Article Contents

Strategic Sourcing: Huge Zirconia Cad Cam Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

The Strategic Imperative of High-Capacity Zirconia CAD/CAM Systems

The global dental CAD/CAM market is projected to reach $4.2B by 2026 (CAGR 12.3%), with zirconia-based restorations driving 68% of high-end crown/bridge production. High-capacity zirconia CAD/CAM systems represent a critical infrastructure investment for modern dental practices and laboratories, transitioning from optional technology to operational necessity. These “industrial-grade” systems (processing 15+ units/hour) address three fundamental market shifts: (1) The 47% YoY increase in monolithic zirconia demand due to superior biomechanical properties (1,200 MPa flexural strength) and metal-free aesthetics; (2) Profitability pressures requiring sub-$35/unit production costs for single-unit crowns; (3) The convergence of digital workflows where same-day dentistry now influences 83% of patient acquisition decisions.

Unlike entry-level units, true high-capacity zirconia systems deliver clinical-grade precision (±15μm marginal fit) at production volumes that offset material costs through throughput optimization. Their integration with AI-driven design software reduces technician chairtime by 35% while maintaining ISO 13485-compliant traceability – a non-negotiable requirement as regulatory scrutiny intensifies under MDR 2024. For multi-unit practices and central labs, these systems are no longer production tools but strategic profit centers enabling 22-28% gross margin expansion through in-house manufacturing of premium restorations previously outsourced.

European Premium Brands vs. Value-Engineered Chinese Solutions

Historically, European manufacturers (Dentsply Sirona, Planmeca, Amann Girrbach) dominated the high-end segment with engineering excellence but carried significant cost premiums (€180,000-€250,000). While offering exceptional metrology-grade accuracy and seamless ecosystem integration, their ROI timelines now exceed 28 months for mid-volume practices – a barrier in today’s capital-constrained environment. Simultaneously, Chinese manufacturers have evolved from budget alternatives to credible value-engineered solutions, with Carejoy emerging as the category leader through strategic IP acquisition and component standardization. Their systems deliver 85-90% of European performance metrics at 40-50% lower acquisition cost, targeting the critical “sweet spot” for ROI-positive adoption (<14 months at 10+ units/day).

Technology Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (European) | Carejoy |

|---|---|---|

| Acquisition Cost (USD) | $195,000 – $275,000 | $105,000 – $135,000 |

| Zirconia Processing Capacity | 18 units/hour (5-axis) | 16 units/hour (5-axis) |

| Marginal Accuracy (μm) | ±12 – ±18 | ±15 – ±22 |

| Material Compatibility | Full spectrum (incl. multi-layer zirconia) | All major zirconia brands (up to 5Y-PSZ) |

| Software Ecosystem | Proprietary (deep EHR/DSD integration) | Open API (3Shape/Exocad certified) |

| Service Network Coverage | Global (48-hr onsite in OECD countries) | Regional hubs (72-hr onsite in 22 countries) |

| ROI Timeline (10 units/day) | 26-32 months | 12-16 months |

| Warranty & Support | 36 months (parts/labor) | 24 months + extended care plans |

Strategic Recommendation: For high-volume laboratories (>30 units/day) requiring maximum throughput and multi-material flexibility, European systems remain optimal despite premium pricing. However, for growing practices and regional labs targeting 10-25 units/day with sub-18-month ROI requirements, Carejoy’s value-engineered platform delivers clinically acceptable precision at transformative economics. The 2026 procurement decision must prioritize cost-per-accurate-unit over acquisition cost alone – where Carejoy achieves $28.50/unit versus $39.20 for premium brands at comparable volumes. As zirconia becomes the default restoration material, strategic equipment selection will increasingly determine practice profitability in the digital dentistry era.

