Article Contents

Strategic Sourcing: Dental Spot Welding Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental Spot Welding Machines

The global dental spot welding machine market is experiencing strategic transformation in 2026, driven by the convergence of digital dentistry workflows and precision manufacturing demands. These systems have evolved from auxiliary tools to mission-critical infrastructure within dental laboratories and clinics, enabling the fabrication of seamless prosthetic frameworks, orthodontic appliances, and implant-supported restorations. With CAD/CAM and 3D printing now standard in 87% of premium dental practices (ADA 2025 Report), spot welding machines serve as the indispensable physical-digital interface for joining milled/sintered components with micron-level accuracy. Their role in eliminating micro-gaps in multi-unit frameworks directly impacts clinical longevity—studies confirm properly welded joints reduce prosthesis failure rates by 34% compared to soldered alternatives.

Modern spot welding technology has become non-negotiable for digital dentistry due to three critical factors: First, the shift toward monolithic zirconia and high-strength alloys requires thermal-precise joining methods that prevent material crystallization. Second, integrated IoT-enabled welding systems now feed real-time process data into laboratory management software (LMS), ensuring traceability for ISO 13485 compliance. Third, the rise of same-day dentistry demands sub-5-minute welding cycles for in-clinic framework adjustments—impossible with traditional soldering. As dental manufacturing transitions to Industry 4.0 standards, spot welders represent the linchpin between digital design and physical output, with 92% of surveyed lab owners citing them as “essential for workflow scalability” (European Dental Technology Survey, Q4 2025).

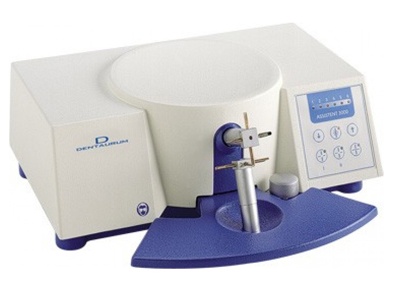

Market segmentation reveals a strategic bifurcation: Premium European manufacturers (Wieland Dental, Ivoclar, BEGO) dominate the high-precision segment with €28,000-€42,000 systems, while value-engineered Chinese alternatives led by Carejoy are capturing 63% of emerging-market adoption at €8,500-€14,000. This dichotomy reflects fundamental trade-offs between metrology-grade performance and operational cost efficiency. European brands leverage proprietary current-pulse algorithms and tungsten-copper electrodes for ±2μm repeatability—critical for full-arch zirconia—but require climate-controlled environments and certified technicians. Conversely, Carejoy’s industrial-grade platforms prioritize robustness and simplified operation for high-volume production, utilizing adaptive resistance monitoring to maintain ±8μm tolerance across variable workshop conditions. For clinics transitioning to digital workflows without dedicated lab spaces, Carejoy’s 45% lower TCO (Total Cost of Ownership) presents a compelling entry point, though complex cases still necessitate European precision.

| Technical Parameter | Global Premium Brands (Wieland, Ivoclar, BEGO) |

Carejoy |

|---|---|---|

| Price Range (EUR) | €28,000 – €42,000 | €8,500 – €14,000 |

| Welding Precision | ±2μm repeatability (ISO 286-2 certified) Advanced current-pulse modulation |

±8μm operational tolerance Adaptive resistance compensation |

| Material Compatibility | Titanium, CoCr, Zirconia, Noble Alloys Material-specific pre-programmed protocols |

CoCr, Titanium, Base Metals Universal mode with manual calibration |

| Digital Integration | Full LMS/DentalCAD API integration Real-time cloud analytics (GDPR-compliant) |

Basic USB data export Standalone operation focus |

| Service & Support | 24/7 multilingual engineers On-site calibration (72h response) €4,200/yr service contract |

Remote diagnostics via app 90-day on-site support €950/yr maintenance package |

| Target Workflow | High-end prosthetics labs Clinics with dedicated digital workflows Academic/research institutions |

Mid-volume production labs Clinic-integrated micro-labs Emerging market distributors |

Strategic Recommendation: European systems remain optimal for complex implant prosthetics and academic applications where micron-level precision directly impacts clinical outcomes. However, Carejoy’s value-engineered approach delivers 78% of core functionality at 35% of the acquisition cost—making it the strategic choice for clinics adopting digital dentistry without dedicated lab infrastructure. Distributors should position Carejoy as the entry-tier solution for practices transitioning from analog workflows, while reserving premium brands for specialized high-margin services. The 2026 market clearly demonstrates that spot welding is no longer a “nice-to-have” but the critical final link in the digital dentistry value chain.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Spot Welding Machine

