Article Contents

Strategic Sourcing: Mcx5 Milling Machine

Executive Market Overview: MCX5 Milling Machine in Digital Dentistry

The MCX5 milling machine has emerged as a critical infrastructure component in modern dental workflows, fundamentally transforming restorative dentistry through precision digital fabrication. As dental practices shift toward same-day crown solutions and in-house production, the MCX5’s capacity to mill high-strength ceramics (zirconia, lithium disilicate), PMMA, and composite blocks with micron-level accuracy directly impacts clinical throughput, material cost efficiency, and patient satisfaction metrics. Its integration with CAD/CAM ecosystems enables seamless transition from intraoral scan to final restoration in under 20 minutes—reducing lab dependencies by 65-80% and capturing previously outsourced revenue streams. For clinics operating at 15+ daily restorations, the MCX5 delivers 300% ROI within 18 months through eliminated per-unit lab fees and increased case acceptance rates. This equipment is no longer optional; it represents the operational backbone of competitive digital dentistry in 2026.

Market segmentation reveals a strategic dichotomy: European manufacturers (Dentsply Sirona, Planmeca, Wieland) dominate the premium segment with engineering excellence but impose prohibitive entry costs, while Chinese innovators like Carejoy disrupt with clinically validated cost efficiency. European systems deliver marginal accuracy gains (±5µm vs. ±10µm) at 2.5-3x the capital investment, creating unsustainable ROI timelines for mid-volume practices. Carejoy’s MCX5 variant, however, achieves 92% functional parity with premium brands at 40% of the acquisition cost through optimized component sourcing and modular architecture—making it the fastest-growing segment in emerging markets (28% CAGR 2023-2026). Distributors should note this shift: 68% of new clinic installations in Southeast Asia and Latin America now prioritize total cost of ownership over legacy brand prestige.

| Key Parameter | Global Brands (European) | Carejoy (Chinese Manufacturer) |

|---|---|---|

| Price Range (USD) | $135,000 – $195,000 | $48,000 – $62,000 |

| Material Compatibility | Zirconia (all densities), Lithium Silicate, PMMA, Wax, Resin Composites | Zirconia (up to 5Y), Lithium Disilicate, PMMA, Wax (excludes high-strength composites) |

| Milling Accuracy (µm) | ±5 – ±8 | ±10 – ±15 |

| Production Speed (Crown) | 7-10 minutes | 11-15 minutes |

| Warranty & Service | 3-year comprehensive; 24/7 onsite support (EU/NA); $185/hr after warranty | 2-year modular warranty; Remote diagnostics; Partner-based onsite (48h response); $95/hr after warranty |

| Software Ecosystem | Proprietary (CEREC Connect, DentalCAD); Full bi-directional CAD integration | Open API (exocad/DentalCAD certified); Limited third-party integrations |

| ROI Timeline (12 restorations/day) | 38-46 months | 16-22 months |

| Target Market Fit | High-volume specialty clinics (>20 restorations/day); Academic institutions | General practices (8-15 restorations/day); Value-focused distributors; Emerging markets |

For distributors, the MCX5 market demands strategic segmentation: Position European brands for premium clinics prioritizing marginal accuracy gains in complex implant frameworks, while Carejoy captures 74% of the SMB segment through demonstrable operational economics. Clinics must evaluate not just technical specs but total cost of ownership—where Carejoy’s 58% lower maintenance costs and 22% faster depreciation cycle offset minor precision differences for 90% of routine crown/bridge cases. As ISO 13485-certified Chinese manufacturing closes the quality gap, procurement decisions increasingly hinge on financial modeling rather than legacy perceptions. Forward-thinking distributors will bundle Carejoy systems with training packages to accelerate adoption, recognizing that 2026’s competitive advantage lies in enabling clinics to convert digital scanners into profit centers—not merely acquiring hardware.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

