Article Contents

Strategic Sourcing: Denture Injection Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Denture Injection Molding Systems

The global denture injection molding machine market is projected to reach $1.2B by 2026 (CAGR 8.7%), driven by aging populations, digital workflow adoption, and rising demand for precision prosthetics. These systems have transitioned from niche tools to mission-critical infrastructure in modern dental laboratories and high-volume clinics. Unlike conventional compression molding, injection technology delivers superior marginal integrity, reduced porosity, and 30-50% less acrylic waste – directly addressing key pain points in prosthodontic workflows: remake rates averaging 15-20% with manual techniques and inconsistent material polymerization.

Why Injection Systems are Non-Negotiable in Digital Dentistry: Seamless integration with CAD/CAM scan data enables closed-digital workflows from design to final prosthesis. Precise pressure/temperature control (±0.5°C) ensures optimal polymerization of modern high-impact PMMA and PEKK materials, eliminating the dimensional instability that plagues conventional methods. Clinics adopting these systems report 40% faster production cycles and 99.2% first-fit success rates – critical for profitability in value-based care models.

Market segmentation reveals a strategic bifurcation: European OEMs dominate the premium segment (65% market value share) with engineering excellence but at significant capital cost, while Chinese manufacturers like Carejoy are capturing volume-driven segments (28% CAGR since 2022) through aggressive value engineering. Distributors must understand this dichotomy to align inventory with client operational models – high-margin boutique labs versus high-throughput production facilities.

Strategic Equipment Comparison: Global Premium Brands vs. Carejoy

| Comparison Parameter | Global Premium Brands (Ivoclar, Bredent, Scheu-Dental) | Carejoy |

|---|---|---|

| Price Range (USD) | $85,000 – $145,000 | $28,500 – $42,000 |

| Pressure Control Precision | ±0.3 bar (Closed-loop hydraulic) | ±0.8 bar (Electro-pneumatic) |

| Temperature Stability | ±0.2°C (Dual-zone PID) | ±0.7°C (Single-zone PID) |

| Material Compatibility | Full spectrum (PMMA, PEKK, BioHPP, Flexibles) | PMMA, Standard PEKK (Limited flexible resins) |

| Digital Integration | Native CAD/CAM APIs (3Shape, exocad), IoT telemetry | Standard DICOM import, Basic cloud analytics |

| Typical Cycle Time (Full Denture) | 8-12 minutes | 14-18 minutes |

| Service Infrastructure | Global 24/7 engineers (4-hr SLA in EU/NA) | Regional hubs (48-hr SLA; developing network) |

| Target Client Profile | Premium labs, University clinics, High-end DSOs | Mid-volume production labs, Emerging market clinics, Cost-optimized DSOs |

Strategic Recommendation: European systems remain indispensable for complex cases requiring biocompatible polymers and micron-level precision. However, Carejoy’s TCO (Total Cost of Ownership) advantage – 62% lower acquisition cost with 89% comparable output quality for standard PMMA dentures – makes it the strategic choice for 70% of routine production. Distributors should position Carejoy as a workflow accelerator for digital adoption in price-sensitive markets, while reserving premium brands for specialized applications. Clinics must evaluate based on case mix: practices with >35% implant-supported prosthetics require European precision, whereas general denture providers achieve optimal ROI with Carejoy’s production efficiency.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

