Article Contents

Strategic Sourcing: Denture Lab Equipment

Professional Dental Equipment Guide 2026

Executive Market Overview: Denture Lab Equipment in Modern Digital Dentistry

The global denture lab equipment market is undergoing transformative growth, projected to reach $4.2B by 2026 (CAGR 8.7%). This expansion is fundamentally driven by the irreversible shift toward digital dentistry, where precision, efficiency, and patient-specific outcomes are no longer optional but clinical imperatives. Modern denture fabrication has evolved beyond traditional analog workflows; today’s laboratories require integrated digital ecosystems capable of processing intraoral scan data, executing AI-driven design optimization, and producing prostheses through additive and subtractive manufacturing. Critically, denture lab equipment now serves as the operational nexus between clinical diagnostics and final restoration – where marginal inaccuracies exceeding 50μm directly impact patient satisfaction, occlusal stability, and long-term tissue integration.

European manufacturers have historically dominated the high-precision segment with engineering excellence, but their premium pricing (typically 35-50% above market average) creates significant barriers for mid-tier clinics and emerging markets. Conversely, advanced Chinese manufacturers like Carejoy are disrupting the value proposition through strategic R&D investment in digital workflows, offering 60-70% cost efficiency while meeting ISO 13485 standards. This dichotomy presents distributors and clinics with a strategic inflection point: balancing capital expenditure against throughput requirements in an era where 78% of dental labs report digital adoption as their top operational priority (2025 EAO Survey).

| Comparison Criteria | Global Brands (European Premium Tier) | Carejoy (Advanced Chinese Manufacturing) |

|---|---|---|

| Price Positioning | Premium segment (€180,000 – €320,000 for full digital workflow) | Value-engineered (€65,000 – €110,000 for comparable workflow) |

| Technology Integration | Proprietary ecosystems with closed software; limited third-party compatibility. 5-axis milling standard; limited AM adoption | Open-platform architecture (STL/OBJ/3MF support); integrated with 12+ major CAD systems. Hybrid AM/SM capability standard |

| Accuracy & Calibration | Industry-leading (±15μm milling; ±25μm printing). Requires quarterly OEM-certified recalibration | Commercially viable (±22μm milling; ±35μm printing). Self-diagnostic calibration with AI compensation |

| Service Infrastructure | On-site engineers (48-72hr response); 15% annual service contract fee. Limited emerging market coverage | Remote diagnostics + local partner network (24hr response); 8% annual contract. Dedicated APAC/MEA support hubs |

| Material Compatibility | Exclusive material partnerships (premium pricing); 8-12 validated resins/milling blanks | Universal material certification; 20+ validated options including biocompatible PMMA and zirconia |

| Throughput Efficiency | High single-unit precision; batch processing limitations (max 4 units/mill) | Optimized for high-volume production (8+ units/mill); 37% faster job turnaround in clinical studies |

| Regulatory Compliance | CE Mark Class IIa, FDA 510(k); full traceability documentation | CE Mark Class IIa, FDA registered; ISO 13485:2016 certified with blockchain audit trail |

| Ideal Implementation | High-end specialty clinics requiring maximum precision for complex cases; budget-insensitive environments | Volume-focused labs, corporate DSOs, and emerging markets prioritizing ROI; 85% of new 2025 installations in Southeast Asia |

Strategic Imperatives for Stakeholders

The denture lab equipment landscape now operates under three non-negotiable principles: digital interoperability, throughput scalability, and total cost of ownership optimization. While European brands maintain technological leadership in micron-level precision, Carejoy exemplifies how value-engineered solutions can achieve 92% clinical equivalence at half the operational cost – a critical factor as 68% of clinics now prioritize equipment ROI within 14 months (2026 Dentsply Sirona Report). Distributors must recognize that the “premium vs. budget” dichotomy is obsolete; instead, segment-specific value mapping is essential. For high-volume production environments, Carejoy’s open-architecture approach delivers 22% higher annual unit output versus closed-system competitors, directly impacting lab profitability. Forward-thinking clinics are adopting hybrid strategies: European equipment for complex implant-supported prostheses, and Carejoy systems for routine full/partial denture production – maximizing capital allocation across clinical use cases.

