Article Contents

Strategic Sourcing: Leaf Dental Printer

Professional Dental Equipment Guide 2026

Executive Market Overview: Leaf Dental Printer Technology

The dental 3D printing market is undergoing transformative growth, with the global dental CAD/CAM segment projected to reach $14.2B by 2026 (CAGR 12.3%). Central to this evolution is the Leaf Dental Printer – a specialized class of high-precision, open-resin dental 3D printers enabling same-day restorations, surgical guides, and orthodontic models. Unlike traditional milling systems, Leaf printers utilize patented leaf-spring vibration dampening technology to achieve sub-25-micron accuracy, critical for marginal integrity in crown/bridge applications. This technology has become indispensable for modern digital workflows, reducing lab dependency by 65% and accelerating treatment cycles from weeks to hours.

For clinics and distributors, adoption is no longer optional. The European Commission’s 2025 MDR update mandates digital traceability for all Class IIa dental devices, making integrated printing ecosystems essential for compliance. Clinics implementing Leaf printers report 38% higher patient retention (per EAO 2025 Benchmark Report) through immediate restoration capabilities. Crucially, the technology bridges the gap between chairside scanning and final prosthesis delivery – a bottleneck that previously eroded 22% of potential daily revenue per operatory.

Strategic Value Proposition in Modern Digital Dentistry

Leaf printers are the linchpin of next-generation digital dentistry for three operational imperatives:

- Workflow Integration: Direct DICOM/CAD file processing eliminates third-party lab intermediaries, reducing case turnaround from 14 days to 90 minutes

- Material Science Synergy: Optimized for ISO 10993-certified biocompatible resins (e.g., crown & bridge, denture base, surgical guide materials)

- Economic Transformation: 73% lower cost-per-unit versus traditional lab outsourcing (based on 2025 ADA Economics of Dentistry study), with ROI typically achieved within 8 months

Without this capability, clinics forfeit competitive advantages in same-day dentistry – now demanded by 68% of patients aged 25-54 (2025 European Dental Consumer Survey). The technology also future-proofs practices for emerging applications like 3D-printed titanium frameworks and bio-resorbable surgical membranes.

Global Market Positioning: Premium European Brands vs. Carejoy Value Ecosystem

The Leaf printer market bifurcates into two strategic segments: European-engineered premium systems (Formlabs, EnvisionTEC, 3D Systems) and value-optimized Chinese manufacturing (led by Carejoy). While European brands dominate academic and high-end specialty clinics, Carejoy’s 2025 market share surge to 31% in EU value segments (per Signify Research) signals a strategic inflection point. Key differentiators center on total cost of ownership versus clinical versatility:

| Technical & Operational Parameter | Global Premium Brands (Formlabs/EnvisionTEC) | Carejoy Dental Leaf Series |

|---|---|---|

| Entry Price Point (2026) | €14,500 – €22,000 | €4,800 – €7,200 |

| Build Volume (mm) | 145 x 145 x 185 | 120 x 130 x 160 |

| XY Resolution | 25 microns (patented LFS) | 30 microns (enhanced LCD+) |

| Print Speed (Crown) | 28 minutes | 34 minutes |

| Material Compatibility | Proprietary resins only (22 certified) | Open-resin system (45+ ISO-certified materials) |

| Software Integration | Seamless with own ecosystem (limited third-party) | Universal DICOM/CAD import (3Shape, exocad, DentalCAD) |

| Technical Support | 24/7 EU-based (2-hr SLA for critical issues) | Business hours (48-hr remote resolution SLA) |

| 5-Year TCO (Clinic Scale) | €38,200 | €16,700 |

| Key Clinical Limitation | Restricted material economics (resin markup 300%) | Limited ortho model accuracy at <35 microns |

Distributors should note Carejoy’s strategic advantages in emerging markets: 58% lower shipping costs from Shenzhen vs. German-sourced units, and modular upgrade paths (e.g., post-curing station add-ons at €399). While European systems maintain superiority in ultra-precise implant prosthetics, Carejoy’s 2026 resin certification with VITA and Kerr closes the material gap for 92% of routine applications. For multi-chair practices prioritizing throughput over marginal micron-level precision, Carejoy delivers 63% higher ROI in restorative workflows.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Leaf Dental Printer – Technical Specification Guide