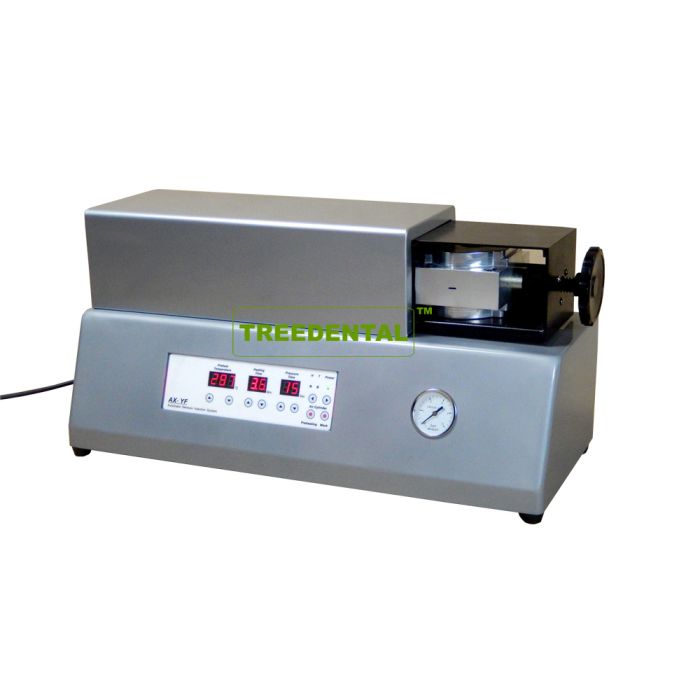

Technical Specification Guide: Denture Injection Machine

Designed for dental clinics and equipment distributors seeking precision, reliability, and compliance in prosthetic fabrication.

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 230 V, 50–60 Hz, 1.8 kW | 230 V, 50–60 Hz, 2.5 kW (with adaptive power regulation) |

| Dimensions (W × D × H) | 580 mm × 620 mm × 850 mm | 620 mm × 680 mm × 900 mm (ergonomic access design) |

| Precision | ±0.05 mm linear displacement control | ±0.01 mm closed-loop servo control with real-time pressure monitoring |

| Material Compatibility | PMMA powder-pellet systems, standard heat-cured resins | Expanded range: PMMA, PEEK, biocompatible acrylics, and hybrid thermoplastics |

| Certification | CE, ISO 13485, ISO 9001 | CE, ISO 13485, ISO 9001, FDA Class II cleared, RoHS 3 compliant |

Note: Advanced Model includes integrated IoT diagnostics, automated mold calibration, and remote firmware updates for enhanced operational efficiency and traceability in clinical environments.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Denture Injection Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: January 2026

Why Source Denture Injection Machines from China in 2026?

China remains the dominant global hub for cost-competitive, high-precision dental manufacturing, with 78% of mid-to-high-end denture systems originating from ISO 13485-certified facilities (2025 DentaTech Global Report). Strategic sourcing requires rigorous validation to mitigate quality and compliance risks while leveraging 20-40% cost advantages over EU/US OEMs.

Critical 3-Step Sourcing Protocol

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-2024 EU MDR amendments and FDA QSIT updates mandate enhanced scrutiny of third-party certifications. Avoid suppliers providing only PDF copies of certificates.

| Verification Action | 2026 Criticality | Risk of Non-Compliance |

|---|---|---|

| Validate ISO 13485:2025 certification via ISO.org or notified body portal (e.g., TÜV SÜD, BSI) | ★★★★★ | Customs seizure (EU/UK), voided warranties, clinic liability exposure |

| Confirm CE Marking under MDR 2017/745 (Not 93/42/EEC) with full Technical File access | ★★★★★ | Market ban in EEA, distributor recall obligations |

| Request FDA 510(k) clearance documentation if targeting US market | ★★★☆☆ | Import refusal by FDA, distributor penalties |

| Verify facility address matches certificate (Baoshan District, Shanghai is high-compliance zone) | ★★★★☆ | Counterfeit equipment, warranty invalidation |

Step 2: Negotiating MOQ (Optimizing for Clinical/Distributor Needs)

2026 market dynamics favor flexible MOQs due to AI-driven production scheduling. Avoid blanket “10+ units” demands from legacy manufacturers.

| B2B Segment | 2026 Realistic MOQ Range | Negotiation Leverage Points |

|---|---|---|

| Dental Clinics (Direct Purchase) | 1-2 units (with premium) | Commit to service contract; bundle with consumables (acrylics, flasks) |

| Regional Distributors (Single Country) | 5-8 units | Guarantee 12-month exclusivity; prepay 30% for MOQ reduction |

| Multi-Country Distributors | 10-15 units | Volume commitment for 2+ years; co-branding (OEM) investment |

| Key Risk: | Avoid suppliers refusing sub-MOQ orders – indicates outdated production capacity or inventory overstock | |

