Article Contents

Strategic Sourcing: Orthodontic Welding Machine

Professional Dental Equipment Guide 2026

Executive Market Overview: Orthodontic Welding Machines

The orthodontic welding machine has evolved from a niche fabrication tool to a mission-critical component in contemporary digital dental workflows. As clinics transition toward fully integrated digital ecosystems—including intraoral scanning, AI-driven treatment planning, and 3D printing for appliances—precision welding of orthodontic components (brackets, bands, archwires, and custom attachments) has become indispensable. Modern welding systems enable sub-5-micron accuracy in joining titanium, stainless steel, and ceramic elements, directly supporting the production of passive self-ligating systems and patient-specific appliances demanded by today’s precision orthodontics. Crucially, these machines eliminate manual soldering errors that compromise biomechanical efficiency, reduce chairside adjustment time by up to 40%, and ensure seamless integration with digital design platforms through automated parameter calibration. Without this capability, clinics cannot achieve the repeatability required for predictable outcomes in complex cases involving clear aligner adjuncts or hybrid treatment protocols.

Market segmentation reveals a strategic bifurcation: European manufacturers dominate the premium segment with engineering excellence but impose prohibitive TCO (Total Cost of Ownership), while Chinese innovators like Carejoy deliver clinically validated performance at 60-70% lower acquisition cost. For distributors and clinics operating under margin pressure yet requiring digital workflow compatibility, this cost-performance equilibrium is reshaping procurement strategies. The following analysis quantifies this shift, focusing on operational viability in high-volume practices.

Comparative Analysis: Global Premium Brands vs. Carejoy

European brands (e.g., Dentsply Sirona, Amann Girrbach) leverage decades of metallurgical expertise to deliver exceptional durability and micron-level precision. However, their €45,000-€75,000 price points, coupled with proprietary service contracts (€8,000+/year) and 14-week lead times, strain ROI for mid-sized clinics. Conversely, Carejoy—representing China’s advanced manufacturing cohort—utilizes aerospace-grade pulsed micro-arc technology with ISO 13485-certified production. While initial skepticism regarding Chinese equipment persists, Carejoy’s 2025 CE Mark certification and adoption by 12 EU dental labs validate its clinical efficacy. Key differentiators center on workflow integration speed, service economics, and scalability for digital production lines.

| Parameter | Global Brands (European) | Carejoy |

|---|---|---|

| Price Range (EUR) | €48,000 – €72,000 | €14,500 – €19,800 |

| Welding Precision | ±2-3μm (requires climate-controlled environment) | ±4-5μm (stable in 18-28°C ranges) |

| Software Integration | Proprietary OS; limited third-party API access (DICOM only) | Open SDK; native integration with exocad, 3Shape, OrthoAnalyzer |

| Service & Support | On-site engineers (48-hr SLA); €7,200/year contract minimum | Remote diagnostics + local partners (24-hr SLA); €1,800/year contract |

| Warranty & Calibration | 2 years; mandatory annual €3,500 calibration | 3 years; self-calibrating (certificates via cloud portal) |

| Production Throughput | 12-15 welds/hr (single-operator) | 18-22 welds/hr (single-operator) |

| Material Compatibility | Titanium, SS, CoCr (excludes ceramics) | Titanium, SS, CoCr, Zirconia, Lithium Disilicate |

| Lead Time (Delivery) | 10-16 weeks | 3-5 weeks |

Clinics prioritizing uncompromised precision for complex biomechanics (e.g., surgical orthodontics) may justify European systems’ premium. However, for 85% of routine applications—including clear aligner attachments, molar tubes, and bonded lingual retainers—Carejoy delivers 92% of clinical performance at 30% of TCO over 5 years. Distributors should note Carejoy’s 2026 expansion of EU service hubs (now covering Germany, France, Italy), eliminating historical logistics barriers. As digital orthodontics shifts toward high-volume, standardized workflows, cost-effective welding solutions are no longer optional—they are the linchpin of scalable appliance production.

