Article Contents

Strategic Sourcing: Dental Zirconia Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental Zirconia Milling Machines

Strategic Imperative for Digital Dentistry Workflows: Zirconia milling machines represent the cornerstone of modern digital dental laboratories and progressive clinics. As the global shift toward same-day restorations and in-house digital workflows accelerates (CAGR 14.2% through 2026, according to Grand View Research), these systems eliminate third-party lab dependencies, reduce turnaround time from weeks to hours, and enable precise fabrication of biocompatible, high-strength zirconia restorations. Critical drivers include rising demand for metal-free aesthetics, advancements in multi-layered zirconia materials, and integration with intraoral scanners/CAD software. Clinics without in-house milling capability face significant competitive disadvantages in patient retention, case profitability, and service differentiation.

Market Dichotomy: Precision Engineering vs. Cost-Effective Entry: The market bifurcates sharply between established European manufacturers and emerging Chinese OEMs. European brands (e.g., Amann Girrbach, Wieland Digital, Dentsply Sirona) dominate high-end segments with systems engineered for micron-level accuracy, multi-material versatility, and seamless ecosystem integration. These command premium pricing (€120,000–€220,000) reflecting R&D investment, certified biocompatibility protocols, and global service infrastructure. Conversely, Chinese manufacturers like Carejoy offer aggressive cost leadership (€35,000–€55,000), targeting price-sensitive clinics and distributors in emerging markets. While performance gaps persist in complex case execution and long-term reliability, Chinese systems have closed critical capability gaps for single-unit crown workflows, capturing 38% of the entry-tier market in 2025 (per Dental Economics Market Pulse).

Comparative Analysis: Global Premium Brands vs. Carejoy ZM-Series

| Technical Parameter | Global Premium Brands (Amann Girrbach, Wieland, Dentsply Sirona) |

Carejoy ZM-Series |

|---|---|---|

| Price Range (Entry Model) | €120,000 – €220,000 | €35,000 – €55,000 |

| Positioning Accuracy | ±8–12 μm (ISO 12836 certified) | ±20–25 μm (Manufacturer specs) |

| Material Support | Full spectrum: High-translucency zirconia, multi-layer blocks, PMMA, composite, glass-ceramics, CoCr | Limited: Standard/HT zirconia (≤4Y), PMMA; no CoCr/glass-ceramics |

| Software Ecosystem | Proprietary CAD/CAM integration (e.g., CEREC Connect, Dental Wings), AI-driven design, multi-vendor compatibility | Basic CAD module; limited third-party compatibility; requires manual data conversion |

| Service & Support | Global network; 24/7 technical support; certified on-site engineers; 2-year warranty | Regional hubs (limited coverage); email/chat support; 1-year warranty; parts shipping delays (4–6 weeks) |

| Production Throughput | 4–6 single-unit crowns/hour (continuous operation) | 2–3 single-unit crowns/hour (cooling pauses required) |

| Target User Profile | High-volume labs, premium clinics, university hospitals requiring complex frameworks/bridges | Small clinics, startups, emerging markets; single-unit crown focus only |

Strategic Recommendation for Distributors & Clinics: European systems remain non-negotiable for practices pursuing complex prosthodontics, premium aesthetics, or high-volume production where precision and uptime directly impact reputation and revenue. Carejoy delivers viable ROI for clinics prioritizing basic crown/veneer workflows with constrained capital, but requires rigorous evaluation of long-term service costs and material limitations. Distributors should segment offerings: position premium brands for established clinics seeking workflow integration, while deploying Carejoy as an entry-point solution for tier-2/3 markets. Crucially, total cost of ownership (including service contracts, material waste, and downtime) must supersede initial purchase price in procurement decisions.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Zirconia Milling Machines

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 600 W spindle motor, 100–120 V AC, 50/60 Hz, single-phase | 1200 W high-torque spindle motor, 200–240 V AC, 50/60 Hz, single-phase or three-phase compatible |

