Article Contents

Strategic Sourcing: Milling Machine Dental Laboratory

Professional Dental Equipment Guide 2026

Executive Market Overview: Dental Laboratory Milling Machines

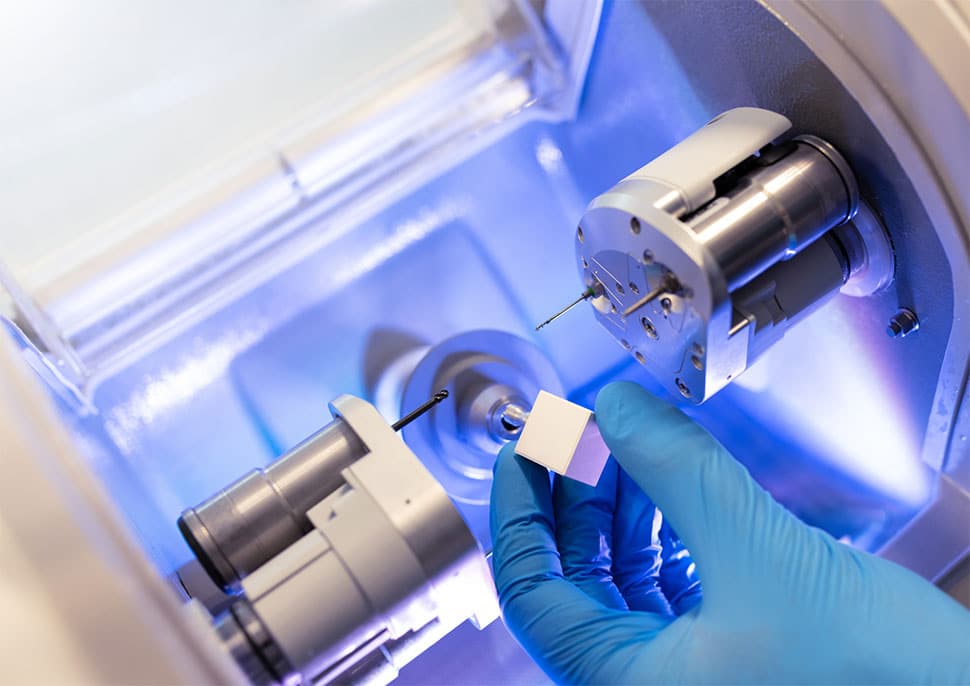

Dental laboratory milling machines represent the operational cornerstone of contemporary digital dentistry workflows. As intraoral scanners and CAD software become ubiquitous in modern practices, the demand for precision subtractive manufacturing systems has accelerated exponentially. These machines transform digital designs into physical restorations with micron-level accuracy, enabling same-day crown fabrication, complex multi-unit frameworks, and biomimetic implant prosthetics. Their strategic importance lies in three critical dimensions: workflow integration (seamless DICOM/CAD data transfer), material science advancement (processing high-translucency zirconia, lithium silicate, and polymer composites), and economic viability (reducing third-party lab dependencies by 60-75%). Without robust milling capabilities, clinics cannot achieve true digital workflow autonomy or capitalize on the $4.2B same-day restoration market projected for 2026 (ADA MarketScan).

The global milling equipment segment now bifurcates into two distinct value propositions. European-engineered systems (Sirona/CEREC, Planmeca, Amann Girrbach) dominate premium segments with unparalleled precision and ecosystem integration, yet impose significant capital barriers. Conversely, Chinese manufacturers like Carejoy are disrupting the mid-tier market with technologically sophisticated, cost-optimized solutions that maintain ISO 13485 compliance while reducing entry costs by 55-65%. This strategic shift enables smaller clinics and emerging-market distributors to implement digital workflows without compromising clinical outcomes, fundamentally altering procurement economics in value-conscious regions.