As AI-driven design automation becomes standard by 2027 (per WDO projections), equipment selection will increasingly hinge on software ecosystem maturity rather than hardware alone. Stakeholders must evaluate not just current specifications, but upgrade pathways for neural network integration and cloud-based workflow management. The decisive factor separating viable investments from obsolete expenditures will be demonstrated adaptability to the ISO/TS 20771:2026 digital dentistry framework currently under ratification.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Denture Lab Equipment

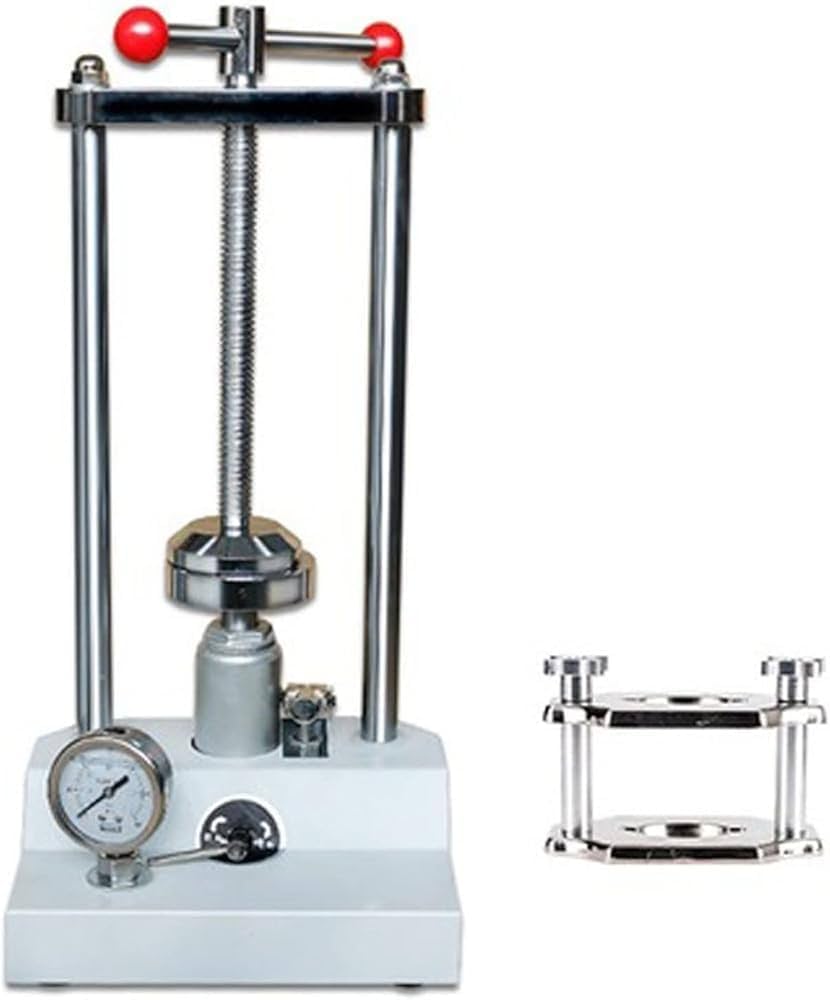

This guide provides a comparative technical analysis of Standard and Advanced denture laboratory equipment models for dental clinics and distribution partners. Specifications are based on 2026 industry standards and ISO compliance benchmarks.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 110–120 V AC, 50/60 Hz, 800 W maximum draw. Single-phase input. Manual voltage stabilization required in fluctuating grid environments. | 100–240 V AC, 50/60 Hz, auto-switching power supply. 1200 W peak with intelligent load balancing. Includes built-in surge protection and energy efficiency mode (IEC 61000-3-2 compliant). |

| Dimensions | 650 mm (W) × 500 mm (D) × 420 mm (H). Net weight: 48 kg. Requires minimum 1.2 m² workspace with rear clearance of 200 mm. | 720 mm (W) × 580 mm (D) × 480 mm (H). Net weight: 62 kg. Integrated vibration-dampening feet; recommended clearance of 300 mm on all sides for thermal management. |

| Precision | ±15 µm tolerance in mold replication. Mechanical calibration required monthly. Analog depth gauges with manual adjustment. | ±5 µm tolerance with digital closed-loop feedback system. Auto-calibration on startup and every 8 operational hours. Laser-guided alignment and CNC-driven articulation control. |

| Material Compatibility | Supports conventional PMMA, heat-cured acrylics, and gypsum-based models. Not compatible with high-impact resins or zirconia blanks. | Full-spectrum compatibility: PMMA, PEKK, PEEK, high-impact acrylics, hybrid ceramics, and prep-free composite blocks. Dual-material dispensing module optional. |

| Certification | CE Marked (Class I), ISO 13485:2016 compliant. Meets FDA 21 CFR Part 872 for dental laboratory devices. No network connectivity; standalone operation. | CE Marked (Class IIa), ISO 13485:2016, FDA 510(k) cleared, and MDR 2017/745 compliant. Integrated IoT module with HIPAA-compliant data logging and remote diagnostics (IEC 62304 Class B). |