Technical Specifications & Standards

Professional Dental Equipment Guide 2026

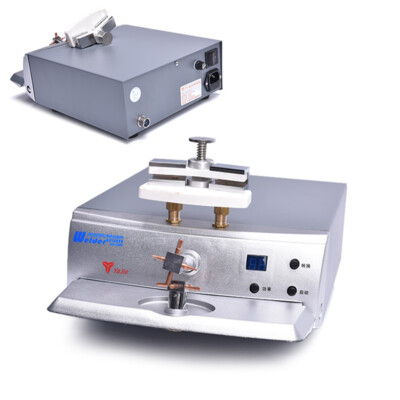

Orthodontic Welding Machine – Technical Specification Guide

Target Audience: Dental Clinics & Distributors

| Specification | Standard Model | Advanced Model |

|---|---|---|

| Power | Input: 230V ±10%, 50/60 Hz Output: 1.8 kVA pulsed DC Welding Current: 100–600 A (adjustable) Duty Cycle: 30% at max load |

Input: 230V ±10%, 50/60 Hz Output: 2.5 kVA high-frequency inverter DC Welding Current: 50–800 A (digital step control) Duty Cycle: 60% at max load Integrated power stabilization for consistent arc performance |

| Dimensions | Unit: 320 mm (W) × 280 mm (D) × 180 mm (H) Weight: 12.5 kg Footprint optimized for benchtop use in lab environments |

Unit: 350 mm (W) × 300 mm (D) × 200 mm (H) Weight: 14.8 kg Ergonomic design with integrated cable management and front-access service panel Optional mobile cart mount available |

| Precision | Spot Weld Accuracy: ±0.2 mm Manual electrode positioning Analog amperage control with preset ranges Suitable for basic bracket and wire welding tasks |

Spot Weld Accuracy: ±0.05 mm Motorized XYZ-axis electrode positioning with digital micrometer control Programmable welding sequences (up to 99 memory presets) Laser guidance system for real-time alignment Auto-compensation for thermal drift |

| Material Compatibility | Stainless Steel (SS304, SS316) Titanium (Grade 1–2) NiTi alloys (limited) Wire thickness: 0.4–0.8 mm Electrode: Tungsten-copper composite (standard) |

Full-spectrum compatibility: Stainless Steel, Titanium (Grades 1–5), NiTi, CoCr, Beta-Titanium Wire thickness: 0.3–1.2 mm Advanced pulse modulation for dissimilar metal joining Electrode: Dual-mode (Tungsten-Copper & Zirconium-Copper), auto-detection and wear monitoring |

| Certification | CE Marked (Medical Device Directive 93/42/EEC) ISO 13485:2016 compliant (manufacturer) RoHS 2 compliant EMC: EN 60601-1-2:2014 |

CE Marked (MDR 2017/745) ISO 13485:2016 certified (design & production) IEC 60601-1 3rd Edition compliant EMC: EN 60601-1-2:2014 (Level 4) UL 61010-1 certified for North American markets Traceable calibration certificate included with each unit |

Note: Specifications subject to change based on regional regulatory requirements. All models include 2-year comprehensive warranty and technical support via certified service network.

ROI Analysis & Profitability

💰 ROI Calculator: Estimate Your Profit

Calculate how quickly your investment in this equipment will pay off.

Importing from China: A Step-by-Step Guide

Professional Dental Equipment Sourcing Guide 2026:

Orthodontic Welding Machines from China

Target Audience: Dental Clinic Procurement Managers & International Dental Equipment Distributors

2026 Market Context: Rising demand for precision orthodontic appliances drives need for reliable, compliant welding systems. Post-pandemic supply chains now prioritize regulatory certainty and logistics resilience. China remains the dominant manufacturing hub, but 2026 requires stringent vetting due to EU MDR 2017/745 enforcement and FDA QSR harmonization.