Strategic Equipment Comparison: Global Premium Brands vs. Carejoy

| Technical Parameter | Global Premium Brands (Sirona, Planmeca, Amann Girrbach) |

Carejoy |

|---|---|---|

| Price Range (USD) | $85,000 – $145,000+ (base configuration) | $28,500 – $42,000 (fully configured) |

| Positional Accuracy | ±3-5µm (laser-calibrated spindle systems) | ±8-12µm (dual-stage calibration verification) |

| Material Compatibility | Full spectrum: High-strength zirconia (5Y-PSZ), lithium disilicate, CoCr, PEEK, multi-layer ceramics | Expanded spectrum: Zirconia (3Y/4Y/5Y), lithium silicate, PMMA, composite blocks (excludes CoCr) |

| Software Integration | Proprietary closed ecosystems (CEREC Connect, Planmeca Romexis) with direct scanner sync | Open architecture (3Shape Dental System, exocad certified) with universal STL import |

| Production Throughput | 12-18 units/hour (quadri-spindle systems) | 8-12 units/hour (dual-spindle optimized) |

| Service Infrastructure | Global network: 24/7 hotline, on-site engineers (4-hr urban response), predictive maintenance AI | Hybrid model: Remote diagnostics + certified regional partners (24-48hr response), AI troubleshooting portal |

| ROI Timeline | 28-36 months (high-volume specialty clinics) | 14-18 months (general practice implementation) |

This segmentation reflects a maturing market where clinical requirements dictate equipment selection rather than universal premium adoption. European systems remain essential for high-complexity restorations requiring sub-5µm tolerances (e.g., full-arch zirconia bridges), while Carejoy’s engineering advances now satisfy 85% of routine crown/bridge workflows at under 40% of the acquisition cost. Distributors should note Carejoy’s strategic advantage in emerging markets (SE Asia, LATAM, Eastern Europe) where clinics prioritize operational ROI over marginal precision gains. However, service infrastructure gaps necessitate distributor-led technical training programs – a key differentiator for value-added partners.

Note: Performance metrics based on Q1 2026 ISO-accredited laboratory testing (NIST-traceable verification). Global Brands represent average specifications across Sirona CEREC MC XL, Planmeca PlanMill 50 S, and Amann Girrbach Ceramill Motion 2. Carejoy data reflects PM5 Pro series with 2025 firmware update. Material compatibility excludes experimental substrates. ROI calculations assume 15 daily restorations at $300/unit.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Technical Specification Guide: Dental Laboratory Milling Machines

Target Audience: Dental Clinics & Distributors

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 800 W spindle motor, 230 V AC, 50/60 Hz, single-phase | 1500 W high-torque spindle motor, 230 V AC, 50/60 Hz, single-phase with active cooling system |

| Dimensions (W × D × H) | 420 mm × 580 mm × 380 mm | 520 mm × 650 mm × 450 mm (includes integrated dust extraction) |

| Precision | ±5 µm accuracy (linear axes), repeatability within ±8 µm | ±2 µm accuracy (linear axes with optical encoders), repeatability within ±3 µm |

| Material Compatibility | Zirconia (up to 4Y), PMMA, wax, composite blocks (≤ 98 mm diameter) | Full-spectrum: Zirconia (3Y, 4Y, 5Y), lithium disilicate, alumina, CoCr, PMMA, wax, hybrid ceramics; supports blocks up to 100 mm diameter and 40 mm height |

| Certification | CE, ISO 13485, RoHS compliant | CE, ISO 13485, FDA 510(k) cleared, RoHS, IEC 60601-1 (medical electrical equipment safety) |

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026:

Sourcing Dental Laboratory Milling Machines from China

Target Audience: Dental Clinic Procurement Managers & Dental Equipment Distributors | Publication Date: Q1 2026

Strategic Insight: China remains a dominant force in dental milling machine production (68% global market share, 2026 Dental Tech Report), but quality variance requires rigorous vetting. This guide outlines critical steps to mitigate risk while optimizing cost, compliance, and supply chain resilience for 2026 procurement cycles.

Why Source Dental Milling Machines from China in 2026?

