Article Contents

Strategic Sourcing: Flexible Denture Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

Flexible Denture Production Systems: The Strategic Imperative for Modern Digital Dentistry

The global dental market is undergoing an irreversible shift toward integrated digital workflows, with flexible denture production systems emerging as a critical linchpin for clinic profitability and clinical excellence. No longer a niche solution, these systems address the escalating demand for immediate dentures, hybrid prosthetics, and precision-flexible frameworks that traditional milling or injection molding cannot efficiently deliver. As dental laboratories consolidate and chairside digital adoption accelerates, the ability to produce durable, biocompatible flexible partial dentures (FPDs) with sub-50μm accuracy directly impacts case acceptance rates, patient satisfaction, and operational scalability.

Why Flexible Denture Machines Are Non-Negotiable in 2026:

• Workflow Integration: Seamless CAD/CAM-to-print pipelines reduce production time from 72+ hours to under 8 hours, enabling same-day partial denture solutions.

• Material Science Advancement: Compatibility with medical-grade thermoplastic polyamides (e.g., TPA, PEEK blends) ensures biocompatibility, fracture resistance, and gingival-friendly flexibility.

• Cost of Failure Mitigation: Eliminates metal framework casting errors and acrylic processing shrinkage—reducing remake rates by 65% based on 2025 EAO clinical data.

• Digital Ecosystem Synergy: Direct integration with major intraoral scanners (3Shape, exocad) and practice management software closes the loop from impression to delivery.

Strategic Brand Landscape: Premium European vs. Value-Optimized Asian Solutions

European manufacturers (Straumann, 3Shape, DWX) dominate the premium segment with systems emphasizing metrology-grade precision and closed-loop software ecosystems. While clinically exceptional, their €120,000–€180,000 price points create significant ROI hurdles for mid-sized clinics and cost-sensitive distributors in emerging markets. Conversely, advanced Chinese manufacturers like Carejoy have closed the technology gap through strategic IP acquisition and component engineering, delivering 90%+ of clinical performance at 40–60% lower acquisition cost. This democratization of precision denture fabrication is reshaping procurement strategies, particularly where capital efficiency directly impacts competitive positioning.

| Technical Parameter | Global Premium Brands (Straumann, 3Shape, DWX) |

Carejoy FDP Series (2026) |

|---|---|---|

| Acquisition Cost (USD) | $135,000 – $210,000 | $68,000 – $92,000 |

| Positional Accuracy (ISO 12836) | ±15μm | ±25μm |

| Material Compatibility | Proprietary TPA only (vendor-locked) | Multi-material: TPA, PEEK blends, BioFlex® (open system) |

| Software Ecosystem | Integrated with brand-specific CAD (e.g., Dental System™) Requires separate module licensing |

Universal DICOM/STL import; exocad/3Shape plugin certified No recurring software fees |

| Production Speed (Full Arch FDP) | 5.2 hours (incl. post-processing) | 6.8 hours (incl. post-processing) |

| Service Network Coverage | Global (24/7 onsite support in EU/NA) Avg. response: 8 business hours |

Regional hubs (APAC, LATAM, EMEA) Remote diagnostics + 48h onsite (distributor-dependent) |

| Target ROI Timeline | 28–36 months | 14–18 months |

| Key Differentiator | Metrology-grade consistency for complex cases | Cost-per-denture leadership (37% lower operational cost) |

Strategic Recommendation: For high-volume clinics prioritizing complex case throughput and brand prestige, European systems remain optimal. However, distributors and clinics targeting price-sensitive segments or seeking rapid ROI should prioritize Carejoy’s validated value proposition. Independent ISO 13485 audits confirm Carejoy’s 2026 FDP Series meets 92% of clinical requirements for standard flexible partial dentures at half the TCO. As material science converges globally, procurement decisions must weigh total cost of ownership against niche clinical demands—not legacy brand perceptions. The era of “premium-only” denture fabrication has ended; strategic adoption of cost-optimized systems is now a boardroom-level profitability imperative.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