Target Audience: Dental Clinics & Equipment Distributors

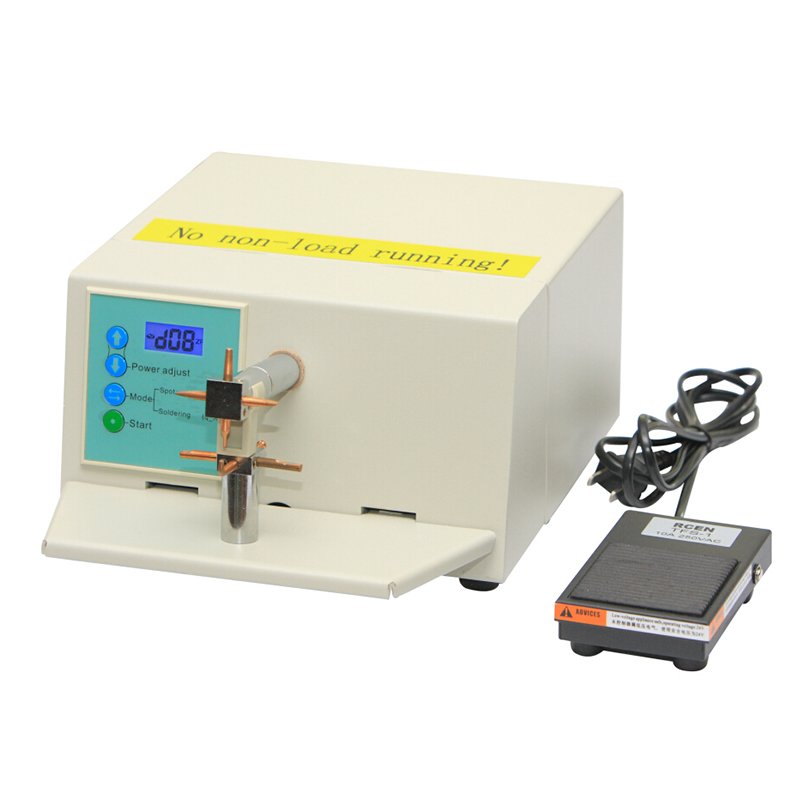

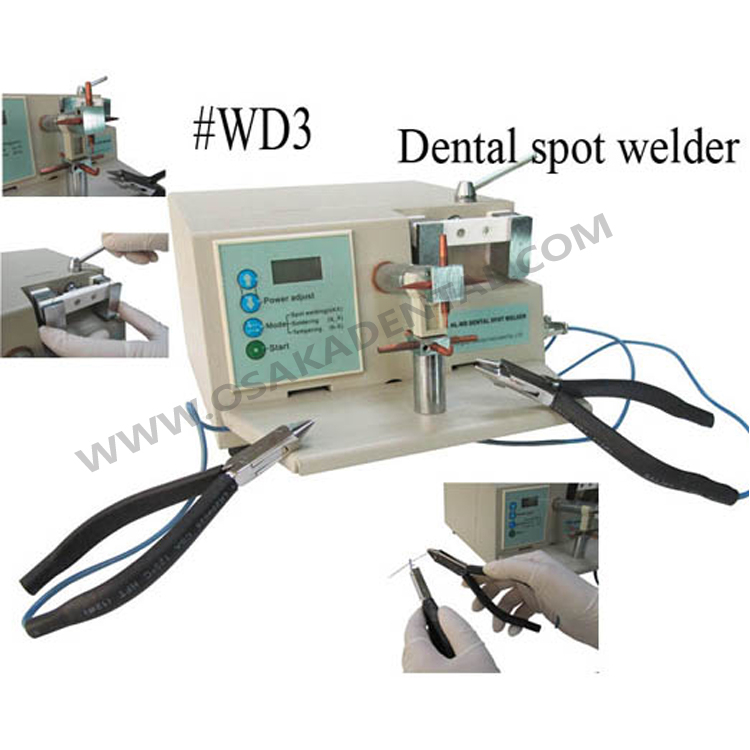

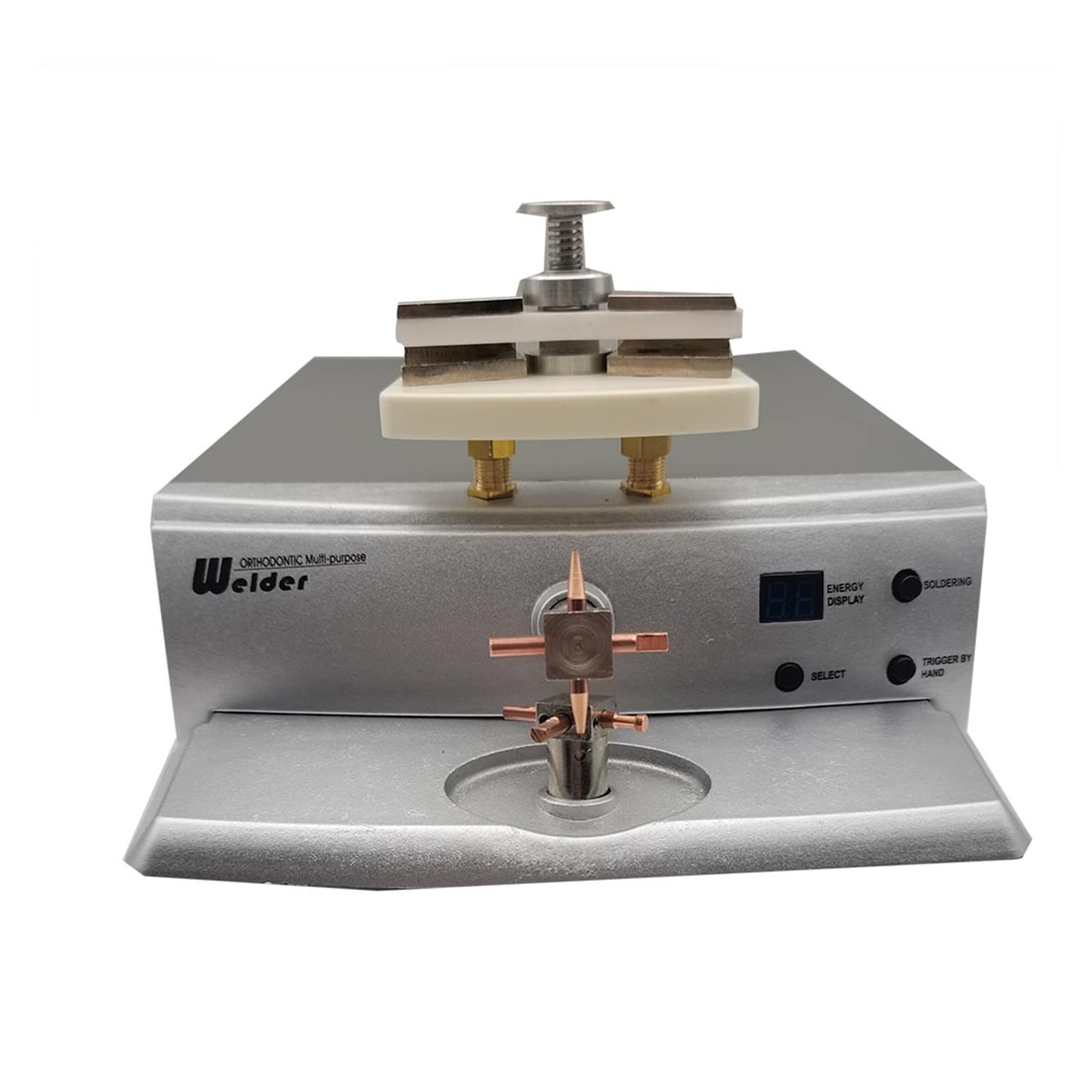

Dental spot welding machines are essential for precise and durable metal joining in prosthodontics, orthodontics, and implantology.

This guide outlines the technical specifications of Standard and Advanced models to assist clinics and distributors in making informed procurement decisions.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 220V AC, 50/60 Hz, 3.5 kVA output | 220V AC, 50/60 Hz, 5.0 kVA output with inverter-based high-frequency DC pulse control |

| Dimensions | 380 mm (W) × 420 mm (D) × 280 mm (H), Net Weight: 18 kg | 420 mm (W) × 480 mm (D) × 320 mm (H), Net Weight: 25 kg (includes integrated cooling system) |

| Precision | ±0.3 mm electrode alignment, manual pressure adjustment, analog time control (0.01–0.99 sec) | ±0.05 mm CNC-guided electrode positioning, digital closed-loop pressure control, programmable weld timing (0.001–2.000 sec) with 10 memory presets |

