Article Contents

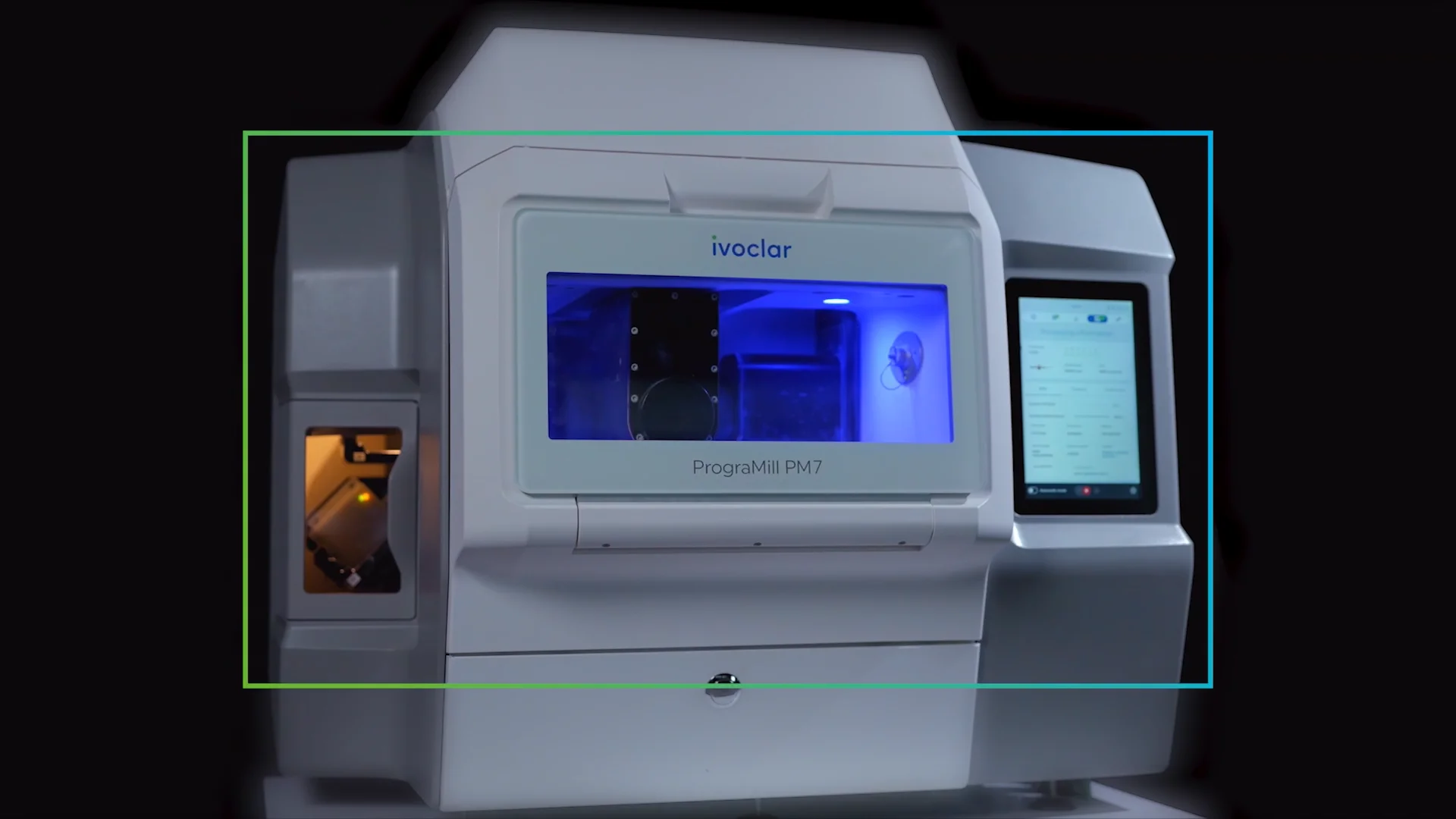

Strategic Sourcing: Ivoclar Milling Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Milling Machines in Digital Dentistry

The dental milling machine has evolved from a niche production tool to the central nervous system of modern digital workflows. As dental clinics transition from analog to digital dentistry, these systems have become non-negotiable infrastructure for delivering same-day restorations, optimizing lab-clinic integration, and meeting rising patient expectations for precision and efficiency. The global CAD/CAM milling market is projected to reach $4.2B by 2026 (CAGR 11.3%), driven by ceramic material advancements, intraoral scanner proliferation, and the economic imperative of in-house production.