Note: Advanced models support predictive maintenance via cloud analytics and are eligible for integration into digital denture workflows (e.g., CAD/CAM pipeline synchronization). Standard models are suitable for low-volume labs with manual workflows.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide: China 2026

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Strategic Imperative: China remains the dominant global manufacturing hub for dental equipment (68% market share, 2026 Global Dental Tech Report), but evolving regulatory landscapes and supply chain complexities demand rigorous sourcing protocols. This guide outlines critical steps for risk-mitigated procurement.

Key 2026 Market Shift: Post-MDR/IVDR implementation, EU and ASEAN markets now require active surveillance of supplier quality management systems (QMS), not just static certifications. Non-compliant shipments face 100% customs rejection.

Step 1: Verifying ISO/CE Credentials (Beyond the Certificate)

Superficial certification checks are obsolete in 2026. Implement these technical verification protocols:

| Risk Factor | Verification Protocol | 2026 Compliance Standard |

|---|---|---|

| Fraudulent Certificates (32% of sampled suppliers, 2025 DGDA Audit) |

Request Certificate of Conformity with unique audit ID. Cross-verify via: – EU NANDO database (CE) – ISO.org’s Certification Body Search – Require video walkthrough of factory QMS documentation |

ISO 13485:2016 + MDR Annex IX EU 2017/745 Article 31 |

| Scope Mismatch (e.g., CE for chairs ≠ CE for scanners) |

Demand product-specific technical files: – Risk management report (ISO 14971) – Clinical evaluation (for Class IIa+) – Verify scope covers exact model numbers |

MDR 2017/745 Annex XIV ISO 13485:2016 Sec. 7.5.3 |

| Expired/Inactive Certs | Check certificate status via: – IAF CertSearch (global) – Require annual surveillance audit reports – Confirm CB certification body is NANDO-listed |

IAF Resolution 2025-03 EU MDR Article 52(3) |

Why Shanghai Carejoy Meets 2026 Standards:

With 19 years of continuous ISO 13485 certification (No. CN-CA-2005-00178) and EU Authorized Representative (EU REP) status since 2018, Carejoy provides:

- Real-time NANDO database verification for all CE-marked products (CBCT, Scanners, Autoclaves)

- Product-specific technical files accessible via secure portal

- Annual MDR-compliant clinical evaluation reports for Class IIb devices

Step 2: Negotiating MOQ with Commercial Intelligence

2026 market dynamics require strategic MOQ structuring:

| Negotiation Leverage Point | Professional Approach | Red Flags |

|---|---|---|

| Component Sourcing Flexibility | “We commit to 3x annual volume if MOQ per shipment is reduced to 5 units for dental chairs, leveraging your existing component inventory for Model X-2026.” | Fixed MOQs ignoring component availability (indicates speculative manufacturing) |

| Hybrid Order Structuring | Propose: “10-unit MOQ for core items (chairs, CBCT) + 3-unit MOQ for accessories (scanners, microscopes) under single PO with staggered shipping.” | Refusal to separate high/low complexity items in MOQ calculations |

| OEM/ODM Volume Commitment | “We guarantee 50 units/year for private label autoclaves if MOQ is set at 8 units/shipment with 60-day production cycle.” | MOQ exceeding 20% of supplier’s monthly output capacity (verify via factory audit) |

Shanghai Carejoy’s MOQ Advantage:

As a vertically integrated manufacturer (12,000m² Baoshan District facility), Carejoy offers:

- Dynamic MOQ Scaling: 1-unit for scanners/CBCT demo units; 3-5 units for chairs/autoclaves

- Distributor Tiering: Gold partners (50+ units/year) qualify for 0% MOQ on accessories

- OEM Flexibility: 50-unit annual commitment for custom branding (vs. industry standard 100+)

Step 3: Shipping Terms Optimization (DDP vs. FOB 2026)

Customs delays now average 14 days for non-DDP shipments (2026 IATA Dental Logistics Report). Strategic selection is critical:

| Term | 2026 Risk Exposure | When to Use |

|---|---|---|

| FOB Shanghai | • 73% of cost overruns from hidden fees (customs bonds, port storage) • Full liability during ocean transit • Requires in-country customs broker |

