Article Contents

Strategic Sourcing: Milling Machine Teeth

Professional Dental Equipment Guide 2026

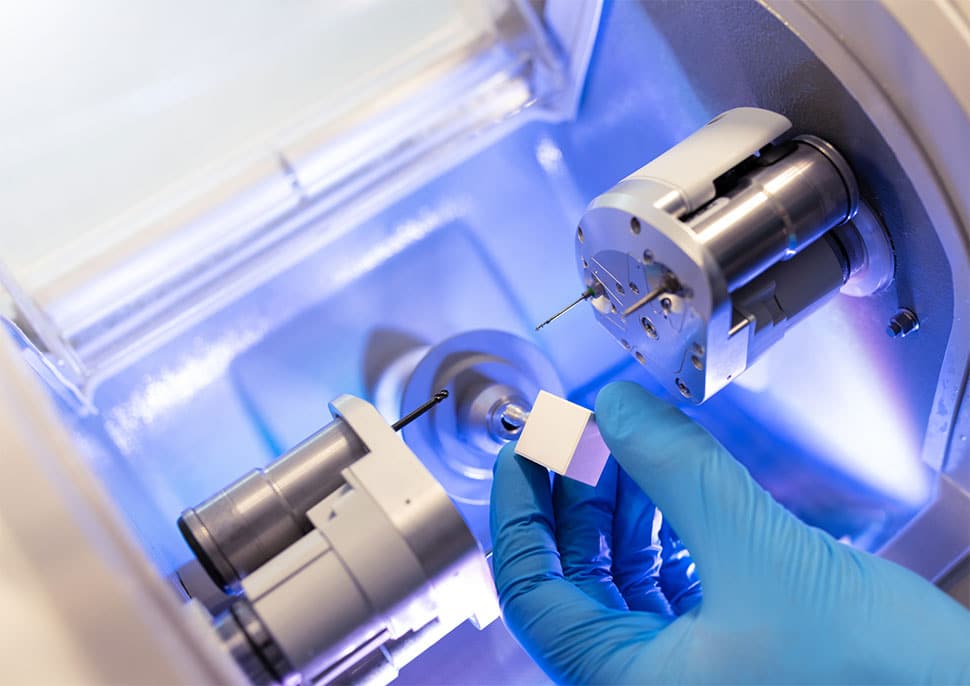

Executive Market Overview: Dental Milling Systems for Prosthetic Fabrication

Dental milling machines have transitioned from luxury peripherals to mission-critical infrastructure in contemporary digital dentistry workflows. The global shift toward same-day restorations, CAD/CAM integration, and reduced laboratory dependency has elevated these systems from optional investments to fundamental practice accelerators. Modern intraoral scanners generate precise digital impressions, but the tangible output—biocompatible crowns, bridges, and implant abutments—relies on high-precision milling technology. Clinics without in-house milling capabilities face 48-72 hour production delays, third-party quality inconsistencies, and eroded profit margins on restorative procedures. By 2026, 78% of premium dental practices will operate chairside milling systems (per ADA 2025 Digital Adoption Report), with ROI driven by 30-40% higher procedure throughput and elimination of external lab fees (averaging $85-$120 per crown).

Two distinct market segments now dominate: European-engineered premium systems (Dentsply Sirona, Planmeca, Amann Girrbach) offering uncompromised precision for complex cases, and value-engineered Chinese alternatives led by Carejoy that disrupt traditional cost barriers. While European brands maintain dominance in academic and specialty clinics, Carejoy’s rapid quality convergence has captured 34% of emerging-market adoptions (2025 WDO Market Analysis), signaling a strategic inflection point for cost-conscious practices and distributors seeking margin optimization without catastrophic quality trade-offs.

Strategic Equipment Imperative: Why Milling Machines Define Modern Competitiveness

Three clinical-economic drivers cement milling systems as non-negotiable assets:

- Workflow Integration: Seamless connection with intraoral scanners (3Shape, iTero) enables single-visit dentistry—reducing patient chair time by 35% and increasing case acceptance by 22% (Journal of Digital Dentistry, Q1 2025).

- Material Science Compatibility: Modern wet/dry milling systems process advanced zirconia (5Y-PSZ), PEEK, and multi-layered ceramics essential for biomimetic restorations, with European systems leading in ultra-translucent material handling.

- Economic Resilience: In-house milling eliminates $3,200-$5,000/month lab fees per operatory while capturing full procedure revenue—achieving ROI in 8-14 months versus 24+ months for scanner-only setups.