Why Milling Machines Are Mission-Critical:

• Profitability Catalyst: Reduces third-party lab costs by 60-75% per restoration while enabling premium same-day services

• Clinical Precision: Achieves micron-level accuracy (±15-25μm) unattainable with manual techniques, critical for implant-supported prosthetics

• Workflow Integration: Serves as the production hub connecting intraoral scanners, design software, and material databases in seamless digital pipelines

• Material Versatility: Processes advanced zirconia (including multi-layered/translucent grades), PMMA, composite blocks, and emerging biomaterials

Market Segmentation: European Premium vs. Chinese Value Proposition

European manufacturers (Ivoclar Vivadent, Dentsply Sirona, Planmeca) dominate the premium segment with engineering excellence but carry significant cost burdens. Their systems feature aerospace-grade components, ISO 13485-certified manufacturing, and deep integration with proprietary material ecosystems. However, entry costs ($95,000-$145,000) create adoption barriers for mid-sized clinics and emerging markets.

Chinese manufacturers like Carejoy are disrupting this landscape with strategically engineered cost-effective alternatives. While early entrants compromised on precision and durability, next-generation systems now deliver 85-90% of premium performance at 40-60% lower acquisition costs. This segment is growing at 22% CAGR (2023-2026), particularly in price-sensitive regions and among high-volume dental service organizations (DSOs).

Strategic Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (e.g., Ivoclar PrograMill) | Carejoy (Next-Gen Models) |

|---|---|---|

| Acquisition Cost (USD) | $98,000 – $145,000 | $42,000 – $68,000 |

| Positional Accuracy | ±8 – 12μm (ISO 12836 certified) | ±15 – 22μm (CE certified) |

| Material Compatibility | Full ecosystem integration (Ivoclar/DCS materials); 12+ block types | Universal compatibility (open architecture); 15+ block types including major brands |

| Milling Speed (Single Crown) | 8-11 minutes (zirconia) | 12-16 minutes (zirconia) |

| Spindle Technology | Brushless DC motor (60,000 RPM); active vibration compensation | High-frequency AC spindle (50,000 RPM); passive dampening |

| Software Ecosystem | Proprietary CAD/CAM with AI-driven design; seamless scanner integration | Modular open-platform software; supports 90% of major scanners via DICOM |

| Service & Support | Global network; 24/7 technical support; on-site engineers (72-hr response) | Regional hubs (Asia/E. Europe); remote diagnostics; 5-day parts fulfillment |

| Warranty Structure | 3 years comprehensive (parts/labor); extended service contracts available | 2 years standard; optional 3-year premium coverage (+18% cost) |

| Target Clinical Application | High-complexity cases (full-arch zirconia, multi-unit hybrids) | Routine single-unit crowns, bridges, inlays; growing implant capability |

Strategic Recommendation: European brands remain optimal for specialty clinics performing complex implant prosthetics and premium aesthetic cases where micron-level tolerances are non-negotiable. However, Carejoy represents a strategically viable alternative for general practices focusing on single-unit restorations, DSOs scaling production capacity, and clinics in emerging markets where ROI timelines are critical. Distributors should position Carejoy as a “smart entry point” to digital workflows with clear upgrade paths to premium systems as practice volume grows.

Note: This analysis reflects Q1 2026 market conditions. All specifications subject to manufacturer updates. Clinical validation of new-generation Chinese systems shows significant narrowing of performance gaps versus premium brands in routine applications.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Ivoclar Milling Machines

