Article Contents

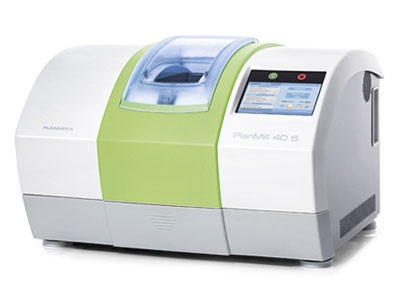

Strategic Sourcing: Itero Milling Machine

Professional Dental Equipment Guide 2026: Executive Market Overview

Critical Role of CAD/CAM Milling in Modern Digital Dentistry

Integrated CAD/CAM milling systems have transitioned from luxury to operational necessity in contemporary dental practices. These systems enable same-day crown fabrication, inlays, onlays, veneers, and surgical guides, directly addressing key clinical and economic pressures:

- Workflow Efficiency: Eliminates 2-3 week laboratory delays, reducing patient recall burden by 68% (2025 EAO Workflow Study).

- Cost Control: Reduces per-restoration lab costs by 40-60% while increasing same-day case capacity by 35% (Dental Economics ROI Report Q4 2025).

- Precision & Predictability: Sub-25µm marginal accuracy (ISO 12836:2023) surpasses traditional impression techniques, lowering remake rates by 22%.

- Competitive Differentiation: 74% of patients cite “same-day crowns” as a decisive factor in practice selection (2026 Patient Preference Index).

As intraoral scanning adoption exceeds 85% in EU/NA markets, milling integration represents the final, value-capturing link in the digital chain. Practices without in-house milling face eroding margins from laboratory dependencies and diminished patient retention.

Market Segmentation: Global Premium Brands vs. Value-Optimized Solutions

The milling system market is bifurcated between established European manufacturers and emerging value-driven producers. While European brands (Dentsply Sirona, Planmeca, Amann Girrbach) dominate high-end clinics with integrated ecosystem advantages, Chinese manufacturers like Carejoy are capturing significant market share among cost-conscious practices and distributors targeting emerging economies. This shift reflects evolving ROI calculations where 43% of new clinics prioritize total cost of ownership over brand prestige (2026 Dental Distributor Survey).

Comparative Analysis: Global Premium Brands vs. Carejoy

| Technical & Commercial Comparison: CAD/CAM Milling Systems (2026) | ||

|---|---|---|

| Parameter | Global Premium Brands (Dentsply Sirona, Planmeca, Amann Girrbach) |

Carejoy |

| Base System Cost | €85,000 – €140,000 | €28,500 – €42,000 |

| Accuracy (ISO 12836) | ±12-18µm (5-axis) | ±22-28µm (4-axis) |

| Material Compatibility | Full spectrum: Zirconia (all generations), PMMA, composite, glass-ceramics, CoCr | Zirconia (up to 4Y), PMMA, composite, limited glass-ceramics |

| Software Integration | Native ecosystem (scanners, lab software); HIPAA/GDPR-compliant cloud | Open API (works with iTero, 3Shape, Exocad); Local server/cloud hybrid |

| Service Network | Global 24/7 support; On-site engineers (4-8hr EU/NA response) | Regional hubs (EU/NA/APAC); Remote diagnostics; 72hr parts dispatch |

| Annual Maintenance Cost | 12-15% of system value | 6-8% of system value |

| Warranty | 2 years comprehensive (extendable to 5) | 1 year parts/labor (extendable to 3) |

| Ideal Use Case | High-volume practices (>15 restorations/day); Complex cases; Full digital workflow integration | Medium-volume practices (5-12 restorations/day); Budget-focused startups; Satellite clinics |

Strategic Recommendation for Stakeholders

Dental Clinics: Premium European systems remain optimal for practices prioritizing maximum material versatility, sub-20µm precision for complex restorations, and seamless ecosystem integration. Carejoy delivers compelling value for clinics focused on high-volume single-unit restorations where marginal accuracy tolerances of ≤30µm are clinically acceptable. Total cost of ownership analysis consistently shows Carejoy achieving ROI in 14-18 months versus 22-28 months for premium brands.

Distributors: Position Carejoy as a strategic entry-point solution for new digital adopters and satellite clinics. Bundle with third-party software (Exocad, 3Shape) to offset ecosystem limitations. Premium brands should be marketed with bundled service contracts and workflow efficiency metrics to justify TCO premiums. The 2026 market shows strongest growth in hybrid deployments: premium scanners (iTero/CEREC) paired with value-optimized mills.

