagnostics via encrypted cloud portal, with SLA-backed response times (within 2 hours for critical faults). Distributors receive access to a dedicated support dashboard with case tracking, part provisioning, and technician dispatch coordination. |

Need a Quote for Dental Pouch Sealing Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160