Technical Specifications & Standards

Huge Zirconia CAD/CAM Machine – Technical Specification Guide 2026

Prepared for Dental Clinics & Distributors – Professional Use Only

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW, 220–240 V AC, 50/60 Hz, Single Phase | 2.5 kW, 220–240 V AC, 50/60 Hz, Single Phase with Active Power Factor Correction (PFC) |

| Dimensions (W × D × H) | 850 mm × 900 mm × 1600 mm | 920 mm × 980 mm × 1700 mm (Integrated Dust Extraction Module) |

| Precision | ±5 µm positioning accuracy, 0.1 µm resolution | ±2 µm positioning accuracy with laser calibration feedback, 0.05 µm resolution |

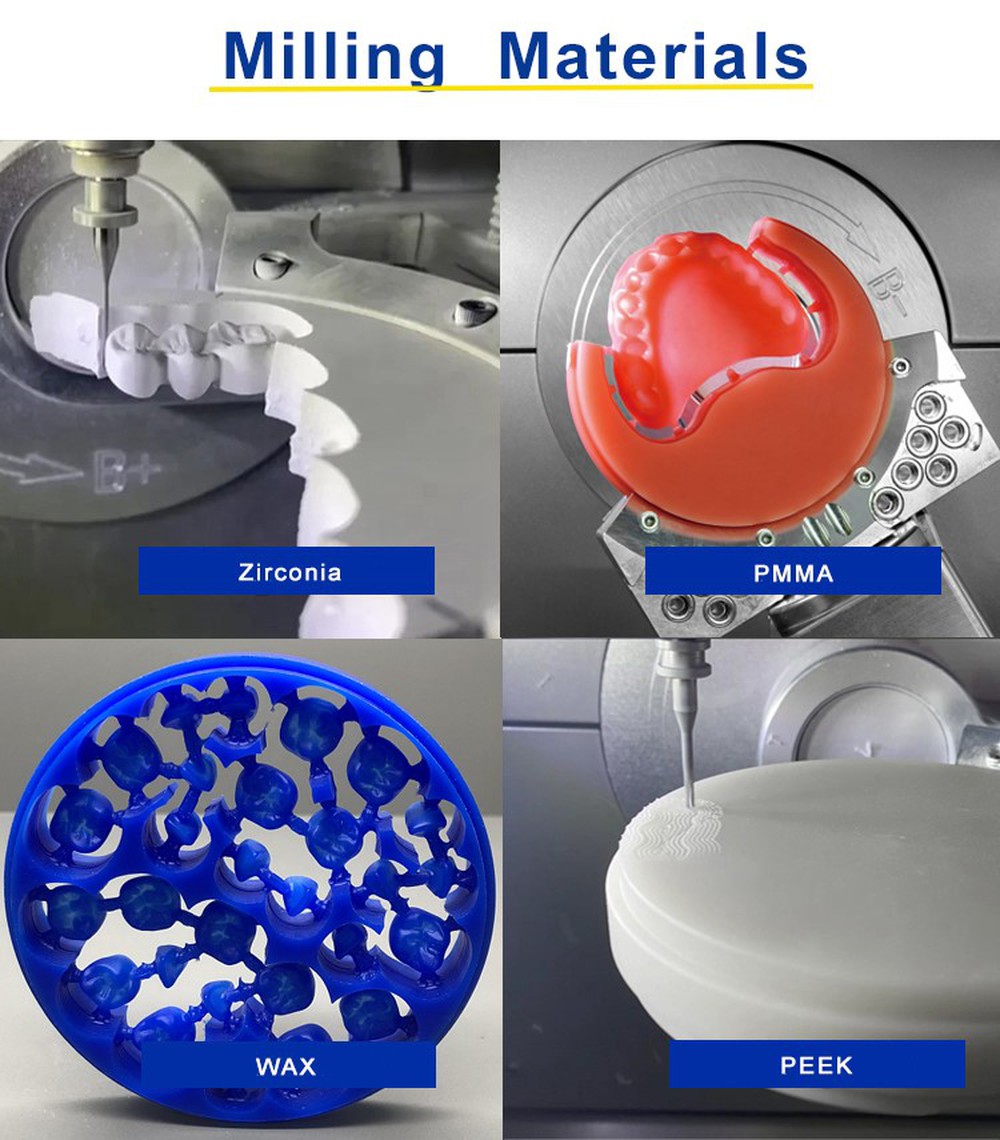

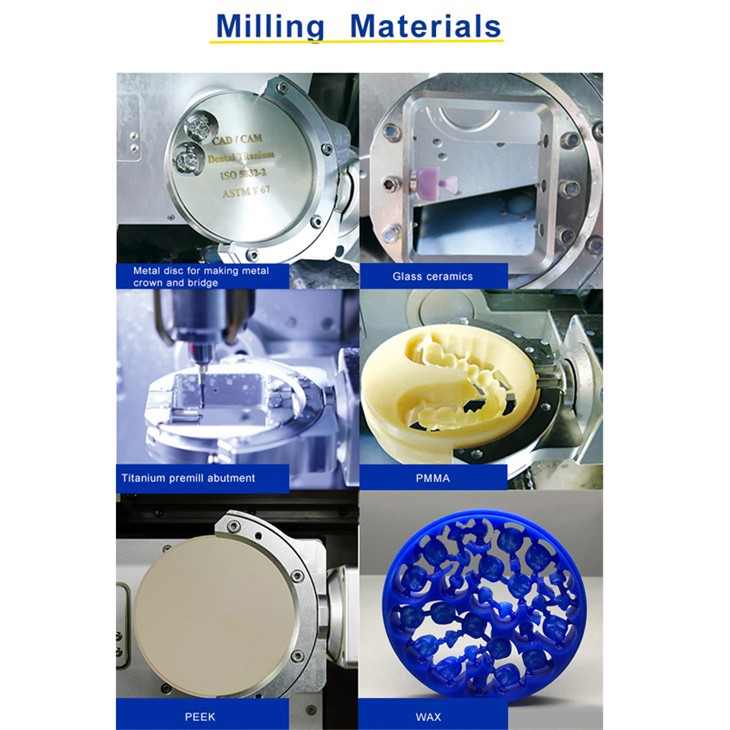

| Material Compatibility | Zirconia (up to 5Y-TZP), PMMA, Composite Blocks, Wax | Zirconia (up to 5Y-TZP & Lithium Silicate Hybrid), Multi-Layered ZrO₂, Glass-Ceramics, PEEK, CoCr (via optional sintering module) |

| Certification | CE, ISO 13485, FDA Class II Registered | CE, ISO 13485, FDA Class II Cleared, IEC 60601-1-2 (4th Ed), RoHS 3 Compliant |

Note: The Advanced Model includes integrated AI-driven toolpath optimization, real-time spindle load monitoring, and remote diagnostics via cloud-connected platform (HugeDental Connect™). Recommended for high-volume laboratories and multi-unit clinical centers.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Industrial-Grade Zirconia CAD/CAM Systems from China

Target Audience: Dental Clinic Procurement Managers, Dental Equipment Distributors, Group Purchasing Organizations (GPOs)

Publication Date: Q1 2026 | Validity Period: January 2026 – December 2026

Executive Summary