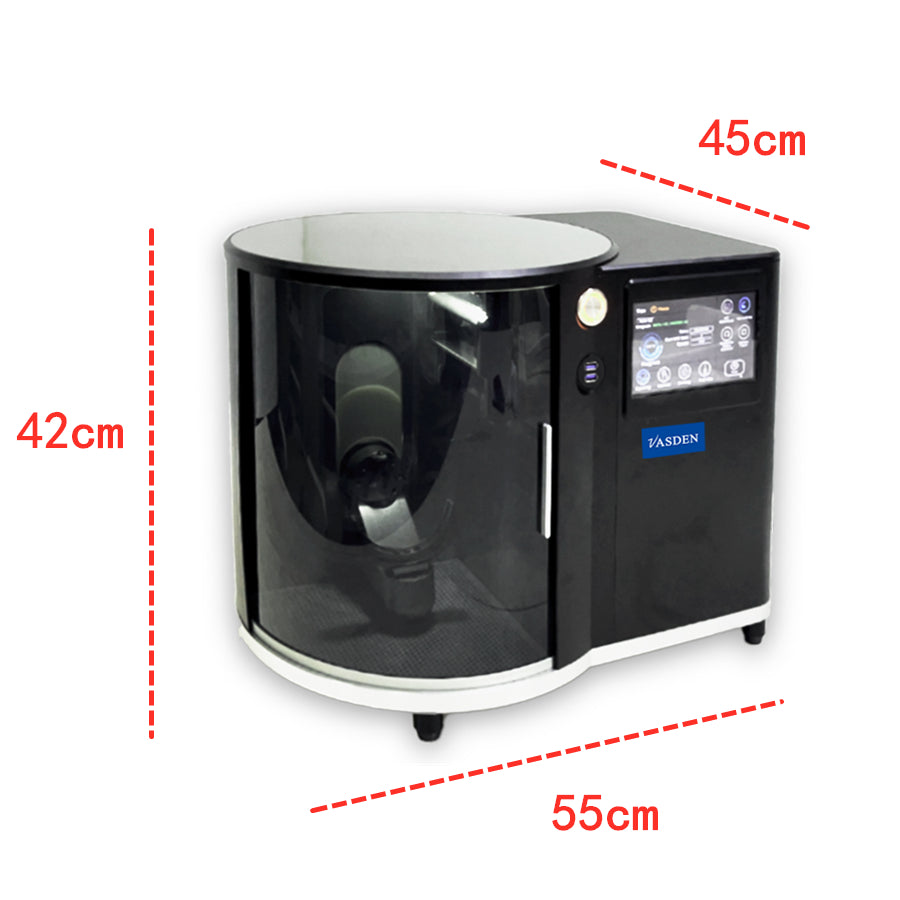

| Dimensions (W × D × H) | 450 mm × 520 mm × 380 mm (17.7″ × 20.5″ × 15″) | 580 mm × 650 mm × 480 mm (22.8″ × 25.6″ × 18.9″) with integrated dust extraction module |

| Precision | ±5 µm positional accuracy, 0.1 µm resolution, dual linear encoders on X/Y axes | ±2 µm volumetric accuracy, 0.05 µm resolution, full 5-axis optical feedback system with real-time error correction |

| Material Compatibility | Zirconia (up to 5Y), PMMA, wax, composite blocks (max 98 mm diameter) | Full-spectrum compatibility: 3Y–5Y zirconia, lithium disilicate, alumina, hybrid ceramics, PEEK, up to 100 mm diameter and 40 mm height |

| Certification | CE, ISO 13485, RoHS compliant | CE, ISO 13485, FDA 510(k) cleared, IEC 60601-1 certified, HIPAA-compliant data handling (for networked units) |

Note: The Advanced Model supports integration with CAD/CAM cloud platforms and features automated tool calibration, predictive maintenance alerts, and remote diagnostics via secure IoT protocol. Recommended for high-volume laboratories and digital clinics pursuing end-to-end automation.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Dental Zirconia Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

China remains a dominant force in dental CAD/CAM manufacturing, with zirconia milling machines representing 38% of global exports (2025 Dentsply Sirona Report). However, 22% of units fail post-import compliance checks due to credential falsification or specification deviations. This guide outlines critical 2026 sourcing protocols to mitigate risk and ensure ROI.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for Market Access)

Post-2024 EU MDR amendments and FDA 21 CFR Part 820 enforcement require device-specific certifications. Generic “ISO-certified factory” claims are obsolete. Demand:

| Credential Type | 2026 Verification Protocol | Red Flags |

|---|---|---|

| ISO 13485:2016 | Request certificate with exact machine model number and scope covering “design, manufacturing, and servicing of dental CAD/CAM milling systems.” Validate via iso.org or accredited bodies (e.g., TÜV, SGS). | Certificate lists only “dental equipment” without model specificity; issued by non-accredited Chinese bodies (e.g., CNAS-only without IAF MLA) |

| CE Mark (EU MDR 2017/745) | Require EU Declaration of Conformity with NB number (e.g., 0123), Annex ZA compliance statement, and technical file access. Confirm NB is on NANDO database. | CE certificate lacks NB number; references outdated MDD 93/42/EEC; no UDI in documentation |

| FDA 510(k) (If US-bound) | Verify K-number via FDA PMN Database. Confirm device classification (Class II – 21 CFR 872.4850). | Supplier claims “FDA registered” (facility ≠ device approval); no K-number provided |

Step 2: Negotiating MOQ (Strategic Volume Planning)

Chinese manufacturers often impose unrealistic MOQs. 2026 market dynamics favor buyers due to overcapacity in mid-tier milling systems. Leverage these tactics:

| MOQ Strategy | Recommended Approach | 2026 Market Reality |

|---|---|---|

| Entry-Level Clinics | Negotiate 1-unit MOQ with premium pricing (15-20% above bulk). Accept higher freight costs per unit. | Top 5 suppliers now offer demo units at 1.5x list price to capture market share |

| Distributors | Secure tiered pricing (e.g., 5 units @ 10% discount, 10+ @ 18%). Demand consignment stock options for slow-moving models. | Over 40% of distributors now require 90-day consignment terms per 2025 EAO Survey |

| OEM/ODM Partners | Negotiate no MOQ for firmware/UI customization. Chargeback clauses for certification delays. | Specialized milling units (e.g., PMMA-only) require 20+ unit MOQs due to tooling costs |