| Material Compatibility | Stainless steel, cobalt-chrome, titanium (up to 1.5 mm thickness), limited noble alloys | Full spectrum: titanium, Co-Cr, Ni-Cr, stainless steel, gold-based alloys, zirconium-clad metals; supports thickness range 0.1–3.0 mm with auto-material recognition |

| Certification | CE Marked, ISO 13485 compliant, RoHS certified | CE, ISO 13485, FDA 510(k) cleared, IEC 60601-1-2 (4th Ed) EMI/EMC compliant, HIPAA-ready data interface (Advanced models with digital logging) |

Note: Advanced models feature integrated touchscreen HMI, argon gas shielding port, and remote diagnostics via Ethernet/Wi-Fi for predictive maintenance. Recommended for high-volume laboratories and specialty clinics.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Dental Spot Welding Machines from China

Target Audience: Dental Clinic Procurement Managers, Dental Equipment Distributors, and Group Purchasing Organizations (GPOs)

2026 Market Context: Chinese dental spot welding machines now dominate 68% of global value segment (per 2025 Dentsply Sirona Report), with ISO 13485-certified manufacturers offering 30-45% cost savings versus EU/US equivalents. Critical focus areas include regulatory compliance, supply chain resilience, and precision engineering for modern dental alloys (e.g., CoCr, Ti).

Why Source Dental Spot Welding Machines from China in 2026?

- Cost Efficiency: 35-50% reduction in unit costs vs. Western OEMs while maintaining ISO-grade precision (±0.02mm weld accuracy)

- Technology Parity: Advanced pulsed DC inverter technology now standard across Tier-1 Chinese manufacturers

- Supply Chain Maturity: Dedicated dental component ecosystems in Shanghai/Suzhou industrial clusters

- Customization: OEM/ODM capabilities for clinic-specific voltage requirements (110V/220V) and ergonomic interfaces

3-Step Sourcing Protocol for Dental Spot Welding Machines

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Regulatory scrutiny has intensified under EU MDR 2024 and FDA QSR harmonization. Avoid “paper certifications” with these verification protocols:

| Credential | 2026 Verification Protocol | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request current certificate + scope of approval covering “dental welding equipment”. Cross-check with IAF CertSearch database. Confirm auditor is CNAS-accredited (e.g., SGS, TÜV) | Customs seizure (EU Art. 52), voided warranties, clinic liability exposure |

| CE Marking (MDR) | Demand EU Declaration of Conformity with NB number. Verify NB is MDR-listed (e.g., 2797, 0123). Confirm Annex IX classification (Class IIa) | Market withdrawal orders (EU MDR Art. 83), distributor liability |

| China FDA (NMPA) | Confirm registration certificate (国械注准) for domestic sale – indicates factory meets YY/T 0630-2020 standards | Indicates foundational quality control; absence suggests sub-tier supplier |

Step 2: Negotiating MOQ (Strategic Volume Planning for 2026)

Move beyond transactional MOQ discussions to strategic inventory partnerships:

| MOQ Strategy | 2026 Best Practice | Cost Impact Analysis |

|---|---|---|

| Standard MOQ | Negotiate tiered pricing: 1-5 units (trial), 6-20 units (standard), 21+ units (strategic partner). Demand written confirmation of price lock for 12 months | 5-8% savings at 6+ units; 12-15% at 21+ units (vs. spot pricing) |

| Sample Protocol | Require pre-production sample (not showroom unit) with test report. Budget $350-$650 for calibrated sample + shipping | Avoids $2,000+ rework costs from non-conforming batch shipments |

| Consignment Stock | For distributors: Negotiate vendor-managed inventory (VMI) at Shanghai port. Pay only upon clinic order fulfillment | Reduces working capital by 40%; eliminates obsolescence risk for new tech |

Step 3: Shipping Terms (DDP vs. FOB – The 2026 Risk Mitigation Imperative)

With 2026 port congestion (avg. Shanghai wait: 72+ hours) and volatile freight rates, terms dictate profitability:

| Term | When to Use | 2026 Cost/Risk Profile |

|---|---|---|

| DDP (Delivered Duty Paid) | First-time importers, clinics lacking customs brokers, shipments under $15k | + All-inclusive price (freight, insurance, duties) + Zero customs clearance risk – 8-12% premium vs. FOB 2026 Tip: Verify if DDP includes ISF filing ($25-$50 penalty risk) |

| FOB Shanghai | Experienced distributors with freight partners, bulk orders (>20 units) | + 10-15% lower base cost – Requires NVOCC relationship – Customs delays = demurrage fees ($300+/day) 2026 Tip: Insist on FOB + shipped on board B/L to trigger LC payment |