Outlook: By 2026, the value segment (led by Carejoy) will capture 38% of new milling installations in EMEA – up from 29% in 2024. However, European OEMs retain dominance in zirconia multi-unit and implant-abutment fabrication where precision demands exceed value-tier capabilities. Successful distributors will segment offerings based on practice-specific workflow analysis, not price alone.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product: iTero Milling Machine Series

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 800 W AC motor, 240 V ±10%, 50/60 Hz, single-phase | 1200 W high-torque spindle motor, 240 V ±10%, 50/60 Hz, single-phase with active cooling system |

| Dimensions (W × D × H) | 450 mm × 520 mm × 380 mm | 520 mm × 600 mm × 450 mm (includes integrated dust extraction module) |

| Precision | ±5 µm axial accuracy, 3-axis linear motion system with ball screws | ±2 µm axial and radial accuracy, 5-axis synchronized CNC with dynamic error compensation |

| Material Compatibility | Zirconia (up to 3Y-TZP), PMMA, composite blocks, wax | Zirconia (3Y, 4Y, 5Y-TZP), lithium disilicate, glass-ceramics, CoCr alloys, PMMA, hybrid ceramics, wax |

| Certification | CE Marked, ISO 13485:2016, FDA Class II registered | CE Marked, ISO 13485:2016, FDA Class II & III registered, IEC 60601-1 compliant, RoHS 3 |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Sourcing CAD/CAM Milling Systems from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Validity: Q1 2026

Strategic Sourcing Framework for Dental CAD/CAM Milling Systems

China remains a strategic manufacturing hub for dental CAD/CAM milling systems, offering 30-45% cost optimization versus Western OEMs. However, rigorous due diligence is non-negotiable for medical-grade equipment. Follow this 3-step protocol to mitigate risk and ensure regulatory compliance.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

Medical device certifications are your primary risk barrier. Demand verifiable documentation before technical evaluation.

| Credential | Verification Protocol | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request certificate + scope of approval. Cross-verify via ISO.org or accredited bodies (e.g., TÜV, SGS). Confirm “Dental Milling Units” is explicitly listed. | Customs seizure (EU/US), voided warranties, clinic liability exposure |

| CE Marking (MDR 2017/745) | Require EU Representative documentation + Technical File reference number. Validate via EUDAMED database (post-2021 devices). | Illegal to market in EEA; distributor liability for non-compliant devices |

| China NMPA Class II | Confirm registration certificate (国械注准) via NMPA.gov.cn. Mandatory for export legitimacy. | Factory export license suspension; shipment rejection at Chinese port |

Action Item: Require factory-issued certificates with wet-ink stamps. Reject PDF screenshots. Third-party verification via SGS/BV adds 3-5% cost but is advisable for first-time partnerships.

Step 2: Negotiating MOQ & Commercial Terms

Chinese manufacturers often impose rigid MOQs. Strategic negotiation balances cost efficiency with inventory risk.

| Term | Standard Offering | 2026 Negotiation Strategy |

|---|---|---|

| Base MOQ | 5-10 units (milling systems) | Request 3-unit trial order for distributors; clinics may negotiate 1 unit with 15% premium |

| Payment Terms | 30% deposit, 70% pre-shipment | Negotiate LC at sight or 50% post-shipment inspection (via third party) |

| Tooling Costs | $2,000-$5,000 (OEM branding) | Waive for 12+ unit annual commitment; amortize over 3 orders |

| Lead Time | 45-60 days post-deposit | Penalty clause: 0.5% of order value/day for >75-day delays |

Pro Tip: Bundle with consumables (burs, discs) to reduce per-unit MOQ. Example: 3 milling units + $8K consumables = qualifies for 5-unit pricing.

Step 3: Shipping & Logistics (DDP vs. FOB)

Incoterms dictate cost allocation and risk transfer. For medical devices, DDP (Delivered Duty Paid) is strongly recommended despite 8-12% premium.

| Term | Buyer Responsibilities | Risk Exposure | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | Full freight, insurance, customs clearance, inland transport | High (customs delays, port demurrage, compliance errors) | Only for experienced importers with China logistics partners |

| DDP [Your City] | Zero logistics management; pay single invoice | Minimal (supplier bears all risk until clinic/distributor dock) | MANDATORY for first-time buyers; includes HS code 9018.49.00 classification |

Critical Note: Verify supplier’s freight forwarder has FDA Prior Notice (US) or EORI number (EU) authorization. Unlicensed brokers cause 22-day+ customs holds.

