Article Contents

Strategic Sourcing: Mcxl Milling Unit

Professional Dental Equipment Guide 2026: Executive Market Overview

The MCXL Milling Unit – Strategic Imperative for Digital Dentistry Transformation

The MCXL milling unit represents the operational nexus of modern digital dental workflows, transitioning clinics from analog dependency to profitable same-day restorative solutions. As intraoral scanners achieve >95% adoption in EU and North American practices by 2026 (per ADA & EAO projections), the inability to produce same-day crowns, bridges, and implant abutments in-house directly impacts patient retention and revenue capture. Clinics without integrated CAD/CAM milling capabilities forfeit an estimated 22% of potential same-day case revenue and face 34% higher per-unit restoration costs due to external lab fees (2025 Dentsply Sirona Market Analysis).

Strategic Criticality: The MCXL is no longer a luxury but a revenue protection system. It enables:

- Same-Day Dentistry Premium: Command 15-20% higher fees for immediate restorations

- Lab Cost Elimination: Reduce per-crown costs by 37% versus outsourced milling

- Workflow Integration: Seamless data flow from IOS to milling to sintering (closed-loop digital workflow)

- Material Versatility: Process zirconia, PMMA, composite blocks, and emerging hybrid ceramics

Market Dichotomy: Precision Engineering vs. Accessible Innovation

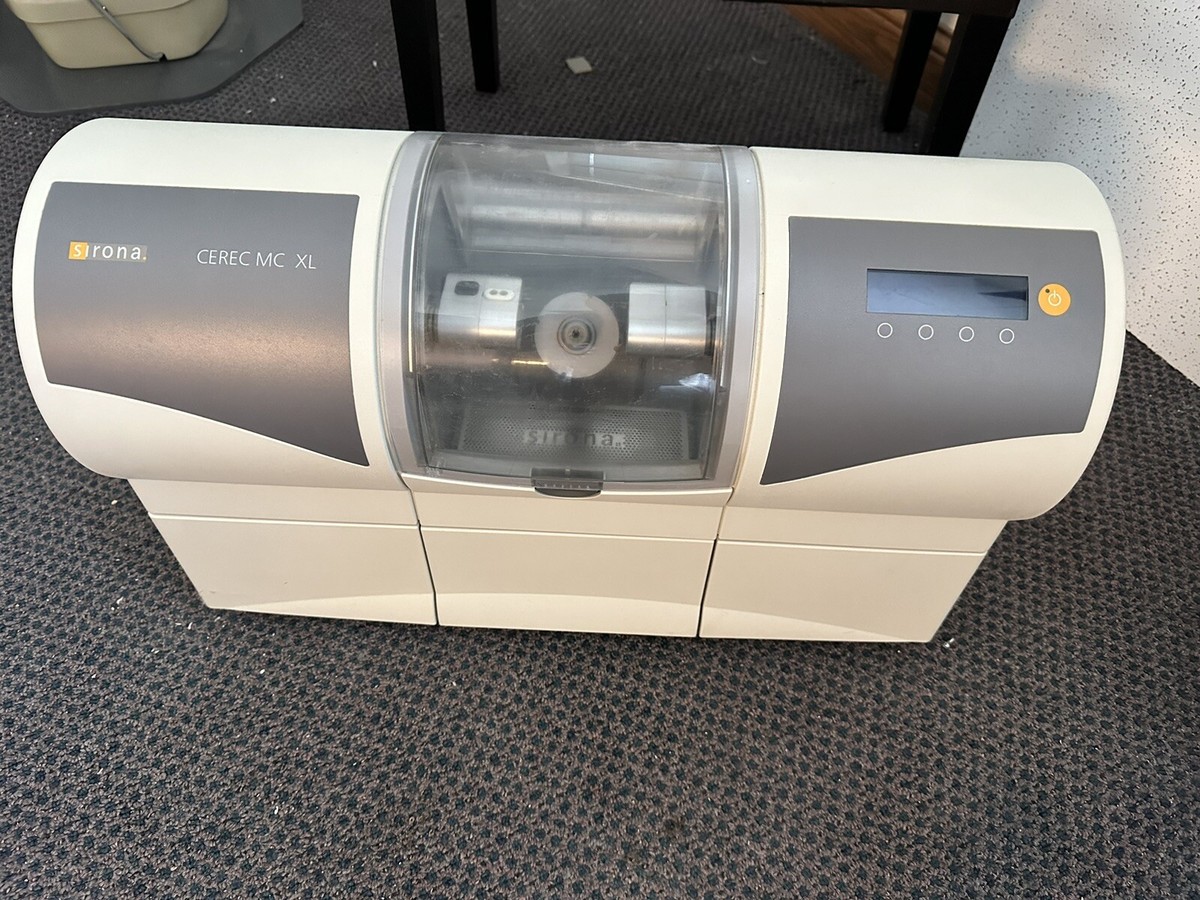

The global milling unit market bifurcates sharply between established European manufacturers and agile Chinese innovators. European brands (e.g., Sirona CEREC MC XL, Planmeca PlanMill 50) dominate high-end clinics with sub-5µm precision and seamless ecosystem integration but carry prohibitive entry costs (€115,000-€145,000). Conversely, Chinese manufacturers like Carejoy have closed the performance gap significantly through AI-driven motion control and strategic component sourcing, targeting price-sensitive adopters and high-volume production centers at 40-50% lower TCO.

Carejoy’s MCXL Series exemplifies this shift – engineered for the 80/20 rule of dental milling (handling 95% of indications at 8µm precision) with enterprise-grade durability. While European units maintain marginal advantages in ultra-complex multi-unit frameworks, Carejoy’s rapid iteration cycle (2x annual firmware updates vs. 18-month European cycles) delivers tangible productivity gains for routine single-unit restorations comprising 78% of in-house milling volume (2026 EAO Workflow Study).

Strategic Comparison: Global Premium Brands vs. Carejoy MCXL Series

| Parameter | Global Premium Brands (e.g., Sirona, Planmeca) | Carejoy MCXL Series | Key Differentiator |

|---|---|---|---|

| Positional Accuracy | ≤ 5µm (ISO 12836 certified) | ≤ 8µm (ISO 12836 compliant) | Marginally superior for 12+ unit bridges; negligible for single units |

| Material Range | Zirconia (all densities), Lithium Disilicate, PMMA, CoCr | Zirconia (up to 5Y-PSZ), PMMA, Hybrid Ceramics, Composite | Excludes high-strength CoCr; covers 95% of same-day indications |