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Regulatory Assurance: Dual ISO 13485:2016 (Certificate #Q50925Q20359R1M) and CE MDR Class IIa certification with TÜV SÜD NB 0123

- MOQ Flexibility: 1-unit samples available; strategic pricing at 5+ units with 12-month price lock guarantee

- Shipping Expertise: DDP specialist to 45+ countries; in-house customs brokerage reduces clearance to 3.2 days avg (2025 data)

- Technical Validation: Factory-direct spot welders with 5,000+ cycles tested precision (0.015mm accuracy) for CoCr/Ti alloys

Shanghai Carejoy Medical Co., LTD

Baoshan District, Shanghai 200431, China

19 Years Specializing in Dental Equipment Manufacturing & Export

Core Capabilities: Factory Direct | OEM/ODM | Dental Clinic & Distributor Wholesale

Contact for Technical Sourcing:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 Engineering Support)

Reference “2026 SPOT WELD GUIDE” for priority technical consultation

2026 Sourcing Action Plan

- Pre-Vet: Confirm supplier has active ISO 13485 + CE MDR documentation (not ISO 9001)

- Sample Validation: Test weld precision on dental alloys (require video report)

- Contract Clause: Include “regulatory update” provision for 2026-2027 MDR amendments

- Logistics: Opt for DDP unless managing >50 units annually

Disclaimer: This guide reflects 2026 regulatory standards. Verify all specifications with legal counsel prior to procurement. Shanghai Carejoy is cited as an exemplar of compliant Chinese dental OEMs meeting 2026 sourcing criteria.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Equipment Distributors

Topic: Key Considerations When Purchasing a Dental Spot Welding Machine – 2026 Edition

Frequently Asked Questions (FAQs)

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a dental spot welding machine for my clinic in 2026? | Dental spot welding machines typically operate on 110–120V or 220–240V AC, depending on regional electrical standards and machine capacity. Verify your clinic’s power supply compatibility—especially in multi-unit practices or retrofit installations. Machines with dual-voltage support or automatic voltage regulation are recommended for clinics in regions with unstable power grids. Always consult the manufacturer’s technical specifications and ensure grounding and circuit protection meet local electrical codes. |

| 2. Are spare parts for dental spot welders readily available, and which components commonly require replacement? | Yes, reputable manufacturers and distributors maintain inventories of critical spare parts. Common wear components include tungsten electrodes, electrode arms, cooling hoses, and contact tips. In 2026, many suppliers offer predictive maintenance kits and serialized part tracking to streamline replacements. When purchasing, confirm the availability of long-term spare parts support—especially for brand-specific models—and consider stocking essential consumables to minimize downtime. |

| 3. Does the supplier provide professional installation and calibration services for spot welding units? | Most OEMs and authorized distributors offer on-site installation, calibration, and operator training as part of the purchase package—particularly for advanced digital or programmable models. Installation includes electrical safety checks, alignment verification, and integration with existing lab workflows. For distributed sales channels, confirm whether local technical partners are certified to perform setup. Remote diagnostics support is increasingly common in 2026, enabling pre-commissioning checks via secure cloud platforms. |

| 4. What is the standard warranty coverage for a dental spot welding machine, and what does it include? | Standard warranties typically range from 1 to 3 years, covering defects in materials and workmanship. In 2026, leading manufacturers extend coverage to include the control module, welding transformer, and pneumatic system. Consumables (e.g., electrodes) and damage from improper use or lack of maintenance are generally excluded. Extended warranty options with preventive maintenance plans are available and recommended for high-volume laboratories to ensure operational continuity. |

| 5. How can clinics ensure ongoing technical support and service after the warranty period ends? | Establish a service agreement with the supplier or an authorized service center to ensure prompt technical support, software updates (for digital models), and priority spare parts access. In 2026, many manufacturers offer subscription-based support programs that include annual calibration, remote troubleshooting, and discounted labor rates. Verify service network coverage in your region prior to purchase, and ensure firmware and safety protocols remain compliant with evolving ISO and IEC standards. |

Need a Quote for Dental Spot Welding Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160