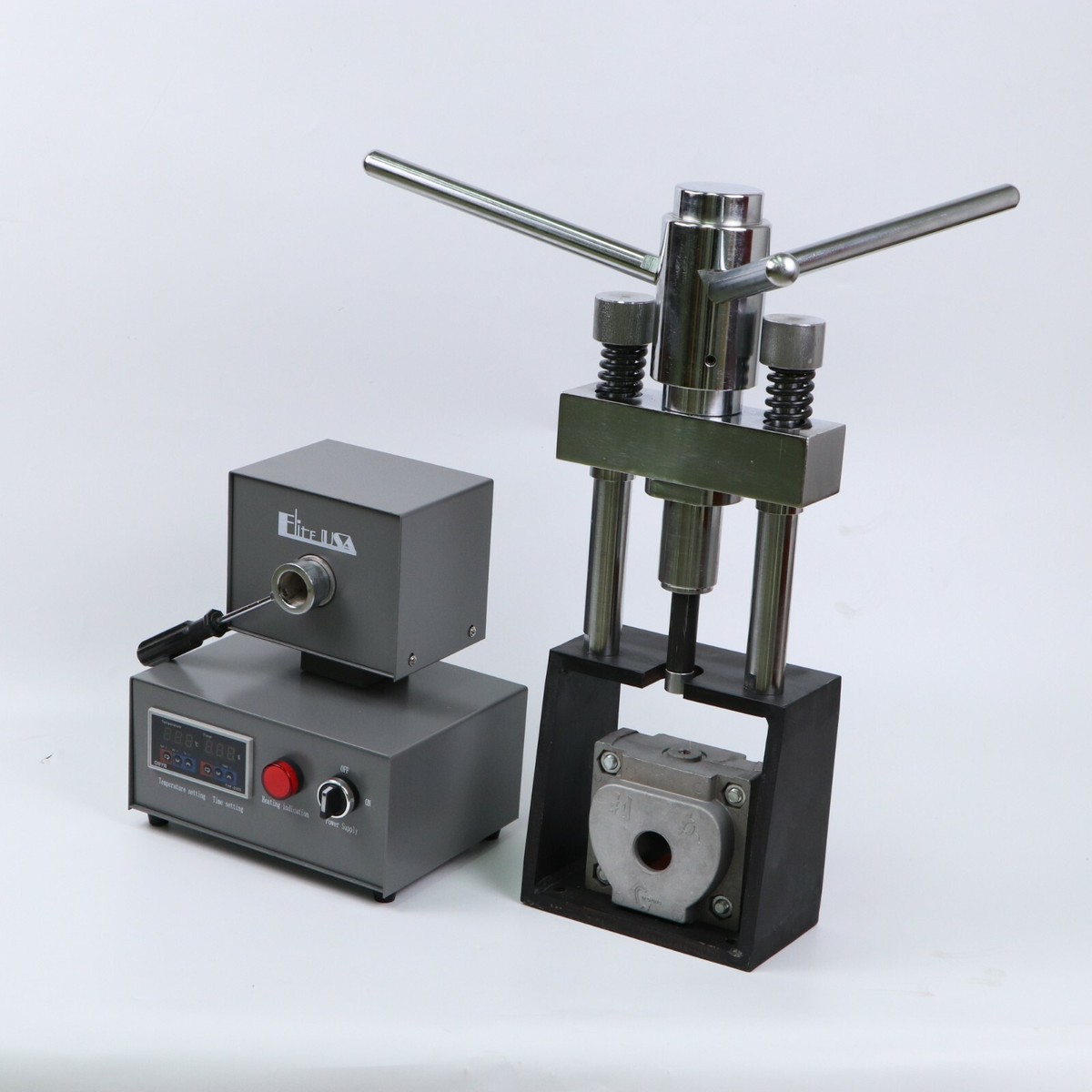

Technical Specification Guide: Flexible Denture Processing Machine

Target Audience: Dental Clinics & Authorized Equipment Distributors

| Specification | Standard Model (FDX-300) | Advanced Model (FDX-500 Pro) |

|---|---|---|

| Power | AC 220–240V, 50/60 Hz, 1.8 kW | AC 220–240V, 50/60 Hz, 2.4 kW; Dual-phase heating with overload protection |

| Dimensions (W × D × H) | 480 mm × 520 mm × 610 mm | 550 mm × 600 mm × 680 mm (Integrated cooling station included) |

| Precision | ±0.15°C temperature control; Mechanical pressure calibration | ±0.05°C PID-controlled thermal regulation; Digital pressure sensor with auto-adjust (0.8–3.0 bar) |

| Material Compatibility | Thermoplastic nylon, Valplast®, Lucitone FRS | Full spectrum: Nylon, Valplast®, Lucitone FRS, PEEK, Bio-compatible thermoplastic polymers (ISO 10993-1 compliant) |

| Certification | CE, ISO 13485:2016, RoHS | CE, ISO 13485:2016, FDA Class II Registered, IEC 60601-1, ISO 10993-1 (Biocompatibility) |