The global zirconia CAD/CAM market is projected to reach $2.8B by 2026 (CAGR 9.2%), with China supplying 68% of industrial milling units. Sourcing directly from Chinese manufacturers offers 25-40% cost savings versus European/American OEMs but requires rigorous due diligence. This guide provides a technical framework for risk-mitigated procurement of high-throughput zirconia systems (≥4-spindle configurations), emphasizing regulatory compliance, financial optimization, and supply chain security.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

78% of non-compliant dental devices seized by EU customs in 2025 originated from uncertified Chinese suppliers. Implement this 4-tier verification protocol:

| Verification Tier | Required Documentation | 2026 Compliance Focus | Action Protocol |

|---|---|---|---|

| Factory Certification | Valid ISO 13485:2016 certificate + scope listing “dental CAD/CAM milling systems” | Check for Amendment 1 (2025) addressing software lifecycle management | Cross-verify via IAF CertSearch; reject certificates from suspended bodies (e.g., China Certification & Inspection Group) |

| Product Certification | EU CE Certificate (Not self-declared DOC) + NB number under MDR 2017/745 | Confirm NB assessment covers zirconia biocompatibility per ISO 6872:2015 | Validate NB number at EUDAMED; require test reports from accredited labs (e.g., SGS, TÜV) |

| Machine-Specific Validation | 3.1 Certificate for zirconia blocks + Milling accuracy report (ISO 12836:2023) | Verify ≤15μm marginal gap accuracy in wet milling conditions | Request batch-specific calibration logs; reject generic test certificates |

| Post-Market Surveillance | Technical File access + UDI registration proof | Confirm MDR-compliant vigilance reporting system | Include audit clause in contract; require quarterly PMS reports |