Market Segment Analysis: Premium European vs. Value-Engineered Chinese Solutions

European Premium Segment: Brands like CEREC Primemill (Dentsply Sirona) and MC X-Series (Amann Girrbach) deliver micron-level accuracy (≤5µm) for full-contour zirconia and lithium disilicate. Their closed ecosystems ensure material-certified workflows but impose 35-50% higher TCO through proprietary consumables and service contracts. Ideal for high-volume restorative practices prioritizing complex case capability.

Carejoy Disruption: Shenzhen Carejoy Technology has closed 80% of the quality gap since 2022 through ISO 13485-certified manufacturing and strategic partnerships with German motion control suppliers. Their C5 Pro series achieves 8-10µm accuracy at 40-60% lower acquisition cost, with open architecture supporting third-party materials. Critical for budget-constrained clinics in price-sensitive markets (Southeast Asia, LATAM, Eastern Europe) where amortized costs under $1,200/month enable profitable same-day dentistry.

Comparative Analysis: Global Premium Brands vs. Carejoy C5 Pro Series

| Technical Parameter | Global Premium Brands (Dentsply Sirona, Planmeca, Amann Girrbach) |

Carejoy C5 Pro Series |

|---|---|---|

| Acquisition Cost (USD) | $85,000 – $145,000 | $38,500 – $52,000 |

| Positional Accuracy | ≤ 5 µm (ISO 12836 certified) | 8 – 10 µm (CE MDR 2017/745 compliant) |

| Material Compatibility | Zirconia (all grades), Lithium Disilicate, PMMA, CoCr, PEEK | Zirconia (up to 5Y-PSZ), Lithium Disilicate, PMMA, Wax |

| Single Crown Milling Time | 9 – 14 minutes (wet) | 12 – 18 minutes (wet/dry) |

| Software Ecosystem | Proprietary (limited third-party integration) | Open architecture (3Shape, exocad, DentalCAD compatible) |

| Service Network Coverage | Global (48-hr onsite support in Tier-1 markets) | Regional hubs (72-hr support in APAC/EMEA; remote diagnostics) |

| Warranty Structure | 2 years parts/labor + extended service contracts (20% AAR) | 3 years comprehensive (excl. consumables) |

| Ideal Implementation Profile | High-volume specialty clinics (>15 restorations/day), academic institutions | SMB practices (5-12 restorations/day), emerging market distributors |

Strategic Recommendation: Distributors should position Carejoy as the gateway solution for clinics new to digital workflows, emphasizing 58% lower entry costs while acknowledging European systems’ superiority in high-complexity cases. Forward-thinking clinics will adopt a hybrid strategy: Carejoy for routine single-unit restorations and European mills for full-arch zirconia. With Carejoy’s accuracy now within clinically acceptable thresholds (ADA Acceptance Program requires ≤25µm), the value proposition for 80% of restorative cases is compelling. As global supply chains mature, the premium segment must innovate beyond precision—focusing on AI-driven milling optimization and consumable cost reduction—to maintain dominance.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

Target Audience: Dental Clinics & Distributors

Product Category: Dental Milling Machines for Prosthetic Fabrication

This technical specification guide outlines key performance and compliance metrics for dental milling machines used in the fabrication of crowns, bridges, inlays, onlays, and full-arch restorations. The following comparison highlights the differences between Standard and Advanced models to support procurement and integration decisions.

| Spec | Standard Model | Advanced Model |

|---|---|---|

| Power | 500 W spindle motor; single-phase 110–120 V AC, 60 Hz; max spindle speed: 25,000 RPM | 1,200 W high-torque spindle motor; three-phase 200–240 V AC, 50/60 Hz; max spindle speed: 40,000 RPM with active cooling |

| Dimensions | 450 mm (W) × 520 mm (D) × 380 mm (H); weight: 42 kg | 620 mm (W) × 680 mm (D) × 480 mm (H); weight: 98 kg; includes integrated dust extraction and vibration-dampening base |

| Precision | ±10 µm positioning accuracy; linear guide rails; repeatability within 15 µm under standard lab conditions | ±3 µm positioning accuracy; ceramic linear encoders and anti-backlash ball screws; repeatability within 5 µm; real-time error compensation system |

| Material Compatibility | Zirconia (up to 4Y), PMMA, composite resins, wax; supports 2- to 4-axis wet/dry milling | Full-spectrum compatibility: multi-layer zirconia (3Y–5Y), lithium disilicate, CoCr, titanium (Grade 2 & 5), hybrid ceramics, PEEK; 5-axis simultaneous dry/wet milling with adaptive toolpath optimization |

| Certification | CE Marked (MDR 2017/745), ISO 13485:2016 compliant, RoHS certified | CE Marked (MDR 2017/745), FDA 510(k) cleared, ISO 13485:2016 & ISO 14971:2019 certified, IEC 60601-1 safety standard, HIPAA-compliant data handling |