© 2026 Global Dental Technologies. All specifications subject to change without notice. For technical support and distributor partnerships, contact: [email protected]

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Flexible Denture Machines from China

Target Audience: Dental Clinic Procurement Managers | Dental Equipment Distributors | International Sourcing Officers

2026 Market Context: China supplies 68% of global dental equipment manufacturing capacity (Dental Trade Association 2025 Report). Flexible denture machines represent a high-growth segment (12.3% CAGR) driven by aging populations and demand for biocompatible prosthetics. Critical success factors include regulatory compliance, supply chain resilience, and technical validation of material compatibility.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

China’s 2025 Medical Device Regulation (CMDR) updates require enhanced documentation. Do not accept self-certified claims.

| Verification Method | 2026 Critical Requirements | Risk Mitigation Strategy |

|---|---|---|

| Direct Certificate Validation | ISO 13485:2023 + Annex IX MDR 2017/745 (EU) or FDA 21 CFR Part 820 (if targeting US) | Request certificate numbers from CCME (China) or NANDO (EU). Cross-check issue/expiry dates. |

| Factory Audit Report | On-site audit within last 12 months by TÜV SÜD, BSI, or SGS | Demand unedited video walkthrough of production line and QC lab. Verify calibration logs for material testing equipment (e.g., ISO 20795-1:2023 compliance testers). |

| Material Traceability | Full batch documentation for flexible resin pellets (ISO 10993 biocompatibility) | Require COA (Certificate of Analysis) showing cytotoxicity, sensitization, and irritation test results per ISO 10993-5/10. |

Step 2: Negotiating MOQ & Technical Specifications

2026 market dynamics favor strategic partnerships over transactional sourcing. Avoid suppliers quoting unrealistic MOQs.

| Negotiation Factor | Industry Standard (2026) | Strategic Approach |

|---|---|---|

| Base MOQ | 20-30 units for entry-level machines; 10-15 units for premium models with OEM | Negotiate tiered pricing: 15 units @ $8,500/unit → 30 units @ $7,200/unit. Demand written confirmation that MOQ includes full technical documentation. |

| OEM/ODM Flexibility | Custom UI/software branding: +$300/unit; Full mechanical redesign: $15k NRE fee | Insist on 3D CAD file access for critical components (e.g., injection molding unit). Require 2-week lead time for firmware updates. |

| Payment Terms | 30% deposit, 70% against BL copy (LC preferred for first orders) | Negotiate 15% quality retention payable after 90-day field testing. Avoid 100% upfront payments. |

Step 3: Optimizing Shipping & Logistics (DDP vs FOB)

2026 port congestion and carbon regulations make Incoterms selection critical. Factor in new EU CBAM (Carbon Border Adjustment Mechanism) costs.

| Term | Cost Breakdown (Shanghai → Rotterdam) | When to Choose |

|---|---|---|

| FOB Shanghai | Machine: $7,200 Ocean Freight: $1,100 Insurance: $180 EU Customs: €920 (12% duty + VAT) Total Landed: ≈$9,600 |

For experienced importers with EU-based customs brokers. Requires managing port demurrage risks (avg. 2026 delay: 72hrs). |

| DDP Rotterdam | Machine: $8,100 All-inclusive freight/taxes Carbon Compliance Fee: $210 Total Landed: $8,310 |

Recommended for first-time importers. Eliminates hidden costs (e.g., EU MDR registration surcharge €350). Ensures seamless delivery to clinic/distribution center. |

Note: DDP pricing should include EU Representative fees under MDR Article 31 (mandatory since May 2024).

Recommended Strategic Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Excels for 2026 Sourcing:

- Regulatory Mastery: 19 years exporting to 87 countries with 100% clean audit record (TÜV SÜD 2023-2025). Holds ISO 13485:2023 + EU MDR-compliant QMS.

- Technical Flexibility: Specializes in adjacent technologies (CBCT, intraoral scanners) with material science expertise critical for flexible denture systems. Offers in-house R&D for custom polymer processing parameters.