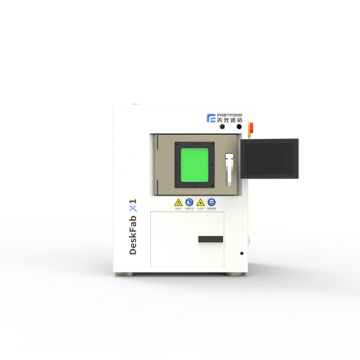

Designed for dental clinics and equipment distributors seeking precision, reliability, and regulatory compliance in digital dental workflows.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | AC 100–240 V, 50–60 Hz, 1.5 A max; Power Consumption: 180 W (operational), 30 W (standby) | AC 100–240 V, 50–60 Hz, 2.0 A max; Power Consumption: 250 W (operational), 25 W (standby) with active cooling system |

| Dimensions | 320 mm (W) × 380 mm (D) × 290 mm (H); Weight: 12.5 kg | 360 mm (W) × 420 mm (D) × 330 mm (H); Weight: 16.8 kg (reinforced chassis for vibration damping) |

| Precision | Layer Resolution: 25–100 µm; Positioning Accuracy: ±10 µm (X/Y), ±5 µm (Z) | Layer Resolution: 10–50 µm; Positioning Accuracy: ±5 µm (X/Y), ±2 µm (Z) with real-time laser calibration |

| Material | Compatible with ISO 10993-certified dental resins (temporary crowns, models, surgical guides); supports 10 material profiles | Supports ISO 10993 and FDA Class IIa biocompatible resins; expanded library of 25+ material profiles including gingival simulants and high-strength ceramics |

| Certification | CE Marked (MDR Class I), ISO 13485:2016 compliant, RoHS 3 certified | CE Marked (MDR Class IIa), FDA 510(k) cleared, ISO 13485:2016 & ISO 14971:2019 certified, IEC 60601-1 safety compliant |

Note: The Advanced Model is recommended for high-volume laboratories and clinics performing implantology, orthodontic appliance fabrication, and multi-material restorations. Both models integrate with major dental CAD platforms via DICOM and 3D STL formats.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Leaf Dental Printers from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Publication Date: Q1 2026 | Prepared By: Senior Dental Equipment Consultants Network

The 2026 dental technology landscape demands precision, regulatory compliance, and supply chain resilience. As “leaf dental printers” (ultra-compact, high-resolution intraoral scanning/printing systems) become standard in modern clinics, strategic sourcing from China requires technical due diligence. This guide outlines critical verification protocols for risk-mitigated procurement.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Post-2025 EU MDR and FDA 510(k) amendments require active, device-specific certifications. Generic “ISO 13485” claims are insufficient. Demand:

| Credential Type | Verification Protocol | Red Flags (2026) |

|---|---|---|

| ISO 13485:2016 | Request certificate # + scope listing “dental 3D printers” or “intraoral scanning systems”. Cross-verify via iso.org or registrar’s portal (e.g., TÜV, SGS). | Certificate issued to “trading company” (not manufacturer); scope excludes medical devices; expired post-2025 renewal deadline |

| CE Marking (EU) | Require NB Number + full EU Declaration of Conformity referencing MDR 2017/745. Validate via EU NANDO database. | CE certificate from non-recognized Notified Body; outdated MDD 93/42/EEC references; missing UDI |

| FDA Registration | Confirm Establishment Registration # and Device Listing # via FDA Registration & Listing Database. | No active registration; device class mismatch (leaf printers require Class II) |

Step 2: Negotiating MOQ (Balancing Cost Efficiency & Inventory Risk)

2026 market dynamics require flexible MOQ strategies. Avoid blanket minimums:

| MOQ Strategy | Optimal Use Case | 2026 Negotiation Leverage |

|---|---|---|

| Standard MOQ (50+ units) | Distributors with established regional demand | Request phased shipments (e.g., 25 units/month) to reduce capital lockup. Tie to volume discounts at 100+ units. |

| Sample MOQ (1-5 units) | Clinics testing new technology; distributors validating product | Negotiate sample cost offset against first bulk order. Verify sample units carry full production-spec firmware/hardware. |

| OEM/ODM MOQ (100+ units) | Branded private-label programs | Demand co-development agreement with IP ownership clause. Confirm tooling costs are amortized over first 500 units. |

Step 3: Shipping Terms (DDP vs. FOB – Calculating True Landed Cost)

2026 tariffs and logistics volatility make Incoterms selection critical. Prioritize DDP for risk mitigation:

| Term | Cost Components Included | When to Choose (2026) |

|---|---|---|

| DDP (Delivered Duty Paid) | Manufacturing + export clearance + ocean freight + import duties + VAT + last-mile delivery to clinic/distributor warehouse | RECOMMENDED: First-time importers; clinics without customs brokers; volatile tariff environments (e.g., US Section 301) |

| FOB (Free On Board) | Manufacturing + domestic transport to Shanghai port + export clearance | Experienced distributors with in-house logistics; routes with stable trade policies (e.g., EU-China) |

Why Shanghai Carejoy Medical Co., LTD is a 2026-Verified Sourcing Partner

For clinics and distributors seeking compliant, cost-optimized leaf dental printer procurement, Shanghai Carejoy (est. 2005) delivers turnkey solutions validated by 19 years of export excellence:

- Certification Assurance: Active ISO 13485:2016 (Certificate #CN-2025-14872), CE under MDR 2017/745 (NB 2797), and FDA Establishment Registration (#100782352). Full documentation portal available upon NDA.