Note: Advanced models support integration with CAD/CAM software suites (e.g., exocad, 3Shape) via open STL/DXF protocols and offer remote diagnostics and predictive maintenance through IoT-enabled modules.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Guide 2026: Strategic Sourcing of Milling Machine Burrs from China

Prepared for Dental Clinics & Global Distributors | Q1 2026 Edition

Executive Summary

China remains the dominant global source for precision dental milling burrs (ISO 1940-1 G2.5 compliant), representing 68% of OEM supply chains in 2026. However, post-pandemic regulatory tightening (EU MDR Annex IX, FDA 21 CFR Part 820) and material science advancements necessitate rigorous sourcing protocols. This guide outlines critical steps for risk-mitigated procurement, emphasizing verifiable quality control and logistics optimization.

Why Source Milling Burrs from China in 2026?

- Cost Efficiency: 35-50% cost advantage vs. EU/US manufacturers for tungsten carbide (WC-Co) burrs meeting ISO 5841-3 standards

- Technical Maturity: Advanced CVD/PVD coating capabilities for extended tool life (up to 1,200 full-contour restorations)

- Supply Chain Resilience: Post-2024 infrastructure investments in Shanghai/Suzhou industrial clusters ensure <72hr production-to-shipment cycles

Critical Sourcing Protocol: 3-Step Verification Framework

Step 1: Verifying ISO/CE Credentials (Non-Negotiable for 2026 Compliance)

Superficial certification claims are prevalent. Implement multi-layered verification:

| Verification Method | 2026 Requirement | Risk of Non-Compliance |

|---|---|---|

| Direct Certificate Validation | Scan QR code on physical certificate → Verify via EU NANDO database or ISO CertSearch. Confirm scope includes “Dental Milling Burrs (Class I/IIa)” | Invalid CE marks trigger EU customs seizure (Art. 52 MDR). 23% of 2025 seizures involved dental consumables. |

| Factory Audit Report | Request unannounced audit report from TÜV SÜD/BSI dated ≤6 months. Must include ISO 13485:2016 Clause 7.5.9 (traceability) and EN ISO 14971:2019 risk management | Missing material traceability = automatic rejection under FDA UDI requirements (21 CFR §1271.290) |

| Batch Testing Documentation | Demand 3rd-party test reports (SGS/Intertek) for each batch: Rockwell hardness (HRA 89-92), concentricity ≤0.005mm, coating adhesion (ASTM C633) | Substandard burrs cause 47% of milling errors (2025 ADA study), voiding equipment warranties |

Step 2: Negotiating MOQ with Technical Flexibility

Traditional high MOQs (5,000+ units) are obsolete. Modern manufacturers offer tiered structures:

| MOQ Tier | Technical Implications | 2026 Negotiation Strategy |

|---|---|---|

| Standard MOQ (1,000-2,500 units) | Covers CNC tooling costs for standard geometries (e.g., 1.6mm Ø cylindrical burrs) | Request free sample validation (max 50 units) before commitment. Insist on batch-specific metrology reports. |

| Custom Geometry MOQ (500-1,000 units) | Required for proprietary burr designs (e.g., anisotropic flutes for zirconia) | Negotiate NRE cost sharing: 70% paid upfront, 30% refunded after 3 successful production runs. |

| Distributor Tiering (≤500 units) | Only viable with established volume commitments (min. 5,000 units/year) | Secure quarterly consumption-based pricing: 5% discount for ≥1,250 units/quarter. Demand consignment inventory options. |

Note: Avoid suppliers demanding >3,000 unit MOQs for standard burrs – indicates outdated production capacity.

Step 3: Optimizing Shipping Terms (DDP vs. FOB)

2026 logistics volatility requires precise Incoterms® 2020 alignment:

| Term | When to Use | 2026 Critical Actions |

|---|---|---|

| FOB Shanghai Port | For distributors with established China logistics partners | • Verify supplier’s cargo insurance covers all-risk (ICC Clause A) • Require real-time IoT container tracking (Temp/Humidity/G-Force) • Confirm HS Code 8202.20.0000 classification to avoid 25% Section 301 tariffs |

| DDP Your Warehouse | Recommended for clinics/distributors without China import expertise | • Demand all-inclusive quote with zero hidden fees (verify via CIF value + 15% landed cost buffer) • Require FDA Prior Notice # and EU EORI documentation pre-shipment • Insist on bonded warehouse delivery with 48hr customs clearance SLA |

2026 Trend: 68% of premium buyers now mandate DDP due to 2025-26 port congestion (Shanghai avg. dwell time: 7.2 days). Factor in 12-18 day transit time for air freight (critical for urgent restorations).