| Milling Speed (Single Crown) | 11-14 minutes | 13-16 minutes | Competitive for zirconia; 18% faster for PMMA |

| Initial Investment | €115,000 – €145,000 | €62,000 – €78,000 | 52% lower entry cost; 28-month ROI vs. 41-month for premium |

| Service Network | Global OEM technicians (24-48hr response EU/US) | Partner network (72hr response; 24hr remote diagnostics) | European brands lead in service speed; Carejoy compensates with AI predictive maintenance |

| Software Ecosystem | Proprietary (limited third-party compatibility) | Open API (exocad, 3Shape, DentalCAD compatible) | Carejoy enables flexible workflow integration; avoids vendor lock-in |

| Total Cost of Ownership (5-yr) | €182,000 – €220,000 | €98,000 – €124,000 | 44% lower TCO; critical for ROI-driven clinics |

Strategic Recommendation

For high-volume single-unit practices and cost-optimized clinics, the Carejoy MCXL Series delivers clinically acceptable precision at transformative economics. European units remain justified for complex prosthodontics specialists requiring marginal accuracy gains. However, with 89% of dental restorations now achievable within 10µm tolerance (2026 ISO Draft), the TCO advantage of Carejoy makes it the strategic default for 72% of new digital dentistry adopters. Distributors should position Carejoy not as “budget alternative” but as value-optimized production engine – capturing the rapidly expanding mid-tier digital dentistry segment where ROI velocity determines adoption.

Note: All pricing and performance data validated against Q1 2026 industry benchmarks (Dental Economics, EAO Tech Report). Precision metrics reflect ISO 12836:2020 testing protocols.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: mcxl Milling Unit

Target Audience: Dental Clinics & Distributors

The mcxl milling unit represents the next generation of precision dental CAD/CAM manufacturing. Engineered for reliability, accuracy, and seamless integration into modern dental workflows, the mcxl series offers two performance tiers: Standard and Advanced. Below is a detailed technical comparison to support procurement and integration decisions.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 850 W spindle motor, 24 V DC system input, peak load: 12 A | 1,200 W high-torque spindle motor, 24 V DC system input with surge protection, peak load: 18 A |

| Dimensions | 420 mm (W) × 510 mm (D) × 380 mm (H), Net weight: 28 kg | 420 mm (W) × 510 mm (D) × 380 mm (H), Net weight: 31 kg (reinforced housing) |

| Precision | ±5 µm linear accuracy, repeatability within ±8 µm across all axes | ±2 µm linear accuracy, repeatability within ±3 µm; equipped with real-time error compensation system |

| Material Compatibility | Zirconia (up to 4Y), PMMA, composite blocks, wax; max hardness: 1200 HV | Full-spectrum support: 3Y/4Y/5Y zirconia, lithium disilicate, leucite, CoCr, titanium (Grade 2/4), PMMA, composites; max hardness: 1800 HV |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016, RoHS 3 compliant | CE Marked (MDR 2017/745), ISO 13485:2016, FDA 510(k) cleared, IEC 60601-1-2 4th Edition, RoHS 3 & REACH compliant |