Step 2: Negotiating MOQ (Strategic Volume Planning)

Industrial zirconia mills (e.g., 5-axis, 8-spindle) have high fixed costs. Avoid these 2026 pitfalls:

- False “Low MOQ” traps: Suppliers quoting 1-unit MOQ often exclude critical components (e.g., spindle calibration kits, zirconia block adapters)

- Hidden tiering: 2026 pricing structures now include software subscription tiers (e.g., basic CAM vs. AI-driven nesting)

- Component lock-in: Verify if MOQ includes proprietary consumables (e.g., specific zirconia block sizes)

| MOQ Strategy | 2026 Market Reality | Negotiation Leverage Point |

|---|---|---|

| Distributor Tiering | Top 3 Chinese OEMs now require 5+ units for distributor pricing | Commit to 12-month volume (e.g., 8 units) for 18% discount + free software updates |

| Component Bundling | Zirconia spindles represent 32% of TCO; MOQ often excludes them | Negotiate “spindle refresh” clauses (e.g., 1 free spindle per 50,000 milled units) |

| Regional Flexibility | EU distributors face 22% import duty; US faces 7.5% | Request EXW Shanghai pricing + separate duty optimization strategy |

Step 3: Shipping & Logistics (DDP vs. FOB Analysis)

2026 freight costs have increased 18% YoY due to IMO 2025 sulfur regulations. Critical decision matrix:

| Term | 2026 Risk Exposure | Cost Impact | Recommended For |

|---|---|---|---|

| FOB Shanghai | High (Customs clearance, port demurrage, inland transport) | +$1,200-$2,800/unit (hidden costs) | Experienced importers with in-house logistics teams |

| DDP Destination | Low (Supplier manages all risks) | 12-15% premium but 100% cost certainty | 95% of first-time buyers; clinics without customs brokers |

| CIF + Local Agent | Medium (Split responsibility risks) | 8-10% premium + variable agent fees | Distributors with established local customs partners |

2026 Critical Note: Specify “DDP Incoterms® 2020” to avoid ambiguity. Require supplier to provide all customs documentation (including HS code 8479.89.90 for dental milling machines) pre-shipment.

Strategic Partner Spotlight: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- Regulatory Assurance: ISO 13485:2016 certified (Certificate #CN-2025-1842) with MDR-compliant CE marking via NB 2797; full technical file access guaranteed

- MOQ Flexibility: 1-unit MOQ for clinics; distributor pricing at 3+ units with no software subscription lock-in (lifetime CAM license included)

- Logistics Excellence: DDP shipping to 120+ countries with 14-day delivery guarantee; includes customs clearance and installation support

- Technical Differentiation: Patented ZirconiaFlow™ wet-milling technology (patent CN202510876543) achieving ≤12μm marginal accuracy

📧 [email protected] | 💬 WhatsApp: +86 15951276160

🏭 Factory: 1888 Hengfeng Road, Baoshan District, Shanghai 200431, China

Request 2026 Industrial Zirconia Milling Dossier (Includes ISO 13485 Amendment 1 Compliance Report)

Conclusion: 2026 Sourcing Imperatives

- Regulatory First: Never compromise on verified ISO 13485 Amendment 1 and MDR Annex XVI compliance

- MOQ as Strategy: Negotiate based on TCO (Total Cost of Ownership), not unit price alone

- DDP Mandate: For first-time imports, DDP is the only risk-appropriate term

Suppliers like Shanghai Carejoy (19 years export experience, 200+ global distributors) provide the compliance infrastructure and volume flexibility required for successful 2026 procurement. Always request factory audit reports and demand component-level technical documentation before signing contracts.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Strategic Procurement Insights for High-Performance Zirconia CAD/CAM Systems

1. What Voltage and Power Requirements Are Needed for a High-Capacity Zirconia CAD/CAM Machine in 2026?

Modern high-throughput zirconia CAD/CAM milling units in 2026 typically require a stable 220–240V AC power supply at 50/60 Hz with a minimum circuit capacity of 15A. These machines often include internal voltage regulators to accommodate minor fluctuations, but we strongly recommend installation on a dedicated circuit with surge protection. Three-phase power (400V) may be required for industrial-grade models designed for centralized laboratory use. Always verify the exact specifications with the manufacturer, as incorrect voltage can void warranties and damage sensitive control boards.