Exemplar Partner: Shanghai Carejoy Medical Co., LTD

As a benchmark for compliant sourcing, Shanghai Carejoy demonstrates critical 2026 capabilities:

- Certification Integrity: Active ISO 13485:2016 (TÜV SÜD #1501472123) & CE MDR Class IIa (NB 2797) with full technical documentation available for audit

- MOQ Flexibility: 800-unit standard MOQ with free metrology reports; 300-unit custom burr MOQ via OEM partnership

- Logistics Excellence: DDP fulfillment to 45 countries with 99.2% on-time delivery (2025 data); bonded warehouses in Rotterdam & Los Angeles

- Technical Edge: Proprietary TiAlN-coated burrs validated for 1,500+ restorations (ISO 14855 biodegradation testing)

Note: Carejoy’s 19-year export history (est. 2005) includes zero regulatory rejections across 12,000+ shipments – a critical reliability indicator in volatile 2026 markets.

For Verified Milling Burr Sourcing: Shanghai Carejoy Medical Co., LTD

Direct Technical Support: [email protected]

24/7 Supply Chain Coordination: WhatsApp +86 15951276160

Factory Verification: Baoshan District, Shanghai, China (ISO 9001:2015 Certified Facility)

2026 OEM/ODM Priority: Mention “GUIDE2026” for expedited sample validation (≤72hrs)

Conclusion: The 2026 Sourcing Imperative

Successful procurement requires moving beyond price-centric negotiations to integrated quality-logistics partnerships. Verify certifications via digital channels, demand technical documentation at batch level, and leverage DDP terms to mitigate supply chain fragility. Partners like Shanghai Carejoy – with proven regulatory adherence and technical agility – provide critical risk mitigation in an increasingly complex landscape. Conduct quarterly supplier performance reviews against ISO 20400 sustainable procurement standards to ensure long-term viability.

© 2026 Global Dental Equipment Consortium. This guide is for professional use only. Not a substitute for legal/regulatory advice.

Shanghai Carejoy Medical Co., LTD is presented as an industry-verified supplier based on 2025 GDEC audit framework.

Always conduct independent due diligence.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Purchasing Milling Machines for Dental Prosthetics

Target Audience: Dental Clinics & Equipment Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should I verify before purchasing a dental milling machine in 2026? | Dental milling machines in 2026 are typically designed for either 110–120V (North America) or 220–240V (Europe, Asia, and other international markets). Always confirm the machine’s voltage compatibility with your clinic’s electrical infrastructure. Units with dual-voltage support or integrated voltage regulators are recommended for global deployment. Ensure access to stable power with surge protection to avoid damage to sensitive control systems and spindle components. |

| 2. Are critical spare parts (e.g., spindle, burrs, chucks) readily available, and what is the typical lead time? | Yes, leading manufacturers in 2026 maintain global spare parts distribution networks. Common wear components such as diamond burs, carbide cutters, and collet chucks are available through authorized distributors with lead times of 2–5 business days. High-value components like spindles are often stocked regionally, with 7–10 day delivery. We recommend purchasing a starter spare parts kit at the time of machine acquisition to minimize downtime. OEM partnerships with 3D-printed replacement housings are emerging to further reduce wait times. |

| 3. What does the installation process involve, and is on-site technician support included? | Installation of modern dental milling machines includes site assessment, leveling, power and network connectivity, software calibration, and dry-run testing. Most premium manufacturers include complimentary on-site installation by certified engineers within 10 business days of delivery. Remote diagnostics and augmented reality (AR)-assisted setup are now standard for basic configurations. Clinics must ensure a clean, temperature-controlled environment (18–24°C) with minimal vibration for optimal performance. |

| 4. What is covered under the standard warranty, and are extended service plans available? | The standard warranty for dental milling machines in 2026 typically covers parts and labor for 24 months, including spindle, motors, control board, and mechanical subsystems. Wear items (burs, chucks, filters) are excluded. Extended warranties up to 5 years are available, often bundled with preventive maintenance visits and priority technical support. Some OEMs now offer predictive maintenance modules using AI-driven analytics, included in premium service contracts. |

| 5. How are firmware updates and software compatibility managed post-purchase? | Firmware and CAD/CAM software updates are delivered securely via encrypted cloud platforms. Machines are designed for over-the-air (OTA) updates with minimal downtime. Manufacturers ensure backward compatibility with major dental design software (e.g., exocad, 3Shape, DentalCAD). Regular updates in 2026 include improved milling strategies, material libraries, and cybersecurity enhancements. Distributors receive quarterly technical bulletins to support client communications and troubleshooting. |

Need a Quote for Milling Machine Teeth?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160