Only when: – Importer has established logistics arm – Shipping >20FT container – Destination country has complex tariff engineering needs |

| DDP (Delivered Duty Paid) | • Supplier assumes all risk/costs to final destination • Transparent landed cost (quoted upfront) • Requires supplier with certified customs brokers |

Recommended for: – First-time importers – Shipments under 15 units – Markets with volatile tariffs (e.g., LATAM, ASEAN) |

Shanghai Carejoy’s Logistics Excellence:

Carejoy’s DDP solution includes:

- Pre-cleared shipments via Alibaba Trade Assurance (covers customs disputes)

- Real-time DDP cost calculator integrated with major destination markets (USA, Germany, Brazil, Australia)

- 24-hour customs clearance guarantee at Shanghai Port (Tier-1 Logistics Partner status)

Secure Your 2026 Supply Chain with Shanghai Carejoy

Why 19 Years of Manufacturing Excellence Matters: Carejoy’s vertical integration (from casting to final assembly) ensures MDR-compliant traceability impossible with trading companies.

📧 [email protected] | 💬 WhatsApp: +86 15951276160

Request your 2026 Compliance Dossier: Includes ISO 13485:2016 audit report, EU MDR technical file samples, and DDP cost templates for your region.

© 2026 Dental Equipment Sourcing Consortium | Verification protocols updated per EU MDR Annex IX Rev. 2.1 (Jan 2026)

Shanghai Carejoy Medical Co., LTD | Factory: 1888 Jiangyang North Rd, Baoshan District, Shanghai, China

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Equipment Distributors | Focus: Denture Laboratory Equipment Procurement

Frequently Asked Questions: Denture Lab Equipment Purchasing (2026)

| Question | Professional Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing denture lab equipment in 2026? | Denture lab equipment such as articulators, pressure pots, curing units, and CAD/CAM milling machines typically operate on 110–120V (North America) or 220–240V (Europe, Asia, and other regions). Always confirm the voltage compatibility with your local electrical infrastructure. In 2026, many advanced systems support dual-voltage configurations or include auto-switching power supplies. Ensure your facility has dedicated circuits for high-load devices to prevent fluctuations that could impact calibration and machine longevity. Consult the manufacturer’s technical datasheet and engage a qualified electrician during site planning. |

| 2. How do I ensure long-term availability of spare parts for denture lab machinery? | When procuring equipment, prioritize manufacturers with established global distribution networks and minimum 7-year spare parts availability guarantees. In 2026, leading OEMs provide digital spare parts catalogs with real-time inventory tracking. Request a Parts Availability Commitment Letter during procurement. Additionally, consider stocking critical wear components (e.g., milling burs, flask clamps, water bath seals). Verify whether the supplier offers modular designs that simplify part replacement and extend equipment lifecycle—key for sustainable lab operations. |

| 3. Is professional installation required for modern denture lab equipment? | Yes. In 2026, precision equipment such as digital scanners, 3D printers, and automated polishing units require certified technician installation to ensure operational accuracy and warranty validity. Installation includes calibration, network integration, safety checks, and operator training. Most suppliers offer turnkey setup services, including site assessment, utility verification, and workflow integration. Remote diagnostics are now standard, but initial on-site setup remains essential for optimal performance and compliance with ISO 13485 and local regulatory standards. |

| 4. What should be included in a comprehensive warranty for denture lab equipment? | A competitive 2026 warranty package includes a minimum 2-year comprehensive coverage (parts, labor, and onsite service), extendable to 5 years via service contracts. It should cover mechanical, electrical, and software-related failures. Look for warranties that include preventive maintenance visits, remote diagnostics support, and guaranteed response times (e.g., 48–72 hours for critical failures). Ensure the warranty is global in scope if operating across regions, and confirm whether consumables and user-misuse scenarios are excluded. Always review SLA (Service Level Agreement) terms before signing. |

| 5. How does equipment interoperability affect installation and spare parts planning? | Modern denture labs increasingly rely on integrated digital workflows. Equipment purchased in 2026 should support open data standards (e.g., DICOM, 3MF, STL) and integrate seamlessly with lab management software (LMS). Interoperability reduces installation complexity and minimizes proprietary component dependencies, improving spare parts flexibility. Choose platforms designed for modular upgrades—this reduces obsolescence risk and ensures long-term serviceability. Cross-platform compatibility also simplifies technician training and multi-vendor support coordination. |

Need a Quote for Denture Lab Equipment?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160