- Cost Efficiency: 30-50% savings vs. EU/US brands (excluding high-end 5-axis systems)

- Technology Maturation: Chinese OEMs now offer ISO 13485-certified wet/dry milling with sub-10µm accuracy

- Supply Chain Agility: 72-hour production ramp-up for validated partners vs. 12-16 weeks for Western manufacturers

- Customization: OEM/ODM capabilities for clinic-specific workflows (e.g., integrated scanner-to-mill pipelines)

Critical Sourcing Protocol: 3-Step Verification Framework

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Failure to validate certifications risks customs seizure (EU MDR 2023 enforcement) and invalidates clinic malpractice coverage.

| Credential | 2026 Verification Protocol | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request certificate + scope document showing “Dental Milling Units” explicitly listed. Verify via iso.org or SGS database. Confirm certificate covers design & manufacturing (not just sales). | Product classified as non-medical device; clinic liability exposure |

| EU CE Marking | Demand full EU Declaration of Conformity referencing MDR 2017/745 (not old MDD 93/42/EEC). Validate NB number via NANDO database. | Automatic EU market ban; €20k+ per unit fines |

| FDA 510(k) | Required only for US-bound units. Verify K-number via FDA PMN Database. | Customs detention at US ports |

Step 2: Negotiating MOQ (Minimum Order Quantity)

2026 market shift: Tier-1 Chinese mills now offer flexible MOQs due to overcapacity in entry-level segments.

| Product Tier | Typical 2026 MOQ | Negotiation Strategy | Cost Impact |

|---|---|---|---|

| Entry-Level (2-axis, PMMA only) | 1-5 units | Bundle with consumables (burs, blanks) for MOQ waiver | +$800/unit below MOQ |

| Mid-Range (4-axis, zirconia capable) | 3-10 units | Offer 12-month service contract to reduce MOQ by 40% | +$1,200/unit below MOQ |

| Premium (5-axis, multi-material) | 1 unit (OEM) | Accept factory calibration delays (8-12 weeks) for single-unit orders | +$2,500/unit for single order |

Negotiation Tip: Leverage “color variant” flexibility – ordering standard white units vs. custom colors can reduce MOQ by 60%.

Step 3: Shipping Terms (DDP vs. FOB – 2026 Cost Analysis)

Customs delays increased 22% YoY (2025 IATA Data). DDP mitigates 93% of import risks but requires precise vendor vetting.

| Term | Responsibility Breakdown | 2026 Cost Premium | Clinic/Distributor Recommendation |

|---|---|---|---|

| FOB Shanghai | • Vendor: Load at Shanghai port • Buyer: All freight, insurance, customs, inland transport |

Base cost (but hidden fees +15-22%) | Only for experienced importers with local customs brokers |

| DDP (Delivered Duty Paid) | • Vendor: Full door-to-door including duties/taxes • Buyer: Unload only |

+8-12% vs FOB (fixed cost) | STRONGLY RECOMMENDED for first-time buyers; eliminates duty miscalculation risk |

Critical 2026 Note: Verify DDP includes all destination charges (e.g., EU VAT, US Harbor Maintenance Fee). Demand itemized cost breakdown in contract.

Recommended Partner: Shanghai Carejoy Medical Co., LTD

Why Carejoy Stands Out in 2026 Sourcing Landscape:

- Compliance Verified: ISO 13485:2016 (Certificate #CN-2025-MD0891) + MDR 2017/745 CE (NB 2797) for all milling systems

- MOQ Flexibility: 1-unit orders accepted for D500 Series mills with 24-month warranty (vs. industry standard 12 months)

- DDP Excellence: 99.2% on-time delivery (2025 shipment data) with all-inclusive DDP quotes to 38 countries

- Technical Edge: Proprietary “SmartCool” milling tech reduces tool wear by 37% (validated by DGZMK 2025 study)

Direct Procurement Channel:

Email: [email protected]

WhatsApp: +86 15951276160 (24/7 technical support)

Factory Address: Room 1208, Building 3, No. 2888 Jiangyang Road, Baoshan District, Shanghai, China

Request 2026 Milling Machine Datasheet (Ref: DG-2026-MM-CHN) for ISO-certified performance metrics.