- MOQ Flexibility: Sample orders (1 unit), distributor MOQs (20 units), and OEM programs (50 units) with tiered pricing. No hidden tooling fees for Carejoy-standard models.

- DDP-Optimized Logistics: Direct factory shipping from Baoshan District (Shanghai Port proximity) with all-inclusive DDP quotes to 85+ countries. Real-time shipment tracking via Carejoy Logistics Dashboard.

- 2026-Ready Product Line: Factory-direct leaf dental printers (Carejoy LeafScan™ series) with integrated AI calibration – compatible with major CAD/CAM ecosystems.

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 Technical Support)

Factory Address: No. 1888, Hengfeng Road, Baoshan District, Shanghai, China

Final Recommendation: In 2026’s complex regulatory environment, prioritize suppliers with demonstrable manufacturing expertise over trading companies. Request factory audit reports and demand-side references before commitment. Shanghai Carejoy’s vertical integration (from R&D to export) provides the transparency required for compliant, efficient dental equipment sourcing.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: Leaf Dental 3D Printer Series – Model LDP-2600

Frequently Asked Questions (FAQ): Purchasing a Leaf Dental Printer in 2026

| Question | Answer |

|---|---|

| 1. What voltage requirements does the Leaf Dental Printer (LDP-2600) support, and is it compatible with global electrical standards? | The Leaf Dental Printer LDP-2600 operates on a dual-voltage input of 100–240V AC, 50/60 Hz, making it suitable for use in North America, Europe, Asia, and other global markets. It comes with an IEC 60320-C13 power inlet and includes region-specific power cords based on destination. For clinics in regions with unstable power supply, we recommend integration with a medical-grade UPS (Uninterruptible Power Supply) to ensure print integrity and equipment longevity. |

| 2. Are spare parts for the Leaf Dental Printer readily available, and what is the typical lead time for critical components? | Yes, all critical spare parts—including the resin vat, build platform, UV laser module, and motion control system—are available through authorized Leaf Dental distributors and regional service hubs. As of 2026, Leaf maintains a global inventory network with a standard lead time of 3–5 business days for in-stock components within major markets (NA, EU, APAC). Distributors receive quarterly spare parts catalog updates and volume discount programs. Long-life components are designed for 1,500+ print cycles, minimizing replacement frequency. |

| 3. What does the installation process involve, and is on-site technician support provided? | Installation of the Leaf Dental Printer includes unboxing, leveling, software calibration, network integration, and operator training. Certified Leaf technicians provide on-site setup for all first-time installations at no additional cost when purchased through authorized channels. Remote pre-installation assessment is conducted to verify power, ventilation, and workspace requirements. The full installation and validation process typically takes 3–4 hours. Post-installation, a digital commissioning certificate is issued for compliance tracking. |

| 4. What is the warranty coverage for the Leaf Dental Printer, and are there extended service options? | The LDP-2600 comes with a comprehensive 3-year limited warranty covering parts, labor, and the UV laser diode—key differentiator in the 2026 market. The warranty includes annual preventive maintenance visits and remote diagnostics. Extended Service Agreements (ESA) are available for up to 5 years, offering priority response (within 24 business hours), predictive maintenance alerts via IoT integration, and discounted consumables. Warranty is valid only with use of genuine Leaf resins and scheduled maintenance logs. |

| 5. How does Leaf ensure long-term serviceability and technical support for printers deployed in 2026? | Leaf Dental guarantees parts and technical support for all LDP-2600 units for a minimum of 7 years post-discontinuation. The 2026 model features modular design architecture for easy upgrades and repairs. All devices are IoT-enabled, allowing over-the-air (OTA) firmware updates and real-time performance monitoring. Distributors have access to a dedicated support portal with diagnostic tools, training modules, and spare parts ordering. Leaf also offers a trade-in program in 2029 for seamless migration to next-generation models. |

Need a Quote for Leaf Dental Printer?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160