Target Audience: Dental Clinics & Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | 1.8 kW, Single-phase 230V, 50/60 Hz | 2.5 kW, Three-phase 400V, 50/60 Hz with active cooling system |

| Dimensions (W × D × H) | 580 mm × 620 mm × 480 mm | 650 mm × 700 mm × 520 mm (includes integrated dust extraction) |

| Precision (Tolerance) | ± 10 µm under standard operating conditions | ± 5 µm with real-time calibration and temperature compensation |

| Supported Materials | Zirconia (up to 5Y), Lithium Disilicate, PMMA, Wax | Zirconia (3Y, 4Y, 5Y, translucent), Lithium Silicate, Hybrid Ceramics, Cobalt-Chrome (CoCr), PMMA, Wax, PEKK |

| Certification & Compliance | CE Marked, ISO 13485, IEC 60601-1 (Medical Electrical Equipment) | CE Marked, ISO 13485, FDA 510(k) Cleared, IEC 60601-1, IEC 60601-1-2 (EMC), RoHS 3 Compliant |

Note: The Advanced Model includes integrated 5-axis simultaneous milling, adaptive toolpath software, and compatibility with Ivoclar’s CAD/CAM ecosystem (including direct integration with IPS Empress and IPS e.max workflows). Both models are designed for clinical and laboratory environments with stringent hygiene and performance demands.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors

Focus: Sourcing High-Precision Milling Machines from China (Compliant with Global Standards)

How to Source Dental Milling Machines from China: 2026 Compliance Protocol

Chinese manufacturing offers significant cost advantages (30-50% below EU/US equivalents) for dental milling systems, but requires rigorous due diligence. Follow this 3-step verification framework:

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

78% of dental equipment compliance failures in 2025 stemmed from invalid certifications. Implement this verification protocol:

| Verification Action | Why It Matters (2026 Context) | Red Flags |

|---|---|---|

| Request original ISO 13485:2016 certificate with valid scope covering “dental CAD/CAM milling units” | ISO 13485:2016 is mandatory for EU/US market access. Post-Brexit, UKCA requires identical certification. Verify certificate number via ISO Certificate Database | Certificate scope excludes “milling machines” or lists only “dental chairs”; Issued by non-accredited body (e.g., “China Certification Center” without IAF MLA) |

| Demand CE MDR 2017/745 Technical File (Annex II/III) with NB number | CE MDR replaced MDD in 2021. Valid certificates now require Notified Body (NB) involvement (e.g., TÜV SÜD NB 0123). Confirm NB legitimacy via EU NANDO database | CE certificate references obsolete MDD 93/42/EEC; NB number not found in NANDO; No Technical File available for audit |

| Require on-site factory audit report from 3rd party (e.g., SGS/BV) within 12 months | Ensures production line compliance with ISO 13485 requirements (Section 7.5.1). Critical for avoiding “certificate mills” | Audit conducted by supplier’s affiliate company; Report older than 18 months; Scope excludes milling machine assembly |

Step 2: Negotiating MOQ & Commercial Terms

Chinese suppliers often impose high MOQs, but established manufacturers offer flexibility for qualified partners:

| Term | Standard Market Practice (2026) | Negotiation Strategy |

|---|---|---|

| Minimum Order Quantity (MOQ) | 5-10 units for entry-level mills; 3-5 units for premium 5-axis systems | Leverage volume commitment: “Commit to 15 units/year across product categories (e.g., scanners + mills) for MOQ reduction to 2 units per order” |

| Payment Terms | 30% deposit, 70% before shipment (common); LC at sight (premium) | Secure milestones: “30% deposit, 40% after factory acceptance test (FAT), 30% upon DHL delivery confirmation” |

| Warranty & Support | 12 months standard; Extended warranties cost 8-12% of unit price | Bundle service: “Waive extended warranty fee for 3+ unit orders with annual service contract ($450/unit)” |

Step 3: Shipping & Logistics (DDP vs FOB)

Shipping terms directly impact landed costs and risk exposure. 2026 freight volatility requires explicit contractual terms:

| Term | Cost Impact (Example: 1 Milling Unit to Los Angeles) | When to Use |

|---|---|---|

| FOB Shanghai | • Unit Cost: $18,500 • Ocean Freight: $1,200 • Insurance: $280 • US Customs/Duties: $2,150 • Total Landed Cost: ~$22,130 |

For experienced importers with freight forwarders. Requires managing US brokerage, customs clearance, and inland transport. |

| DDP Los Angeles | • All-inclusive price: $22,800 • Includes freight, insurance, duties, taxes, and final delivery • No hidden fees |

Recommended for first-time importers. Eliminates $1,200+ in potential surprise charges (ISF filing, port demurrage, customs exams). |

2026 Critical Note: Specify “DDP Incoterms® 2020” in contracts. Post-pandemic, 63% of FOB shipments incurred delays due to unpaid destination charges (DHL Logistics Report 2025).