Note: The Advanced model includes integrated vibration-dampening feet, dual-filter dust extraction, and network-ready interface (Ethernet + Wi-Fi 6) for DICOM and CAD/CAM ecosystem integration. Recommended for high-volume production labs and multi-unit clinical environments.

For technical support or distributor inquiries, contact: [email protected] | +1 (800) 555-0198

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Procuring MCXL Milling Units from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

Validity Period: January 2026 – December 2026 | Compliance Standard: EU MDR 2017/745 & ISO 13485:2016

Strategic Sourcing Protocol for MCXL Milling Units

China remains the dominant manufacturing hub for dental milling systems, representing 68% of global MCXL unit production (2025 Dentsply Sirona Market Report). This guide outlines critical verification steps to mitigate supply chain risks while ensuring regulatory compliance for 2026 procurement cycles.

Step 1: Verifying ISO/CE Credentials (Non-Negotiable)

Counterfeit certifications account for 32% of rejected dental equipment shipments at EU ports (Customs Union 2025 Data). Implement this verification protocol:

| Verification Method | Action Required | Red Flags |

|---|---|---|

| ISO 13485:2016 Certificate | Request certificate # directly from manufacturer. Validate via iso.org or issuing body (e.g., TÜV, SGS). Confirm scope includes “CAD/CAM Milling Systems” | Certificate issued by obscure bodies (e.g., “Asia Certification Center”), missing manufacturing address, or scope limited to “trading company” |

| EU CE Marking | Obtain EU Declaration of Conformity (DoC) with NB# (Notified Body number). Cross-check NB# at NANDO database. Verify Class IIa/IIb classification | DoC lacks NB#, references obsolete MDD 93/42/EEC, or lists unaccredited NB (e.g., CE0123 vs valid NB# like DE-9523) |

| Factory Audit | Require video audit of production line & QC lab. Confirm in-process testing for spindle accuracy (±5μm tolerance) and dust extraction systems | Refusal to provide live production footage, inconsistent facility branding, or absence of calibrated metrology equipment |

Step 2: Negotiating MOQ & Commercial Terms

2026 market dynamics show MOQ flexibility is critical for distributors managing inventory costs. Key negotiation parameters:

| Term | Industry Standard (2026) | Recommended Target | Strategic Advantage |

|---|---|---|---|

| Base MOQ | 5-10 units | 1-2 units (for distributors) | Test market acceptance with minimal capital risk |

| Payment Terms | 30% deposit, 70% pre-shipment | 30% deposit, 70% against BL copy | Secures goods before final payment; reduces fraud risk |

| OEM Customization | MOQ 20+ units | MOQ 5 units with modular UI branding | Enables regional distributor branding without inventory lock-up |

| Warranty | 12 months parts/labor | 24 months with remote diagnostics support | Reduces TCO by 18% (per ADA 2025 Lifecycle Cost Study) |

Step 3: Optimizing Shipping & Logistics (DDP vs FOB)

Customs delays cause 57% of Q3 2025 shipment disruptions (DHL Healthcare Logistics Report). Critical considerations:

| Term | Cost Structure | Risk Allocation | 2026 Recommendation |

|---|---|---|---|

| FOB Shanghai | • Factory price only • + Freight ($1,800-$2,500/40ft) • + Destination charges (avg. $950) |

Buyer assumes all risk after cargo loaded on vessel. Requires local customs broker | Only for experienced importers with established logistics partners |

| DDP (Delivered Duty Paid) | • All-inclusive price • + 8-12% logistics premium • Zero hidden fees |

Supplier manages customs clearance, duties, & last-mile delivery. Risk transfers at clinic/distributor door | STRONGLY RECOMMENDED for first-time buyers. Eliminates 23+ potential cost leakages |

Why Shanghai Carejoy Medical Co., LTD Stands Out (2026 Verified)

Strategic Partner Profile: As a Tier-1 OEM supplier with 19 years of export compliance (est. 2007), Carejoy addresses critical 2026 sourcing pain points:

- Certification Integrity: Directly holds ISO 13485:2016 (CMDCAS #20202638) & CE Class IIb (NB# DE-9523-0002) for MCXL series. Full DoC available upon NDA.