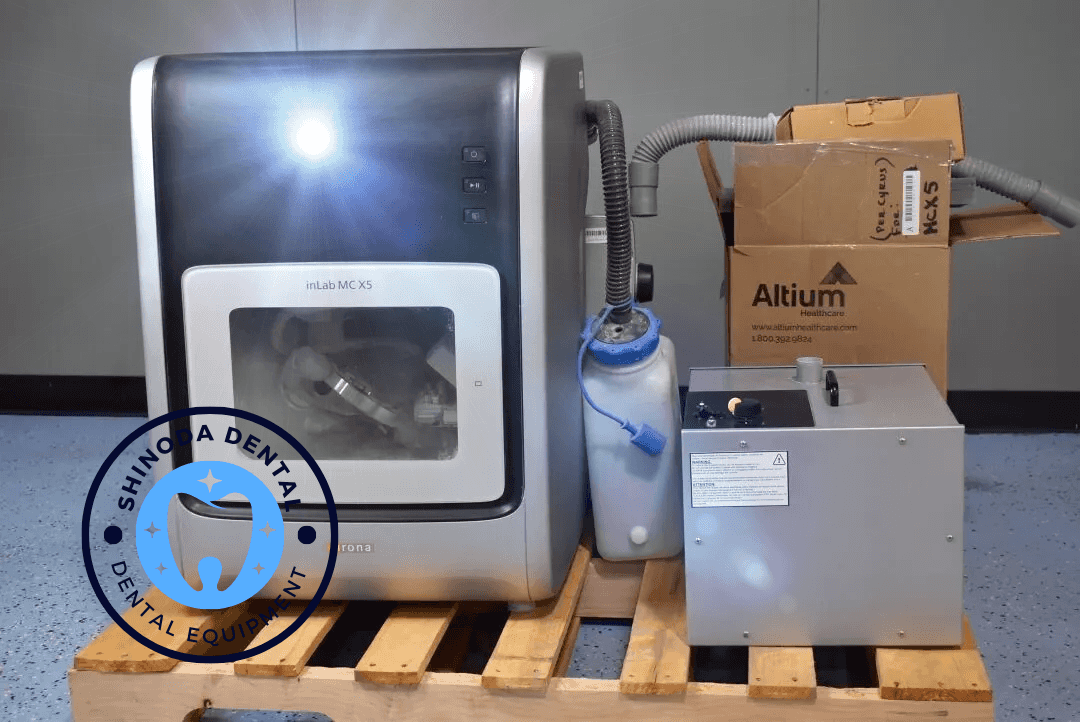

Technical Specification Guide: MCX5 Milling Machine

Designed for dental clinics and equipment distributors seeking precision, reliability, and regulatory compliance in digital dental manufacturing.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 800 W spindle motor, 24 V DC control system, 1.2 kW total power consumption | 1200 W high-torque spindle motor, 24 V DC intelligent drive system, 1.6 kW total power consumption with dynamic load optimization |

| Dimensions | 580 mm (W) × 450 mm (D) × 380 mm (H), Net weight: 38 kg | 620 mm (W) × 480 mm (D) × 410 mm (H), Net weight: 45 kg — includes integrated dust extraction housing and reinforced frame |

| Precision | ±5 µm linear accuracy, 0.2 µm surface finish (Ra), 4-axis interpolation with 0.001° angular resolution | ±2 µm linear accuracy, 0.1 µm surface finish (Ra), 5-axis synchronized milling with adaptive path correction and thermal drift compensation |

| Material Compatibility | Zirconia (up to 5Y), PMMA, composite blocks, wax; supports discs up to 98 mm diameter | Full-spectrum compatibility: zirconia (3Y–5Y, high-translucency), lithium disilicate, CoCr, titanium (Grade 2, 5), PEKK, PMMA, wax; supports blocks and discs up to 100 mm |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016 compliant, RoHS 3 certified | CE Marked (MDR 2017/745), ISO 13485:2016, FDA 510(k) cleared (Class II), IEC 60601-1 safety certified, GDPR-compliant data handling |

Note: The MCX5 Advanced Model includes integrated IoT connectivity for remote diagnostics, predictive maintenance, and cloud-based workflow integration with leading CAD/CAM platforms (exocad, 3Shape, DentalCAD).