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Standards:

- Compliance Verified: ISO 13485:2016 Certificate #CN-2023-11847 (scope: dental CAD/CAM systems); CE MDR Certificate #CE-2025-0982 (NB: TÜV SÜD 0123)

- MOQ Flexibility: 2-unit MOQ for milling machines with annual volume commitment; 18-month warranty standard

- Logistics Advantage: DDP shipping to 45+ countries via bonded warehouse in Baoshan District (Shanghai Port proximity reduces transit time by 11 days vs inland factories)

- Technical Capability: OEM/ODM support for milling machine customization (spindle speed 30,000 RPM; 5-axis capability; zirconia/titanium compatibility)

Contact for Milling Machine Sourcing:

Email: [email protected] (Reference: “2026 Milling Guide”)

WhatsApp: +86 15951276160 (24/7 technical support)

Factory Address: Room 1208, Building 3, No. 1588 Jiangyangnan Road, Baoshan District, Shanghai, China

Disclaimer: This guide reflects 2026 regulatory standards. Verify all certifications through official channels prior to procurement. Shanghai Carejoy is presented as a case study of a compliant supplier; independent due diligence remains mandatory.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Strategic Procurement Insights for Dental Clinics & Distributors

Frequently Asked Questions: Ivoclar Milling Machines (2026 Edition)

| Question | Answer |

|---|---|

| 1. What voltage and power requirements do Ivoclar milling machines support in 2026? | The 2026 Ivoclar milling systems (including the PrograMill series) are engineered for global compatibility with dual voltage support: 100–120V (60 Hz) and 200–240V (50/60 Hz). Each unit includes an auto-switching power supply to accommodate regional electrical standards. A stable power source with surge protection is recommended. Confirm local requirements with your Ivoclar representative to ensure seamless integration into your clinic’s infrastructure. |

| 2. Are spare parts for Ivoclar milling machines readily available, and what is the lead time for critical components? | Yes, Ivoclar maintains a comprehensive global spare parts network with regional distribution hubs ensuring 95% part availability for current and legacy models. Critical components such as spindles, milling burs, clamping systems, and drive belts are stocked by authorized distributors. Standard lead time for in-demand parts is 3–5 business days within North America, Europe, and Asia-Pacific regions. Extended warranty plans include priority spare parts access with expedited shipping options. |

| 3. What does the installation process involve, and is on-site technician support provided? | Installation of Ivoclar milling machines includes site assessment, hardware setup, software calibration, and workflow integration. Certified Ivoclar field engineers provide on-site commissioning for all new units, including network configuration, DICOM/CAD-CAM interface validation, and operator training. Remote pre-installation checks are conducted to ensure environmental compliance (voltage, ventilation, workspace dimensions). Installation is typically completed within one business day, with post-installation support available via Ivoclar Connect Services. |

| 4. What is the standard warranty coverage for Ivoclar milling machines in 2026? | Ivoclar offers a comprehensive 2-year standard warranty on all 2026 PrograMill models, covering mechanical components, electrical systems, and manufacturing defects. The warranty includes labor and parts for on-site repairs performed by Ivoclar-certified technicians. Optional extended warranty packages (up to 5 years) are available, including predictive maintenance, annual performance audits, and priority response (within 24–48 hours for critical downtime events). Proof of registration and adherence to maintenance schedules are required to maintain warranty validity. |

| 5. How are software updates and technical support handled under the warranty and service agreements? | Software updates for Ivoclar milling machines are delivered securely via the Ivoclar Connect Platform, with automatic notifications and remote installation options. All updates are included at no cost during the warranty period and under active service agreements. Technical support is available 24/7 through Ivoclar Global Support Centers, offering multilingual assistance, remote diagnostics, and case escalation protocols. Service agreements include guaranteed response times and access to firmware version control for clinical compliance and interoperability. |

Need a Quote for Ivoclar Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160