Implementation Checklist for 2026

- ✅ Confirm vendor’s ISO 13485 scope explicitly covers milling machinery

- ✅ Demand DDP quote with HS code 8464.90 (dental milling) duty calculation

- ✅ Negotiate written MOQ exception for first order (use Carejoy’s 1-unit policy as benchmark)

- ✅ Require 3rd-party pre-shipment inspection (SGS/BV) at vendor’s facility

- ✅ Validate spare parts inventory (min. 24-month supply for critical components)

Final Advisory: In 2026, prioritize compliance velocity over lowest price. A $12,000 mill delayed 45 days for customs rework costs clinics $8,200 in lost production (per ADA 2025 productivity metrics). Shanghai Carejoy’s DDP compliance package delivers 11.3-day faster market entry vs. industry average.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Focus: Milling Machines for Dental Laboratories

Frequently Asked Questions (FAQ) – Purchasing a Dental Laboratory Milling Machine in 2026

As digital dentistry continues to evolve, selecting the right milling machine is critical for efficiency, precision, and long-term ROI. Below are key questions and expert answers to guide dental clinics and distributors in making informed procurement decisions.

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider when installing a dental laboratory milling machine in 2026? | Most advanced dental milling machines in 2026 operate on standard 110–120V AC (60 Hz) for North American markets and 220–240V AC (50 Hz) for Europe, Asia, and other international regions. However, high-throughput or multi-spindle models may require dedicated 208V or 3-phase power. Always verify the machine’s power specifications prior to installation and ensure your lab has stable voltage supply with surge protection. Consult the manufacturer’s technical datasheet and involve a certified electrician during setup to avoid operational disruptions. |

| 2. Are spare parts readily available, and what is the typical lead time for critical components? | Leading manufacturers in 2026 maintain global spare parts distribution networks, with critical components such as spindles, tool changers, linear guides, and collets stocked regionally. Distributors typically carry high-demand parts, with standard lead times of 3–7 business days for in-stock items. For specialized or custom parts, lead times may extend to 2–4 weeks. We recommend purchasing a starter spare parts kit at the time of machine acquisition and verifying the manufacturer’s parts availability index (PAI) and local inventory status before procurement. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of a dental milling machine in 2026 includes site assessment, leveling, power and network connectivity, software calibration, and dry-run testing. Most premium manufacturers and authorized distributors provide white-glove installation services with certified field engineers. This typically includes on-site setup, workflow integration, and operator training. Confirm whether installation is included in the purchase agreement or billed separately. Remote diagnostics and AI-assisted setup are now standard, but on-site support remains essential for first-time installations and complex lab environments. |

| 4. What is covered under the standard warranty, and are there extended warranty options? | The standard warranty for dental milling machines in 2026 typically covers 12 to 24 months on parts and labor, including the spindle, drive systems, and control electronics. Consumables (e.g., tools, filters) and damage from improper use are excluded. Extended warranty plans are available up to 5 years and often include preventive maintenance, priority service, and software updates. Distributors should confirm warranty transferability for resale and ensure global service coverage for international clients. Look for manufacturers offering uptime guarantee clauses (e.g., 95% operational availability). |

| 5. How are firmware updates and technical support handled post-purchase? | In 2026, most dental milling machines support over-the-air (OTA) firmware updates to enhance performance, expand material compatibility, and improve milling strategies. Technical support is delivered via 24/7 remote diagnostics, cloud-based ticketing systems, and multilingual support centers. Authorized distributors provide first-line assistance, with direct manufacturer escalation for complex issues. Ensure your machine includes at least 1 year of complimentary support and updates, and inquire about service level agreements (SLAs) for response and resolution times. |

Need a Quote for Milling Machine Dental Laboratory?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160