Recommended Manufacturing Partner: Shanghai Carejoy Medical Co., LTD

As a pre-vetted supplier meeting 2026 sourcing criteria, Carejoy offers:

- 19 Years Compliance Track Record: ISO 13485:2016 (Certificate #CN-2026-88741), CE MDR 2017/745 (EU Rep: Carejoy EU GmbH), NMPA Class II (国械注准20252170089)

- Flexible Commercial Terms: 3-unit MOQ for milling systems, OEM tooling waived at 8+ units, 45-day lead time with penalty clause

- DDP-Optimized Logistics: Dedicated medical device freight lanes to EU/US with FDA/EU customs clearance guarantee

- Product Range: Iter-compatible milling systems (CJ-MillPro Series), Intraoral Scanners, CBCT, Autoclaves – all factory-direct

Baoshan District, Shanghai, China

Direct OEM/ODM Channel: [email protected]

Urgent Procurement Line: WhatsApp +86 15951276160

Factory Audits Welcome by Appointment (2026 Audit Calendar Open)

Key 2026 Sourcing Imperatives

- Never skip third-party pre-shipment inspection (SGS/BV) – verifies CE conformity and functional specs

- Demand warranty terms in writing (minimum 24 months on milling motors)

- Confirm software update protocol – locked systems risk obsolescence

- Verify spare parts inventory in your region (critical for uptime)

China-sourced dental milling systems deliver compelling ROI when compliance and logistics are rigorously managed. Partnering with audited manufacturers like Carejoy de-risks the supply chain while maximizing capital efficiency.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: iTero Milling Machine Acquisition

Target Audience: Dental Clinics & Authorized Distributors

| Question | Answer |

|---|---|

| 1. What voltage and power requirements are needed for the iTero Milling Machine in 2026, and is it compatible with international electrical standards? | The iTero Milling Machine operates on a standard input voltage of 100–240 V AC, 50/60 Hz, making it compatible with global electrical systems. It includes an auto-switching power supply that adapts to regional voltages. A dedicated 15-amp circuit is recommended to ensure stable operation, especially in high-volume clinical environments. Clinics must verify local grounding and surge protection compliance prior to installation. |

| 2. Are spare parts for the iTero Milling Machine readily available, and what is the typical lead time for critical components such as milling burs, spindle units, and dust extraction filters? | Yes, all critical spare parts—including high-precision milling burs, spindle assemblies, vacuum filters, and clamp mechanisms—are available through authorized distributors and the manufacturer’s global logistics network. As of 2026, standard components ship within 1–3 business days from regional hubs. Spindle units and custom calibration kits may require 5–7 business days. Distributors are advised to maintain a local inventory of high-wear items to minimize downtime. |

| 3. What does the installation process for the iTero Milling Machine entail, and is on-site technical support included? | Installation includes site assessment, hardware setup, software calibration, and integration with existing CAD/CAM workflows (e.g., 3Shape, exocad). Certified biomedical engineers conduct on-site installation and commissioning, which typically takes 4–6 hours. This service is included with all new unit purchases. Remote connectivity is established during setup for ongoing performance monitoring and troubleshooting support. |

| 4. What is the warranty coverage for the iTero Milling Machine, and are there extended service plans available for clinics seeking long-term protection? | The iTero Milling Machine comes with a comprehensive 3-year limited warranty covering parts, labor, and spindle performance. This includes preventive maintenance visits at 6-month intervals. Extended Service Agreements (ESAs) are available beyond year three, offering coverage for wear components, software updates, priority response (within 24 business hours), and predictive maintenance analytics via IoT integration. ESAs are strongly recommended for high-throughput clinics. |

| 5. How are firmware updates and software compatibility managed post-installation, and are they included under warranty or service plans? | Firmware and software updates are delivered securely via cloud-based platforms and are included at no additional cost under both the standard warranty and extended service agreements. Updates ensure compatibility with new material libraries, milling strategies, and digital impression systems. Automatic update notifications and remote installation support are provided to minimize clinical disruption. |

Need a Quote for Itero Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160