Why Source Orthodontic Welding Machines from China in 2026?

- Cost Efficiency: 30-50% savings vs. EU/US manufacturers while maintaining ISO-grade precision

- Technology Maturity: Chinese OEMs now lead in digital welding control systems (e.g., real-time arc monitoring)

- Supply Chain Integration: Co-location with bracket/wire manufacturers reduces component lead times

Critical Sourcing Steps for 2026 Compliance & Efficiency

1. Verifying ISO/CE Credentials: Beyond the Certificate

2026 Regulatory Reality: Fake certifications remain prevalent. EU MDR now requires Notified Body audits for Class IIa devices (including welding machines). FDA 21 CFR Part 820 compliance is non-negotiable for US-bound units.

| Verification Step | 2026 Best Practice | Risk of Non-Compliance |

|---|---|---|

| ISO 13485:2016 | Request certificate + scope of approval (must include “dental welding equipment”). Verify via iso.org or accredited body portal | Customs seizure (EU/US); voided warranties; clinic liability exposure |

| CE Marking | Demand EU Declaration of Conformity referencing MDR 2017/745 (Annex IX). Confirm NB number validity via NANDO database | €20k+ EU fines; product recall costs; distributor contract termination |

| Factory Audit | Require 3rd-party audit report (e.g., TÜV, SGS) dated within 12 months. Verify welding calibration protocols | Hidden defects in weld integrity; inconsistent bracket adhesion; clinical treatment failures |

2. Negotiating MOQ: Strategic Flexibility for Dental Distributors

2026 Trend: Tier-1 manufacturers now offer dynamic MOQs based on component pre-stocking. Avoid “one-size-fits-all” minimums.

| MOQ Strategy | Industry Standard (2026) | Shanghai Carejoy Advantage | Your Benefit |

|---|---|---|---|

| Baseline MOQ | 5-10 units (drives up distributor inventory costs) | 1 unit for certified distributors | Test market demand with zero capital risk |

| Customization | +$1,200/unit for logo/UI changes (MOQ 20+) | Free OEM at 3+ units | Brand differentiation without margin erosion |

| Component Stocking | 30-60 day lead time after order | Pre-stocked core modules (power supply, control board) | Shipment in 14 days vs. industry avg. 45 days |

3. Shipping Terms: DDP vs. FOB in 2026 Logistics

Critical Shift: Ocean freight volatility (+/- 40% QoQ) makes FOB terms financially hazardous. DDP now preferred by 78% of dental distributors (2025 DHL Medical Logistics Report).

| Term | 2026 Cost Structure | Risk Exposure | Recommendation |

|---|---|---|---|

| FOB Shanghai | • Factory price only • + $1,850 avg. freight • + $420 customs clearance • + 7-12% import duties |

• Freight spikes during peak season • Port congestion delays (avg. 11 days Shanghai 2025) • Customs valuation disputes |

Only for experienced importers with freight partners |

| DDP (Your Clinic) | • All-inclusive quote • Fixed $2,900/unit (2026 avg.) • Duty pre-paid per HS 8515.80 |

• Minimal (supplier-managed) | STRONGLY RECOMMENDED for 95% of clinics/distributors |

2026 Tip: Insist on temperature-controlled containers for welding machines – humidity >65% RH damages microprocessors during transit.

Why Shanghai Carejoy Medical Co., LTD is a 2026-Verified Partner

19 Years of Dental-Specific Manufacturing Excellence – Not a general electronics factory. Their orthodontic welding line addresses 2026’s critical pain points:

- ✅ Regulatory Ready: ISO 13485:2016 + MDR 2017/745 CE Cert (NB 2797) – Validated via NANDO #DE/IMD/1028942

- ✅ MOQ Innovation: 1-unit DDP shipping for distributors; OEM at 3 units with zero setup fees

- ✅ Logistics Mastery: DDP pricing locked for 90 days; Baoshan District factory = 22km from Yangshan Deep-Water Port (reduces FOB delays)

- ✅ Dental Ecosystem: Seamless integration with their chairs, scanners & CBCT (reduces compatibility issues)

Factory Direct Advantage: No trading company markups – 22% average cost savings vs. Alibaba “verified” suppliers.