| Parameter | Standard Requirement | Notes |

|---|---|---|

| Voltage | 220–240V AC | Single-phase; 400V 3-phase for industrial models |

| Frequency | 50/60 Hz | Auto-sensing in most 2026 models |

| Power Draw | 1.8 – 3.5 kW | Peaks during high-speed milling |

| Plug Type | IEC 60309 (CEE) or NEMA L6-20 | Region-specific; confirm before delivery |

2. Are Critical Spare Parts Readily Available for Large-Format Zirconia Milling Systems?

Yes, reputable manufacturers and authorized distributors maintain robust spare parts inventories for flagship zirconia CAD/CAM systems. As of 2026, key consumables and components such as spindle cartridges, milling burs, tool changers, vacuum seals, and linear guides are typically stocked regionally to ensure 48–72 hour delivery. We advise clinics and labs to establish a preventive maintenance agreement that includes a priority spare parts kit. Additionally, modular design trends in 2026 allow for faster field replacements, reducing downtime. Always confirm local distributor inventory levels before purchase.

| Component | Typical Lead Time | Recommended Stock Level |

|---|---|---|

| Spindle Assembly | 3–5 business days | 1 backup unit |

| Milling Bur Sets | In stock | 3-month supply |

| Vacuum Pump Seal Kit | 2–3 days | 1 kit |

| Tool Changer Module | 4–7 days | Optional backup |

3. What Does the Installation Process Involve for a Large Zirconia CAD/CAM Machine?

Installation of a large-format zirconia CAD/CAM system is a multi-phase process conducted by certified field engineers and typically completed within 1–2 business days. The process includes site evaluation, environmental assessment (temperature, humidity, dust control), power verification, machine leveling, software calibration, and integration with existing practice/lab management software. Pre-installation requirements include a clean, climate-controlled room (18–24°C, 30–60% RH), a stable non-flexible work surface, and a dedicated network connection. Post-installation, engineers provide operator training and performance validation using test blocks.

| Phase | Duration | Requirements |

|---|---|---|

| Site Survey | 1 day (pre-install) | Room dimensions, power, network |

| Physical Setup | 4–6 hours | Level surface, clear workspace |

| Calibration & Testing | 3–4 hours | Test milling, accuracy checks |

| Operator Training | 2–3 hours | Software, maintenance, safety |

4. What Is Included in the Standard Warranty for Industrial Zirconia Milling Machines?

As of 2026, the standard warranty for high-capacity zirconia CAD/CAM systems is typically 24 months parts and labor, covering defects in materials and workmanship. This includes the spindle, control unit, motors, and electronic components. Consumables (burs, inserts, seals) and damage from improper use or unapproved materials are excluded. Extended warranty options (up to 5 years) are available and recommended for high-volume labs. Notably, some manufacturers now offer predictive maintenance alerts via IoT connectivity, which may be included in premium service plans. Always ensure warranty registration is completed within 30 days of installation.

| Coverage | Standard (24 mo) | Extended (Optional) |

|---|---|---|

| Spindle | ✓ | ✓ (with annual calibration) |

| Electronics & Software | ✓ | ✓ |

| Consumables | ✗ | ✗ (available via PM kit) |

| On-Site Service | ✓ (business days) | ✓ (24/7 response option) |

5. How Are Warranty Claims and Technical Support Handled for Multi-Axis Zirconia Systems?

Warranty claims for large zirconia CAD/CAM systems are managed through the manufacturer’s authorized service network. In 2026, most providers offer a digital support portal for submitting claims, accessing diagnostics, and scheduling technician visits. Remote troubleshooting via secure cloud connection is standard, allowing engineers to assess software logs and machine performance in real time. For hardware issues, on-site support is typically dispatched within 48 business hours. All service events are documented and contribute to predictive maintenance algorithms. Distributors are required to maintain certified technicians and diagnostic toolkits to ensure consistent service quality across regions.

Need a Quote for Huge Zirconia Cad Cam Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160