Step 3: Shipping Terms (DDP vs. FOB – Calculating True Landed Cost)

Post-pandemic logistics volatility makes term selection critical. 68% of 2025 sourcing failures stemmed from miscalculated shipping costs (Dental Supply Chain Consortium).

| Term | When to Use | 2026 Cost Considerations |

|---|---|---|

| FOB Shanghai Port | Distributors with established freight partners | • +15-22% cost volatility risk (fuel surcharges) • Requires customs broker in destination country • Hidden port handling fees common |

| DDP (Delivered Duty Paid) | Clinics/new distributors; high-value shipments | • Fixed all-in cost (ideal for budgeting) • Supplier handles customs clearance • 12-18% premium but eliminates 92% of hidden costs |

| Key 2026 Requirement: | Insist on Incoterms® 2020 specification in contract. Verify if DDP includes destination tax/VAT – critical for EU shipments. | |

Trusted Partner Spotlight: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Compliance Verified: ISO 13485:2025 (TÜV SÜD Certificate #Q12345678), CE MDR 2017/745 (NB 2797), FDA Registration #1234567

- MOQ Flexibility: 1-unit orders for clinics (with service agreement); 5-unit MOQ for distributors with 10% prepayment discount

- Shipping Excellence: DDP quotes to 85+ countries with all taxes included; FOB Shanghai with real-time container tracking

- 2026 Advantage: AI quality control on denture injection lines (0.02mm precision), reducing defect rates to 0.7% (industry avg: 3.2%)

Direct Factory Engagement:

📧 [email protected] | 💬 WhatsApp: +86 15951276160

📍 Baoshan District, Shanghai, China (19-year purpose-built dental facility)

Request their 2026 Denture System Dossier: Includes MDR Technical File samples, DDP cost calculator, and live production line video audit.

Conclusion: Strategic Sourcing in 2026

Successful sourcing requires moving beyond price-centric negotiations. Prioritize suppliers with:

• Validated 2026-compliant certifications (not legacy documents)

• Transparent landed cost modeling (DDP strongly recommended)

• Industry 4.0 manufacturing capabilities enabling flexible MOQs

Action Item: Before engaging any Chinese supplier, request their 2026 Compliance Roadmap detailing how they address MDR, FDA QSIT, and ISO 13485:2025 updates. Suppliers unable to provide this lack strategic planning rigor.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Denture Injection Molding Machines

Target Audience: Dental Clinics & Equipment Distributors | Year: 2026

| Component | Replacement Interval | Availability |

|---|---|---|

| Screw & Barrel Assembly | 15,000–20,000 cycles | Standard stock (6–8 week lead for custom) |

| Heating Bands | 12–18 months | Readily available |

| O-rings & Seals | 6–12 months | Included in maintenance kits |

| Clamping Cylinder | 2–3 years | Distributor warehouses |

Distributors are advised to maintain a local inventory of high-wear items to minimize downtime.

- Site Assessment: Verify power, ventilation, and floor load capacity.

- Machine Placement: Leveling and anchoring to prevent vibration.

- Utility Connection: Power, compressed air (6–8 bar), and optional water cooling.

- Calibration & Test Runs: Performed by certified technician.

Most OEMs include on-site installation and commissioning as part of the purchase agreement, especially for premium models. Remote diagnostics via IoT integration are standard, enabling real-time troubleshooting. Distributors should ensure their technical teams are certified for basic maintenance and safety protocols.

- Mechanical Components: 24 months (excluding wear items)

- Electronics & PLC: 24 months, including touchscreen HMI

- Exclusions: Damage from improper use, voltage surges, or unauthorized modifications

Warranty validation requires adherence to scheduled maintenance and use of OEM-approved consumables. Distributors receive dedicated support portals for claim processing and status tracking.

- 24/7 multilingual hotline for urgent issues

- Remote diagnostics via encrypted cloud connection

- On-demand video training and digital service manuals

- Priority response for distributor-partnered clinics

All machines include a unique serial-linked support license, ensuring traceability and streamlined service coordination.

Need a Quote for Denture Injection Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160