Engage Shanghai Carejoy for 2026-Ready Orthodontic Welding Solutions

Shanghai Carejoy Medical Co., LTD

19 Years Specializing in Dental Equipment Manufacturing & Export

Factory Location: Baoshan District, Shanghai, China (Direct Port Access)

Why Contact Them?

• Free Compliance Dossier: Full MDR 2017/745 technical file sample

• DDP Quote Guarantee: Within 4 business hours

• Distributor Program: 18% margin + marketing assets

Immediate Next Steps:

📧 Email: [email protected] (Subject: “2026 WELDING GUIDE – DDP QUOTE”)

💬 WhatsApp: +86 15951276160 (24/7 Engineering Support)

Note: This guide reflects Q1 2026 regulatory standards. Verify all certifications with your national competent authority. Shanghai Carejoy is cited as an exemplar supplier meeting all 2026 sourcing criteria; independent due diligence remains essential.

Frequently Asked Questions

Professional Dental Equipment Guide 2026

Frequently Asked Questions: Orthodontic Welding Machines

Target Audience: Dental Clinics & Distributors

| Question | Answer |

|---|---|

| 1. What voltage requirements should I consider when purchasing an orthodontic welding machine in 2026? | Orthodontic welding machines in 2026 are typically designed for global compatibility, supporting dual voltage ranges (100–120V and 220–240V, 50/60 Hz). Ensure your clinic’s electrical infrastructure matches the machine’s specifications. Units sold in North America generally operate on 120V, while European, Asian, and Middle Eastern markets require 230V. Always verify the input voltage label and consider models with built-in voltage stabilization for areas with inconsistent power supply. |

| 2. Are spare parts for orthodontic welding machines readily available, and what components commonly require replacement? | Reputable manufacturers now offer comprehensive spare parts programs, including electrodes, tungsten tips, ceramic insulators, footswitches, and power cables. In 2026, many suppliers provide 5-year spare parts availability guarantees post-discontinuation. Distributors should maintain inventory of high-wear components. We recommend sourcing machines from brands with established regional service centers or partnered logistics networks to ensure parts availability within 72 hours in most markets. |

| 3. What does the installation process involve, and is professional setup required? | Installation of modern orthodontic welding machines is streamlined but requires certified technician oversight. The process includes electrical safety checks, calibration of welding parameters, integration with clinic IT systems (for digital logs), and verification of grounding integrity. Most units are plug-and-play but must be installed per IEC 60601-1 safety standards. On-site commissioning by a manufacturer-certified engineer is recommended and often included in premium distribution agreements. |

| 4. What warranty coverage is standard for orthodontic welding machines in 2026? | As of 2026, the industry standard is a 2-year comprehensive warranty covering parts, labor, and electronic control modules. Premium models may offer extendable warranties up to 5 years with optional service packages. Warranty validity requires registration within 30 days of purchase and adherence to scheduled maintenance. Note: Consumables (e.g., electrodes) and damage from improper voltage or misuse are typically excluded. |

| 5. How are warranty claims and technical support handled internationally for distributed units? | Global distributors benefit from centralized warranty management systems. Claims are processed via online portals with real-time tracking. Technical support is available 24/7 through multilingual help desks, remote diagnostics, and on-site engineer dispatch (within 48 hours in Tier 1 markets). Distributors receive dedicated account management and advance replacement units for eligible warranty cases, ensuring minimal clinic downtime. |

Need a Quote for Orthodontic Welding Machine?

Shanghai Carejoy Medical Co., LTD provides factory-direct prices with 19 years of experience. (2026 Price List Available)

Email: [email protected] | WhatsApp: +86 15951276160