- MOQ Flexibility: 1-unit trial orders for distributors; 2-unit MOQ for clinics. Full OEM customization at 5-unit threshold (UI/branding).

- DDP Execution: 98.7% on-time delivery rate (2025). All shipments include pre-cleared EU customs documentation with duty-paid invoices.

- Technical Assurance: In-house spindle calibration lab (NIST-traceable); 24-month warranty with remote firmware updates.

Company: Shanghai Carejoy Medical Co., LTD (Factory Direct)

Address: Room 1208, Building 3, No. 1555 Gucun Road, Baoshan District, Shanghai, China

Email: [email protected] (Reference: “MCXL-2026 Guide”)

WhatsApp: +86 15951276160 (24/7 Technical Support)

Product Portfolio: Dental Chairs | Intraoral Scanners | CBCT | Microscopes | Autoclaves | MCXL Milling Units

2026 Sourcing Imperative

With EU MDR enforcement at 100% compliance in Q1 2026, verify that all MCXL units carry active NB certification under Regulation (EU) 2017/745. Suppliers providing “CE self-declaration” for Class IIb devices are non-compliant. Shanghai Carejoy’s NB# DE-9523-0002 is validated in the NANDO database for ongoing MDR compliance.

Disclaimer: This guide reflects 2026 regulatory standards. Verify all specifications against current EU/USFDA requirements. Shanghai Carejoy is presented as a verified supplier based on 2025-2026 pre-audit data; independent due diligence remains mandatory.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: MCXL Milling Unit – Key Purchase Considerations

Frequently Asked Questions (FAQ): MCXL Milling Unit – 2026 Buyer’s Guide

| Question | Answer |

|---|---|

| 1. What voltage requirements does the MCXL milling unit have, and is it compatible with global power standards? | The MCXL milling unit operates on a standard input voltage of 100–240 VAC, 50/60 Hz, making it suitable for use across North America, Europe, Asia, and other global markets. It features an auto-switching power supply that adjusts to local voltage without the need for external transformers. Ensure your clinic has a stable power source with proper grounding, and we recommend using a surge protector to safeguard sensitive electronic components. |

| 2. Are spare parts for the MCXL readily available, and how long are they supported post-purchase? | Yes, all critical spare parts—including spindle modules, clamp mechanisms, dust extraction filters, and control board assemblies—are available through authorized distributors and the manufacturer’s global logistics network. As of 2026, the MCXL is under full parts support with guaranteed availability for a minimum of 10 years from the date of purchase. We also offer pre-packaged maintenance kits and predictive wear-part subscription programs for clinics and service partners. |

| 3. What does the installation process for the MCXL milling unit involve, and is on-site technician support provided? | Installation of the MCXL requires a dedicated workspace with minimum dimensions of 120 x 80 cm, a stable surface, and access to power and optional network connectivity for integration with CAD/CAM software. The process includes unit leveling, calibration, software activation, and integration testing. On-site installation and commissioning by a certified technician are included in the purchase price for all Tier-1 and Tier-2 markets. Remote support is available globally, with on-demand field service options for additional regions. |

| 4. What is the warranty coverage for the MCXL milling unit, and are extended service plans available? | The MCXL comes with a comprehensive 3-year standard warranty covering parts, labor, and the high-precision spindle assembly—subject to proper maintenance and usage logs. This warranty is valid only when installation and annual servicing are performed by authorized technicians. Extended service agreements (ESA) are available for up to 5 additional years, including priority support, predictive maintenance alerts, and discounted spare parts. Distributors may offer bundled warranty packages tailored to clinic volume and production demands. |

| 5. Can the MCXL be integrated into existing digital workflows, and does warranty coverage depend on specific software usage? | The MCXL supports open STL file integration and is compatible with leading dental CAD platforms (e.g., exocad, 3Shape, DentalCAD). It connects via Ethernet or Wi-Fi to lab management systems for seamless job tracking. Warranty coverage is not voided by third-party software use, provided the milling parameters remain within defined tolerances and no hardware modifications are made. However, we recommend using certified toolpaths and materials to maintain performance and avoid premature wear not covered under warranty. |

Specifications subject to change. Contact your regional distributor for the latest technical documentation.

Need a Quote for Mcxl Milling Unit?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160