- Logistics Advantage: Baoshan District factory (15km from Yangshan Port) enables DDP Rotterdam delivery in 18 days avg. (2025 data). Includes CBAM compliance documentation.

- Risk Mitigation: Provides 24-month warranty with on-site engineer dispatch (EU/US within 72hrs). MOQ as low as 10 units for distributor partnerships.

Direct Sourcing Channel:

Company: Shanghai Carejoy Medical Co., LTD

Location: No. 1888 Jiangyang Road, Baoshan District, Shanghai 200443, China

Technical Sales: [email protected] (Specify “Flexible Denture Machine 2026 Guide”)

Urgent Procurement: WhatsApp +86 15951276160 (24/7 English-speaking team)

Note: Request their 2026 Flexible Denture Machine Datasheet (Rev. 3.1) with ISO 20795-1:2023 validation report.

2026 Sourcing Imperative

With EU MDR enforcement at 100% and new Chinese export controls on medical AI components (effective Q1 2026), engage suppliers with proven regulatory agility. Prioritize partners like Carejoy who provide full technical documentation packets – not just machine delivery. Always validate material biocompatibility data specific to flexible denture resins, as generic “medical grade” claims are insufficient under 2026 standards.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: Flexible Denture Processing Units – Procurement Advisory

Frequently Asked Questions: Flexible Denture Machine Procurement (2026)

As dental laboratories and multi-unit clinics upgrade to digital and hybrid workflows, the demand for precision flexible denture processing systems has increased. Below are five critical procurement questions and expert answers relevant to 2026 purchasing decisions.

| Question | Answer |

|---|---|

| 1. What voltage and power specifications should I verify before purchasing a flexible denture machine for international or regional deployment? | All flexible denture processing units in 2026 are manufactured with dual-voltage compatibility (110–120V / 220–240V, 50/60Hz) to support global deployment. However, confirm whether the unit includes an auto-switching power supply or requires a manual selector switch. Units intended for high-volume labs (Class II or III duty cycles) may require dedicated 20A circuits. Always verify local regulatory compliance (e.g., CE, UL, FDA 510(k) if applicable) and ensure plug type matches regional standards (NEMA, Schuko, etc.). |

| 2. Are spare parts readily available, and what is the average lead time for critical components like heating elements, clamps, and control boards? | Reputable manufacturers now offer 10+ year spare parts guarantees as part of ISO 13485:2026 compliance. Critical components such as PID temperature controllers, vacuum seals, and articulating clamps are stocked regionally by certified distributors. Average lead time for in-warranty parts is 3–5 business days; out-of-warranty or legacy model parts may require 7–14 days. We recommend purchasing a Spare Parts Kit (SPK-2026) at the time of machine acquisition, which includes 12 commonly replaced items and extends operational uptime by up to 40%. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of modern flexible denture machines (2026 models) includes site assessment, leveling, electrical verification, software calibration, and operator training. Most premium-tier systems come with complimentary on-site installation by a factory-certified technician (within 150 km of distribution hubs). Remote diagnostics and AR-assisted setup are standard for remote clinics. Ensure your facility has a stable power supply, minimum 1.2m² footprint with 30cm clearance on all sides, and ambient temperature control (18–24°C) for optimal performance. |

| 4. What is the standard warranty coverage, and does it include labor, software updates, and consumables? | The industry standard in 2026 is a 36-month comprehensive warranty covering parts, labor, and firmware updates. Software-as-a-Service (SaaS) licensing for machine control interfaces is included for the warranty period. Consumables (e.g., silicone molds, cleaning brushes) and damage from improper use or non-OEM materials are excluded. Extended warranty options (up to 60 months) are available with predictive maintenance packages, including quarterly remote diagnostics and priority dispatch. |

| 5. How are firmware and calibration updates managed post-purchase, and are they covered under warranty? | All 2026-model flexible denture machines feature OTA (Over-the-Air) firmware updates via encrypted cloud connectivity. Calibration routines are automated and triggered after 100 processing cycles or when environmental sensors detect drift. These updates and recalibrations are included under the standard warranty and extended service agreements. Clinics without secure network access can schedule updates during technician visits. Version traceability and audit logs are maintained per ISO 13485:2026 requirements. |

Need a Quote for Flexible Denture Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160