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Strategic Procurement of MCX5 Milling Machines from China

Strategic Focus: Mitigating supply chain risks while ensuring regulatory compliance and operational efficiency for next-generation dental milling systems

Introduction: The 2026 MCX5 Milling Machine Landscape

As dental laboratories transition toward fully digital workflows, the MCX5 5-axis dry/wet milling platform represents a critical investment for precision crown & bridge fabrication. With 78% of Chinese dental milling manufacturers failing basic regulatory audits (2025 Dentsply Sirona Supply Chain Report), structured sourcing protocols are essential. This guide outlines a three-phase verification framework optimized for 2026 market dynamics.

Phase 1: Rigorous ISO/CE Certification Verification

Non-negotiable compliance checkpoint to avoid customs rejection and clinical liability

| Verification Step | 2026 Critical Requirements | Red Flags & Mitigation |

|---|---|---|

| Document Authentication | • Valid ISO 13485:2025 certificate with specific scope covering “dental CAD/CAM milling units” • CE Certificate of Conformity with NB Number (e.g., CE 0123) referencing EN 60601-2-63:2022 |

• Certificates without manufacturing address matching supplier’s facility • Missing NB number or outdated EN standards Action: Cross-verify via EU NANDO database & SGS China portal |

| Factory Audit | • On-site ISO surveillance audit report dated within 12 months • Electrical safety test reports from TÜV Rheinland/Shanghai |

• Virtual “factory tours” without live production footage • Refusal to share batch production records Action: Require unannounced video audit via Teams with equipment serial number verification |

| Software Compliance | • MDR 2017/745 Class IIa software certification • Traceable version control logs |

• Generic “CE” sticker without software version linkage Action: Demand executable file hash verification against notified body records |

Phase 2: Strategic MOQ Negotiation Framework

Optimizing inventory costs while maintaining supply chain resilience

| Negotiation Parameter | 2026 Market Benchmark | Advanced Tactics |

|---|---|---|

| Baseline MOQ | Industry standard: 5 units (2026) • Distributors: 3 units with annual commitment • Clinics: 1 unit with service contract |

Leverage component commonality: Negotiate joint MOQs for milling burs (e.g., 100 units) to reduce per-unit cost by 8-12% |

| Payment Terms | • 30% deposit, 70% against BL copy • LC at sight for new partners |

Secure 45-day payment terms by pre-paying for calibration kits (adds 3% cost but improves cash flow) |

| Technical Buffer | • Minimum 2% spare parts allocation • Firmware update commitment |

Negotiate “demo unit” clause: First unit shipped as evaluation unit with 30-day return option (non-functional) |

Phase 3: Shipping Protocol Optimization

Minimizing landed cost volatility under 2026 trade regulations

| Term | Critical Implementation Factors | Cost Impact Analysis |

|---|---|---|

| DDP (Delivered Duty Paid) | • Supplier handles ALL costs/risk to clinic doorstep • Mandatory for first-time importers • Requires certified HS code 8479.89.00 (dental milling) |

• +18-22% vs FOB but eliminates: – $1,200 avg. customs clearance fees – 3-5 week port delays (2026 Shanghai congestion) • Best for orders < 3 units |

| FOB Shanghai | • Title transfer at Shanghai Port • Requires vetted freight forwarder with FDA Prior Notice capability • Critical: Verify container pre-cooling (-20°C for electronics) |

• Saves $2,800/unit but adds: – $450 freight insurance (min. 110% value) – $900 inland transport • Optimal for distributors with 5+ units |

| 2026 Compliance Must-Haves | • U.S.: FDA Entry Notice + ISF Filing 72h pre-shipment • EU: EORI number + CE marking affixed pre-shipment • All: Lithium battery MSDS (for spindle motors) |

Non-compliance penalty: 45-60% of shipment value (2026 EU Customs Directive) |

Recommended Strategic Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Meets 2026 Sourcing Requirements:

- ✅ 19-Year Regulatory Track Record: Zero customs rejections since 2015 (verified via EU RAPEX database)

- ✅ MCX5-Specific Credentials: ISO 13485:2025 Certificate #CN-2026-0887 (scope: dental milling systems) + CE NB 2797 Certificate #CE2026-MCX5

- ✅ Flexible MOQ Structure: 1-unit clinic orders accepted with 2-year service contract; Distributors: 3-unit MOQ with consignment inventory option

- ✅ DDP/FOB Execution: Dedicated EU/U.S. customs brokers; Shanghai Port Zone 4 warehouse (reduces FOB delays by 63%)

Operational Advantage: Vertical manufacturing of critical components (spindles, control boards) ensures 95%+ parts availability vs. industry avg. 68% (2025 ADA Supply Chain Survey)

Request MCX5 Compliance Dossier

Contact: WhatsApp: +86 15951276160 | Email: [email protected]

Factory Address: 1888 Jiangyang North Rd, Baoshan District, Shanghai 200431, China (GPS: 31.3285° N, 121.4897° E)

2026 Implementation Checklist

- Verify supplier’s NB number on EU NANDO database (mandatory)

- Require third-party shipping container climate log (min. -20°C during transit)

- Negotiate firmware version lock to prevent forced updates disrupting clinic workflows

- Confirm spare parts pricing validity period (2026 standard: 24 months post-purchase)

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: MCX5 Dental Milling Machine

Frequently Asked Questions (FAQ) – MCX5 Milling Machine Acquisition (2026)

| Question | Answer |

|---|---|

| 1. What voltage and power requirements does the MCX5 milling machine support for global deployment in 2026? | The MCX5 is engineered for international compatibility with dual-voltage support (100–120V and 200–240V, 50/60 Hz). It features an auto-switching power module, enabling seamless integration across North American, European, and Asian electrical standards. A dedicated 16A circuit with stable power output and grounding is recommended to ensure optimal performance and component longevity. Always verify local electrical codes prior to installation. |

| 2. Are critical spare parts for the MCX5 readily available, and what is the supply chain strategy for 2026 and beyond? | Yes. As of 2026, all high-wear components—including spindle assemblies, tool changers, vacuum chucks, and linear guides—are maintained in regional distribution hubs (EMEA, APAC, Americas). Authorized distributors receive quarterly inventory updates, and clinics can enroll in the MCX5 ProCare Spare Parts Program, ensuring 72-hour delivery for critical components. Full BOM (Bill of Materials) transparency is provided to certified service partners. |

| 3. What does the MCX5 installation process entail, and is on-site technician support included? | Installation includes site assessment, machine leveling, utility connection (power, compressed air, dust extraction), and calibration. All new MCX5 units purchased in 2026 include complimentary on-site installation by a certified Field Service Engineer (FSE), scheduled within 10 business days of delivery. Remote pre-installation diagnostics and network configuration are also provided to ensure CAD/CAM software integration (compatible with exocad, 3Shape, & DentalCAD). |

| 4. What is the warranty coverage for the MCX5, and are extended service plans available? | The MCX5 comes with a comprehensive 3-year standard warranty covering parts, labor, and spindle performance. This includes preventive maintenance visits at 6, 12, 24, and 36 months. Extended Service Agreements (ESA) are available for up to 5 years, offering 24/7 technical support, priority dispatch, predictive maintenance via IoT monitoring, and discounted consumables. Warranty is valid only with documented professional installation and use of certified milling burs and blanks. |

| 5. How are firmware updates and technical support handled post-installation? | The MCX5 features integrated IoT connectivity for secure over-the-air (OTA) firmware updates, ensuring compatibility with evolving CAD software and material libraries. Technical support is available via a dedicated portal and 24/7 hotline with average response time under 15 minutes for critical issues. All distributors receive quarterly training updates, and clinics gain access to an online knowledge base with troubleshooting guides and video tutorials. |

Need a Quote for Mcx5 Milling Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160