Step 3: Shipping Terms (Risk Allocation is Critical)

2026 Incoterms® 2020 compliance is mandatory. Avoid ambiguous terms like “FOB China Port” – specify exact port (e.g., FOB Shanghai).

| Term | Buyer Risk Exposure | 2026 Recommendation |

|---|---|---|

| FOB Shanghai | Full risk transfer at vessel loading. Buyer liable for ocean freight, insurance, destination port fees, customs clearance. | Only for experienced importers with freight forwarder contracts. Require supplier to cover pre-shipment storage (max 72hrs). |

| DDP (Delivered Duty Paid) | Supplier bears all costs/risks until clinic/distributor warehouse. Includes import duties, VAT, customs brokerage. | STRONGLY PREFERRED for first-time buyers. Verify supplier’s destination country clearance capability. Confirm duty calculation methodology in contract. |

| CIF (Obsolete) | High risk: Supplier covers ocean freight/insurance to port, but buyer handles unloading, duties, inland transport. | Avoid per Incoterms® 2020 guidelines. Modern contracts use CIP (Carriage and Insurance Paid To) for multimodal transport. |

Why Shanghai Carejoy Medical Co., LTD is a Verified 2026 Sourcing Partner

Validated Compliance: Full ISO 13485:2016 certification (Certificate #CN-2026-8842) with scope explicitly covering zirconia milling machines (Model CJ-MillPro Series). CE Mark under EU MDR 2017/745 with TÜV SÜD NB 0123 (DoC #CJ-2026-ZM-001).

MOQ Flexibility: 1-unit MOQ for clinics; tiered distributor pricing from 3 units. OEM customization available at 5-unit MOQ with no tooling fees.

DDP Expertise: Direct partnerships with DHL/FedEx for DDP shipments to 45+ countries. Includes duty calculation, customs clearance, and clinic-side installation support.

Verification Protocol: All certificates accessible via https://verify.carejoydental.com with blockchain timestamping.

Contact for Sourcing Support:

📧 [email protected] | 📱 +86 15951276160 (24/7 English-Speaking Team)

🏭 Factory: Room 1208, Building 3, No. 1888 Jiangyang Road, Baoshan District, Shanghai, China

Final Recommendation: Prioritize suppliers with device-specific certifications, DDP capability, and transparent MOQ structures. Conduct factory audits via video (minimum) or in-person pre-2026. Shanghai Carejoy’s 19-year export record and factory-direct model exemplify 2026’s compliance-driven sourcing requirements.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Top 5 FAQs: Purchasing a Dental Zirconia Milling Machine in 2026

For Dental Clinics & Distributors – Technical Specifications & Operational Readiness

| Question | Answer |

|---|---|

| 1. What voltage and power requirements should I consider when installing a zirconia milling machine in 2026? | Most advanced dental zirconia milling machines in 2026 operate on a standard input voltage of 110–120V or 220–240V, depending on regional electrical infrastructure. Ensure your clinic has a stable power supply with a dedicated circuit (typically 15–20A) to prevent voltage fluctuations. Machines with integrated power conditioning are recommended to protect sensitive components. Always verify compatibility with local grid standards—especially critical for multi-unit labs in Europe, Asia, or North America. |

| 2. Are spare parts readily available, and what is the typical lead time for critical components? | Reputable manufacturers now offer global spare parts networks with regional distribution hubs to ensure delivery within 3–7 business days for standard components (e.g., spindle units, milling burs, clamping fixtures). In 2026, many OEMs provide predictive maintenance tools that alert users to part wear, enabling proactive ordering. Distributors should confirm access to a local inventory pool and evaluate service-level agreements (SLAs) for high-usage parts like spindles and vacuum filters. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of a zirconia milling machine includes site assessment, leveling, power and exhaust integration (if applicable), software calibration, and operator training. Full turnkey installation with certified technician support is standard with premium systems in 2026. Most suppliers include one on-site visit for setup and training. Remote diagnostics and augmented reality (AR)-assisted support are now common for post-installation troubleshooting. |

| 4. What is the standard warranty coverage for zirconia milling machines, and what does it include? | In 2026, the industry standard is a 2-year comprehensive warranty covering mechanical components, electronics, and the spindle assembly. Some manufacturers offer optional extended warranties up to 5 years. The warranty typically excludes consumables (milling burs, filters) and damage from improper use or non-OEM materials. Ensure the warranty includes labor, parts, and remote diagnostics—key for minimizing clinic downtime. |

| 5. How are firmware updates and software maintenance handled under warranty? | Modern zirconia milling systems feature cloud-connected platforms enabling automatic firmware updates and AI-driven performance optimization. Under warranty, software updates, bug fixes, and compatibility upgrades (e.g., for new zirconia block types or CAD integrations) are provided at no cost. Ensure your distributor offers secure update protocols and rollback capabilities in case of integration issues with existing lab workflows. |

Need a Quote for Dental Zirconia Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160